Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview

Abstract

:1. Introduction

2. FRP Reinforcing Bars

2.1. Degradation Mechanism

2.2. Mechanical Properties

3. FRP Laminates

3.1. Degradation Mechanism

3.2. Mechanical Properties

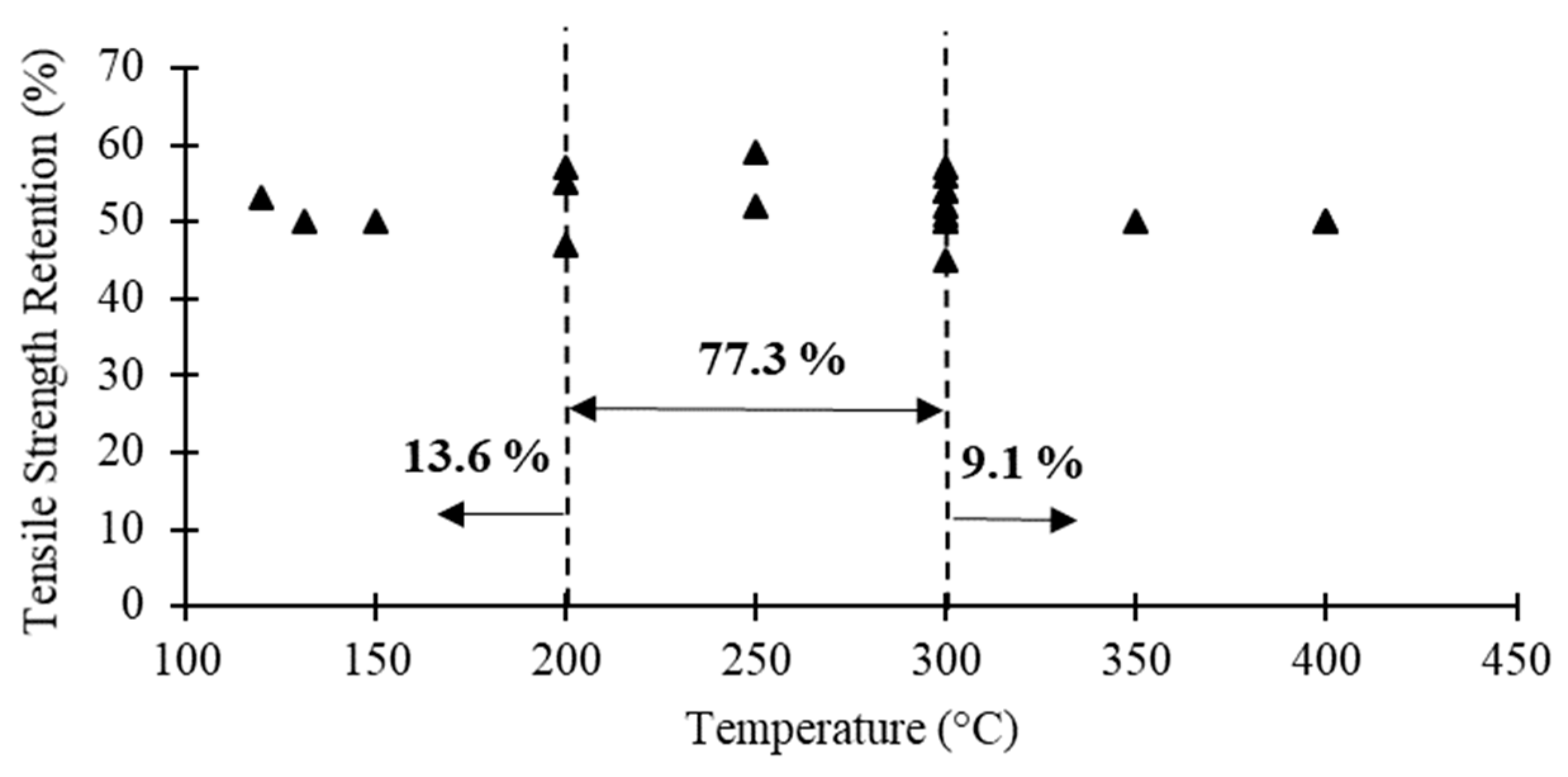

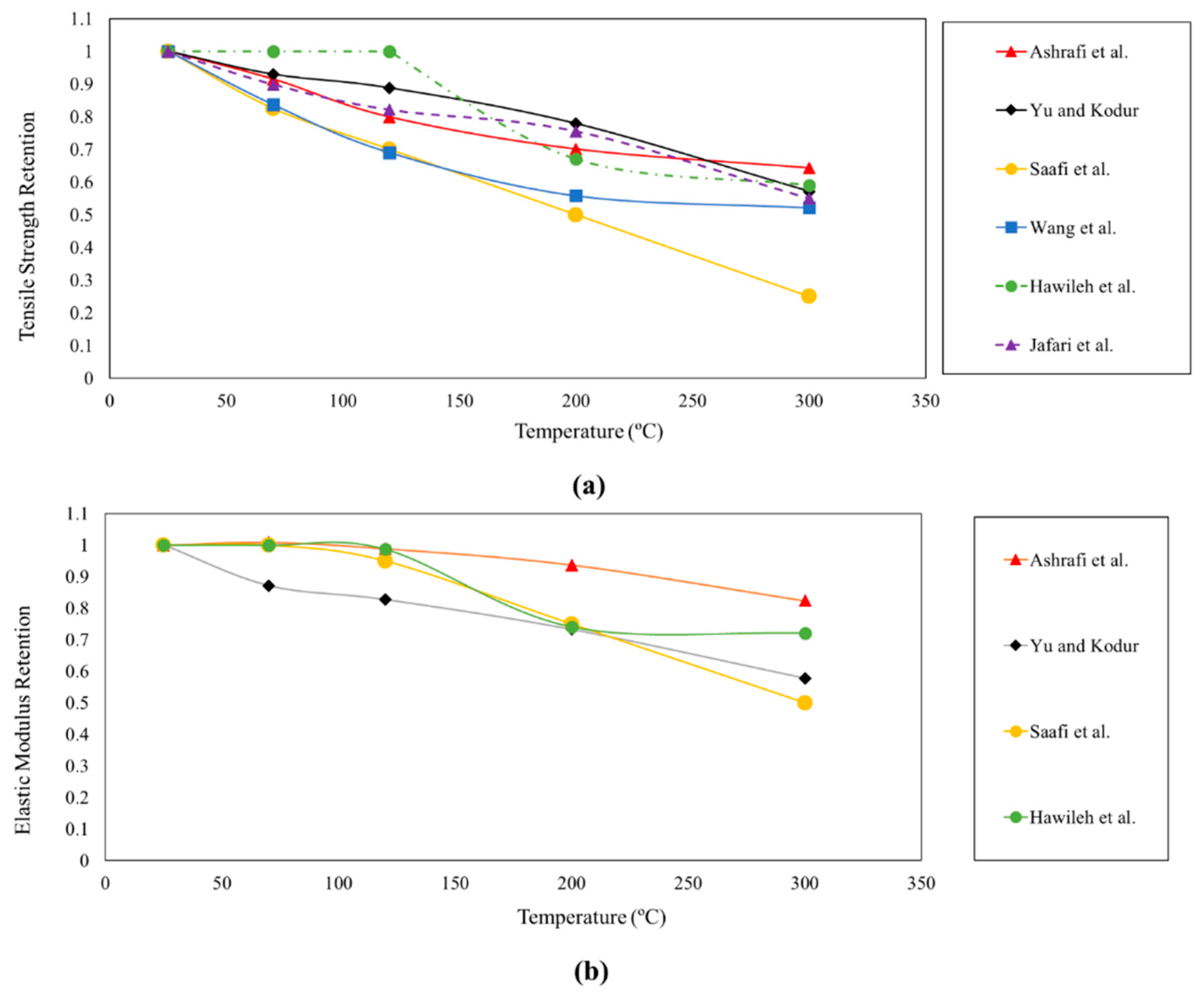

3.2.1. Tensile Properties

3.2.2. Tensile Properties Predicting Models

3.2.3. Flexural Properties

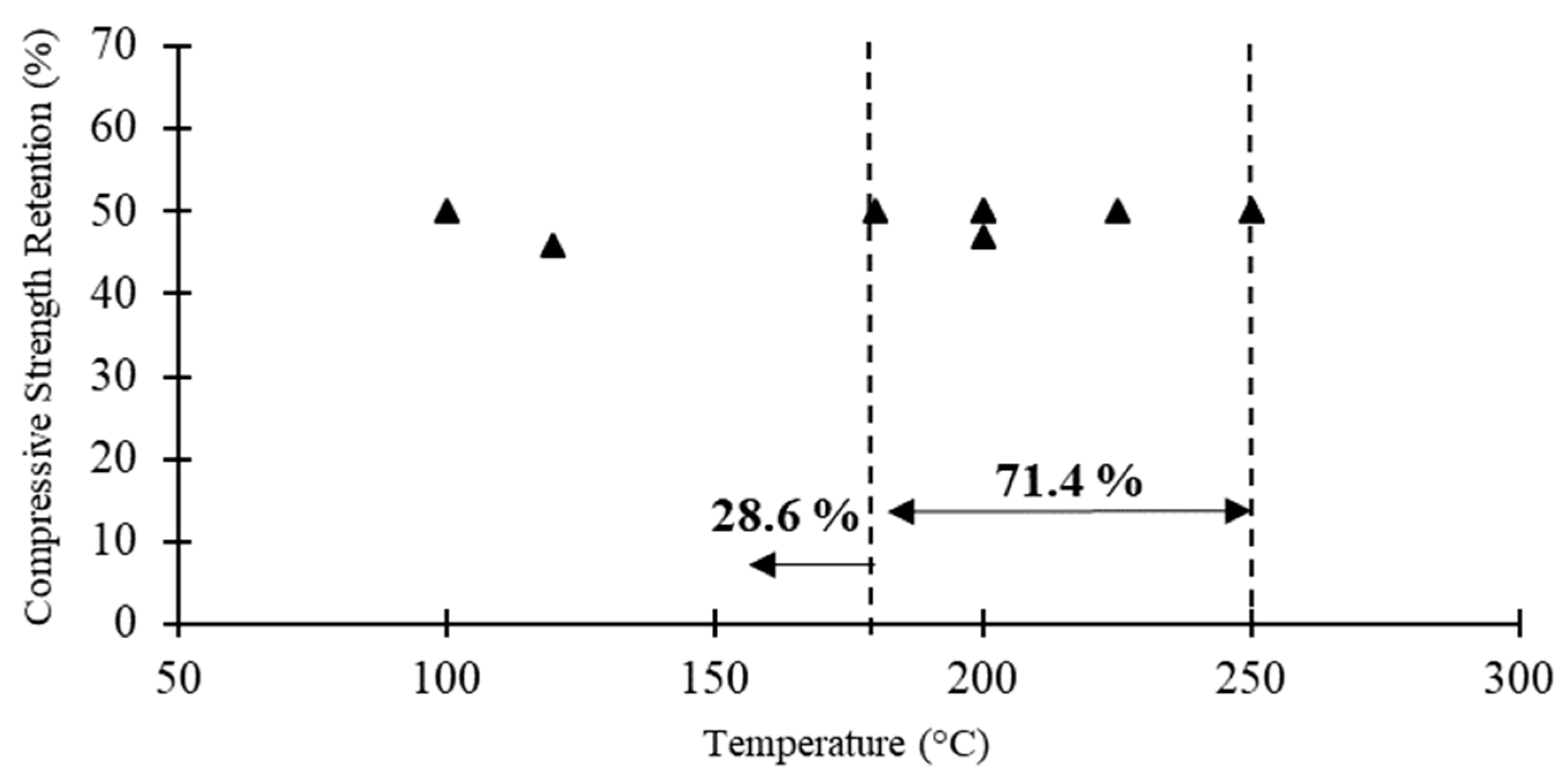

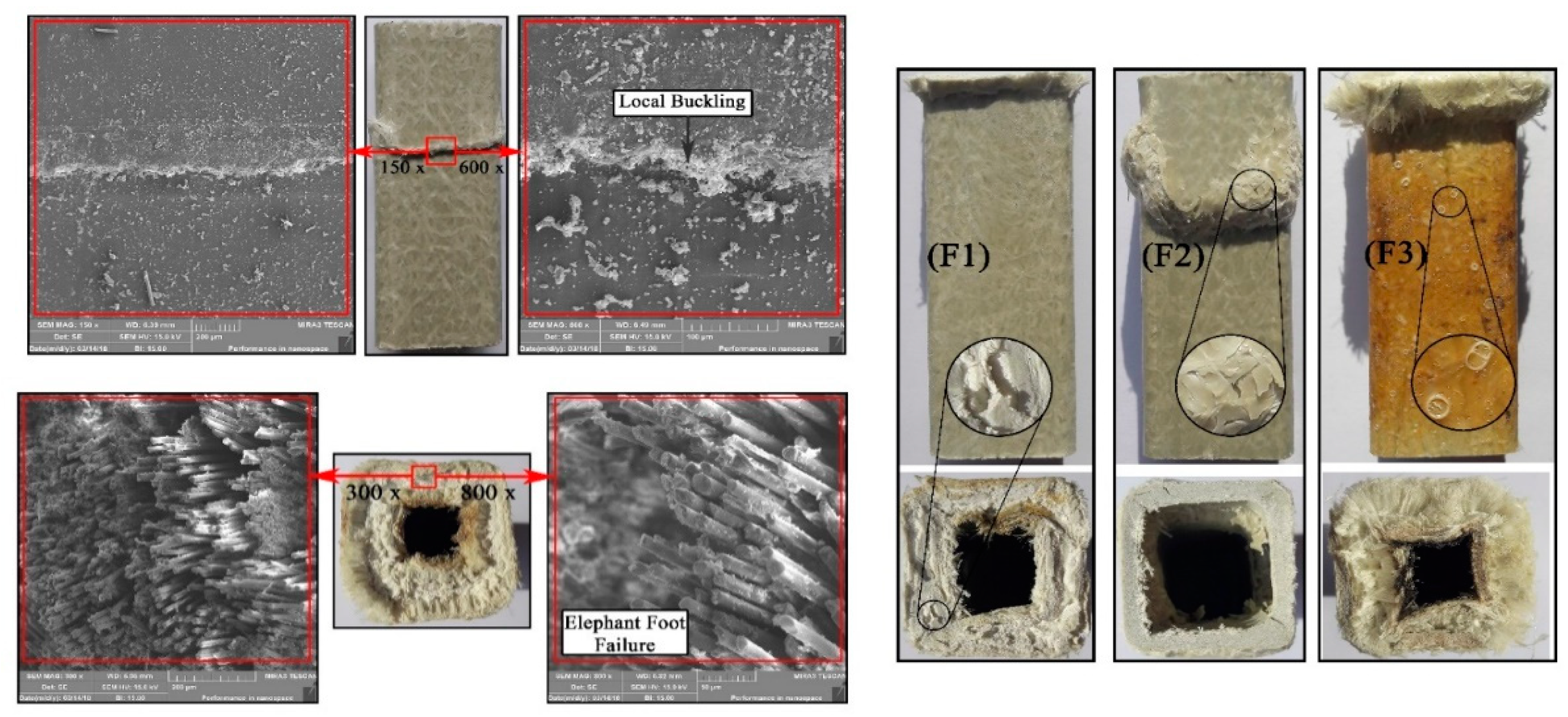

3.2.4. Compressive Properties

4. FRP Profiles

4.1. Beam

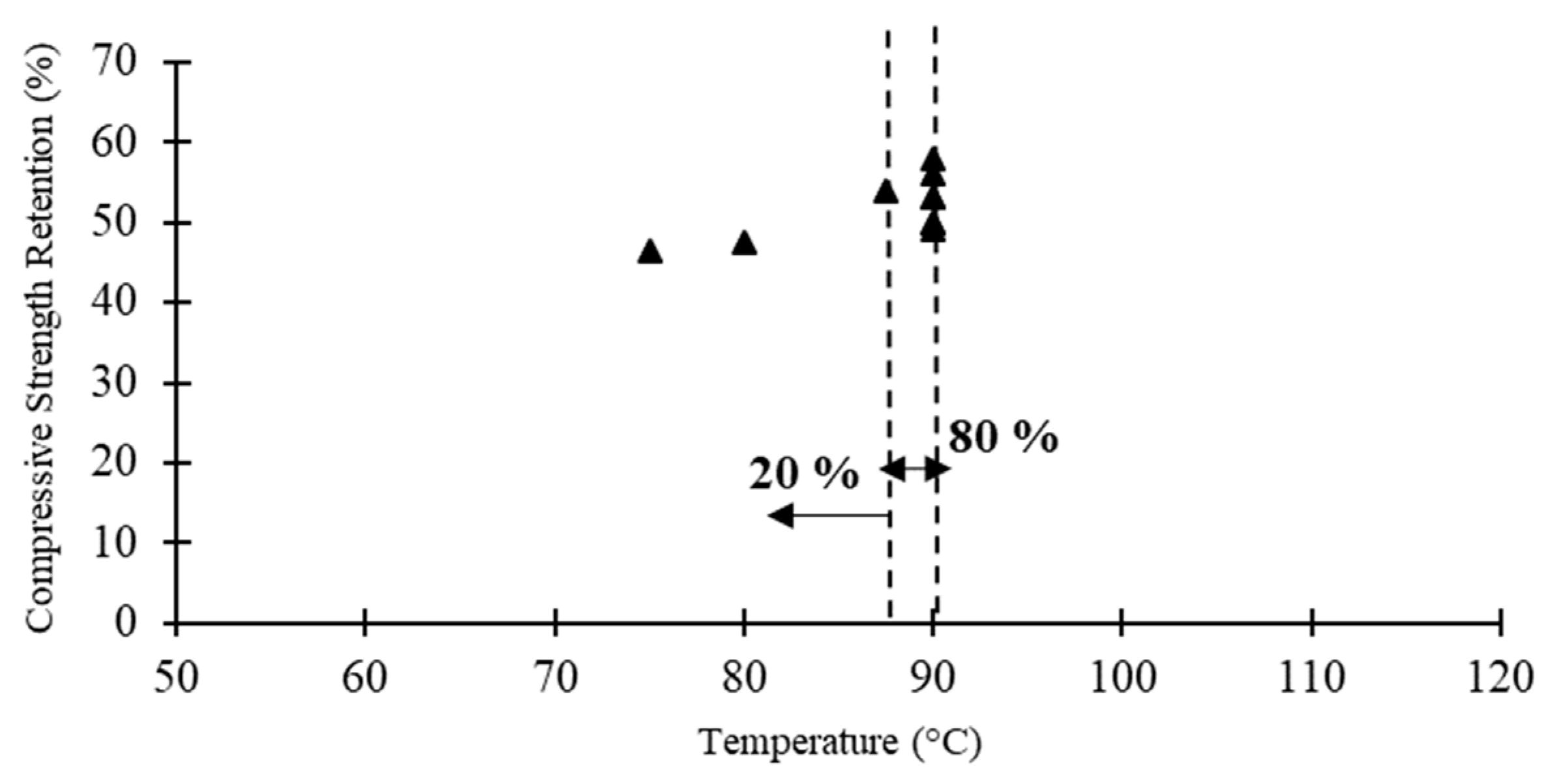

4.2. Columns

5. Recommendations for Future Work

- (1)

- More experimental results under real fire condition (e.g., ISO 834) are needed to understand the effect of different factors, on fire resistance of FRP composites.

- (2)

- The data related to the effects of fibres content and orientations on performance of FRP composites under elevated temperatures exist but are very limited, thus further work is needed in this area.

- (3)

- More experimental tests on BFRP composites are needed to better understand the effects of different factors on performance of such new composites under elevated temperatures.

- (4)

- To investigate whether a structure that was exposed to high temperatures can still be used or damages can be repaired, more studies are required on the post-fire properties of FRP composites.

- (5)

- Finally, by using the available data and proposed models, the current codes and guidelines should be developed to include specific procedures for the fire design of FRP composites.

6. Conclusions

- (1)

- When subjected to elevated temperatures below glass transition temperature, Tg, the resin matrix will not be significantly affected (i.e., some micro cracks may occur) and the surface of the resin matrix will remain rough and similar to the unconditioned sample. In this case, no dramatic strength and stiffness reductions of FRP composites occur.

- (2)

- When FRP composites reach their glass transition temperature Tg, the resin changes from glassy state to rubbery state. In this case, FRP materials soften and creep, causing a considerable reduction of both strength and stiffness.

- (3)

