Durability of PS-Polyurethane Dedicated for Composite Strengthening Applications in Masonry and Concrete Structures

Abstract

:1. Introduction

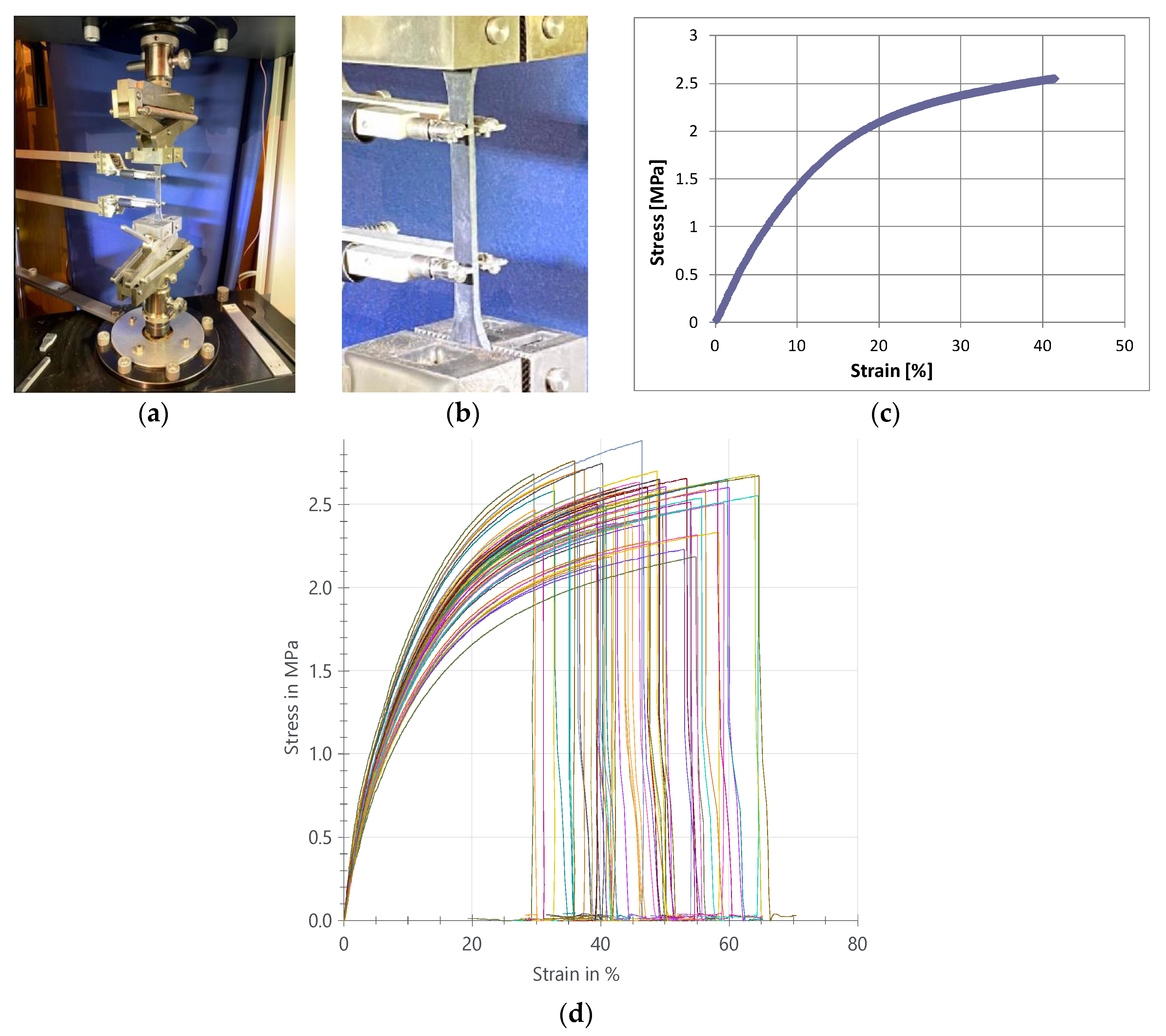

2. Experimental Setup

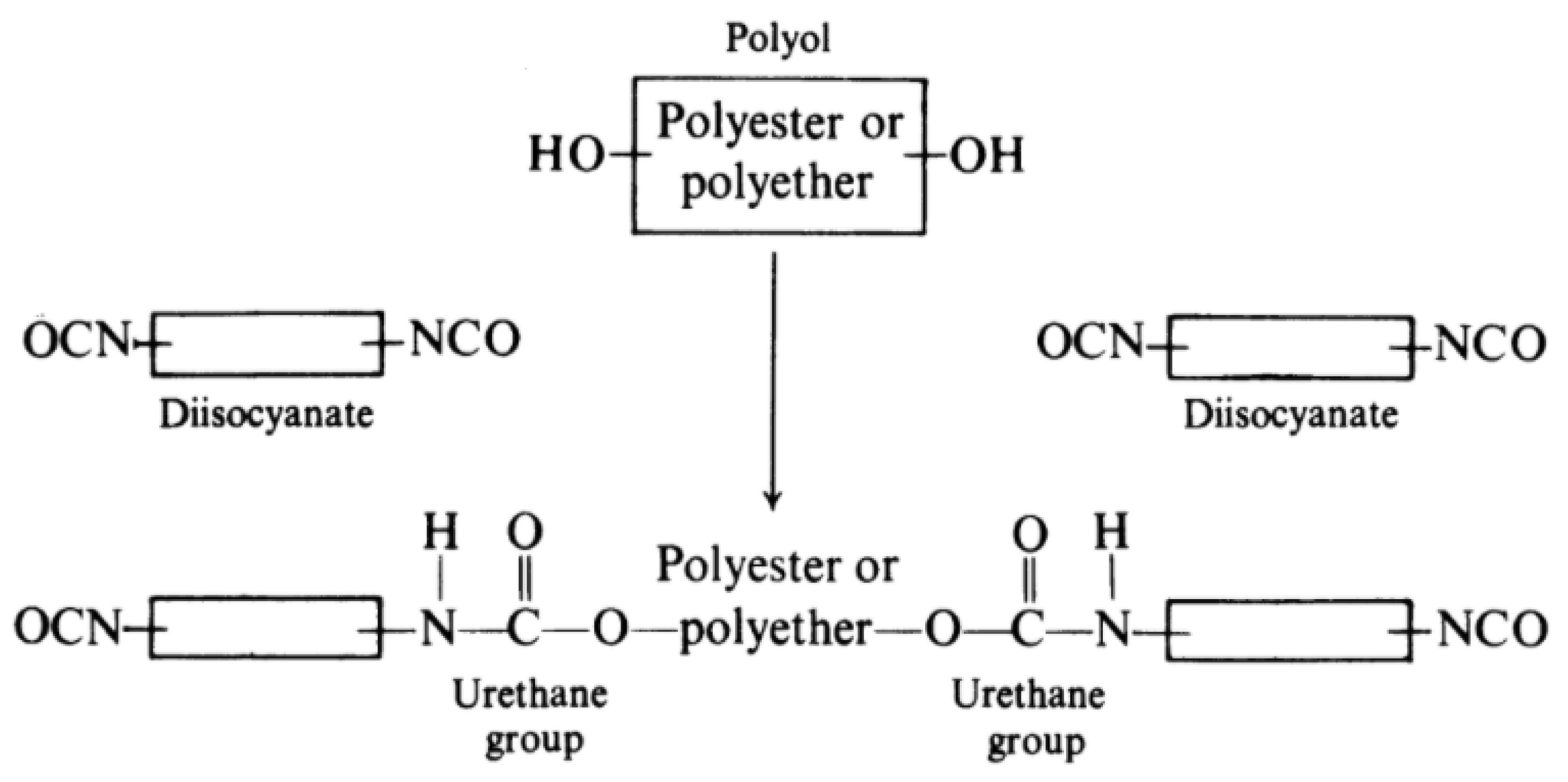

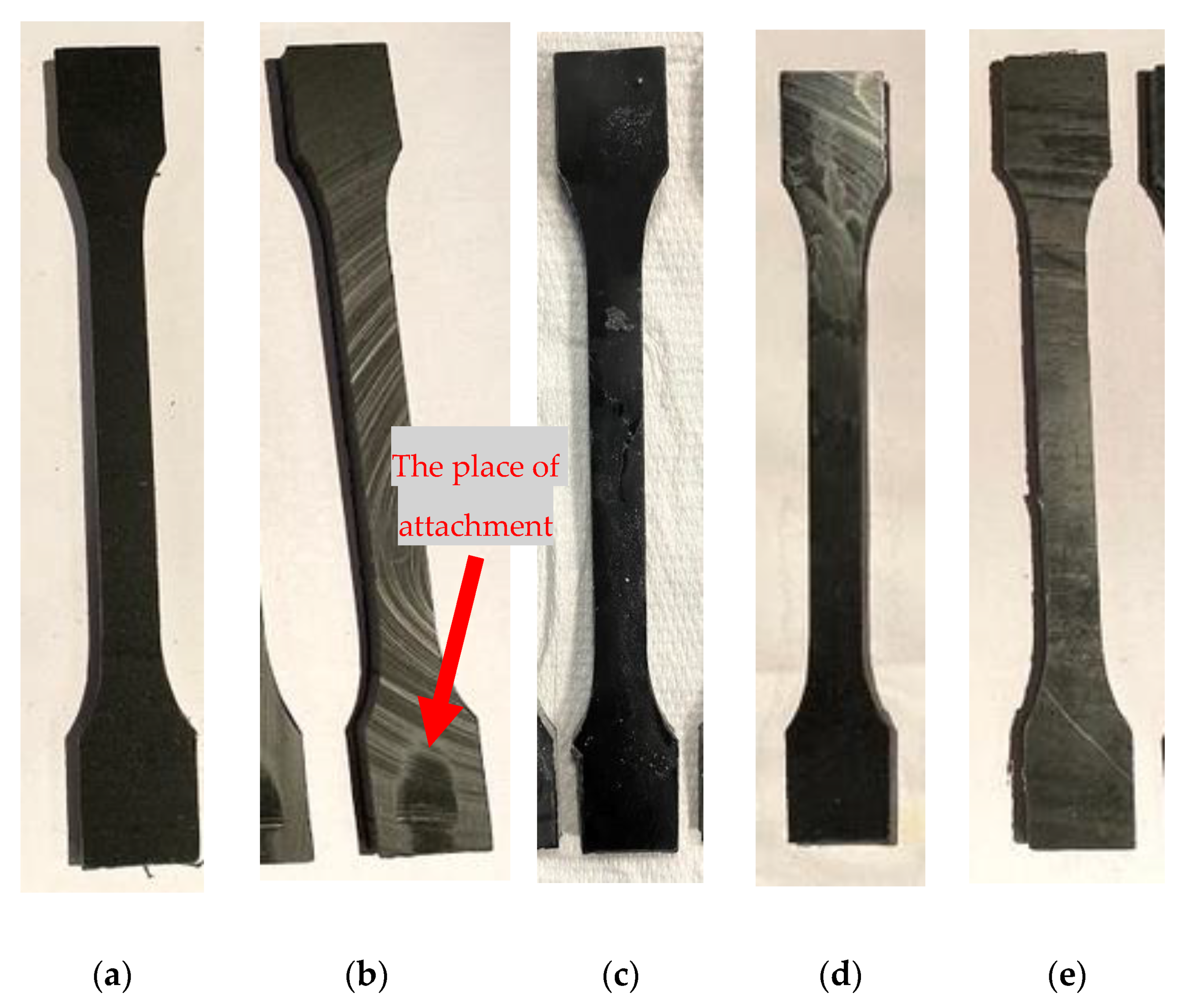

2.1. Materials and Sample Formation

2.2. Degradation Studies

- Reference: air 20 °C (room conditions)

- Weathering: atmospheric conditions (16–31 °C, up to 5 mm/day precipitation), unshaded, uncovered

- Soil: buried 5 cm deep, atmospheric conditions (16–31 °C, up to 5 mm precipitation), unshaded, uncovered

