Properties of Injection Molded Biocomposites Reinforced with Wood Particles of Short-Rotation Aspen and Willow

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparations of Wood Particles

2.2. Injection Molding Process

2.3. Mechanical Properties

2.4. Color Measurement

2.5. Microstructures of Biocomposites

2.6. FTIR Measurement

2.7. Water Absorption

2.8. Statistical Analysis

3. Results and Discussion

3.1. Density and Water Absorption

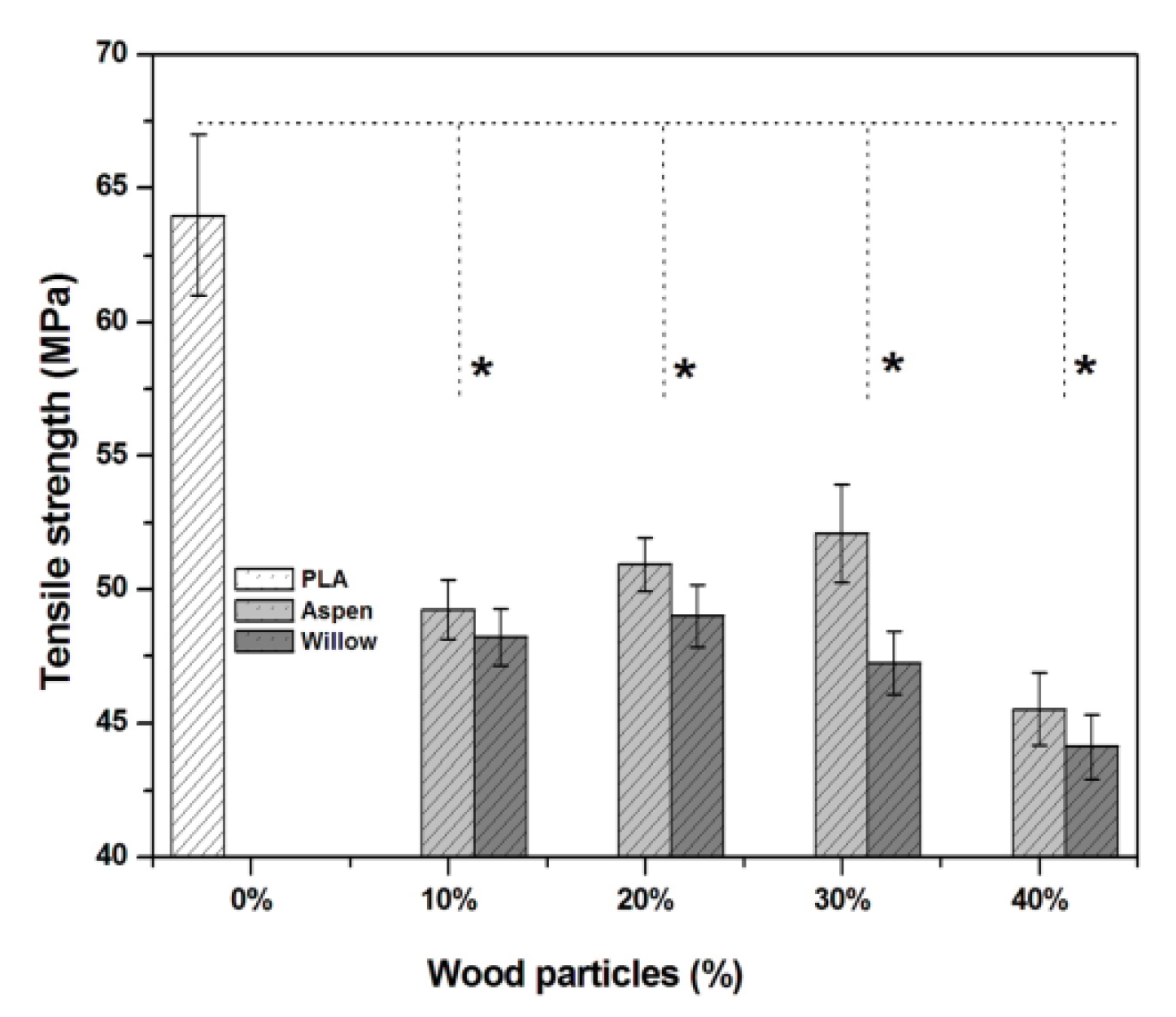

