Backpressure Optimization in Foam Injection Molding: Method and Assessment of Sustainability

Abstract

:1. Introduction

2. Theoretical Background

3. Materials and Methods

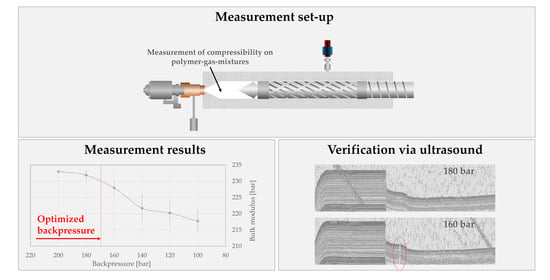

3.1. Optimization Procedure

3.2. Materials and Equipment

4. Results and Discussion

4.1. Backpressure Optimization Using N2

4.2. Backpressure Reduction Using CO2: Mechanical Characterization

4.3. Backpressure Reduction Using CO2: Assessment of Sustainability

5. Conclusions

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lewis, H.; Verghese, K.; Fitzpatrick, L. Evaluating the sustainability impacts of packaging: The plastic carry bag dilemma. Packag. Technol. Sci. 2010, 23, 145–160. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Mendoza, J.M.F.; Azapagic, A. Improving the environmental sustainability of reusable food containers in Europe. Sci. Total Environ. 2018, 628–629, 979–989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eagan, J.M.; Xu, J.; Di Girolamo, R.; Thurber, C.M.; Macosko, C.W.; LaPointe, A.M.; Bates, F.S.; Coates, G.W. Combining polyethylene and polypropylene: Enhanced performance with PE/iPP multiblock polymers. Science 2017, 355, 814–816. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tekkaya, A.E.; Khalifa, N.B.; Grzancic, G.; Hölker, R. Forming of Lightweight Metal Components: Need for New Technologies. Proc. Eng. 2014, 81, 28–37. [Google Scholar] [CrossRef] [Green Version]

- Davies, G. Chapter 8: Environmental and safety considerations. In Materials for Automobile Bodies, 2nd ed.; Davies, G., Ed.; Butterworth-Heinemann: Oxford, UK, 2012; pp. 309–356. [Google Scholar]

- Koltzenburg, S.; Maskos, M.; Nuyken, O. Grundlagen der Kunststoffverarbeitung. In Polymere: Synthese, Eigenschaften und Anwendungen; Koltzenburg, S., Maskos, M., Nuyken, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 461–496. [Google Scholar]

- Heim, H.-P. Preface. In Specialized Injection Molding Techniques, 1st ed.; Heim, H.-P., Ed.; Elsevier: Oxford, UK, 2016; pp. xi–xiv. [Google Scholar]

- Spörrer, A.N.J.; Altstädt, V. Controlling Morphology of Injection Molded Structural Foams by Mold Design and Processing Parameters. J. Cell. Plast. 2007, 43, 313–330. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, G.; Wang, C.; Park, C.B. Injection Molded Strong Polypropylene Composite Foam Reinforced with Rubber and Talc. Macromol. Mater. Eng. 2020, 305, 1900630. [Google Scholar] [CrossRef]

- Kuboki, T. Mechanical properties and foaming behavior of injection molded cellulose fiber reinforced polypropylene composite foams. J. Cell. Plast. 2014, 50, 129–143. [Google Scholar] [CrossRef]

- Moon, Y.; Cha, S.W.; Seo, J. Bubble Nucleation and Growth in Microcellular Injection Molding Processes. Polym. Plast. Technol. Eng. 2008, 47, 420–426. [Google Scholar] [CrossRef]

- Xu, X.; Park, C.B. Injection foam molding. In Injection Molding, Technology and Fundamentals; Kamal, M.R., Isayev, A., Liu, S.J., Eds.; Hanser: Munich, Germany, 2009; pp. 273–307. [Google Scholar]

- Lee, M.; Tzoganakis, C.; Park, C.B. Effects of supercritical CO2 on the viscosity and morphology of polymer blends. Adv. Polym. Technol. 2000, 19, 300–311. [Google Scholar] [CrossRef]

- Royer, J.R.; Gay, Y.J.; Desimone, J.M.; Khan, S.A. High-pressure rheology of polystyrene melts plasticized with CO2: Experimental measurement and predictive scaling relationships. J. Polym. Sci. B Polym. Phys. 2000, 38, 3168–3180. [Google Scholar] [CrossRef]

- Kramschuster, A.; Cavitt, R.; Ermer, D.; Chen, Z.; Turng, L.-S. Quantitative study of shrinkage and warpage behavior for microcellular and conventional injection molding. Polym. Eng. Sci. 2005, 45, 1408–1418. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.H.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-tough and super thermal-insulation nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, L.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur. Polym. J. 2018, 98, 1–10. [Google Scholar] [CrossRef]

- Neyciyani, B.; Kazemi Najafi, S.; Ghasemi, I. Influence of foaming and carbon nanotubes on sound transmission loss of wood fiber-low density polyethylene composites. J. Appl. Polym. Sci. 2017, 134, 45096. [Google Scholar] [CrossRef]

- Scherzer, D. Werkstofftechnologien mit Kunststoffen. In Leichtbau in der Fahrzeugtechnik, 1st ed.; Friedrich, H.E., Ed.; Springer: Wiesbaden, Germany, 2013; pp. 538–621. [Google Scholar]

- Altan, M. Thermoplastic Foams: Processing, Manufacturing, and Characterization. In Polymerization; Çankaya, N., Ed.; IntechOpen: London, UK, 2018; pp. 117–137. [Google Scholar]