- Distilled water: 60 °C

- Alkalis at room temperature: water solution Ca(OH)2 2 g/L, 20 °C

- Alkalis hot: water solution Ca(OH)2 2 g/L, 60 °C

- Seawater: 20 °C,

- Tap water: 20 °C

- Frozen tap water: −16 °C

- Cold air: −16 °C

2.3. Thermal Analysis

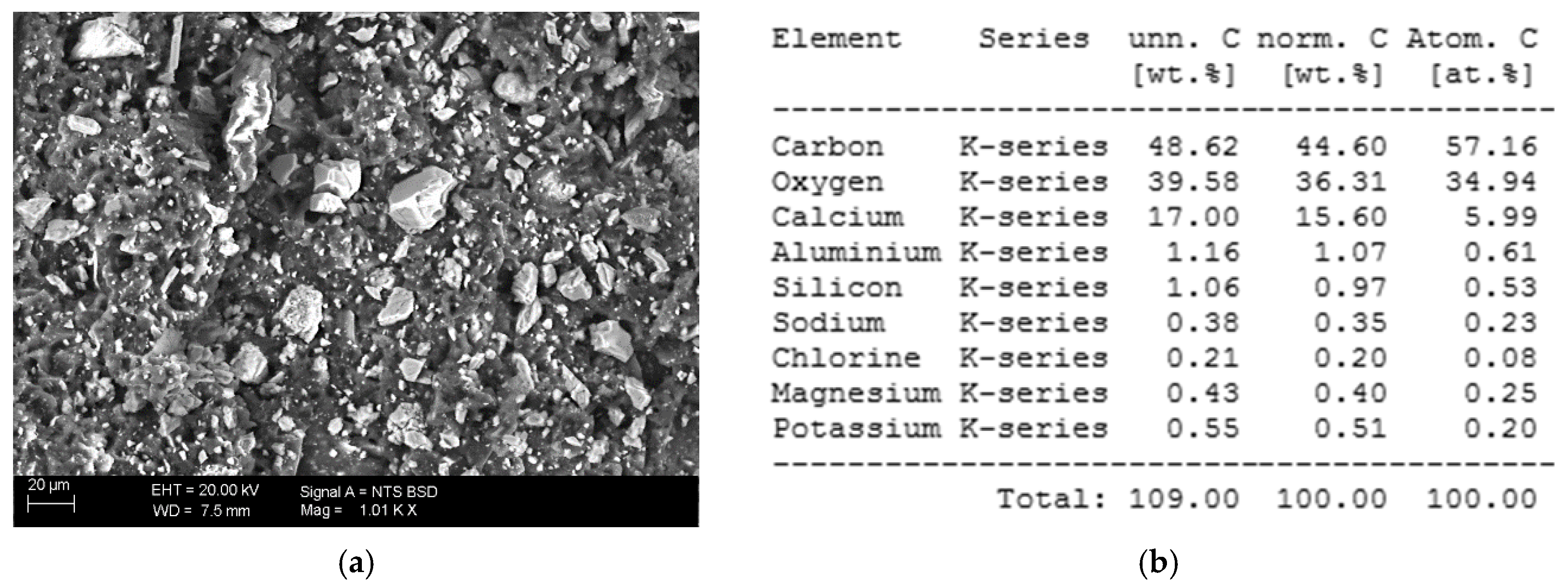

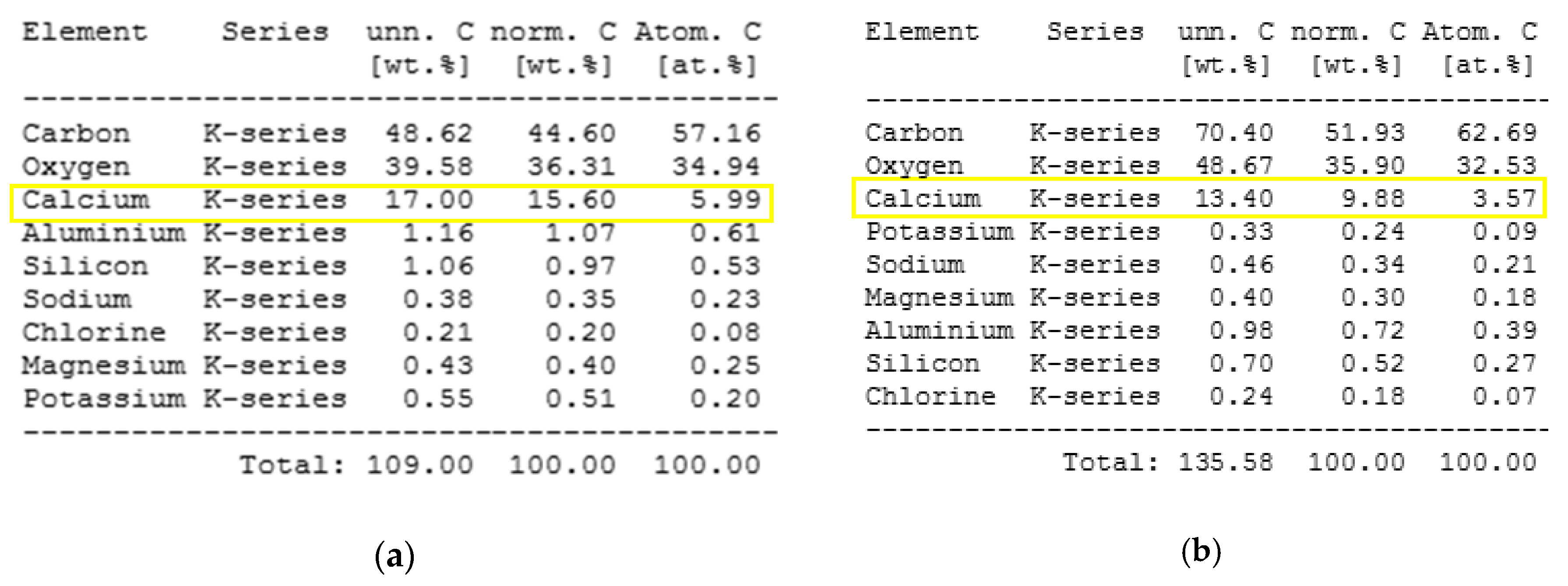

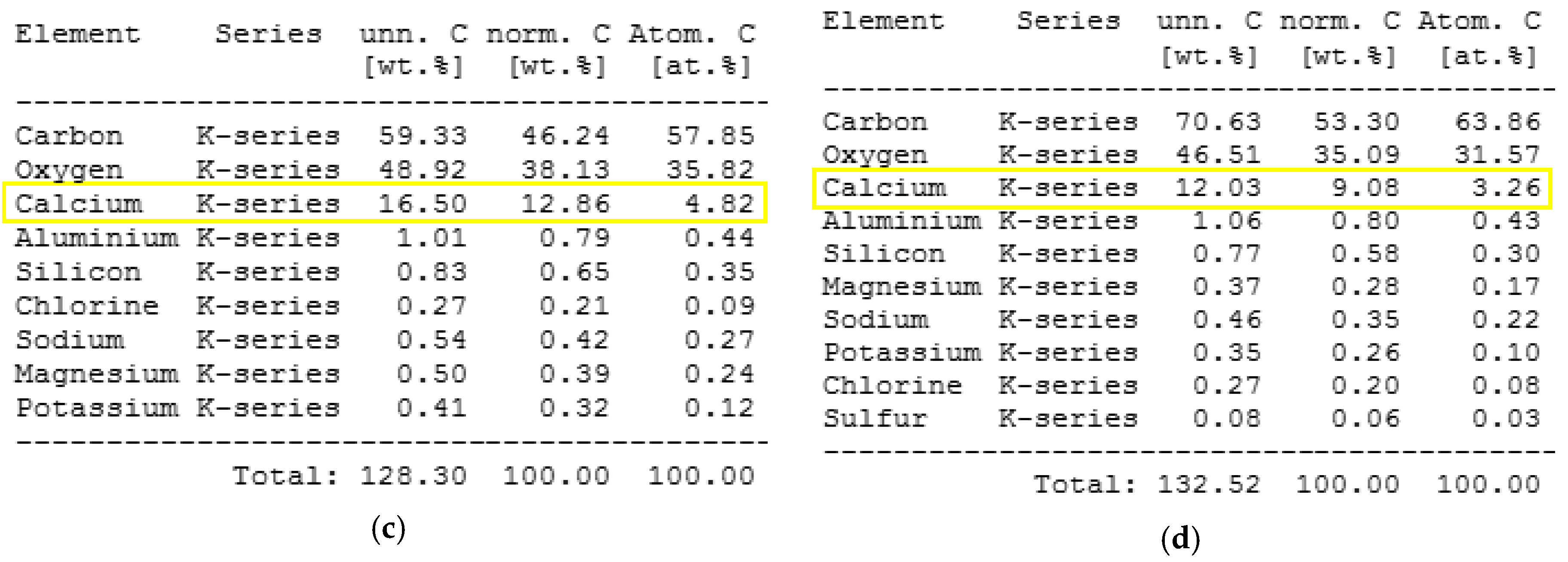

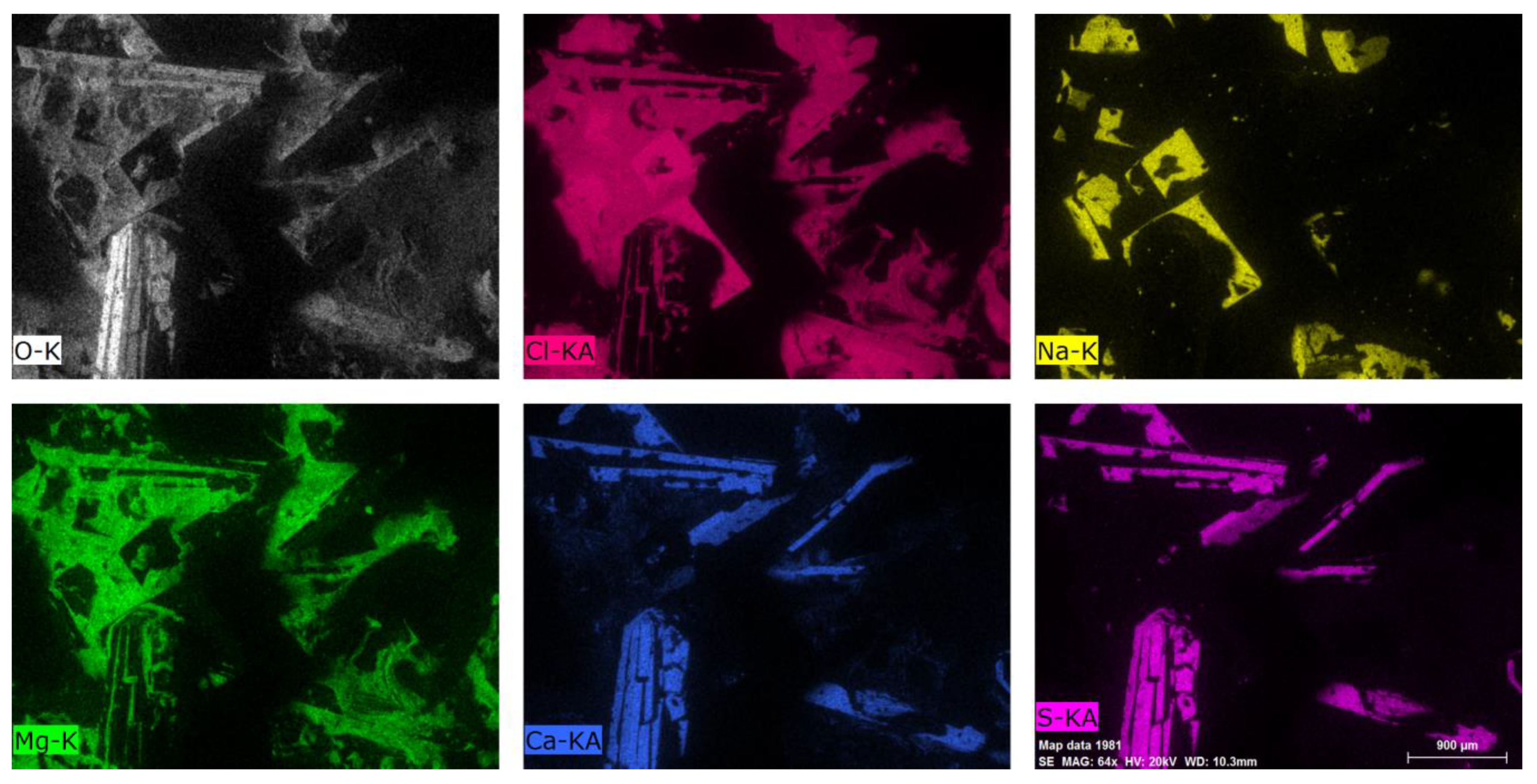

2.4. SEM Observatrions and EDS Evaluation

3. Test Results