- When FRP materials are exposed to temperatures around resin decomposition temperature, their organic matrix decomposes, releasing heat, smoke, soot and toxic volatiles. Exposure to such range of elevated temperatures (e.g., 300–500 °C) leads to breaking of the chemical bonds, modular chains of the resin and bonds between the fibres. The ignition and combustion of the composite occur at higher temperatures.

- (4)

- The critical temperature (i.e., temperature corresponding to 50% strength reduction) is generally 300–330 °C for FRP reinforcing bars, 200–300 °C for laminates in tension, 180–250 °C for laminates in bending and 87–90 °C for pultruded GFRP profiles in compression.

- (5)

- FRP composites fail in compression and interlaminar shear at significantly lower loads and exposure temperature than in tension and flexure.

- (6)

- Elastic modulus of FRP composites is less affected by elevated temperatures compared to the corresponding strength values. This is mainly due to the fact that the elastic modulus of FRP composites is more related to the elastic modulus of fibres than resin.

Author Contributions

Funding

Conflicts of Interest

References

- Oskouei, A.V.; Jafari, A.; Bazli, M.; Ghahri, R. Effect of different retrofitting techniques on in-plane behavior of masonry wallettes. Constr. Build. Mater. 2018, 169, 578–590. [Google Scholar] [CrossRef]

- Jafari, A.; Oskouei, A.V.; Bazli, M.; Ghahri, R. Effect of the FRP sheet’s arrays and NSM FRP bars on in-plane behavior of URM walls. J. Build. Eng. 2018, 20, 679–695. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Raman, R.S.; Bai, Y.; Khezrzadeh, H. Durability of glass-fibre-reinforced polymer composites under seawater and sea-sand concrete coupled with harsh outdoor environments. Adv. Struct. Eng. 2020, 2020, 1369433220947897. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Oskouei, A.V. Enhancement of bond characteristics of ribbed-surface GFRP bars with concrete by using carbon fiber mat anchorage. Constr. Build. Mater. 2017, 134, 507–519. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Papadopoulos, N.A. Investigation of a New Strengthening Technique for RC Deep Beams Using Carbon FRP Ropes as Transverse Reinforcements. Fibers 2018, 6, 52. [Google Scholar] [CrossRef] [Green Version]

