Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

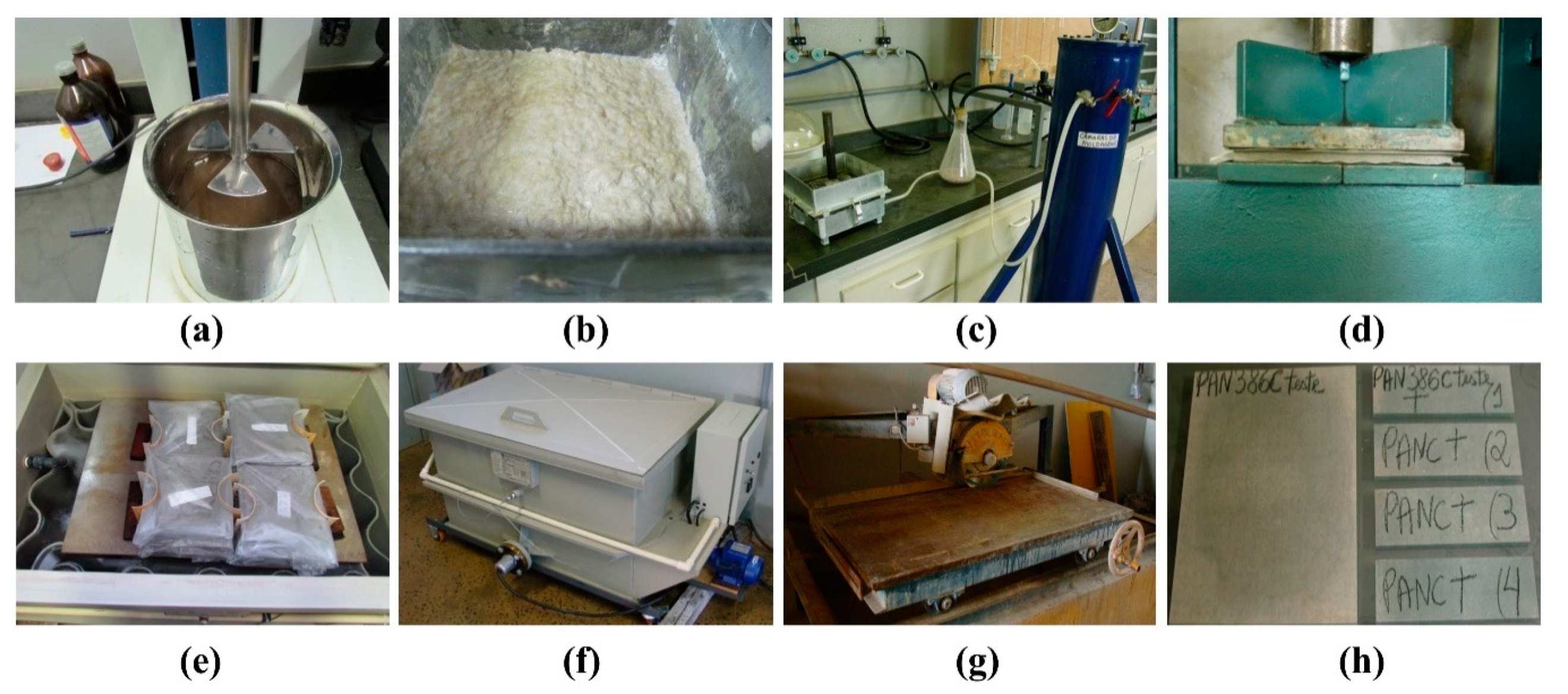

2.2. Methods

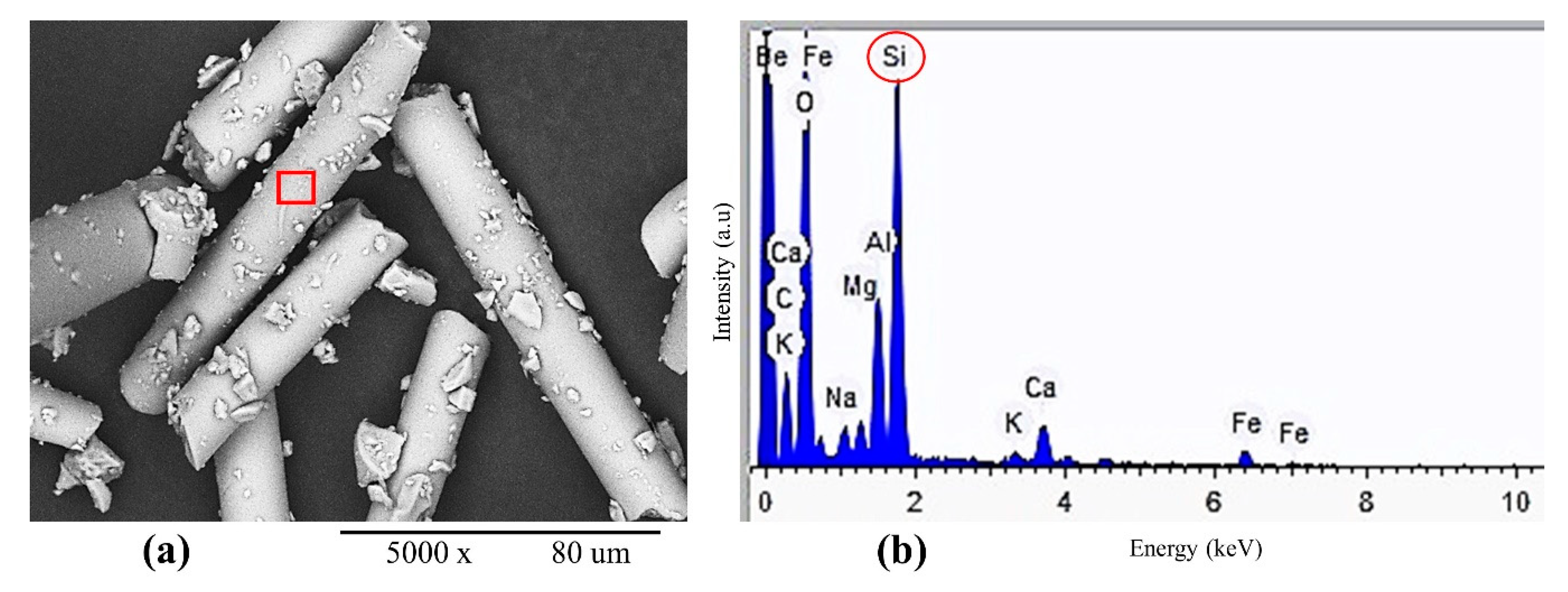

2.2.1. Surface Activation of BFW

2.2.2. Manufacturing of EB-HRCC Samples

2.3. Characterization

3. Results and Discussion

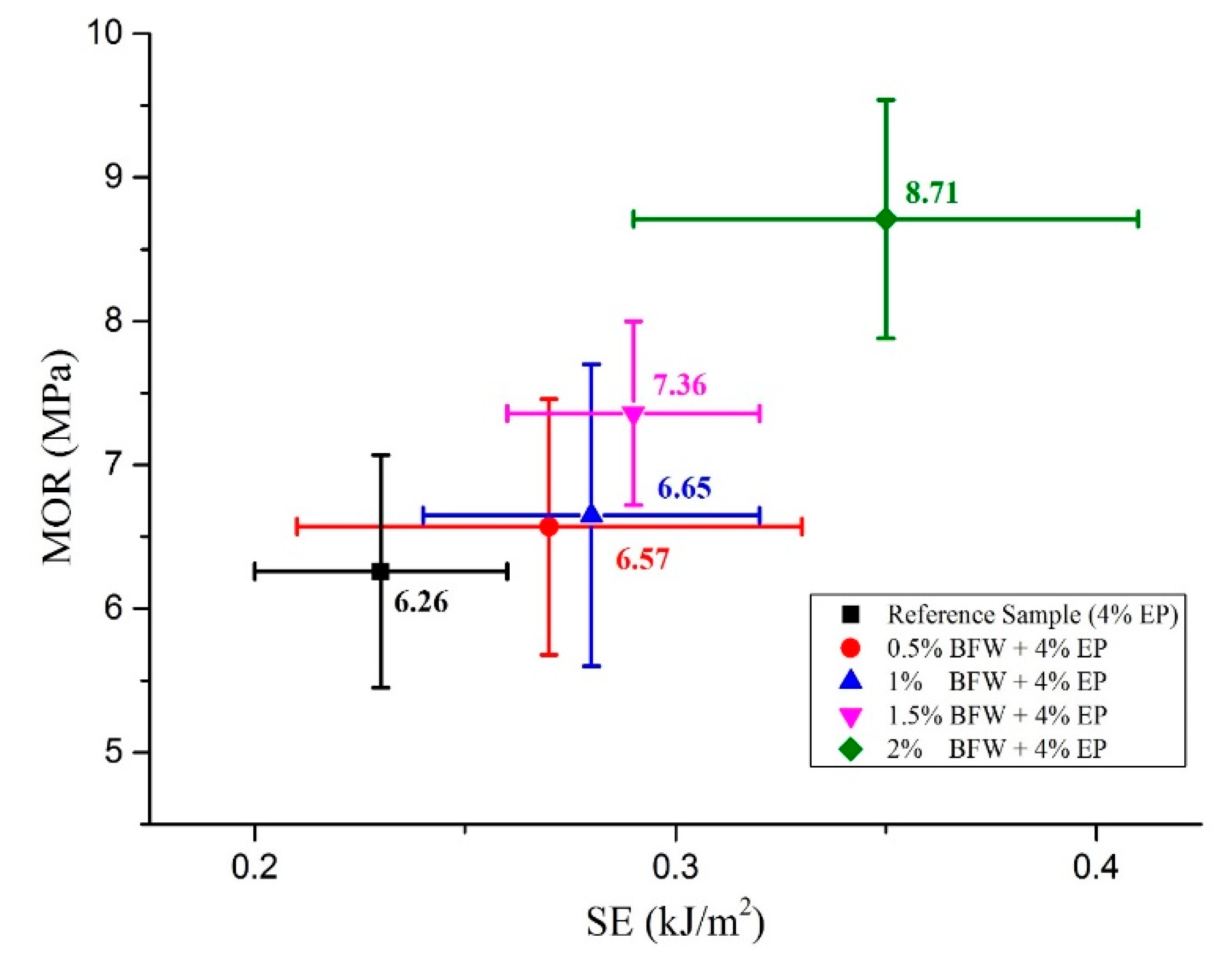

3.1. Mechanical Properties

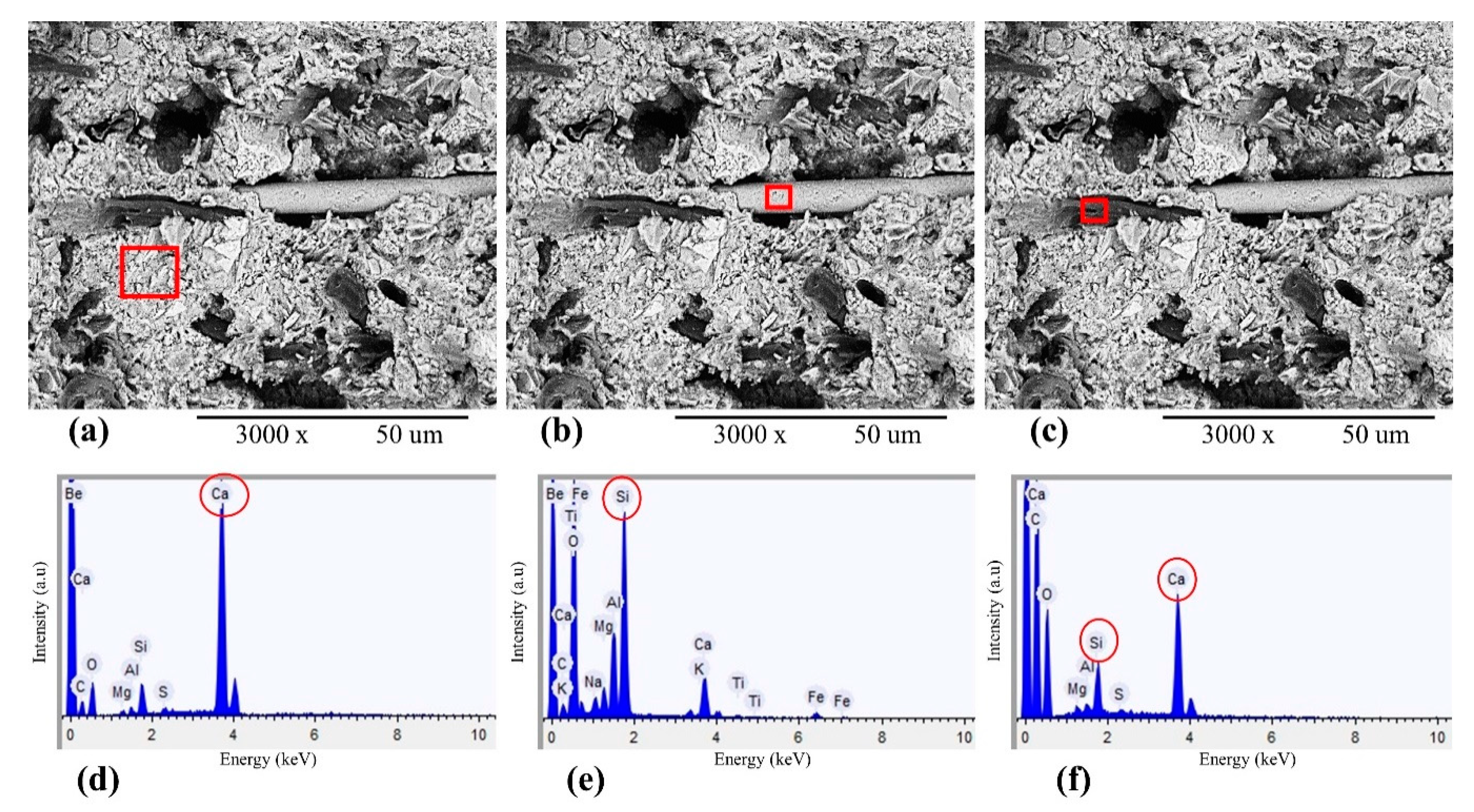

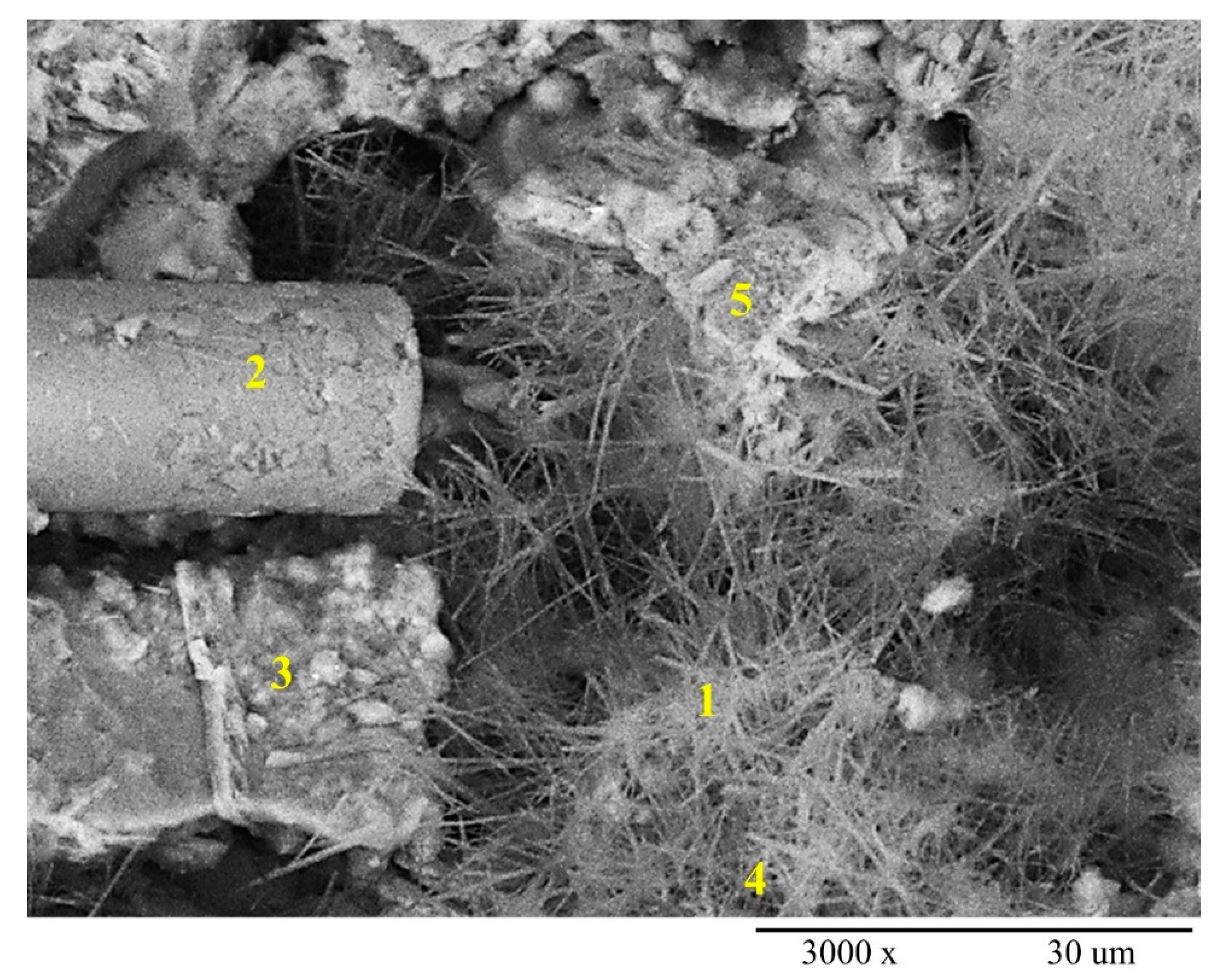

3.2. Microstructural Properties

3.3. Physical Properties

3.4. Zeta Potential

4. Conclusions