- Rohleder, M.; Jakob, F. Foam Injection Molding. In Specialized Injection Molding Techniques Techniques, 1st ed.; Heim, H.-P., Ed.; Elsevier: Oxford, UK, 2016; pp. 53–106. [Google Scholar]

- Kharbas, H.; Nelson, P.; Yuan, M.; Gong, S.; Turng, L.-S.; Spindler, R. Effects of nano-fillers and process conditions on the microstructure and mechanical properties of microcellular injection molded polyamide nanocomposites. Polym. Compos. 2003, 24, 655–671. [Google Scholar] [CrossRef]

- Volpe, V.; Pantani, R. Foam injection molding of poly(lactic) acid: Effect of back pressure on morphology and mechanical properties. J. Appl. Polym. Sci. 2015, 132, 42612. [Google Scholar] [CrossRef]

- Xu, X.; Park, C.B.; Lee, J.W.S.; Zhu, X. Advanced structural foam molding using a continuous polymer/gas melt flow stream. J. Appl. Polym. Sci. 2008, 109, 2855–2861. [Google Scholar] [CrossRef]

- Guo, M.-C.; Heuzey, M.-C.; Carreau, P.J. Cell structure and dynamic properties of injection molded polypropylene foams. Polym. Eng. Sci. 2007, 47, 1070–1081. [Google Scholar] [CrossRef]

- Chien, R.D.; Chen, S.-C.; Lee, P.-H.; Huang, J.-S. Study on the Molding Characteristics and Mechanical Properties of Injection-molded Foaming Polypropylene Parts. J. Reinf. Plast. Compos. 2004, 23, 429–444. [Google Scholar] [CrossRef]

- Rizivi, S.J.A.; Bhatnagar, N. Optimization of Microcellular Injection Molding Parameters. Int. Polym. Process. 2009, 24, 399–405. [Google Scholar] [CrossRef]

- Kastner, C.; Steinbichler, G. Theoretical Background and Automation Approach for a Novel Measurement Method for Determining Dynamic Solubility Limits of Supercritical Fluids in Injection Foam Molding. Polym. Eng. Sci. 2020, 60, 330–340. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, I.; Lacombe, R.H. An elementary molecular theory of classical fluids. Pure fluids. J. Phys. Chem. 1976, 80, 2352–2362. [Google Scholar] [CrossRef]

- Sanchez, I.; Lacombe, R.H. Statistical Thermodynamics of Polymer Solutions. Macromolecules 1978, 11, 1145–1156. [Google Scholar] [CrossRef] [Green Version]

- Kamiya, Y.; Mizoguchi, K.; Naito, Y. Sorption and partial molar volumes of inert gases in rubbery polymers. J. Membr. Sci. 1994, 93, 45–52. [Google Scholar] [CrossRef]

- Lei, Z.; Ohyabu, H.; Sato, Y.; Inomata, H.; Smith, R.L., Jr. Solubility, swelling degree and crystallinity of carbon dioxide-polypropylene system. J. Supercrit. Fluids 2007, 40, 452–461. [Google Scholar] [CrossRef]

- Barzegari, M.R.; Rodrigue, D. The effect of density profile on the flexural properties of structural foams. Polym. Eng. Sci. 2007, 47, 1459–1468. [Google Scholar] [CrossRef]

- Mount, E.M., III. Extrusion Processes. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications, 2nd ed.; Kutz, M., Ed.; Elsevier: Oxford, UK, 2017; pp. 217–264. [Google Scholar]

| . | PP-H | PP-C | Blowing Agent | Application |

|---|---|---|---|---|

| PGC 1 | - | 85% | N2 | Method development, verification |

| PGC 2 | 85% | - | CO2 | Mechanical characterization, sustainability potential |

| Backpressure | (bar) | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

|---|---|---|---|---|---|---|---|---|

| (s) | 22.73 | 23.46 | 23.05 | 22.62 | 23.15 | 22.03 | 22.08 | |

| (rpm) | 56.76 | 63.06 | 71.37 | 79.58 | 85.74 | 97.15 | 104.06 | |

| (Nm) | 1049 | 1123 | 1212 | 1303 | 1370 | 1502 | 1593 | |

| (bar·mm) | 8738 | 11,036 | 13,020 | 15,301 | 17,051 | 19,223 | 21,627 | |

| (Wh) | 39.37 | 48.34 | 58.00 | 68.25 | 79.08 | 93.50 | 106.48 | |

| (W) | 6.24 | 7.42 | 9.06 | 10.86 | 12.30 | 15.28 | 17.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kastner, C.; Mitterlehner, T.; Altmann, D.; Steinbichler, G. Backpressure Optimization in Foam Injection Molding: Method and Assessment of Sustainability. Polymers 2020, 12, 2696. https://doi.org/10.3390/polym12112696

Kastner C, Mitterlehner T, Altmann D, Steinbichler G. Backpressure Optimization in Foam Injection Molding: Method and Assessment of Sustainability. Polymers. 2020; 12(11):2696. https://doi.org/10.3390/polym12112696

Chicago/Turabian StyleKastner, Clemens, Thomas Mitterlehner, Dominik Altmann, and Georg Steinbichler. 2020. "Backpressure Optimization in Foam Injection Molding: Method and Assessment of Sustainability" Polymers 12, no. 11: 2696. https://doi.org/10.3390/polym12112696

APA StyleKastner, C., Mitterlehner, T., Altmann, D., & Steinbichler, G. (2020). Backpressure Optimization in Foam Injection Molding: Method and Assessment of Sustainability. Polymers, 12(11), 2696. https://doi.org/10.3390/polym12112696