- Belarbi, A.; Bae, S.-W.; Brancaccio, A. Behavior of full-scale RC T-beams strengthened in shear with externally bonded FRP sheets. Constr. Build. Mater. 2012, 32, 27–40. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Bai, Y.; Raman, R.S.; Khezrzadeh, H. Mechanical properties of pultruded GFRP profiles under seawater sea sand concrete environment coupled with UV radiation and moisture. Constr. Build. Mater. 2020, 258, 120369. [Google Scholar] [CrossRef]

- Bazli, M.; Bazli, L.; Rahmani, R.; Mansoor, S.; Ahmadi, M.; Pouriamanesh, R. Concrete filled FRP–PVC tubular columns used in the construction sector: A review. J. Compos. Compd. 2020, 2, 155–162. [Google Scholar]

- Hajiloo, H.; Green, M.F.; Gales, J. Mechanical properties of GFRP reinforcing bars at high temperatures. Constr. Build. Mater. 2018, 162, 142–154. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos. Part B Eng. 2016, 99, 203–215. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Bai, Y.; Raman, R.S.; Al-Saadi, S.; Haque, A. Durability of pultruded GFRP tubes subjected to seawater sea sand concrete and seawater environments. Constr. Build. Mater. 2020, 245, 118399. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Experiments and probabilistic models of bond strength between GFRP bar and different types of concrete under aggressive environments. Constr. Build. Mater. 2017, 148, 429–443. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Jafari, A.; Zhao, X.-L.; Raman, R.S.; Bai, Y. Effect of Fibers Configuration and Thickness on Tensile Behavior of GFRP Laminates Exposed to Harsh Environment. Polymers 2019, 11, 1401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bazli, M.; Zhao, X.-L.; Bai, Y.; Raman, R.S.; Al-Saadi, S. Bond-slip behaviour between FRP tubes and seawater sea sand concrete. Eng. Struct. 2019, 197, 109421. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Durability of FRP rods for concrete structures. Constr. Build. Mater. 2004, 18, 491–503. [Google Scholar] [CrossRef]

- Cromwell, J.; Harries, K.; Shahrooz, B. Environmental durability of externally bonded FRP materials intended for repair of concrete structures. Constr. Build. Mater. 2011, 25, 2528–2539. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Zapris, A.G.; Karayannis, C.G.G. U-Jacketing Applications of Fiber-Reinforced Polymers in Reinforced Concrete T-Beams against Shear—Tests and Design. Fibers 2020, 8, 13. [Google Scholar] [CrossRef] [Green Version]

