Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Gel Permeation Chromatography of PLA

2.2. Rotational Rheometry of PLA

2.3. Thermogravimetric Analysis Performed in Isothermal Conditions of EMS

2.4. Thermomechanical Analysis of EMS

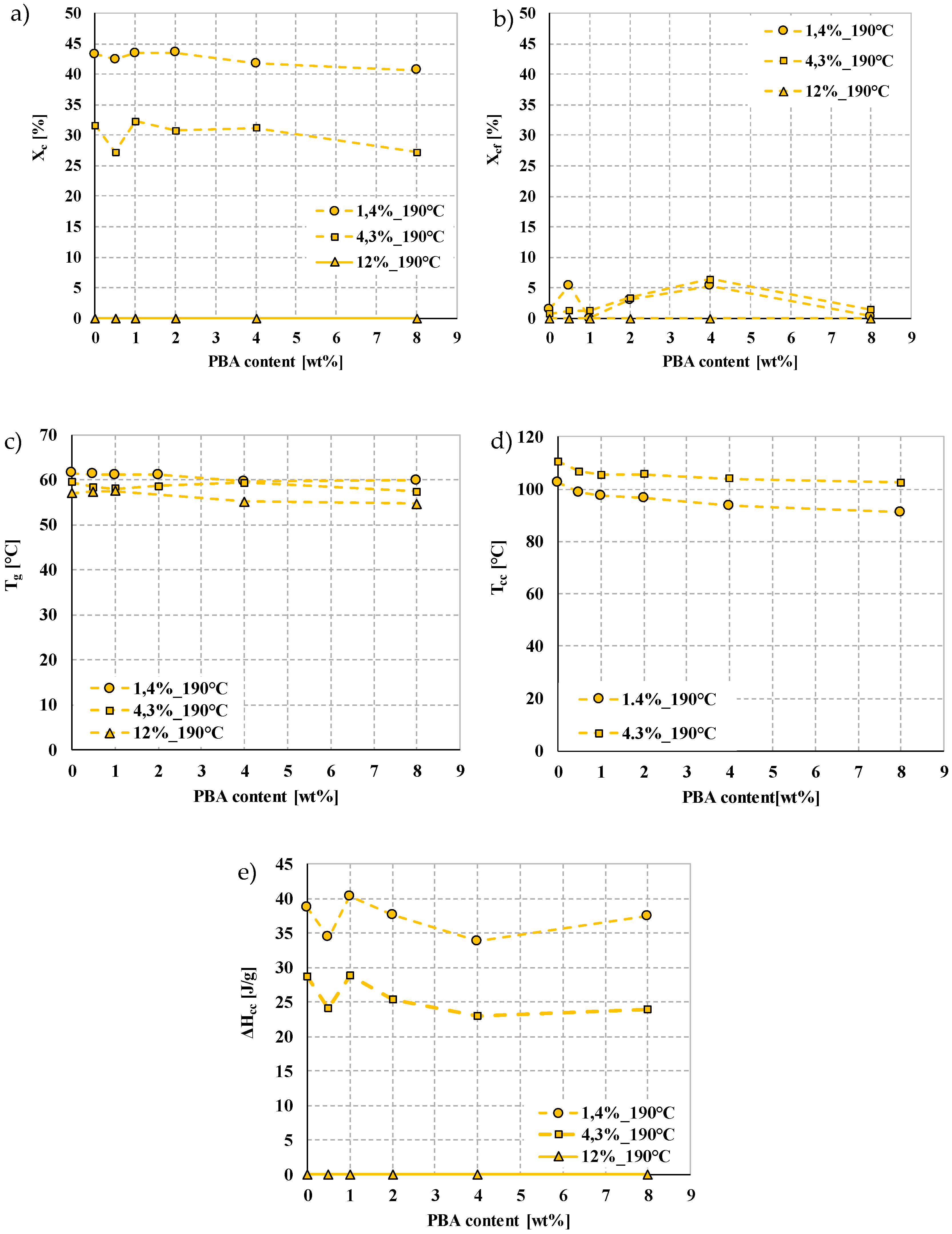

2.5. Differential Scanning Calorimetry of Biopolymer Foams

2.6. Scanning Electron Microscopy

2.7. Foam Characterization

2.8. Compression Strength

2.9. Dynamic Mechanical Analysis