3.2. Tensile Testing

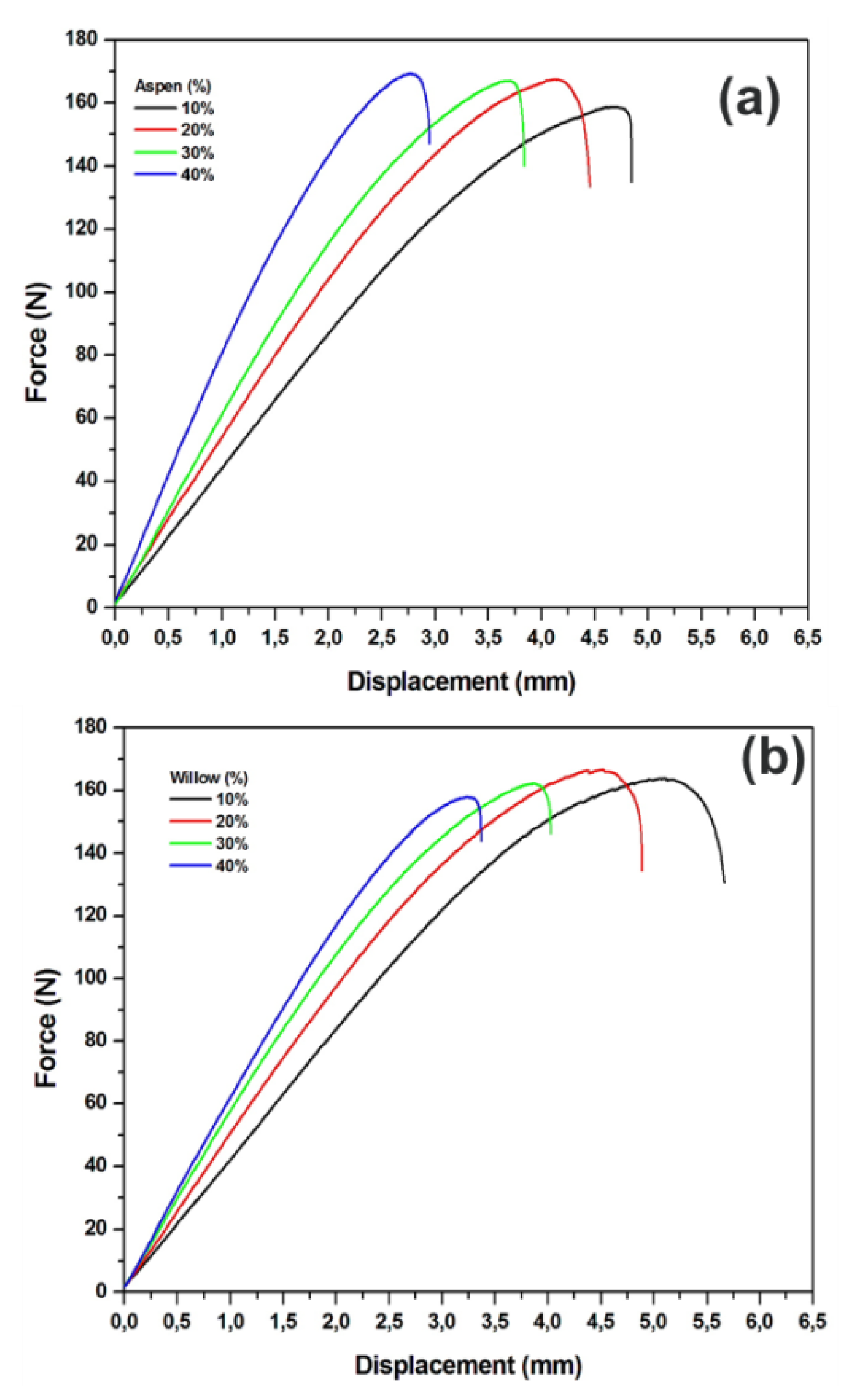

3.3. Bending Strength and Stiffness

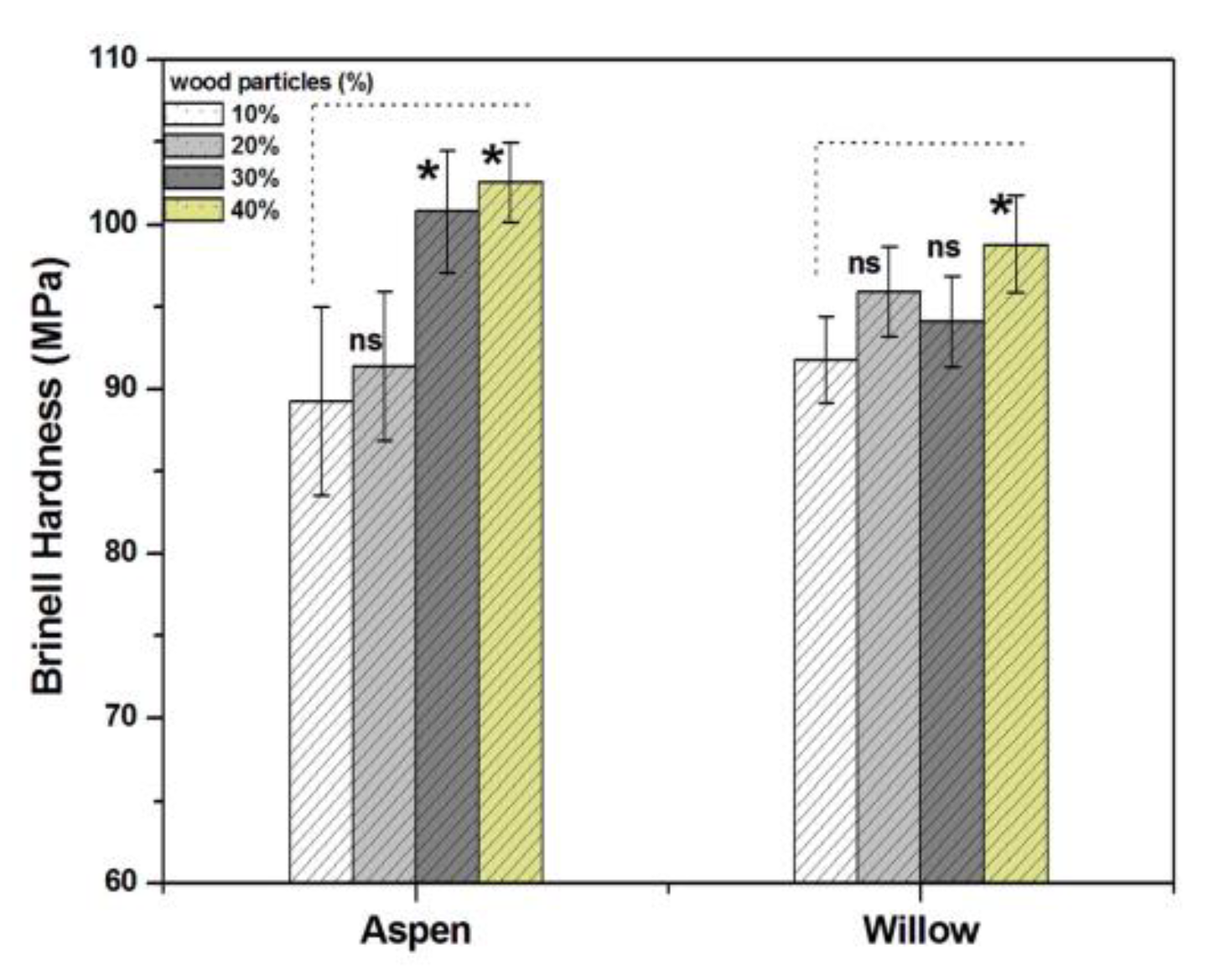

3.4. Brinell Hardness

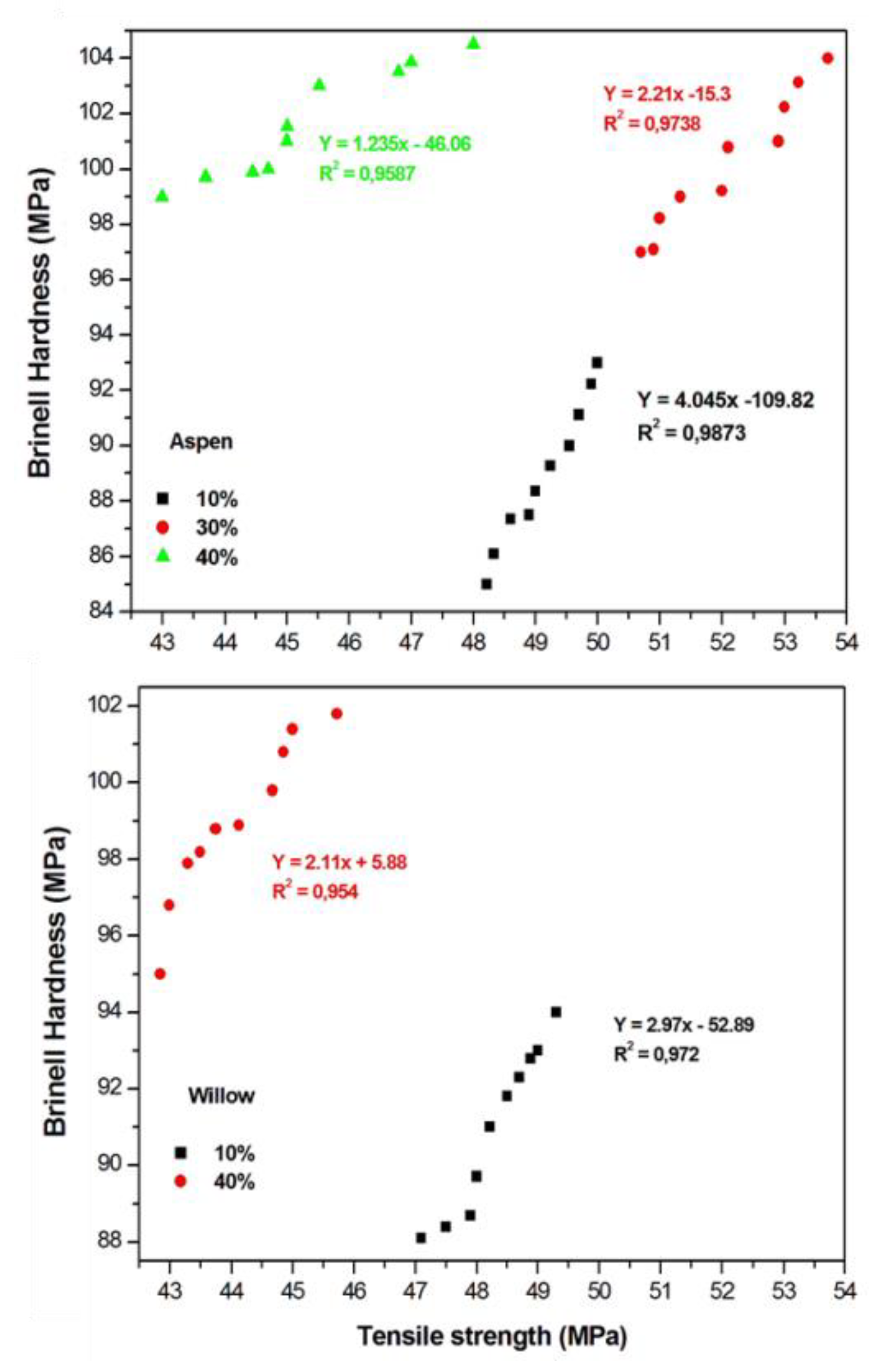

3.5. Correlation between Brinell hardness and Tensile Strength