- Saeed, Y.M.; Aules, W.A.; Rad, F.N.; Raad, A.M. Tensile behavior of FRP anchors made from CFRP ropes epoxy-bonded to uncracked concrete for flexural strengthening of RC columns. Case Stud. Constr. Mater. 2020, 13, e00435. [Google Scholar] [CrossRef]

- Russo, S.; Ghadimi, B.; Lawania, K.K.; Rosano, M. Residual strength testing in pultruded FRP material under a variety of temperature cycles and values. Compos. Struct. 2015, 133, 458–475. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T.; Correia, J.; Branco, F.; Ferreira, J. Fire protection systems for building floors made of pultruded GFRP profiles—Part 2: Modeling of thermomechanical responses. Compos. Part B Eng. 2010, 41, 630–636. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.C.; Aravinthan, T.; Reddy, K.R.; Ferdous, W.; Wong, H.; Nazari, A. Effect of elevated in-service temperature on the mechanical properties and microstructure of particulate-filled epoxy polymers. Polym. Degrad. Stab. 2019, 170, 108994. [Google Scholar] [CrossRef]

- Kodur, V.; Bhatt, P. A numerical approach for modeling response of fiber reinforced polymer strengthened concrete slabs exposed to fire. Compos. Struct. 2018, 187, 226–240. [Google Scholar] [CrossRef]

- Jiangtao, Y.; Yichao, W.; Kexu, H.; Kequan, Y.; Jianzhuang, X. The performance of near-surface mounted CFRP strengthened RC beam in fire. Fire Saf. J. 2017, 90, 86–94. [Google Scholar] [CrossRef]

- Kodur, V.K.; Bisby, L.A.; Foo, S.H. Thermal behavior of fire-exposed concrete slabs reinforced with fiber-reinforced polymer bars. ACI Struct. J. 2005, 102, 799. [Google Scholar]

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite Materials; Springer Science and Business Media LLC: Dodrecht, The Netherlands, 2006. [Google Scholar]

- Hamad, R.J.; Johari, M.M.; Haddad, R.H. Mechanical properties and bond characteristics of different fiber reinforced polymer rebars at elevated temperatures. Constr. Build. Mater. 2017, 142, 521–535. [Google Scholar] [CrossRef]

- Wang, Y.; Wong, P.; Kodur, V. An experimental study of the mechanical properties of fibre reinforced polymer (FRP) and steel reinforcing bars at elevated temperatures. Compos. Struct. 2007, 80, 131–140. [Google Scholar] [CrossRef]

- Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Response to fire of concrete structures that incorporate FRP. Prog. Struct. Eng. Mater. 2005, 7, 136–149. [Google Scholar] [CrossRef]

- Bai, Y.; Vallée, T.; Keller, T. Modeling of thermal responses for FRP composites under elevated and high temperatures. Compos. Sci. Technol. 2008, 68, 47–56. [Google Scholar] [CrossRef]

- Wang, Y.; Kodur, V. Variation of strength and stiffness of fibre reinforced polymer reinforcing bars with temperature. Cem. Concr. Compos. 2005, 27, 864–874. [Google Scholar] [CrossRef]

- Fleischhaker, F.; Haehnel, A.P.; Misske, A.M.; Blanchot, M.; Haremza, S.; Barner-Kowollik, C. Glass-Transition-, Melting-, and Decomposition Temperatures of Tailored Polyacrylates and Polymethacrylates: General Trends and Structure-Property Relationships. Macromol. Chem. Phys. 2014, 215, 1192–1200. [Google Scholar] [CrossRef]

- Chowdhury, E.U.; Eedson, R.; Bisby, L.A.; Green, M.F.; Benichou, N. Mechanical Characterization of Fibre Reinforced Polymers Materials at High Temperature. Fire Technol. 2009, 47, 1063–1080. [Google Scholar] [CrossRef]

- Jafari, A.; Ashrafi, H.; Bazli, M.; Ozbakkaloglu, T. Effect of thermal cycles on mechanical response of pultruded glass fiber reinforced polymer profiles of different geometries. Compos. Struct. 2019, 223, 110959. [Google Scholar] [CrossRef]

- Dodds, N.; Gibson, A.; Dewhurst, D.; Davies, J. Fire behaviour of composite laminates. Compos. Part A Appl. Sci. Manuf. 2000, 31, 689–702. [Google Scholar] [CrossRef]

- Kumahara, S.; Masuda, Y.; Tanano, H.; Shimizu, A. Tensile strength of continuous fiber bar under high temperature. Spec. Publ. 1993, 138, 731–742. [Google Scholar]

- Aydin, F. Effects of various temperatures on the mechanical strength of GFRP box profiles. Constr. Build. Mater. 2016, 127, 843–849. [Google Scholar] [CrossRef]

- Ahmed, A.; Kodur, V. The experimental behavior of FRP-strengthened RC beams subjected to design fire exposure. Eng. Struct. 2011, 33, 2201–2211. [Google Scholar] [CrossRef]

- Firmo, J.; Correia, J.R. Fire behaviour of thermally insulated RC beams strengthened with EBR-CFRP strips: Experimental study. Compos. Struct. 2015, 122, 144–154. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, G.; Zhang, L.; Zhang, J.; Hui, D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos. Part B Eng. 2014, 60, 680–687. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Fire behavior of concrete T-beams strengthened with near-surface mounted FRP reinforcement. Eng. Struct. 2014, 80, 350–361. [Google Scholar] [CrossRef]

- Yu, J.; Liu, K.; Li, L.-Z.; Wang, Y.; Yu, K.; Xu, Q. A simplified method to predict the fire resistance of RC beams strengthened with near-surface mounted CFRP. Compos. Struct. 2018, 193, 1–7. [Google Scholar] [CrossRef]

- Uematsu, Y.; Kitamura, T.; Ohtani, R. Delamination behavior of a carbon-fiber-reinforced thermoplastic polymer at high temperatures. Compos. Sci. Technol. 1995, 53, 333–341. [Google Scholar] [CrossRef]

- Williams, B.; Bisby, L.; Kodur, V.; Green, M.; Chowdhury, E. Fire insulation schemes for FRP-strengthened concrete slabs. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1151–1160. [Google Scholar] [CrossRef]

- Bisby, L.A. Fire Behaviour of Fibre-Reinforced Polymer (FRP) Reinforced or Confined Concrete. Ph.D. Thesis, Queen’s University Kingston, Kingston, OR, Canada, 2003. [Google Scholar]

- Chowdhury, E.U.; Bisby, L.A.; Green, M.F.; Kodur, V.K. Investigation of insulated FRP-wrapped reinforced concrete columns in fire. Fire Saf. J. 2007, 42, 452–460. [Google Scholar] [CrossRef]

- Burke, P.J.; Bisby, L.A.; Green, M.F. Effects of elevated temperature on near surface mounted and externally bonded FRP strengthening systems for concrete. Cem. Concr. Compos. 2013, 35, 190–199. [Google Scholar] [CrossRef]

- Najafabadi, E.P.; Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of applied stress and bar characteristics on the short-term creep behavior of FRP bars. Constr. Build. Mater. 2018, 171, 960–968. [Google Scholar] [CrossRef]

- Carlos, T.B.; Rodrigues, J.P.C.; De Lima, R.C.; Dhima, D. Experimental analysis on flexural behaviour of RC beams strengthened with CFRP laminates and under fire conditions. Compos. Struct. 2018, 189, 516–528. [Google Scholar] [CrossRef]

- Gao, W.-Y.; Dai, J.-G.; Teng, J. Fire resistance design of un-protected FRP-strengthened RC beams. Mater. Struct. 2016, 49, 5357–5371. [Google Scholar] [CrossRef]

- Kodur, V.; Yu, B. Evaluating the Fire Response of Concrete Beams Strengthened with Near-Surface-Mounted FRP Reinforcement. J. Compos. Constr. 2013, 17, 517–529. [Google Scholar] [CrossRef]

- Tan, K.H.; Zhou, Y. Performance of FRP-Strengthened Beams Subjected to Elevated Temperatures. J. Compos. Constr. 2011, 15, 304–311. [Google Scholar] [CrossRef]

- Ahmed, A.; Kodur, V. Effect of bond degradation on fire resistance of FRP-strengthened reinforced concrete beams. Compos. Part B Eng. 2011, 42, 226–237. [Google Scholar] [CrossRef]

