Unique Slow Crack Growth Behavior of Isotactic Polypropylene: The Role of Shear Layer-Spherulites Layer Alternated Structure

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Samples Preparation

2.3. Polarized Optical Microscopy (POM)

2.4. Differential Scanning Calorimeter (DSC)

2.5. Synchrotron Two-Dimensional X-ray Measurements

2.6. Scanning Electron Microscopy (SEM)

2.7. Slow Crack Growth Process (SCG)

3. Results and Discussion

3.1. Crystalline Structure

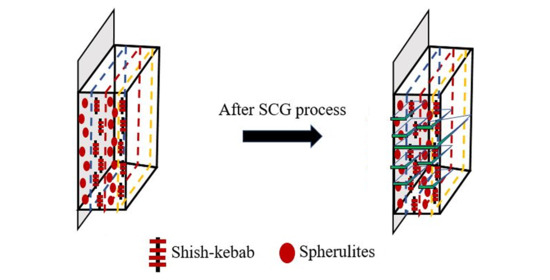

3.2. Slow Crack Growth Process

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Housmans, J.-W.; Gahleitner, M.; Peters, G.W.M.; Meijer, H.E. Structure–property Relations in Molded, Nucleated Isotactic Polypropylene. Polymers 2009, 50, 2304–2319. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, F.; Mi, D.; Zhou, M.; Jiang, Y.; Zhang, J. Self-Reinforcement of Polypropylene Lid-Shaped Samples Induced by Increasing Shish-Kebab Content: Practical Application of Vibration Injection Technology. Ind. Eng. Chem. Res. 2018, 57, 8620–8629. [Google Scholar] [CrossRef]

- Kantz, M.R.; Newman, H.D.; Stigale, F.H. The Skin-Core Morphology and structure–property Relationships in Injection-Molded Polypropylene. J. Appl. Polym. Sci. 1972, 16, 1249–1260. [Google Scholar] [CrossRef]

- Gedde, U.W.; Viebke, J.; Leijström, H.; Ifwarson, M. Long-Term Properties of Hot-Water Polyolefin pipes—A Review. Polym. Eng. Sci. 1994, 34, 1773–1787. [Google Scholar] [CrossRef]

- Chan, M.; Williams, J. Slow Stable Crack Growth in High Density Polyethylenes. Polymer 1983, 24, 234–244. [Google Scholar] [CrossRef]

- Young, R.J.; Beaumont, P.W.R. Failure of Brittle Polymers by Slow Crack Growth. J. Mater. Sci. 1977, 12, 684–692. [Google Scholar] [CrossRef]

- Schouwenaars, R.; Jacobo, V.; Ramos, E.; Ortiz, A. Slow Crack Growth and Failure Induced by Manufacturing Defects in HDPE-Tubes. Eng. Fail. Anal. 2007, 14, 1124–1134. [Google Scholar] [CrossRef]

- Lu, X.; Qian, R.; McGhie, A.R.; Brown, N. The Effect of Annealing on Slow Crack Growth in an Ethylene-Hexene Copolymer. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 899–906. [Google Scholar] [CrossRef]

- Huang, Y.-L.; Brown, N. Dependence of Slow Crack Growth in Polyethylene on Butyl Branch Density: Morphology and Theory. J. Polym. Sci. Part B Polym. Phys. 1991, 29, 129–137. [Google Scholar] [CrossRef]

- Huang, Y.-L.; Brown, N. The Effect of Molecular Weight on Slow Crack Growth in Linear Polyethylene Homopolymers. J. Mater. Sci. 1988, 23, 3648–3655. [Google Scholar] [CrossRef]

- Pan, Y.; Gao, X.; Wang, Z.; Lei, J.; Shen, K.; Li, Z. Effect of Different Morphologies on Slow Crack Growth of High-Density Polyethylene. RSC Adv. 2015, 5, 28191–28202. [Google Scholar] [CrossRef]

- Lu, X.; Zhou, Z.; Brown, N. A Sensitive Mechanical Test for Slow Crack Growth in Polyethylene. Polym. Eng. Sci. 1997, 37, 1896–1900. [Google Scholar] [CrossRef]

- Bohm, L.L.; Enderle, H.F.; Fleifßner, M. High-Density Polyethylene Pipe Resins. Adv. Mater. 1992, 4, 234–238. [Google Scholar] [CrossRef]

- Gent, A.N.; Gregory, B.L.; Jeong, J.; Charrier, J.-M.; Hamel, F. Effect of a Separator in a Sheet Die on the Anisotropy of Tear Strength of Extruded Medium Density Polyethylene. Polym. Eng. Sci. 1987, 27, 1675–1680. [Google Scholar] [CrossRef]

- Capaccio, G.; Rose, L.J.; Kip, B.J. Craze Morphology and Molecular Orientation in the Slow Crack Growth Failure of Polyethylene. J. Appl. Polym. Sci. 2000, 77, 283–296. [Google Scholar]

- De Gennes, P.G. Coil-stretch Transition of Dilute Flexible Polymers under Ultrahigh Velocity Gradients. J. Chem. Phys. 1974, 60, 5030–5042. [Google Scholar] [CrossRef]

- Somani, R.H.; Yang, L.; Zhu, L.; Hsiao, B.S. Flow-Induced Shish-Kebab Precursor Structures in Entangled Polymer Melts. Polymer 2005, 46, 8587–8623. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Liu, F.; Guo, C.; Fu, Q.; Shen, K.; Zhang, J. Shish–kebab-Like Cylindrulite Structures Resulted from Periodical Shear-Induced Crystallization of Isotactic Polypropylene. Polymer 2011, 52, 2970–2978. [Google Scholar] [CrossRef]