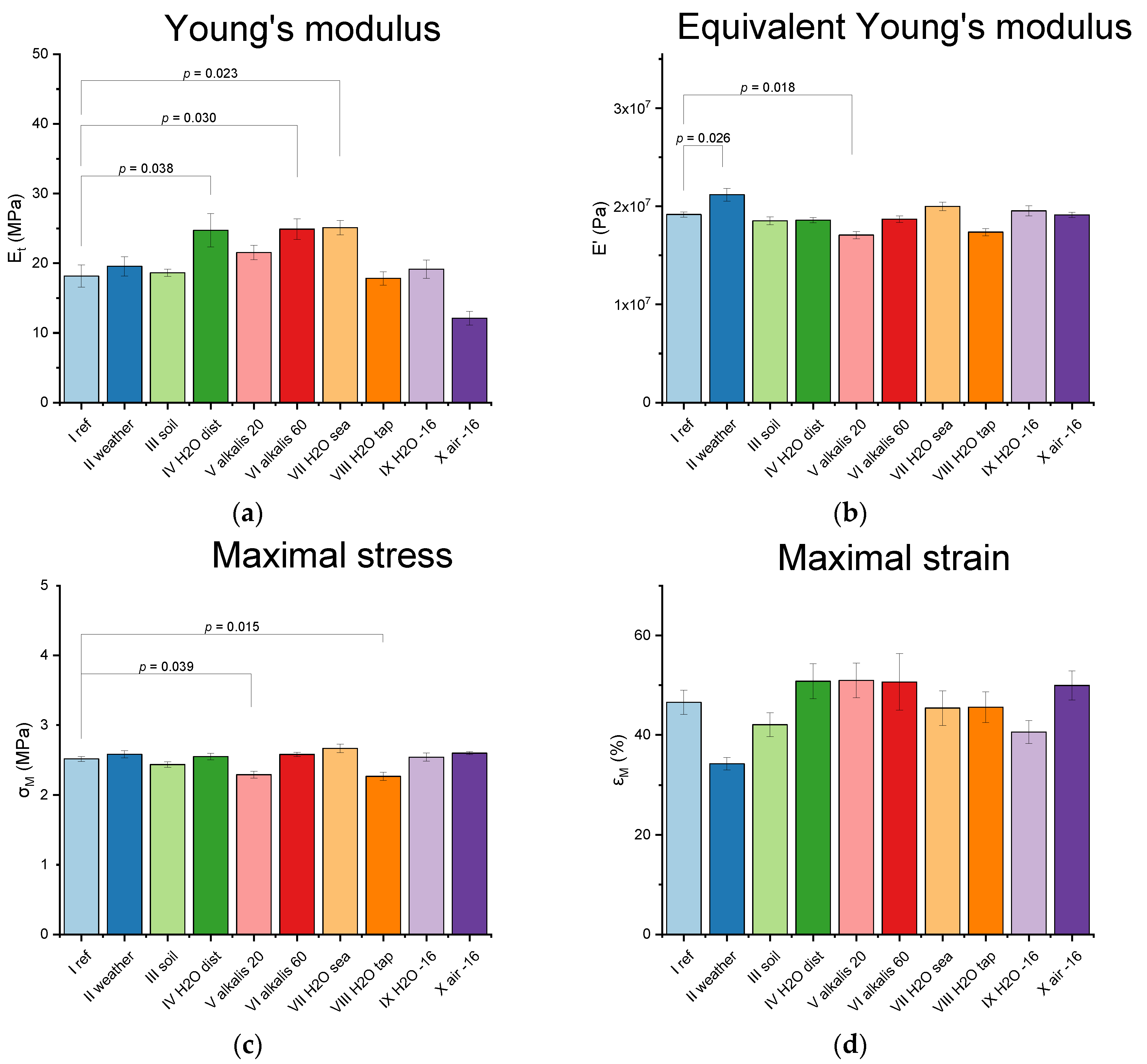

3.1. Degradation Studies

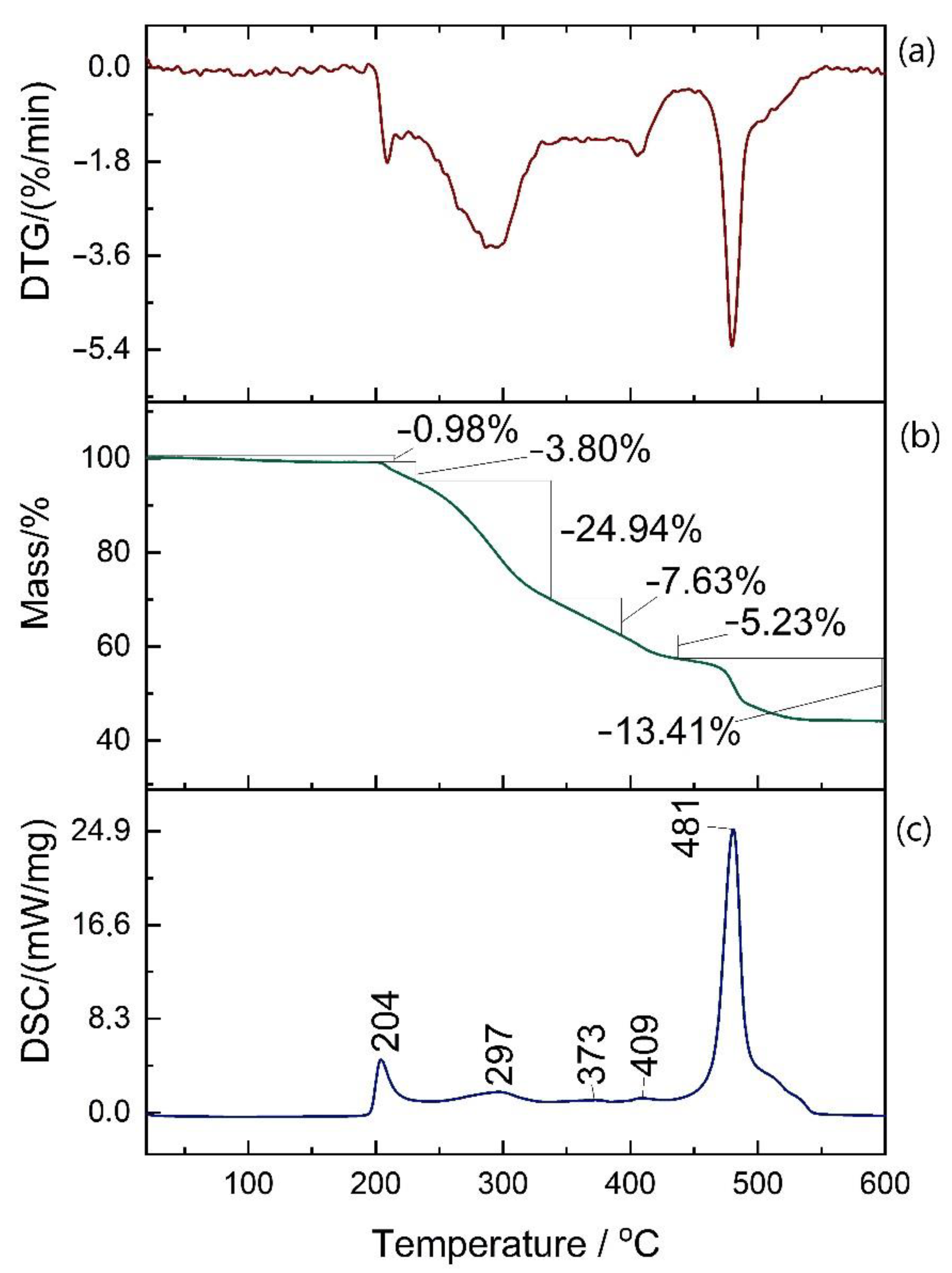

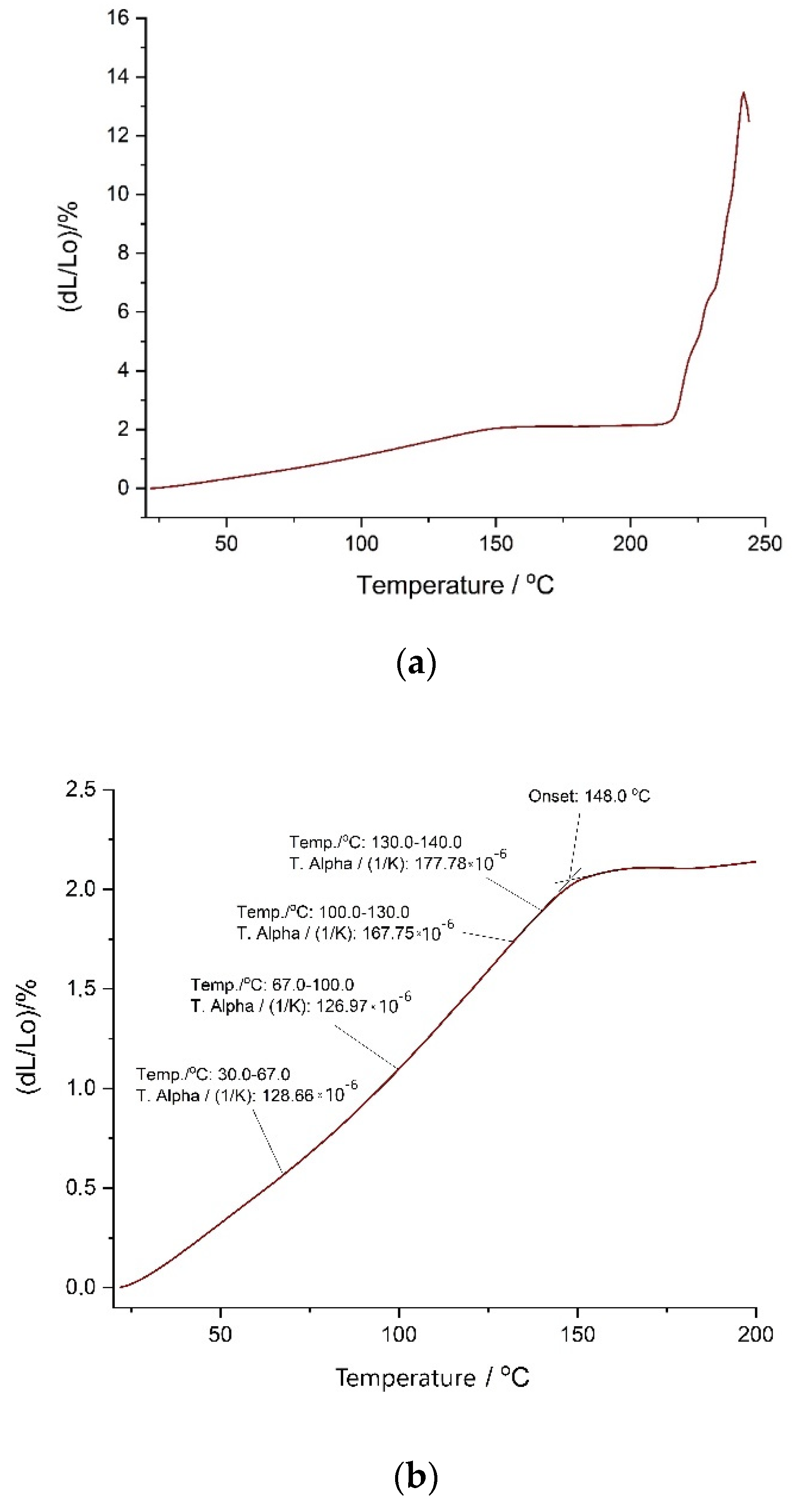

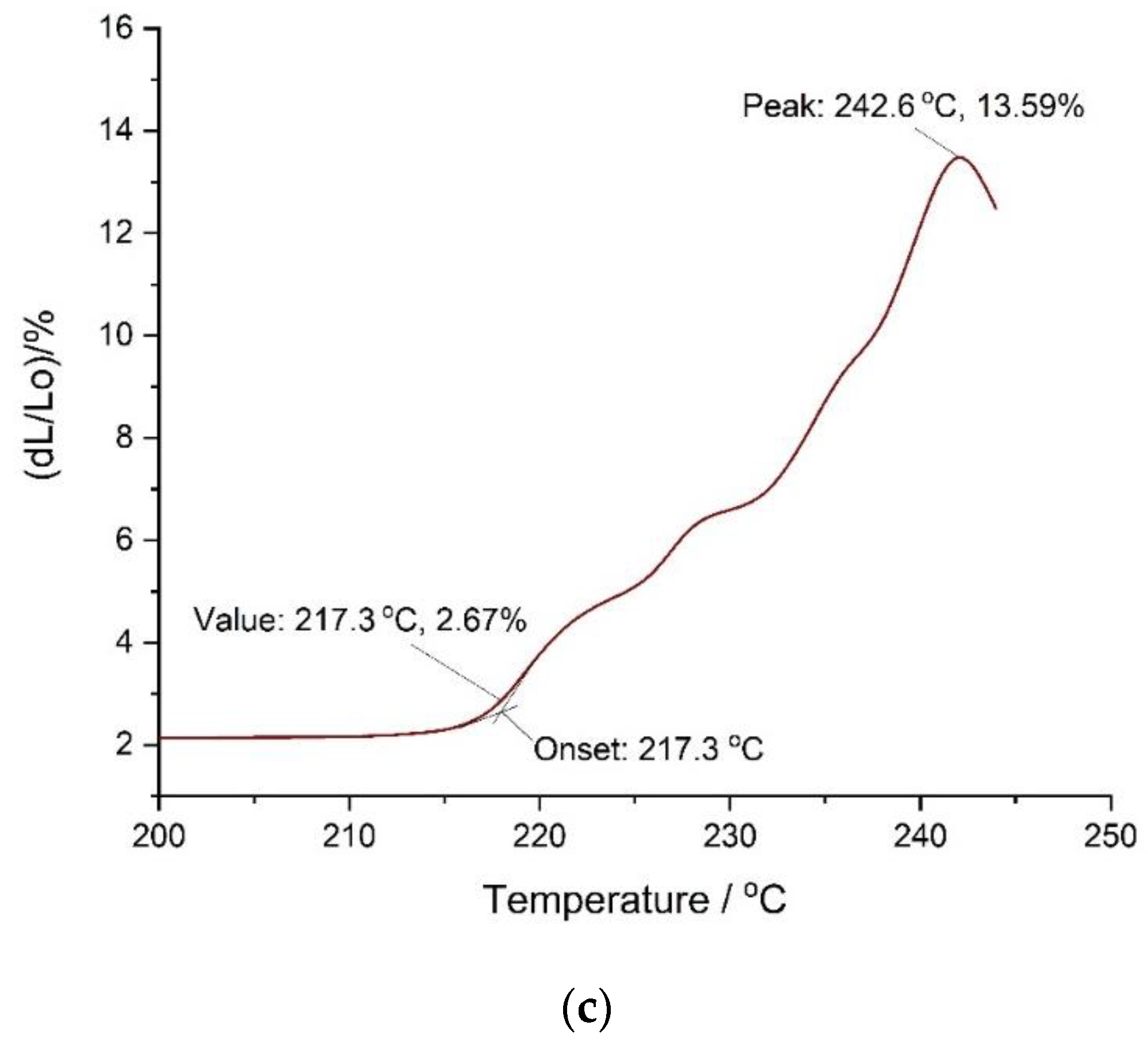

3.2. Thermal Analysis

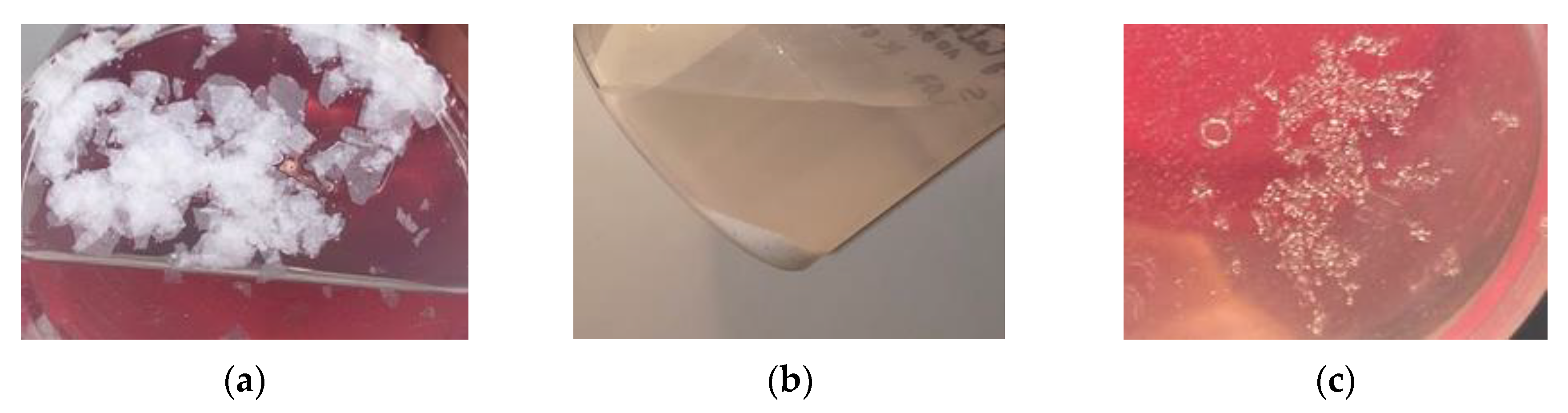

3.3. SEM and EDS Analysis

4. Conclusions

- Specimens subjected to soil (III), frozen water (IX), and cold air (X) showed no significant changes in any of the analyzed parameters. These three corrosive factors are considered to be safe for investigated material.