- Leone, M.; Matthys, S.; Aiello, M.A. Effect of elevated service temperature on bond between FRP EBR systems and concrete. Compos. Part B: Eng. 2009, 40, 85–93. [Google Scholar] [CrossRef]

- Firmo, J.P.; Correia, J.; Pitta, D.; Tiago, C.; Arruda, M. Experimental characterization of the bond between externally bonded reinforcement (EBR) CFRP strips and concrete at elevated temperatures. Cem. Concr. Compos. 2015, 60, 44–54. [Google Scholar] [CrossRef]

- Bisby, L.A.; Kodur, V.K.R.; Green, M.F. Fire Endurance of Fiber-Reinforced Polymer-Confined Concrete Columns. ACI Struct. J. 2005, 102, 883–891. [Google Scholar]

- Adelzadeh, M.; Green, M.F.; Benichou, N. Behaviour of fibre reinforced polymer-strengthened T-beams and slabs in fire. Proc. Inst. Civ. Eng. Struct. Build. 2012, 165, 361–371. [Google Scholar] [CrossRef] [Green Version]

- Grace, N.; Bebawy, M. Fire Protection for Beams with Fiber-Reinforced Polymer Flexural Strengthening Systems. ACI Struct. J. 2014, 111, 537–548. [Google Scholar] [CrossRef] [Green Version]

- Williams, B.; Kodur, V.; Green, M.F.; Bisby, L.A. Fire Endurance of Fiber-Reinforced Polymer Strengthened Concrete T-Beams. ACI Struct. J. 2008, 105, 60. [Google Scholar]

- Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Modeling the Behavior of Fiber Reinforced Polymer-Confined Concrete Columns Exposed to Fire. J. Compos. Constr. 2005, 9, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, E.; Bisby, L.A.; Green, M.F.; Benichou, N.; Kodur, V. Heat transfer and structural response modelling of FRP confined rectangular concrete columns in fire. Constr. Build. Mater. 2012, 32, 77–89. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Kodur, V. Effect of high temperature on bond strength of near-surface mounted FRP reinforcement. Compos. Struct. 2014, 110, 88–97. [Google Scholar] [CrossRef]

- Saafi, M. Effect of fire on FRP reinforced concrete members. Compos. Struct. 2002, 58, 11–20. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Bisby, L.A. Evaluation of Fire Endurance of Concrete Slabs Reinforced with Fiber-Reinforced Polymer Bars. J. Struct. Eng. 2005, 131, 34–43. [Google Scholar] [CrossRef] [Green Version]

- Hajiloo, H.; Green, M.F.; Noël, M.; Bénichou, N.; Sultan, M. Fire tests on full-scale FRP reinforced concrete slabs. Compos. Struct. 2017, 179, 705–719. [Google Scholar] [CrossRef]

- Bilotta, A.; Compagnone, A.; Esposito, L.; Nigro, E. Structural behaviour of FRP reinforced concrete slabs in fire. Eng. Struct. 2020, 221, 111058. [Google Scholar] [CrossRef]

- Wang, X.L.; Zha, X.X. Experimental Research on Mechanical Behavior of GFRP Bars under High Temperature. Appl. Mech. Mater. 2011, 71, 3591–3594. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Behavior of GFRP reinforcing bars subjected to extreme temperatures. J. Compos. Constr. 2010, 14, 353–360. [Google Scholar] [CrossRef]

- Firmo, J.P.; Correia, J.R.; Bisby, L.A. Fire behaviour of FRP-strengthened reinforced concrete structural elements: A state-of-the-art review. Compos. Part B Eng. 2015, 80, 198–216. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Naser, M.; Zaidan, W.; Rasheed, H. Modeling of insulated CFRP-strengthened reinforced concrete T-beam exposed to fire. Eng. Struct. 2009, 31, 3072–3079. [Google Scholar] [CrossRef]

- Kodur, V.; Ahmed, A. Numerical Model for Tracing the Response of FRP-Strengthened RC Beams Exposed to Fire. J. Compos. Constr. 2010, 14, 730–742. [Google Scholar] [CrossRef]

- Zeng, Y.; Caspeele, R.; Matthys, S.; Taerwe, L. Compressive membrane action in FRP strengthened RC members. Constr. Build. Mater. 2016, 126, 442–452. [Google Scholar] [CrossRef]

- Truong, G.T.; Lee, H.-H.; Choi, K.-K. Flexural behavior of RC beams strengthened with NSM GFRP strips after exposed to high temperatures. Eng. Struct. 2018, 173, 203–215. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Kivi, M.P.; Araghi, H.; Bazli, M. Experimental study of the punching behavior of GFRP reinforced lightweight concrete footing. Mater. Struct. 2017, 50, 256. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Kosmidou, P.-M.K.; Chalioris, C.E. Reinforced Concrete Beams with Carbon-Fiber-Reinforced Polymer Bars—Experimental Study. Fibers 2018, 6, 99. [Google Scholar] [CrossRef] [Green Version]

- Adam, M.A.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366. [Google Scholar] [CrossRef]

- Maranan, G.; Manalo, A.; Karunasena, W.; Benmokrane, B.; Lutze, D. Flexural behaviour of glass fibre reinforced polymer (GFRP) bars subjected to elevated temperature. In Proceedings of the 23rd Australasian Conference on the Mechanics of Structures and Materials (ACMSM23), Byron Bay, Australia, 9–12 December 2014. [Google Scholar]

- Blontrock, H.; Taerwe, L.; Matthys, S. Properties of fiber reinforced plastics at elevated temperatures with regard to fire resistance of reinforced concrete members. Spec. Publ. 1999, 188, 43–54. [Google Scholar]

- Sayed-Ahmed, E.Y.; Shrive, N.G. Smart FRP Prestressing Tendons: Properties and Prospects. In Proceedings of the Second Middle East Symposium on Structural Composites for Infrastructure Applications, Hurghada, Egypt, 26 April 1999; pp. 80–93. [Google Scholar]

- Nause, I. Determination of Temperature-Dependent Tensile Strengths of ComBAR Reinforcement Bars; Report No: 072/05-Nau-3740/6345; Brunswick Institute for Concrete Material Testing: Brunswick, Germany, 2005. [Google Scholar]

- Ellis, D.S.; Tabatabai, H.; Nabizadeh, A. Residual Tensile Strength and Bond Properties of GFRP Bars after Exposure to Elevated Temperatures. Materials 2018, 11, 346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alsayed, S.; Al-Salloum, Y.; Almusallam, T.H.; El-Gamal, S.; Aqel, M. Performance of glass fiber reinforced polymer bars under elevated temperatures. Compos. Part B Eng. 2012, 43, 2265–2271. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Najafabadi, E.P.; Oskouei, A.V. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures. Constr. Build. Mater. 2017, 157, 1001–1010. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Oskouei, A.V.; Bazli, L. Effect of Sequential Exposure to UV Radiation and Water Vapor Condensation and Extreme Temperatures on the Mechanical Properties of GFRP Bars. J. Compos. Constr. 2018, 22, 04017047. [Google Scholar] [CrossRef]

- Özkal, F.M.; Polat, M.; Yağan, M.; Öztürk, M.O. Mechanical properties and bond strength degradation of GFRP and steel rebars at elevated temperatures. Constr. Build. Mater. 2018, 184, 45–57. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, J.; Song, S.; Yang, D.; Wang, C. Effect of Temperature on Material Properties of Carbon Fiber Reinforced Polymer (CFRP) Tendons: Experiments and Model Assessment. Materials 2019, 12, 1025. [Google Scholar] [CrossRef] [Green Version]

- Bazli, M. Mechanical and Microstructural Properties of Different FRP Composites under Various Environmental Conditions. Ph.D. Thesis, Monash University, Melbourne, VI, Australia, 2020. [Google Scholar]

- Gibson, A.G.; Wright, P.N.H.; Wu, Y.-S.; Mouritz, A.P.; Mathys, Z.; Gardiner, C.P. The Integrity of Polymer Composites during and after Fire. J. Compos. Mater. 2004, 38, 1283–1307. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Feih, S.; Kandare, E.; Mathys, Z.; Gibson, A.; Jardin, P.D.; Case, S.; Lattimer, B. Review of fire structural modelling of polymer composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1800–1814. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Piscitelli, F.; Prota, A.; Lavorgna, M.; Mensitieri, G.; Manfredi, G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr. Build. Mater. 2012, 31, 273–283. [Google Scholar] [CrossRef]