- The flexural strength (bending strength) of EB-HRCC samples was significantly enhanced by the addition of BFW in the cement matrix. The excellent results were obtained with formulation (2% BFW + 4% EP).

- The positive influence of basalt fiber on flexural strength was because basalt fiber improved the fiber–matrix interface’s transition zone properties.

- The developed samples with 2% BFW provided excellent results for MOR, MOE and SE. Diminutions in WA and porosity in all developed EB-HRCC were clear indications of the improved packing of the composites with respect to the reference sample.

- Microstructural properties explained the excellent adhesion of BFW with the cement matrix. BFW embedded inside the matrix thoroughly, and reduced the porosity percentage by filling the cracks and pores of the cement matrix.

- The more compact microstructure enhanced the mechanical properties. The fibrillation of EP and BFW is responsible for the refinement of the cementitious matrix, and hence responsible for the elimination of entrapped air in EB-HRCC samples and for a denser structure.

Author Contributions

Funding

Conflicts of Interest

References

- Sun, X.; Hou, Y. Experimental Investigation of the Macroscopic Behavior and Microstructure Property Evolution of Hardened Cement Consolidated Tailings. Minerals 2020, 10, 6. [Google Scholar] [CrossRef]

- Musaddaq, A.; Lubos, H.; Jakub, W.; Tayyab, N.M.; Azam, A.; Tariq, M. Comfort properties of nano-filament polyester fabrics: Thermo-physiological evaluation. Ind. Textila 2018, 69, 315–321. [Google Scholar] [CrossRef]

- Azeem, M.; Javed, A.; Morikawa, H.; Noman, M.T.; Khan, M.Q.; Shahid, M.; Wiener, J. Hydrophilization of Polyester Textiles by Nonthermal Plasma. Autex Res. J. 2019, 1. [Google Scholar] [CrossRef]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Filho, R.D.T. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Arslan, M.E. Effects of basalt and glass chopped fibers addition on fracture energy and mechanical properties of ordinary concrete: CMOD measurement. Constr. Build. Mater. 2016, 114, 383–391. [Google Scholar] [CrossRef]