- Specimens subjected to five various aqueous environments showed mild but different changes. Applied time (1000 h) is however relatively short for such an experiment, so longer exposition of the samples on corrosive factors should be tested. We suppose that the changes come from elution and chemical reactions of mineral fillers which are in the form of very fine particles in the size of several dozen µm. They may affect the behavior of the material similarly as in composites. In such a case, no structural changes within the polymer itself would be present. However, this should be investigated in further steps via FTIR (Fourier transformed infrared) spectroscopy to check whether any chemical changes in polyurethane chains are present.

- Specimens subjected to natural weathering increased slightly their stiffness. This is however a reported behavior of polyurethanes at the beginning of photodegradation. A relatively short time and mild natural UV-exposure suggest that the investigated polymer should behave similarly and the observations are signs of initial degradation. Although this happens, the process takes place on the surface and may in fact protect the inner material.

- Neither thermal effect nor significant mass loss in elevated temperatures up to 200 °C.

- Right above 200 °C swelling of the polymer, followed by rapid loss of mechanical properties occurs

- There is an effect observed between 140–150 °C on the dilatometric curve that needs further studies to determine its origin, but it does not seem to worsen mechanical properties of the polymer

- Where the application material will be covered within the walls, this should increase its temperature gradually without rapid failure, enabling people to escape from a burning building. To define the exact time which PS-polyurethane can withstand under fire conditions, more specific research is required, but preliminary results are very promising.

Author Contributions

Funding

Conflicts of Interest

References

- Earthquake Disaster Relief. Available online: https://www.unicefusa.org/mission/emergencies/earthquakes (accessed on 19 September 2020).

- Viskovic, A.; Zuccarino, L.; Kwiecień, A.; Zając, B.; Gams, M. Quick seismic protection of weak masonry infilling in filled framed structures using flexible joints. Key Eng. Mater. 2017, 747, 628–637. [Google Scholar] [CrossRef]

- Kwiecień, A.; Krajewski, P.; Hojdys, Ł.; Tekieli, M.; Słoński, M. Flexible Adhesive in Composite-to-Brick Strengthening—Experimental and Numerical Study. Polymers 2018, 10, 356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Derkowski, W.; Kwiecień, A.; Zajac, B. CFRP strengthening of bent RC elements using stiff and flexible adhesives. Tech. Trans. 2013, R. 110, z. 1-B, 37–52. [Google Scholar]

- Kwiecień, A. Highly deformable polymers for repair and strengthening of cracked masonry structures. Gstf Int. J. Eng. Technol. 2013, 2, 182–196. [Google Scholar] [CrossRef]

- Kwiecień, A. Polymer flexible joints—An innovative repair system protecting cracked masonries against stress concentrations. In Proceedings of the International Conference on Protection of Historical Buildings, Rome, Italy, 21–24 June 2009; pp. 1033–1038. [Google Scholar]

- Kwiecień, A. New repair method of cracked concrete airfield surfaces using of polymer joints. In Proceedings of the ICPIC 2010; University of Minho: Madeira, Portugal, 2010; pp. 657–664. [Google Scholar]

- Akyildiz, A.T.; Kwiecień, A.; Zając, B.; Triller, P.; Bohinc, U.; Rousakis, T.; Viskovic, A. Preliminary in-Plane Shear Test of Infills Protected by PUFJ Interfaces; CRC Press/Balkema Taylor & Francis Group: Kraków, Poland, 2020; pp. 968–975. [Google Scholar]

- Rousakis, T.; Kwiecień, A.; Zając, B.; Hojdys, Ł.; Krajewski, P.; Tekieli, M.; Akyildiz, T. Flexible joints between RC frames and masonry infill for improved seismic performance–shake table tests. In Proceedings of the 17th International Brick and Block Masonry Conference (17th IB2MAC 2020), Kraków, Poland, 5–8 July 2020; pp. 499–507. [Google Scholar]

- Lasowicz, N.; Kwiecień, A.; Jankowski, R. Experimental study on the effectiveness of polymer damper in damage reduction of temporary steel grandstand. J. Phys. Conf. Ser. 2015, 628, 012051. [Google Scholar] [CrossRef]

- Lasowicz, N.; Kwiecień, A.; Jankowski, R. Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations. Polymers 2020, 12, 2364. [Google Scholar] [CrossRef]

- Kwiecień, A. Shear bond of composites-to-brick applied with highly deformable, in relation to resin epoxy, interface materials. Mater. Struct. 2014, 47, 2005–2020. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round Robin Test on tensile and bond behaviour of Steel Reinforced Grout systems. Compos. Part. B Eng. 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Cruz, J.R.; Seręga, S.; Sena-Cruz, J.; Pereira, E.; Kwiecień, A.; Zając, B. Flexural behaviour of NSM CFRP laminate strip systems in concrete using stiff and flexible adhesives. Compos. Part. B Eng. 2020, 195, 108042. [Google Scholar] [CrossRef]

- Ghiassi, B.; Xavier, J.; Oliveira, D.V.; Kwiecien, A.; Lourenço, P.B.; Zajac, B. Evaluation of the bond performance in FRP–brick components re-bonded after initial delamination. Compos. Struct. 2015, 123, 271–281. [Google Scholar] [CrossRef] [Green Version]

- Kwiecień, A.; de Felice, G.; Oliveira, D.V.; Zając, B.; Bellini, A.; De Santis, S.; Ghiassi, B.; Lignola, G.P.; Lourenço, P.B.; Mazzotti, C.; et al. Repair of composite-to-masonry bond using flexible matrix. Mater. Struct. 2016, 49, 2563–2580. [Google Scholar] [CrossRef]

- Sonnenschein, M.F. Introduction to Polyurethane Chemistry. In Polyurethanes: Science, Technology, Markets, and Trends; John Wiley & Sons, Inc.: New York, NY, USA, 2015. [Google Scholar]

- Hepburn, C. Polyurethane Elastomers; Springer Science & Business Media: New York, NY, USA, 2012; ISBN 978-94-011-2924-4. [Google Scholar]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Xie, F.; Tianlong, Z.; Bryant, P.; Kurusingal, V.; Colwell, J.M.; Laycock, B. Degradation and stabilization of polyurethane elastomers. Prog. Polym. Sci. 2019, 90, 211–268. [Google Scholar] [CrossRef]

- Gadea, J.; Rodriguez, A.; Campos, P.L.; Garabito, J.; Calderón, V. Lightweight mortar made with recycled polyurethane foam. Cem. Concr. Compos. 2010, 32, 672–677. [Google Scholar] [CrossRef]