- Jiang, Y.; Mi, D.; Wang, Y.; Wang, T.; Shen, K.; Zhang, J. Insight into Understanding the Influence of Blending Ratio on the Structure and Properties of High-Density Polyethylene/Polystyrene Microfibril Composites Prepared by Vibration Injection Molding. Ind. Eng. Chem. Res. 2019, 58, 1190–1199. [Google Scholar] [CrossRef]

- Zhong, G.-J.; Li, L.; Mendes, E.; Byelov, D.; Fu, Q.; Li, Z.-M. Suppression of Skin−Core Structure in Injection-Molded Polymer Parts by in Situ Incorporation of a Microfibrillar Network. Macromolecules 2006, 39, 6771–6775. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Zhong, G.-J.; Wang, Y.; Li, Z.-M.; Li, L. Unusual Tuning of Mechanical Properties of Isotactic Polypropylene Using Counteraction of Shear Flow and β-Nucleating Agent on β-Form Nucleation. Macromolecules 2009, 42, 4343–4348. [Google Scholar] [CrossRef]

- Kech, A.; Ludwig, H.-C.; Möginger, B.; Eyerer, P.; Christiansen, J.D.C. Mechanical Properties of Isotactic Polypropylene with Oriented and Cross-Hatched Lamellae Structure. Int. Polym. Process. 2000, 15, 202–207. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, Y.; Zhang, L.; Zheng, G.; Yan, X.; Dai, K.; Liu, C.; Shen, C.; Guo, Z. Interfacial Interaction Enhancement by Shear-Induced β-Cylindrite in Isotactic polypropylene/Glass Fiber Composites. Polymer 2016, 100, 111–118. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Z.; Zheng, G.; Guo, Z.; Dai, K.; Liu, C. Enhancing Oriented Crystals in Injection-Molded HDPE through Introduction of Pre-Shear. Mater. Des. 2015, 78, 12–18. [Google Scholar] [CrossRef]

- Mi, D.; Xia, C.; Jin, M.; Wang, F.; Shen, K.; Zhang, J. Quantification of the Effect of Shish-Kebab Structure on the Mechanical Properties of Polypropylene Samples by Controlling Shear Layer Thickness. Macromolecules 2016, 49, 4571–4578. [Google Scholar] [CrossRef]

- Mi, D.; La, R.; Wang, T.; Zhang, X.; Zhang, J. Hierarchic Structure and Mechanical Property of Glass Fiber Reinforced Isotactic Polypropylene Composites Molded by Multiflow Vibration Injection Molding. Polym. Compos. 2015, 38, 2707–2717. [Google Scholar] [CrossRef]

- Hou, F.; Mi, D.; Zhou, M.; Zhang, J. The Influences of a Novel Shear Layer-Spherulites Layer Alternated Structure on the Mechanical Properties of Injection-Molded Isotactic Polypropylene. Polymer 2017, 122, 12–21. [Google Scholar] [CrossRef]

- Gu, X.; Wang, Y.; Jiang, Y.; Liu, M.; Fu, Q.; Zhang, J. High Impact Performance Induced by a Synergistic Effect of Heteroepitaxy and Oriented Layer-Unoriented Layer Alternated Structure in iPP/HDPE Injection Molded Part. Polymer 2019, 175, 206–214. [Google Scholar] [CrossRef]

- Liu, M.; Hong, R.; Gu, X.; Fu, Q.; Zhang, J. Remarkably Improved Impact Fracture Toughness of Isotactic Polypropylene via Combining the Effects of Shear Layer-Spherulites Layer Alternated Structure and Thermal Annealing. Ind. Eng. Chem. Res. 2019, 58, 15069–15078. [Google Scholar] [CrossRef]

| CIM | V1 | V2 | |

|---|---|---|---|

| Injection pressure (MPa) | 40 | 40 | 40 |

| Packing pressure (MPa) | 30 | 30 | 30 |

| Vibration pressure (MPa) | 60 | 100 | |

| Interval time(s) | 1/4/8 | 10/5 |

| Sample | CIM | V1 | V2 |

|---|---|---|---|

| of shear layer (°C) | 165.29 | 164.57 | 165.21 |

| of spherulites layer (°C) | 165.14 | 165.11 | 165.55 |

| of shear layer (%) | 44.4 | 44.6 | 45.3 |

| of spherulites layer (%) | 44.5 | 42.7 | 43.2 |

| Sample | CIM | V1 | V2 |

|---|---|---|---|

| of shish-kebab (nm) | 28.98 | 31.67 | 31.81 |

| of spherulites (nm) | 27.36 | 27.29 | 27.41 |

| of shish-kebab (nm) | 12.87 | 14.12 | 14.41 |

| of spherulites(nm) | 12.18 | 11.65 | 11.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Luo, J.; Chen, J.; Gao, X.; Fu, Q.; Zhang, J. Unique Slow Crack Growth Behavior of Isotactic Polypropylene: The Role of Shear Layer-Spherulites Layer Alternated Structure. Polymers 2020, 12, 2746. https://doi.org/10.3390/polym12112746

Liu M, Luo J, Chen J, Gao X, Fu Q, Zhang J. Unique Slow Crack Growth Behavior of Isotactic Polypropylene: The Role of Shear Layer-Spherulites Layer Alternated Structure. Polymers. 2020; 12(11):2746. https://doi.org/10.3390/polym12112746

Chicago/Turabian StyleLiu, Mingjin, Jiaxu Luo, Jin Chen, Xueqin Gao, Qiang Fu, and Jie Zhang. 2020. "Unique Slow Crack Growth Behavior of Isotactic Polypropylene: The Role of Shear Layer-Spherulites Layer Alternated Structure" Polymers 12, no. 11: 2746. https://doi.org/10.3390/polym12112746