2.10. Extrusion Foaming of PLA (Rod-Shaped Specimen)

2.11. Extrusion Foaming of PLA (Sheet Specimen)

3. Results

3.1. Results of the Investigation of the PLAs and Thermally Expandable Microspheres

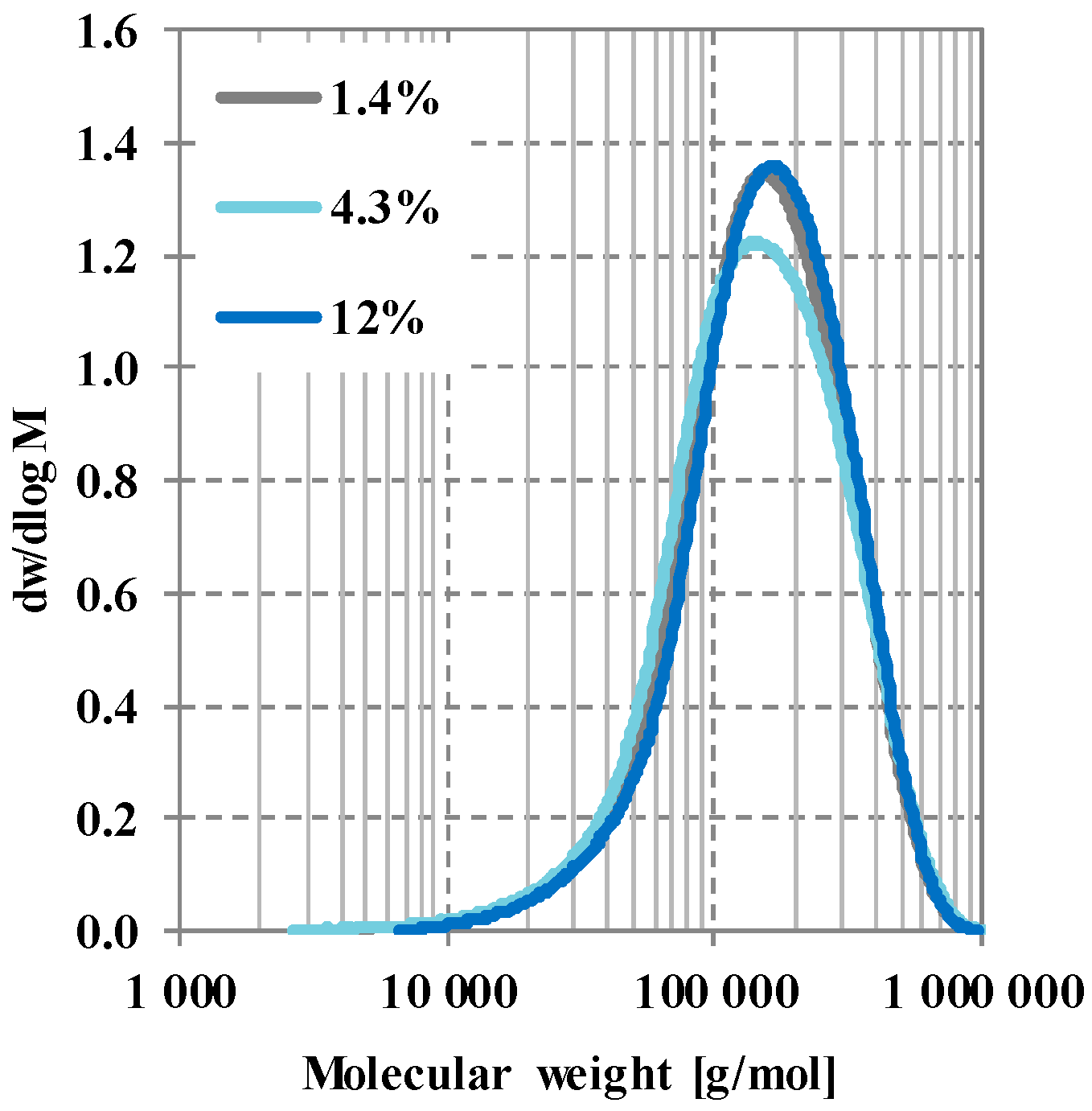