- Noman, M.T.; Ashraf, M.A.; Ali, A. Synthesis and applications of nano-TiO2: A review. Environ. Sci. Pollut. Res. 2019, 26, 3262–3291. [Google Scholar] [CrossRef]

- Noman, M.T.; Militky, J.; Wiener, J.; Saskova, J.; Ashraf, M.A.; Jamshaid, H.; Azeem, M. Sonochemical synthesis of highly crystalline photocatalyst for industrial applications. Ultrasonics 2018, 83, 203–213. [Google Scholar] [CrossRef]

- Teixeira, J.N.; Silva, D.W.; Vilela, A.P.; Savastano, J.H.; Vaz, L.E.V.D.S.B.; Mendes, R.F. Lignocellulosic Materials for Fiber Cement Production. Waste Biomass Valorization 2018, 11, 2193–2200. [Google Scholar] [CrossRef]

- Xie, X.; Chen, X.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Lee, J.-H.; Yoon, Y.-S. Effect of fiber content on mechanical and fracture properties of ultra high performance fiber reinforced cementitious composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Jin, C.; Zhao, W.; Normani, S.D.; Zhao, P.; Emelko, M.B. Synergies of media surface roughness and ionic strength on particle deposition during filtration. Water Res. 2017, 114, 286–295. [Google Scholar] [CrossRef] [PubMed]

- Tonoli, G.; Rodrigues Filho, U.; Savastano, H., Jr.; Bras, J.; Belgacem, M.; Lahr, F.R. Cellulose modified fibres in cement based composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- Tonoli, G.; Savastano, H., Jr.; Santos, S.; Dias, C.; John, V.; Lahr, F.R. Hybrid reinforcement of sisal and polypropylene fibers in cement-based composites. J. Mater. Civ. Eng. 2011, 23, 177–187. [Google Scholar] [CrossRef]

- Azeem, M.; Noman, M.T.; Wiener, J.; Petru, M.; Louda, P. Structural design of efficient fog collectors: A review. Environ. Technol. Innov. 2020, 20, 101169. [Google Scholar] [CrossRef]

- Mansoor, T.; Hes, L.; Bajzik, V.; Noman, M.T. Novel method on thermal resistance prediction and thermo-physiological comfort of socks in a wet state. Text. Res. J. 2020, 90, 1987–2006. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M.; Amor, N.; Yang, T.; Mansoor, T. Thermophysiological comfort of sonochemically synthesized nano TiO2 coated woven fabrics. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Jongvisuttisun, P.; Leisen, J.; Kurtis, K. Key mechanisms controlling internal curing performance of natural fibers. Cem. Concr. Res. 2018, 107, 206–220. [Google Scholar] [CrossRef]

- Machado, P.J.C.; Ferreira, R.A.D.R.; Motta, L.A.D.C. Study of the effect of silica fume and latex dosages in cementitious composites reinforced with cellulose fibers. J. Build. Eng. 2020, 31, 101442. [Google Scholar] [CrossRef]

- Marzuki, A.; Rahim, S.; Hamidah, M.; Ruslan, R.A. Effects of wood: Cement ratio on mechanical and physical properties of three-layered cement-bonded particleboards from Leucaena leucocephala. J. Trop. For. Sci. 2011, 31, 67–72. [Google Scholar]

- Tonoli, G.; Savastano, H., Jr.; Fuente, E.; Negro, C.; Blanco, A.; Lahr, F.R. Eucalyptus pulp fibres as alternative reinforcement to engineered cement-based composites. Ind. Crops Prod. 2010, 31, 225–232. [Google Scholar] [CrossRef]

- Noman, M.T.; Wiener, J.; Saskova, J.; Ashraf, M.A.; Vikova, M.; Jamshaid, H.; Kejzlar, P. In-situ development of highly photocatalytic multifunctional nanocomposites by ultrasonic acoustic method. Ultrason. Sonochem. 2018, 40, 41–56. [Google Scholar] [CrossRef] [PubMed]