- Nguyen, P.L.; Vu, X.H.; Ferrier, E. Thermo-mechanical performance of Carbon Fiber Reinforced Polymer (CFRP), with and without fire protection material, under combined elevated temperature and mechanical loading conditions. Compos. Part B Eng. 2019, 169, 164–173. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of elevated temperatures on the mechanical properties of basalt fibers and BFRP plates. Constr. Build. Mater. 2016, 127, 1029–1036. [Google Scholar] [CrossRef]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar] [CrossRef]

- Jafari, A.; Bazli, M.; Ashrafi, H.; Oskouei, A.V.; Azhari, S.; Zhao, X.-L.; Gholipour, H. Effect of fibers configuration and thickness on tensile behavior of GFRP laminates subjected to elevated temperatures. Constr. Build. Mater. 2019, 202, 189–207. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Jafari, A.; Ozbakkaloglu, T. Tensile properties of GFRP laminates after exposure to elevated temperatures: Effect of fiber configuration, sample thickness, and time of exposure. Compos. Struct. 2020, 238, 111971. [Google Scholar] [CrossRef]

- Jarrah, M.; Najafabadi, E.P.; Khaneghahi, M.H.; Oskouei, A.V. The effect of elevated temperatures on the tensile performance of GFRP and CFRP sheets. Constr. Build. Mater. 2018, 190, 38–52. [Google Scholar] [CrossRef]

- Cao, S.; Wu, Z.; Wang, X. Tensile Properties of CFRP and Hybrid FRP Composites at Elevated Temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar]

- Cao, S.; Wang, X.; Wu, Z. Evaluation and prediction of temperature-dependent tensile strength of unidirectional carbon fiber-reinforced polymer composites. J. Reinf. Plast. Compos. 2011, 30, 799–807. [Google Scholar]

- Gibson, A.; Torres, M.O.; Browne, T.; Feih, S.; Mouritz, A. High temperature and fire behaviour of continuous glass fibre/polypropylene laminates. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1219–1231. [Google Scholar] [CrossRef]

- Kumarasamy, S.; Abidin, M.S.Z.; Abu Bakar, M.N.; Nazida, M.; Mustafa, Z.; Anjang, A. Effects of High and Low Temperature on the Tensile Strength of Glass Fiber Reinforced Polymer Composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 370, p. 012021. [Google Scholar]

- Hawileh, R.A.; Abdalla, J.A.; Hasan, S.S.; Ziyada, M.B.; Abu-Obeidah, A. Models for predicting elastic modulus and tensile strength of carbon, basalt and hybrid carbon-basalt FRP laminates at elevated temperatures. Constr. Build. Mater. 2016, 114, 364–373. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Abu-Obeidah, A.; Abdalla, J.A.; Al-Tamimi, A. Temperature effect on the mechanical properties of carbon, glass and carbon–glass FRP laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Foster, S.K.; Bisby, L.A. Fire Survivability of Externally Bonded FRP Strengthening Systems. J. Compos. Constr. 2008, 12, 553–561. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, X.; Wu, G. Basalt FRP Composite as Reinforcements in Infrastructure. In Proceedings of the 17th Annual International Conference on Composites/Nano Engineering (ICCE-17): International Conference on Composites/Nano Engineering (ICCE), Waikiki, HI, USA, 26–31 July 2009; pp. 21–24. [Google Scholar]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Reis, J.; Coelho, J.; Monteiro, A.; Mattos, H.D.C. Tensile behavior of glass/epoxy laminates at varying strain rates and temperatures. Compos. Part B Eng. 2012, 43, 2041–2046. [Google Scholar] [CrossRef]

- Shekarchi, M.; Farahani, E.M.; Yekrangnia, M.; Ozbakkaloglu, T. Mechanical strength of CFRP and GFRP composites filled with APP fire retardant powder exposed to elevated temperature. Fire Saf. J. 2020, 115, 103178. [Google Scholar] [CrossRef]

- Correia, J.; Gomes, M.M.; Pires, J.M.; Branco, F. Mechanical behaviour of pultruded glass fibre reinforced polymer composites at elevated temperature: Experiments and model assessment. Compos. Struct. 2013, 98, 303–313. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T. Modeling of Strength Degradation for Fiber-reinforced Polymer Composites in Fire. J. Compos. Mater. 2009, 43, 2371–2385. [Google Scholar] [CrossRef]

- Gibson, A.G.; Wu, Y.-S.; Evans, J.T.; Mouritz, A.P. Laminate Theory Analysis of Composites under Load in Fire. J. Compos. Mater. 2005, 40, 639–658. [Google Scholar] [CrossRef]

- Najafabadi, E.P.; Khaneghahi, M.H.; Amiri, H.A.; Estekanchi, H.E.; Ozbakkaloglu, T. Experimental investigation and probabilistic models for residual mechanical properties of GFRP pultruded profiles exposed to elevated temperatures. Compos. Struct. 2019, 211, 610–629. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Jafari, A.; Zhao, X.-L.; Gholipour, H.; Oskouei, A.V. Effect of thickness and reinforcement configuration on flexural and impact behaviour of GFRP laminates after exposure to elevated temperatures. Compos. Part B Eng. 2019, 157, 76–99. [Google Scholar] [CrossRef]

- Ningyun, W.; Evans, J. Collapse of continuous fibre composite beams at elevated temperatures. Composites 1995, 26, 56–61. [Google Scholar] [CrossRef]

- Manalo, A.; Surendar, S.; Van Erp, G.; Benmokrane, B. Flexural behavior of an FRP sandwich system with glass-fiber skins and a phenolic core at elevated in-service temperature. Compos. Struct. 2016, 152, 96–105. [Google Scholar] [CrossRef]

- Vieira, P.S.C.; De Souza, F.S.; Cardoso, D.C.T.; Vieira, J.D.; Silva, F.D.A. Influence of moderate/high temperatures on the residual flexural behavior of pultruded GFRP. Compos. Part B Eng. 2020, 200, 108335. [Google Scholar] [CrossRef]

- Schmidt, D.G.; D’Almeida, J.R.M. Effect of Temperature Exposure on the Flexural Mechanical Behavior of Two Pultruded Composites. Fire Technol. 2018, 54, 1565–1583. [Google Scholar] [CrossRef]

- Asaro, R.; Lattimer, B.; Ramroth, W. Structural response of FRP composites during fire. Compos. Struct. 2009, 87, 382–393. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T. Delamination and kink-band failure of pultruded GFRP laminates under elevated temperatures and compression. Compos. Struct. 2011, 93, 843–849. [Google Scholar] [CrossRef]

- Summers, P.; Lattimer, B.; Case, S.; Feih, S. Predicting compression failure of composite laminates in fire. Compos. Part A Appl. Sci. Manuf. 2012, 43, 773–782. [Google Scholar] [CrossRef]

- Feih, S.; Mathys, Z.; Gibson, A.; Mouritz, A.P. Modelling the tension and compression strengths of polymer laminates in fire. Compos. Sci. Technol. 2007, 67, 551–564. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Bazli, M.; Ashrafi, H.; Imani, M. Flexural and web crippling properties of GFRP pultruded profiles subjected to wetting and drying cycles in different sea water conditions. Polym. Test. 2018, 69, 417–430. [Google Scholar] [CrossRef]

- Bazli, M.; Jafari, A.; Ashrafi, H.; Zhao, X.-L.; Bai, Y.; Raman, R.K.S. Effects of UV radiation, moisture and elevated temperature on mechanical properties of GFRP pultruded profiles. Constr. Build. Mater. 2020, 231, 117137. [Google Scholar] [CrossRef]

- Bazli, M.; Zhao, X.-L.; Raman, R.S.; Bai, Y.; Al-Saadi, S. Bond performance between FRP tubes and seawater sea sand concrete after exposure to seawater condition. Constr. Build. Mater. 2020, 265, 120342. [Google Scholar] [CrossRef]

- Cabova, K.; Ryjacek, P.; Hrasky, O.; Kolpasky, L.; Vujtech, J.; Wald, F. Fire Test of FRP Members Applied to Railway Bridge. In Proceedings of the 9th International Conference on Structures in Fire, Princeton, NJ, USA, 8 June 2016; pp. 784–790. [Google Scholar]

- Bazli, M.; Li, Y.-L.; Zhao, X.-L.; Raman, R.S.; Bai, Y.; Al-Saadi, S.; Haque, A. Durability of seawater and sea sand concrete filled filament wound FRP tubes under seawater environments. Compos. Part B Eng. 2020, 202, 108409. [Google Scholar] [CrossRef]