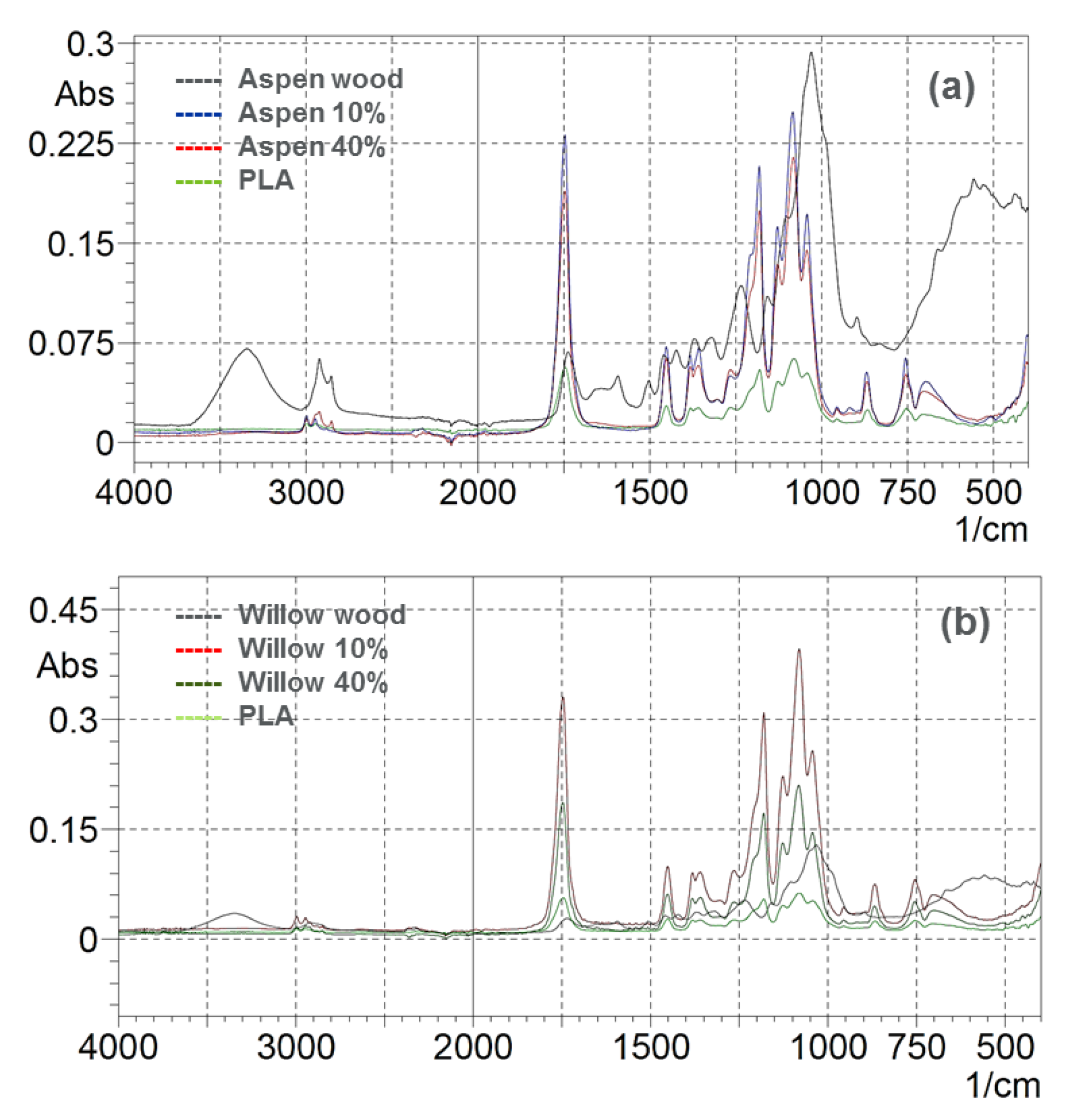

3.6. FTIR Analysis

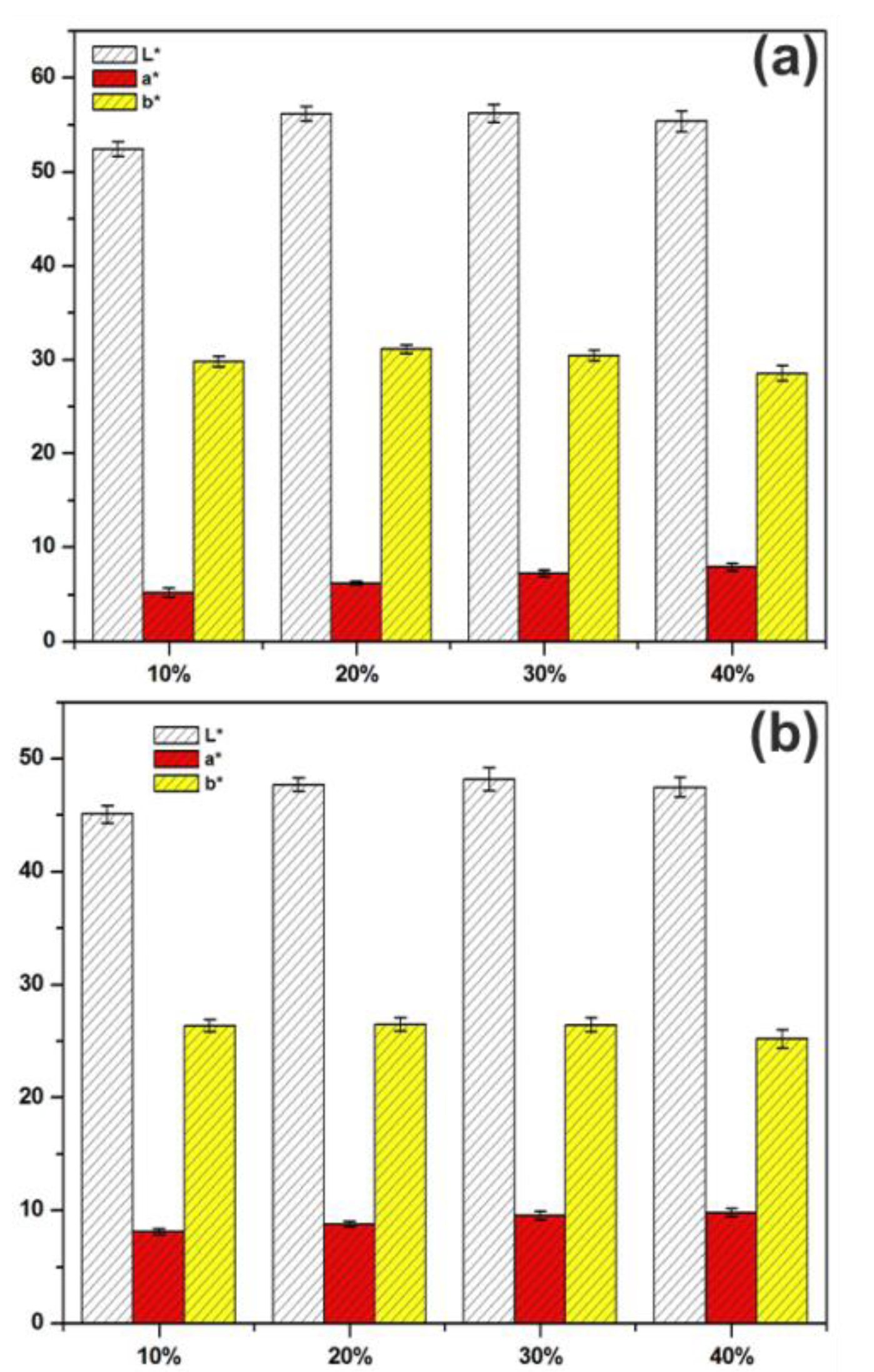

3.7. Color Difference

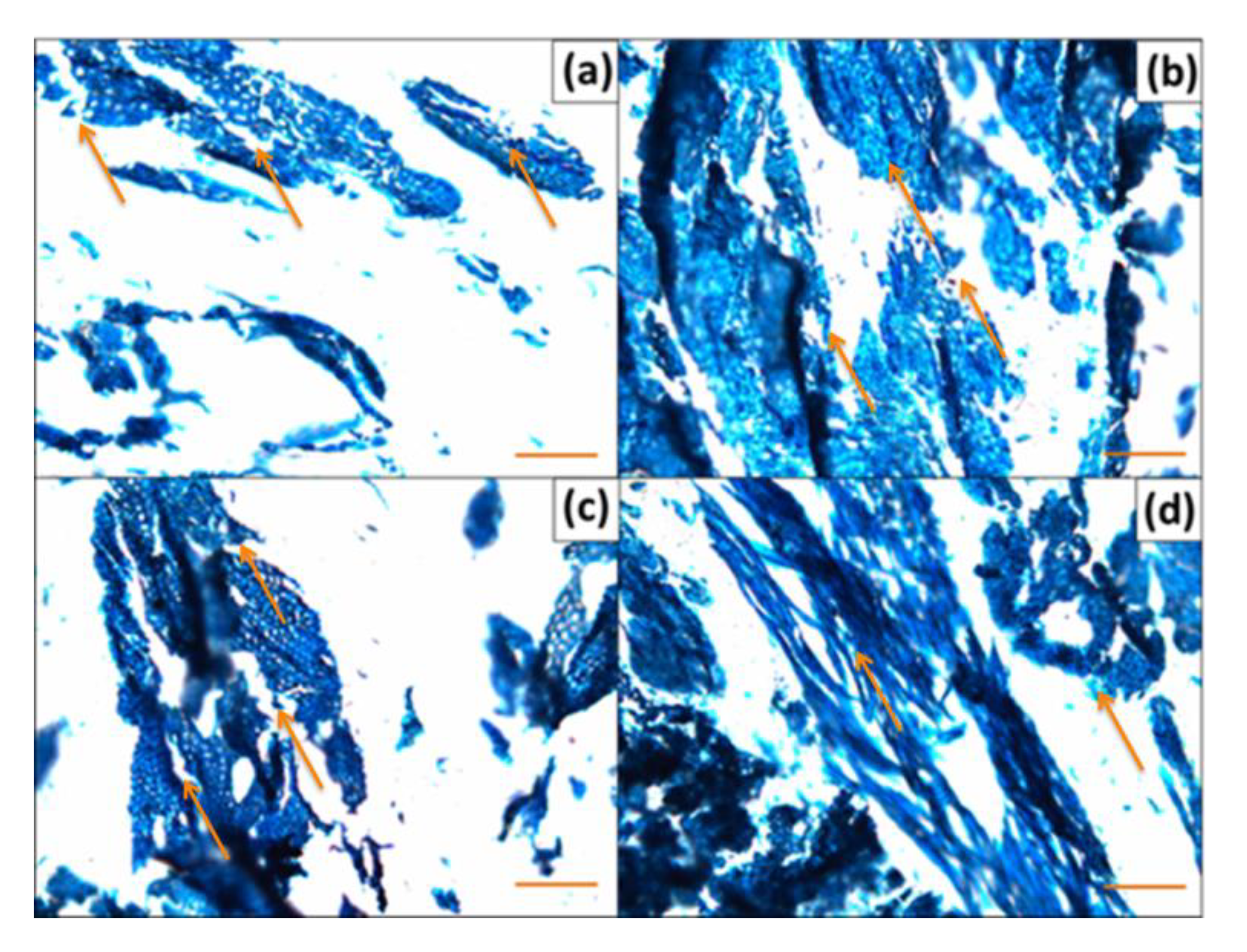

3.8. Microstructure of Biocomposites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, W.; Kumar, A.; Adamopoulos, S. Liquefaction of lignocellulosic materials and its applications in wood adhesives—A review. Ind. Crop. Prod. 2018, 124, 325–342. [Google Scholar] [CrossRef]

- Kumar, A.; Staněk, K.; Ryparová, P.; Hajek, P.; Tywoniak, J. Hydrophobic treatment of wood fibrous thermal insulator by octadecyltrichlorosilane and its influence on hygric properties and resistance against moulds. Compos. Part B: Eng. 2016, 106, 285–293. [Google Scholar] [CrossRef]