- Behera, P.; Baheti, V.; Militky, J.; Louda, P. Elevated temperature properties of basalt microfibril filled geopolymer composites. Constr. Build. Mater. 2018, 163, 850–860. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Militký, J.; Noman, M.T. Interfacial performance and durability of textile reinforced concrete. J. Text. Inst. 2017, 109, 879–890. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Militky, J.; Pechociakova, M.; Noman, M.T. Mechanical, thermal and interfacial properties of green composites from basalt and hybrid woven fabrics. Fibers Polym. 2016, 17, 1675–1686. [Google Scholar] [CrossRef]

- Noman, M.T.; Ashraf, M.A.; Jamshaid, H.; Ali, A. A Novel Green Stabilization of TiO2 Nanoparticles onto Cotton. Fibers Polym. 2018, 19, 2268–2277. [Google Scholar] [CrossRef]

- Noman, M.T.; Petrů, M. Functional Properties of Sonochemically Synthesized Zinc Oxide Nanoparticles and Cotton Composites. Nanomaterials 2020, 10, 1661. [Google Scholar] [CrossRef]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Zhang, X.; Ding, Y.; Xu, P. Mechanical properties and microstructure of basalt fiber-reinforced recycled concrete. J. Clean. Prod. 2021, 278, 123252. [Google Scholar] [CrossRef]

- Özkan, Ş.; Demir, F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites. Constr. Build. Mater. 2020, 263, 120564. [Google Scholar] [CrossRef]

- Liu, Y.; Guan, M.; Chen, X.; Zhang, Y.; Zhou, M. Flexural properties evaluation of carbon-fiber fabric reinforced poplar/eucalyptus composite plywood formwork. Compos. Struct. 2019, 224, 111073. [Google Scholar] [CrossRef]

- Ojo, E.B.; Bello, K.O.; Mustapha, K.; Teixeira, R.S.; Santos, S.F.; Savastano, H., Jr. Effects of fibre reinforcements on properties of extruded alkali activated earthen building materials. Constr. Build. Mater. 2019, 227, 116778. [Google Scholar] [CrossRef]

- De Souza, A.G.; Cesco, C.T.; De Lima, G.F.; Artifon, S.E.; Rosa, D.D.S.; Paulino, A.T. Arabic gum-based composite hydrogels reinforced with eucalyptus and pinus residues for controlled phosphorus release. Int. J. Biol. Macromol. 2019, 140, 33–42. [Google Scholar] [CrossRef]

- Noman, M.T.; Petru, M. Effect of Sonication and Nano TiO2 on Thermophysiological Comfort Properties of Woven Fabrics. ACS Omega 2020, 5, 11481–11490. [Google Scholar] [CrossRef]

- Noman, M.T.; Petrů, M.; Militký, J.; Azeem, M.; Ashraf, M.A. One-Pot Sonochemical Synthesis of ZnO Nanoparticles for Photocatalytic Applications, Modelling and Optimization. Materials 2019, 13, 14. [Google Scholar] [CrossRef]

- Dutra, J.R.; Ribeiro Filho, S.L.M.; Christoforo, A.L.; Panzera, T.H.; Scarpa, F. Investigations on sustainable honeycomb sandwich panels containing eucalyptus sawdust, Piassava and cement particles. Thin Walled Struct. 2019, 143, 106191. [Google Scholar] [CrossRef]

- Guan, M.; Liu, Y.; Zhang, Z. Evaluation of bending performance of carbon fiber-reinforced eucalyptus/poplar composite plywood by digital image correlation and FEA analysis. J. Mater. Sci. 2020, 55, 8388–8402. [Google Scholar] [CrossRef]

- Lisboa, F.J.N.; Scatolino, M.V.; de Paula Protásio, T.; Júnior, J.B.G.; Marconcini, J.M.; Mendes, L.M. Lignocellulosic materials for production of cement composites: Valorization of the alkali treated soybean pod and eucalyptus wood particles to obtain higher value-added products. Waste Biomass Valorization 2020, 11, 2235–2245. [Google Scholar] [CrossRef]

- da Costa Correia, V.; Santos, S.F.; Mármol, G.; da Silva Curvelo, A.A.; Savastano, H., Jr. Potential of bamboo organosolv pulp as a reinforcing element in fiber–cement materials. Constr. Build. Mater. 2014, 72, 65–71. [Google Scholar] [CrossRef]