- American Society of Civil Engineers (ASCE). Pre-Standard for Load and Resistance Factor Design (LRFD) of Pultruded Fiber Reinforced Polymer (FRP) Structures; ASCE: Reston, VA, USA, 2010. [Google Scholar]

- Ascione, L.; Caron, J.F.; Godonou, P.; IJselmuijden, K.V.; Knippers, J.; Mottram, T.; Oppe, M.; Gantriis Sorensen, M.G.; Taby, J.; Tromp, L. EURProspect for New Guidance in the Design of FRP; Publications Office of the European Union: Geneva, Switzerland, 2016. [Google Scholar]

- Association for Engineering Construction Standardization CECS 410: 2015. Technical Specification for Stainless-Steel Structures; China Association for Engineering Construction Standardization: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Correia, J.R.; Bai, Y.; Keller, T. A review of the fire behaviour of pultruded GFRP structural profiles for civil engineering applications. Compos. Struct. 2015, 127, 267–287. [Google Scholar] [CrossRef]

- Correia, J.; Branco, F.; Ferreira, J.; Bai, Y.; Keller, T. Fire protection systems for building floors made of pultruded GFRP profiles. Compos. Part B Eng. 2010, 41, 617–629. [Google Scholar] [CrossRef]

- Wong, P.; Davies, J.; Wang, Y. An experimental and numerical study of the behaviour of glass fibre reinforced plastics (GRP) short columns at elevated temperatures: Part 1: Experimental investigations. Compos. Struct. 2004, 63, 33–43. [Google Scholar] [CrossRef]

- Ludwig, C.; Knippers, J.; Hugi, E.; Ghazi Wakili, K. Damage of Flexural Loaded Composite Beams Subjected to Fire. In Proceedings of the 4th International Conference on FRP Composite in Civil Engineering, Zurich, Switzerland, 22–24 July 2008; pp. 527–536. [Google Scholar]

- Wijayawardane, I.S.K.; Mutsuyoshi, H.; Nguyen, H.; Manalo, A. Flexural behaviour of glass fibre-reinforced polymer and ultra-high-strength fibre-reinforced concrete composite beams subjected to elevated temperature. Adv. Struct. Eng. 2016, 20, 1357–1374. [Google Scholar] [CrossRef]

- Morgado, T.; Correia, J.; Silvestre, N.; Branco, F. Experimental study on the fire resistance of GFRP pultruded tubular beams. Compos. Part B Eng. 2018, 139, 106–116. [Google Scholar] [CrossRef]

- Mouritz, A.P. Post-fire flexural properties of fibre-reinforced polyester, epoxy and phenolic composites. J. Mater. Sci. 2002, 37, 1377–1386. [Google Scholar] [CrossRef]

- Correia, J.R.; Branco, F.A.; Ferreira, J.G. The effect of different passive fire protection systems on the fire reaction properties of GFRP pultruded profiles for civil construction. Compos. Part A Appl. Sci. Manuf. 2010, 41, 441–452. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Bazli, M.; Oskouei, A.V.; Zhao, X.-L. The effect of elevated temperatures on the compressive section capacity of pultruded GFRP profiles. Constr. Build. Mater. 2020, 249, 118725. [Google Scholar] [CrossRef]

- Wong, P.; Wang, Y. An experimental study of pultruded glass fibre reinforced plastics channel columns at elevated temperatures. Compos. Struct. 2007, 81, 84–95. [Google Scholar] [CrossRef]

- Currie, P.; Davies, J.; Wang, Y. Behaviour of short columns of pultruded GRP channels at elevated temperatures. FRP Composites in Civil Engineering. In Proceedings of the International Conference on FRP Composites in Civil Engineering Hong Kong Institution of Engineers, Hong Kong Institution of Steel Construction, Hong Kong, China, 12–15 December 2001. [Google Scholar]

| Study | Fibre Type | Resin Type | Bar Size | Tg | Critical Temperature (T1) | Strength Retention at T1 | Modulus Retention at T1 | Maximum Test Temperature (T2) | Strength Retention at T2 | Modulus Retention at T2 |

|---|---|---|---|---|---|---|---|---|---|---|

| [27,30] | Carbon | Polyester | 9.5 | NA | 250 | 50% | 80% | 600 | 6% | 35% |

| Glass | Polyester | 9.5 | NA | 325 | 50% | 90% | 500 | 16% | NA | |

| [26] | Carbon | Vinyl ester | 10 | NA | 325 | 45% | 68% | 450 | 10% | 37% |

| Glass | Polyester | 10 | NA | 325 | 55% | 79% | 375 | 9% | 52% | |

| Basalt | Epoxy | 10 | NA | 325 | 55% | 79% | 375 | 13% | 47% | |

| [82] | Carbon | Epoxy | 5 | 110 | 300 | 55% | NA | 450 | 35% | NA |

| Glass | Epoxy | 4 | 110 | 300 | 50% | NA | 450 | 29% | NA | |

| Epoxy | 10 | 110 | 450 | 50% | NA | 450 | 50% | NA | ||

| [80] | Glass | Vinyl ester | 19 | NA | NA | NA | 400 | 83% | 83% | |

| [84] | Glass | Epoxy | 9 | NA | 375 | 50% | 75% | 500 | 10% | 7% |

| [86] | Carbon | Epoxy | 8 | 126 | 300 | 53% | NA | 500 | 17% | NA |

| [83] | Glass | Epoxy | 10 | 95 | 300 | 57% | NA | 300 | 57% | NA |

| [67] | Glass | Vinyl ester | 12.7 | 113 | 325 | 47% | NA | 325 | 47% | NA |

| [81] | Glass | Vinyl ester | 12 | NA | 300 | 58% | No change | 300 | 58% | No change |

| [9] | Glass | Vinyl ester | 16 | 110 | 300 | 49% | 75% | 400 | 41% | 75% |

| [85] | Carbon | NA | 6.4 | 80 | 330 | 50% | 60% | 600 | 8% | 20% |

| Study | Fibre Type | Resin Type | Bar Size | Tg | Stress Ratio (%) | Loading Rate (°C/min) | Failure Temperature (°C) |

|---|---|---|---|---|---|---|---|

| [9] | Glass | Vinyl ester | 16 | 110 | 22 | 5 | 518 |

| 35 | 425 | ||||||

| 47 | 327 | ||||||

| 53 | 193 | ||||||

| 59 | 157 | ||||||

| [86] | Carbon | Epoxy | 8 | 126 | 28.8 | 20 | 468 |

| 38.5 | 431 | ||||||

| 48.1 | 366 | ||||||

| 57.7 | 239 | ||||||

| 67.3 | 183 |

| Study | Fibre Type | Fibres Orientation | Resin Type | Specimen Dimensions (in mm) | Tg | Critical Temperature (T1) | Strength Retention at T1 | Modulus Retention at T1 | Maximum Test Temperature (T2) | Strength Retention at T2 | Modulus Retention at T2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [97] | Carbon | Unidirectional | epoxy | 400 × 200 (1 layer of fibre) | 38 | NA | NA | NA | 200 | 68% | NA |

| [102] | Carbon | Unidirectional | epoxy | 250 × 40 × 0.348 | NA | 300 | 54% | 39% | 300 | 54% | 39% |

| Glass | Unidirectional | epoxy | 250 × 40 × 0.352 | NA | 300 | 57% | 70% | 300 | 57% | 70% | |

| [101] | Carbon | Unidirectional | epoxy | 250 × 40 × 0.99 | 85 | 131 | 50% | 20% | 250 | 19% | 9% |

| Basalt | Unidirectional | epoxy | 250 × 40 × 0.95 | 85 | 250 | 59% | 73% | 250 | 59% | 73% | |

| [94] | Glass | Unidirectional | epoxy | Dog-bone (600 × 20 × 2) | 70 | 300 | 56% | NA | 550 | 17% | NA |

| Glass | Woven | epoxy | Dog-bone (600 × 20 × 2) | 70 | 300 | 51% | NA | 400 | 8% | NA | |

| Glass | Chopped strand mat | epoxy | Dog-bone (600 × 20 ×2) | 70 | 60–80 | 50% | NA | 250 | 13% | NA | |

| [95] | Glass | Unidirectional | epoxy | 300 × 20 × 5 | 70 | 300 | 45% | 82% | 300 | 45% | 82% |