- Kumar, A.; Petrič, M.; Kričej, B.; Žigon, J.; Tywoniak, J.; Hajek, P.; Škapin, A.S.; Pavlič, M. Liquefied-wood-based polyurethane–nanosilica hybrid coatings and hydrophobization by self-assembled monolayers of orthotrichlorosilane (OTS). ACS Sustain. Chem. Eng. 2015, 3, 2533–2541. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Hughes, M.; Kanerva, J.; Dahl, O. Forest sector circular economy development in Finland: A regional study on sustainability driven competitive advantage and an assessment of the potential for cascading recovered solid wood. J. Clean. Prod. 2018, 181, 483–497. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Kumar, A.; Verkasalo, E. Wood-based panel industries in Finland–current status and development potential. In Proceedings of the 12th Edition of the International Conference “Wood Science and Engineering in the Third Millennium”—ICWSE 2019, Brasov, Romania, 7–9 November 2019. [Google Scholar]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Ryparovà, P.; Škapin, A.S.; Kovač, J.; Adamopoulos, S.; Hajek, P.; Petrič, M. Influence of liquefied wood polyol on the physical-mechanical and thermal properties of epoxy based polymer. Polym. Test. 2017, 64, 207–216. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A: Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar]

- Migneault, S.; Koubaa, A.; Perré, P. Effect of fiber origin, proportion, and chemical composition on the mechanical and physical properties of wood-plastic composites. J. Wood Chem. Technol. 2014, 34, 241–261. [Google Scholar] [CrossRef]

- Csikós, Á.; Faludi, G.; Domján, A.; Renner, K.; Móczó, J.; Pukánszky, B. Modification of interfacial adhesion with a functionalized polymer in PLA/wood composites. Eur. Polym. J. 2015, 68, 592–600. [Google Scholar] [CrossRef]

- Porebska, R.; Rybak, A.; Kozub, B.; Sekula, R. Polymer matrix influence on stability of wood polymer composites. Polym. Adv. Technol. 2015, 26, 1076–1082. [Google Scholar] [CrossRef]

- Akpan, E.I.; Wetzel, B.; Friedrich, K. Processing and properties of short wood fiber/acrylate resin composites. Polym. Compos. 2019, 40, 91–98. [Google Scholar] [CrossRef]

- Tazi, M.; Sukiman, M.S.; Erchiqui, F.; Imad, A.; Kanit, T. Effect of wood fillers on the viscoelastic and thermophysical properties of HDPE-wood composite. Int. J. Polym. Sci. 2016, 2016, 9032525. [Google Scholar] [CrossRef]

- Dányádi, L.; Janecska, T.; Szabo, Z.; Nagy, G.; Moczo, J.; Pukánszky, B. Wood flour filled PP composites: Compatibilization and adhesion. Compos. Sci. Technol. 2007, 67, 2838–2846. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Injection moulded microcellular wood fibre–polypropylene composites. Compos. Part A: Appl. Sci. Manuf. 2006, 37, 1358–1367. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, J.; Wu, G.; Peng, X.; Ma, X. Significant reinforcement of polypropylene/wood flour composites by high extent of interfacial interaction. J. Thermoplast. Compos. Mater. 2018, 32, 577–592. [Google Scholar] [CrossRef]

- Effah, B.; Van Reenen, A.; Meincken, M. Mechanical properties of wood-plastic composites made from various wood species with different compatibilisers. Eur. J. Wood Wood Prod. 2018, 76, 57–68. [Google Scholar] [CrossRef]

- Barton-Pudlik, J.; Czaja, K. Fast-growing willow (Salix viminalis) as a filler in polyethylene composites. Compos. Part B: Eng. 2018, 143, 68–74. [Google Scholar] [CrossRef]

- Weih, M. Intensive short rotation forestry in boreal climates: Present and future perspectives. Can. J. For. Res. 2004, 34, 1369–1378. [Google Scholar] [CrossRef]

- Mola-Yudego, B. Regional potential yields of short rotation willow plantations on agricultural land in Northern Europe. Silva Fenn. 2010, 44, 63–76. [Google Scholar] [CrossRef]

- Tullus, A.; Rytter, L.; Tullus, T.; Weih, M.; Tullus, H. Short-rotation forestry with hybrid aspen (Populus tremula L.× P. tremuloides Michx.) in Northern Europe. Scand. J. For. Res. 2012, 27, 10–29. [Google Scholar] [CrossRef]

- Heräjärvi, H.; Junkkonen, R. Wood density and growth rate of European and hybrid aspen in southern Finland. Balt. For. 2006, 12, 2–8. [Google Scholar]

- Latva-Karjanmaa, T.; Penttilä, R.; Siitonen, J. The demographic structure of European aspen (Populus tremula) populations in managed and old-growth boreal forests in eastern Finland. Can. J. For. Res. 2007, 37, 1070–1081. [Google Scholar] [CrossRef]