- Schabowicz, K.; Jóźwiak-Niedźwiedzka, D.; Ranachowski, Z.; Kudela, S.; Dvorak, T. Microstructural characterization of cellulose fibres in reinforced cement boards. Arch. Civ. Mech. Eng. 2018, 18, 1068–1078. [Google Scholar] [CrossRef]

- Júnior, J.A.A.; Baldo, J.B. The Behavior of Zeta Potential of Silica Suspensions. New J. Glas. Ceram. 2014, 4, 29–37. [Google Scholar] [CrossRef]

| Constituents | Percentage Amount in Portland Cement (%) | Percentage Amount in Limestone (%) |

|---|---|---|

| Al2O3 | 4.44 | 0.21 |

| CaO | 63.5 | 51.7 |

| Fe2O3 | 2.68 | 0.17 |

| K2O | 1.10 | 0.09 |

| MgO | 2.32 | 3.04 |

| MnO | <0.10 | 0.04 |

| Na2O | 0.36 | 0.01 |

| P2O5 | 0.21 | 0.08 |

| SiO2 | 19.1 | 1.70 |

| SO3 | 2.63 | - |

| TiO2 | 0.24 | 0.03 |

| Loss on ignition (1000 °C) | 3.52 | 43.1 |

| Raw Materials with Amount Used (%) | Cement | Limestone | EP | BFW | Total Percentage (%) |

|---|---|---|---|---|---|

| Formulation 1 | 70.50 | 25.50 | 4 | - | 100 |

| Formulation 2 | 70.25 | 25.25 | 4 | 0.50 | 100 |

| Formulation 3 | 70.00 | 25.00 | 4 | 1.00 | 100 |

| Formulation 4 | 69.75 | 24.75 | 4 | 1.50 | 100 |

| Formulation 5 | 69.50 | 24.50 | 4 | 2.00 | 100 |

| Sample | MOR (MPa) | LOP (MPa) | MOE (GPa) | SE (kJ/m2) | BD (g/cm3) | WA (%) | AVV (%) |

|---|---|---|---|---|---|---|---|

| Reference Sample | 6.26 ± 0.81 | 5.29 ± 0.71 | 10.01 ± 0.84 | 0.23 ± 0.03 | 1.60 ± 0.02 | 21.14 ± 0.82 | 33.71 ± 0.87 |

| 0.5% BFW | 6.57 ± 0.89 | 5.24 ± 0.50 | 10.27 ± 2.13 | 0.27 ± 0.06 | 1.61 ± 0.06 | 20.94 ± 1.38 | 33.59 ± 1.08 |

| 1.0% BFW | 6.65 ± 1.05 | 5.18 ± 1.15 | 11.35 ± 1.12 | 0.28 ± 0.04 | 1.63 ± 0.04 | 20.38 ± 0.93 | 33.21 ± 0.89 |

| 1.5% BFW | 7.36 ± 0.64 | 6.74 ± 0.60 | 12.07 ± 0.77 | 0.29 ± 0.03 | 1.65 ± 0.02 | 20.05 ± 0.79 | 33.12 ± 1.08 |

| 2.0% BFW | 8.71 ± 0.83 | 7.62 ± 0.94 | 13.99 ± 0.85 | 0.35 ± 0.06 | 1.72 ± 0.01 | 18.41 ± 0.32 | 31.69 ± 0.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behera, P.; Noman, M.T.; Petrů, M. Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers 2020, 12, 2837. https://doi.org/10.3390/polym12122837

Behera P, Noman MT, Petrů M. Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers. 2020; 12(12):2837. https://doi.org/10.3390/polym12122837

Chicago/Turabian StyleBehera, Promoda, Muhammad Tayyab Noman, and Michal Petrů. 2020. "Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites" Polymers 12, no. 12: 2837. https://doi.org/10.3390/polym12122837

APA StyleBehera, P., Noman, M. T., & Petrů, M. (2020). Enhanced Mechanical Properties of Eucalyptus-Basalt-Based Hybrid-Reinforced Cement Composites. Polymers, 12(12), 2837. https://doi.org/10.3390/polym12122837