- Junco, C.; Gadea, J.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V. Durability of lightweight masonry mortars made with white recycled polyurethane foam. Cem. Concr. Compos. 2012, 34, 1174–1179. [Google Scholar] [CrossRef]

- Kim, Y.D.; Kim, S.C. Effect of chemical structure on the biodegradation of polyurethanes under composting conditions. Polym. Degrad. Stab. 1998, 62, 343–352. [Google Scholar] [CrossRef]

- Rutkowska, M.; Krasowska, K.; Heimowska, A.; Steinka, I.; Janik, H. Degradation of polyurethanes in sea water. Polym. Degrad. Stab. 2002, 76, 233–239. [Google Scholar] [CrossRef]

- Yang, X.F.; Vang, C.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Weathering degradation of a polyurethane coating. Polym. Degrad. Stab. 2001, 74, 341–351. [Google Scholar] [CrossRef]

- Hawkins, W.L. Polymer Degradation and Stabilization; Polymers Properties and Applications; Springer: Berlin/Heidelberg, Germany, 1984; Volume 8, ISBN 978-3-642-69378-6. [Google Scholar]

- Zhang, Y.; Xia, Z.; Huang, H.; Chen, H. Thermal degradation of polyurethane based on IPDI. J. Anal. Appl. Pyrolysis 2009, 84, 89–94. [Google Scholar] [CrossRef]

- Sarkar, S.; Adhikari, B. Thermal stability of lignin–hydroxy-terminated polybutadiene copolyurethanes. Polym. Degrad. Stab. 2001, 73, 169–175. [Google Scholar] [CrossRef]

- Chen, H.; Lu, H.; Zhou, Y.; Zheng, M.; Ke, C.; Zeng, D. Study on thermal properties of polyurethane nanocomposites based on organo-sepiolite. Polym. Degrad. Stab. 2012, 97, 242–247. [Google Scholar] [CrossRef]

- Król, P.; Pilch-Pitera, B. Phase structure and thermal stability of crosslinked polyurethane elastomers based on well-defined prepolymers. J. Appl. Polym. Sci. 2007, 104, 1464–1474. [Google Scholar] [CrossRef]

- Howard, G.T. Biodegradation of polyurethane: A review. Int. Biodeterior. Biodegrad. 2002, 49, 245–252. [Google Scholar] [CrossRef]

- Nakajima-Kambe, T.; Shigeno-Akutsu, Y.; Nomura, N.; Onuma, F.; Nakahara, T. Microbial degradation of polyurethane, polyester polyurethanes and polyether polyurethanes. Appl. Microbiol. Biotechnol. 1999, 51, 134–140. [Google Scholar] [CrossRef] [PubMed]

- Kozak, A.; Kwiecie, A. Accelerated weathering tests of polyurethane mass for flexible joints to repair concrete and masonry structural elements. In Proceedings of the 7th International Conference AMCM 2011, Kraków, Poland, 13–15 June 2011. [Google Scholar]

- Tedeschi, C.; Kwiecień, A.; Valluzzi, M.R.; Zając, B.; Garbin, E.; Binda, L. Effect of thermal ageing and salt decay on bond between FRP and masonry. Mater. Struct. 2014, 47, 2051–2065. [Google Scholar] [CrossRef]

- De Santis, S.; Stryszewska, T.; Bandini, S.; de Felice, G.; Hojdys, Ł.; Krajewski, P.; Kwiecień, A.; Roscini, F.; Zając, B. Durability of steel reinforced polyurethane-to-substrate bond. Compos. Part. B Eng. 2018, 153, 194–204. [Google Scholar] [CrossRef]

- Zając, B.; Kwiecień, A.; Gams, M.; Tatara, T. Strengthening of masonry and concrete structures working in elevated temperatures and mining tremors area. In Proceedings of the 5th International Scientific Conference on Civil Engineering-Infrastructure-Mining, Kraków, Poland, 17–18 January 2019. [Google Scholar]

- Zając, B.; Kwiecień, A. Thermal Compatibility of Rigid and Flexible Adhesives to Substrates of Historical Structures. In Structural Analysis of Historical Constructions; RILEM Bookseries; Aguilar, R., Torrealva, D., Moreira, S., Pando, M.A., Ramos, L.F., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 18, pp. 1868–1877. ISBN 978-3-319-99440-6. [Google Scholar]

- ISO 527-1:2019 Plastics—Determination of Tensile Properties—Part. 1: General Principles; British Standards Institution: London, UK, 2019.

- Haynes, W. Tukey’s Test. In Encyclopedia of Systems Biology; Dubitzky, W., Wolkenhauer, O., Cho, K.-H., Yokota, H., Eds.; Springer: New York, NY, USA, 2013; pp. 2303–2304. ISBN 978-1-4419-9863-7. [Google Scholar]

- Kwiecień, A.; Gams, M.; Zając, B. Numerical modelling of flexible polymers as the adhesive for FRPs. In Proceedings of the FRPRCS-12 & 5th Asia-Pacific Conference on Fiber Reinforced Polymers in Structures (APFIS-2015), Nanjing, China, 14–16 December 2015. [Google Scholar]

- Kwiecień, A. Constitutive equations modelling of hyperelastic polymers in flexible joints [in polish]. In Współczesna Mechanika Konstrukcji w Projektowaniu Inżynierskim; PAN KILiW: Warsaw, Poland, 2015; pp. 151–178. ISBN 978-83-938648-6-7. [Google Scholar]

- Cui, H.; Hanus, R.; Kessler, M.R. Degradation of ROMP-based bio-renewable polymers by UV radiation. Polym. Degrad. Stab. 2013, 98, 2357–2365. [Google Scholar] [CrossRef]

| STAGE | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| MASS LOSS [%] | 3.20–4.29 | 20.55–26.12 | 6.75–13.48 | 3.68–6.22 | 11.79–13.74 |

| PEAK TEMP [°C] | 204–207 | 294–306 | 338–378 | 404–409 | 476–481 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwiecień, K.; Kwiecień, A.; Stryszewska, T.; Szumera, M.; Dudek, M. Durability of PS-Polyurethane Dedicated for Composite Strengthening Applications in Masonry and Concrete Structures. Polymers 2020, 12, 2830. https://doi.org/10.3390/polym12122830

Kwiecień K, Kwiecień A, Stryszewska T, Szumera M, Dudek M. Durability of PS-Polyurethane Dedicated for Composite Strengthening Applications in Masonry and Concrete Structures. Polymers. 2020; 12(12):2830. https://doi.org/10.3390/polym12122830

Chicago/Turabian StyleKwiecień, Konrad, Arkadiusz Kwiecień, Teresa Stryszewska, Magdalena Szumera, and Marta Dudek. 2020. "Durability of PS-Polyurethane Dedicated for Composite Strengthening Applications in Masonry and Concrete Structures" Polymers 12, no. 12: 2830. https://doi.org/10.3390/polym12122830

APA StyleKwiecień, K., Kwiecień, A., Stryszewska, T., Szumera, M., & Dudek, M. (2020). Durability of PS-Polyurethane Dedicated for Composite Strengthening Applications in Masonry and Concrete Structures. Polymers, 12(12), 2830. https://doi.org/10.3390/polym12122830