- Herrmann, K. Hardness Testing: Principles and Applications; ASM International: Cleveland, OH, USA, 2011. [Google Scholar]

- Sinha, P.; Mathur, S.; Sharma, P.; Kumar, V. Potential of pine needles for PLA-based composites. Polym. Compos. 2018, 39, 1339–1349. [Google Scholar] [CrossRef]

- Averous, L.; Le Digabel, F. Properties of biocomposites based on lignocellulosic fillers. Carbohydr. Polym. 2006, 66, 480–493. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. Part B: Eng. 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Csizmadia, R.; Faludi, G.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/wood biocomposites: Improving composite strength by chemical treatment of the fibers. Compos. Part A: Appl. Sci. Manuf. 2013, 53, 46–53. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A: Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Petinakis, E.; Yu, L.; Edward, G.; Dean, K.; Liu, H.; Scully, A.D. Effect of matrix–particle interfacial adhesion on the mechanical properties of poly (lactic acid)/wood-flour micro-composites. J. Polym. Environ. 2009, 17, 83–94. [Google Scholar] [CrossRef]

- Kord, B. Investigation of reinforcing filler loading on the mechanical properties of wood plastic composites. World Appl. Sci. J. 2011, 13, 171–174. [Google Scholar]

- Zhang, P.; Li, S.; Zhang, Z. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, Y.; Murakami, M.; Nomura, M.; Hamada, H. Physical and mechanical properties of injection-molded wood powder thermoplastic composites. Adv. Compos. Mater. 2013, 22, 425–435. [Google Scholar] [CrossRef]

- Pandey, K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Chieng, B.W.; Azowa, I.N.; Zin, W.Y.W.M.; Hussein, M.Z. Effects of graphene nanopletelets on poly (lactic acid)/poly (ethylene glycol) polymer nanocomposites. Adv. Mater. Res. 2014, 1024, 136–139. [Google Scholar] [CrossRef]

| Wood Species | Height (m) | Stem Diameter (cm) * | ||

|---|---|---|---|---|

| 0 m | 1.3 m | 6 m | ||

| Aspen | 19.6 ± 0.7 | 26.1 ± 1.4 | 20.3 ± 0.6 | 13.0 ± 0.6 |

| Willow | 7.0 ± 2.9 | 4.7 ± 2.2 | 1.7 ± 0.5 | not measured |

| Species and Wood Weight Percentage | Density (g/cm3) | Water Absorption (%) | |

|---|---|---|---|

| 24 h | 4 days | ||

| PLA | 1.22 ± 0.05 | 0.20 ± 0.04 ns | 0.59 ± 0.07 ns |

| Aspen 10% | 1.23 ± 0.05 ns | 0.33 ± 0.04 ns | 0.98 ± 0.06 * |

| Aspen 20% | 1.26 ± 0.06 ns | 0.53 ± 0.07 ns | 1.5 ± 0.15 * |

| Aspen 30% | 1.29 ± 0.05 * | 0.75 ± 0.05 ns | 2.27 ± 0.2 * |

| Aspen 40% | 1.32 ± 0.04 * | 0.90 ± 0.08 ns | 2.79 ± 0.18 * |

| Willow 10% | 1.30 ± 0.05 * | 0.40 ± 0.04 ns | 1.41 ± 0.21 * |

| Willow 20% | 1.31 ± 0.03 * | 0.51 ± 0.03 ns | 2.01 ± 0.10 * |

| Willow 30% | 1.32 ± 0.04 * | 1.25 ± 0.1 * | 5.30 ± 0.30 * |

| Willow 40% | 1.33 ± 0.05 * | 1.56 ± 0.03 * | 6.20 ± 0.27 * |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Jyske, T.; Möttönen, V. Properties of Injection Molded Biocomposites Reinforced with Wood Particles of Short-Rotation Aspen and Willow. Polymers 2020, 12, 257. https://doi.org/10.3390/polym12020257

Kumar A, Jyske T, Möttönen V. Properties of Injection Molded Biocomposites Reinforced with Wood Particles of Short-Rotation Aspen and Willow. Polymers. 2020; 12(2):257. https://doi.org/10.3390/polym12020257

Chicago/Turabian StyleKumar, Anuj, Tuula Jyske, and Veikko Möttönen. 2020. "Properties of Injection Molded Biocomposites Reinforced with Wood Particles of Short-Rotation Aspen and Willow" Polymers 12, no. 2: 257. https://doi.org/10.3390/polym12020257

APA StyleKumar, A., Jyske, T., & Möttönen, V. (2020). Properties of Injection Molded Biocomposites Reinforced with Wood Particles of Short-Rotation Aspen and Willow. Polymers, 12(2), 257. https://doi.org/10.3390/polym12020257