| Glass | Woven | epoxy | 300 × 20 × 5 | 70 | 200 | 55% | 87% | 300 | 35% | 68% | |

| Glass | Chopped strand mat | epoxy | 300 × 20 × 5 | 70 | 120 | 53% | 89% | 300 | 6% | 24% | |

| [96] | Carbon | Woven | epoxy | 500 × 30 (1 layer of fabric) | 60 | 300 | 50% | NA | 600 | 32% | NA |

| Glass | Woven | epoxy | 500 × 30 (1 layer of fabric) | 60 | 400 | 50% | NA | 600 | 13% | NA | |

| [93] | Carbon | Unidirectional | epoxy | 600 × 26 × 1.4 | 60 | 300 | 54% | NA | 700 | 6% | NA |

| [92] | Glass | Unidirectional | epoxy | 15 (width) × 1.27 | 167 | 200 | 57% | 80% | 200 | 57% | 80% |

| Basalt | Unidirectional | epoxy | 16 (width) × 1.27 | 167 | NA | NA | NA | 200 | 63% | 69% | |

| [99] | Glass | Unidirectional | Polypropylene | Dog-bone (300 × 15 × 12) | NA | 150 | 50% | NA | 300 | 25% | NA |

| [98] | Carbon | Unidirectional | epoxy | 250 × 10 × 0.111 | 45 | NA | NA | NA | 120 | 70% | NA |

| [107] | Carbon | Unidirectional | epoxy | 600 × 25 × 2.5 | 100 | 300 | 52% | NA | 500 | 30% | NA |

| Glass | Unidirectional | epoxy | 600 × 25 × 2.5 | 100 | 250 | 52% | NA | 500 | 17% | NA | |

| [36] | Glass | Unidirectional | Polyester | 200 × 20 × 4 | NA | 200 | 47% | NA | 200 | 47% | NA |

| [32] | Glass | Unidirectional | epoxy | 735 × 38 × 2.6 | 75 | 75 | 48% | 77% | 200 | 46% | 81% |

| [85] | Carbon | Unidirectional | NA | 13.5 (wide) × 4.5 (thickness) | 80 | 300 | 50% | 53% | 600 | 11% | NA |

| [103] | Carbon | Unidirectional | epoxy | 1 (thickness) | 78 | 400 | 50% | NA | 400 | 50% | NA |

| Glass | Unidirectional | epoxy | 1.3 (thickness) | 78 | 350 | 50% | NA | 400 | 20% | NA |

| Study | Fibre Type | Fibres Orientation | Resin Type | Laminate Dimensions | Tg | Critical Temperature (T1) | Strength Retention at T1 | Maximum Temperature (T2) | Strength Retention at T2 |

|---|---|---|---|---|---|---|---|---|---|

| [112] | Glass | Unidirectional | epoxy | 70 × 18 × 5 | 70 | 225 | 50% | 300 | 8% |

| Glass | Woven | epoxy | 70 × 18 × 5 | 70 | 200 | 50% | 300 | 4% | |

| Glass | Chopped strand mat | epoxy | 70 × 18 × 5 | 70 | 200 | 47% | 300 | 4% | |

| [92] | Basalt | Unidirectional | epoxy | 7.8 × 2.6 × 1.27 | 167 | 100 | 50% | 200 | 10% |

| [107] | Carbon | Unidirectional | epoxy | 100 × 25 × 2.5 | 100 | 250 | 50% | 350 | 11% |

| Glass | Unidirectional | epoxy | 100 × 25 × 2.5 | 100 | 200 | 50% | 350 | 7% | |

| [113] | Carbon | Unidirectional | Polyetheretherketone | 12 × 30 × 2 | NA | 180 | 50% | 300 | 25% |

| [114] | Glass | Woven and chopped strand mat | phenolic | 220 × 50 × 5 | NA | 120 | 46% | 180 | 52% |

| [116] | Glass | Unidirectional | Polyester | 135 × 25 × 6.9 | NA | 250 | 50% | 250 | 50% |

| Unidirectional | Phenolic | 90.5 × 25 × 4.2 | NA | NA | NA | 250 | 80% | ||

| [115] | Glass | Unidirectional | Polyester | 240 × 25 × 9.5 | 100 | NA | NA | 320 | No reduction |

| Unidirectional | Vinyl ester | 155 × 16 × 6 | 113 | NA | NA | 320 | No reduction | ||

| Unidirectional | Phenolic | 240 × 25 × 9.5 | 120 | NA | NA | 320 | No reduction | ||

| Unidirectional | Polyester | 95 × 47.5 × 9.5 | 100 | NA | NA | 270 | No reduction | ||

| Unidirectional | Vinyl ester | 60 × 30 × 6 | 113 | NA | NA | 270 | 83% | ||

| Unidirectional | Phenolic | 95 × 47.5 × 9.5 | 120 | NA | NA | 270 | 93% |

| Study | Fibre Type | Fibres Orientation | Resin Type | Laminate Dimensions | Tg | Critical Temperature (T1) | Strength Retention at T1 | Maximum Temperature (T2) | Strength Retention at T2 |

|---|---|---|---|---|---|---|---|---|---|

| [118] | Glass | Unidirectional | polyester | 400 × 48 × 12 | 155 | 140 | 57% | 180 | 40% |

| [99] | Glass | Woven | Polypropylene | 125 × 105 × 12 | NA | 80 | 50% | 140 | 7% |

| [120] | Glass | Woven | Vinyl ester | 100 × 100 × 9 | 120 | 100 | 45% | 180 | 7% |

| Study | Cross Section | Span/Height (m) | Number of Sides | Load | Fire Resistance (min) |

|---|---|---|---|---|---|

| [130] | Square tubular (h = 100 mm, tf = tw = 8 mm) | 1.5 | 1 | L/400 (4PB) | 38 |

| [134] | Square tubular (h = 100 mm, tf = tw = 8 mm) | 1.3 | 1 | L/400 (4PB) | 36 |

| Square tubular (h = 100 mm, tf = tw = 8 mm) | 1.3 | 3 | L/400 (4PB) | 8 | |

| Square tubular (h = 100 mm, tf = tw = 8 mm) | 1.3 | 1 | L/250 (4PB) | 31 | |

| [132] | IPE 120 | 1.5 | 4 | 10 kN (3PB) | 1.45 |

| IPE 160 | 1.5 | 4 | 10 kN (3PB) | 2.25 |

| Study | Profile Type (Length × min Thickness) | Tg | Critical Temperature (T1) | Compressive Strength Retention at T1 | Modulus Retention at T1 | Maximum Temperature (T2) | Compressive Strength Retention at T2 | Modulus Retention at T2 |

|---|---|---|---|---|---|---|---|---|

| [137] | I-shaped (4.3 mm) | 95 | 90 | 53% | NA | 400 | 2% | NA |

| Channel (5 mm) | 90 | 53% | NA | 400 | 2% | NA | ||

| Box (3 mm) | 90 | 50% | NA | 400 | 5% | NA | ||

| Angle (6 mm) | 90 | 49% | NA | 400 | 3% | NA | ||

| [138] | Channel (500 mm × 5 mm) | NA | 90 | 56% | 78% | 120 | 40% | 65% |

| Channel (900 mm × 5 mm) | NA | NA | NA | 120 | 62% | 84% | ||

| Channel (1350 mm × 5 mm) | NA | NA | NA | 120 | 67% | 66% | ||

| [131] | Channel (30 mm × 4 mm) | NA | 60–90 | 63%–30% | NA | 250 | 8% | NA |

| [139] | Channel (400 mm × 4 mm) | NA | 90 | 58% | 70% | 250 | 8% | 30% |

| [36] | Box (74 mm × 3 mm) | NA | 75–100 | 75%–33% | NA | 175 | 6% | NA |

| [108] | I-shaped (50 mm × 6 mm) | 136 | 90 | 44% | NA | 250 | 5% | NA |

| [109] | Tube (300 mm × 3 mm) | 110 | 60–100 | 65%–30% | NA | 220 | 10% | NA |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. https://doi.org/10.3390/polym12112600

Bazli M, Abolfazli M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers. 2020; 12(11):2600. https://doi.org/10.3390/polym12112600

Chicago/Turabian StyleBazli, Milad, and Milad Abolfazli. 2020. "Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview" Polymers 12, no. 11: 2600. https://doi.org/10.3390/polym12112600

APA StyleBazli, M., & Abolfazli, M. (2020). Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers, 12(11), 2600. https://doi.org/10.3390/polym12112600