3.1.1. The Molecular Weight Distribution of PLA

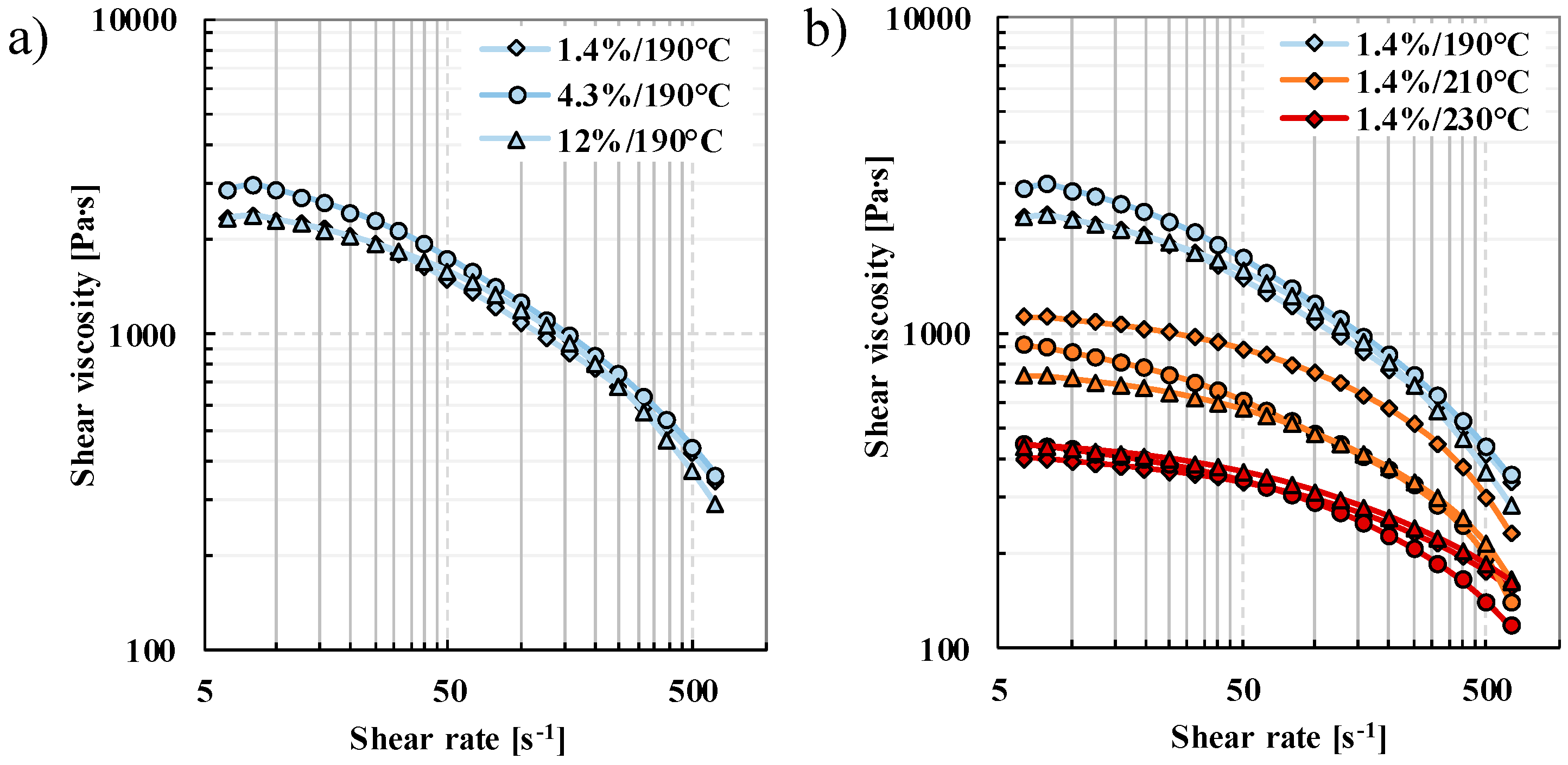

3.1.2. Rheological Tests of PLA

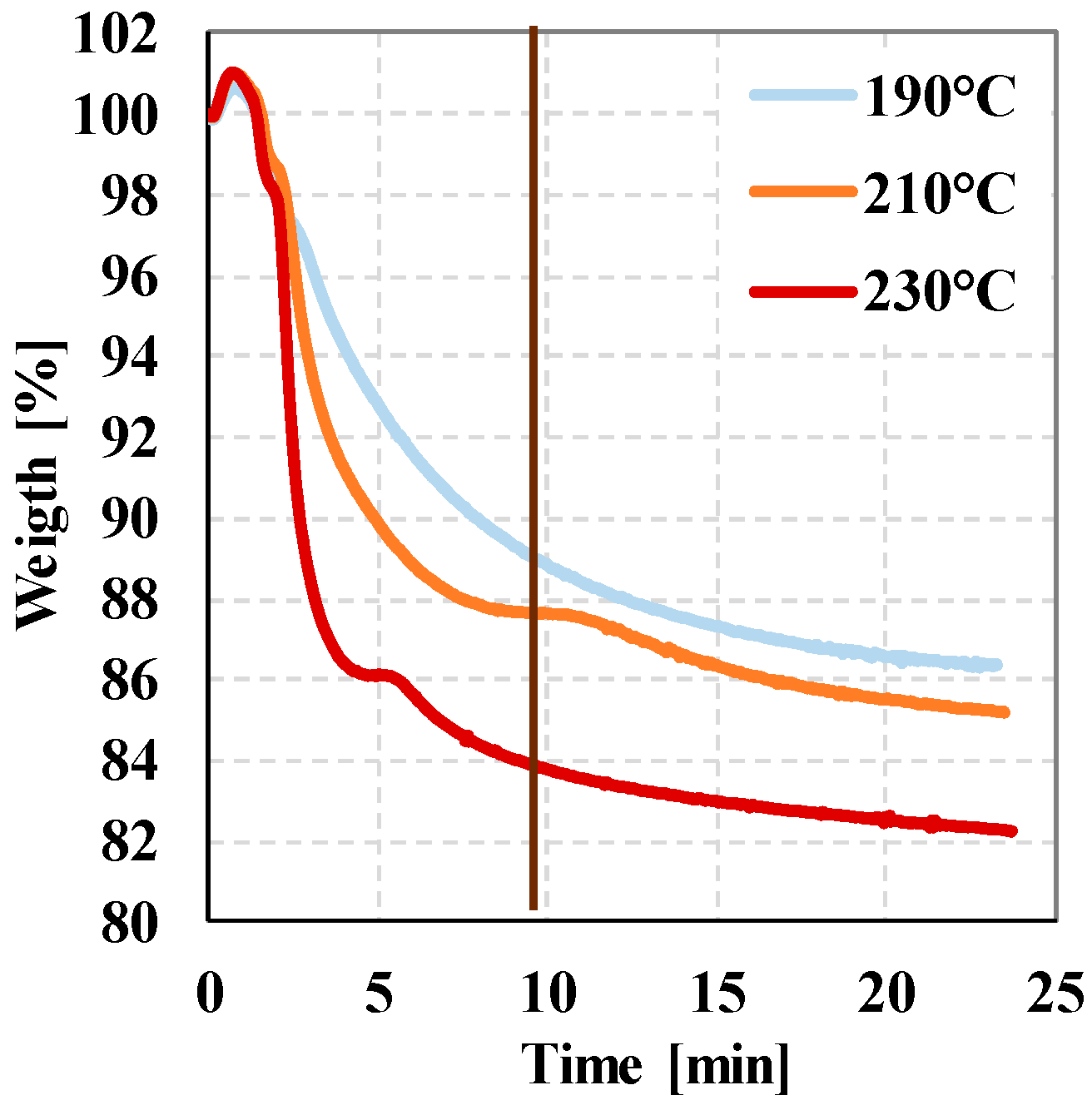

3.1.3. Isothermal Thermogravimetric Analysis of Expandable Microspheres

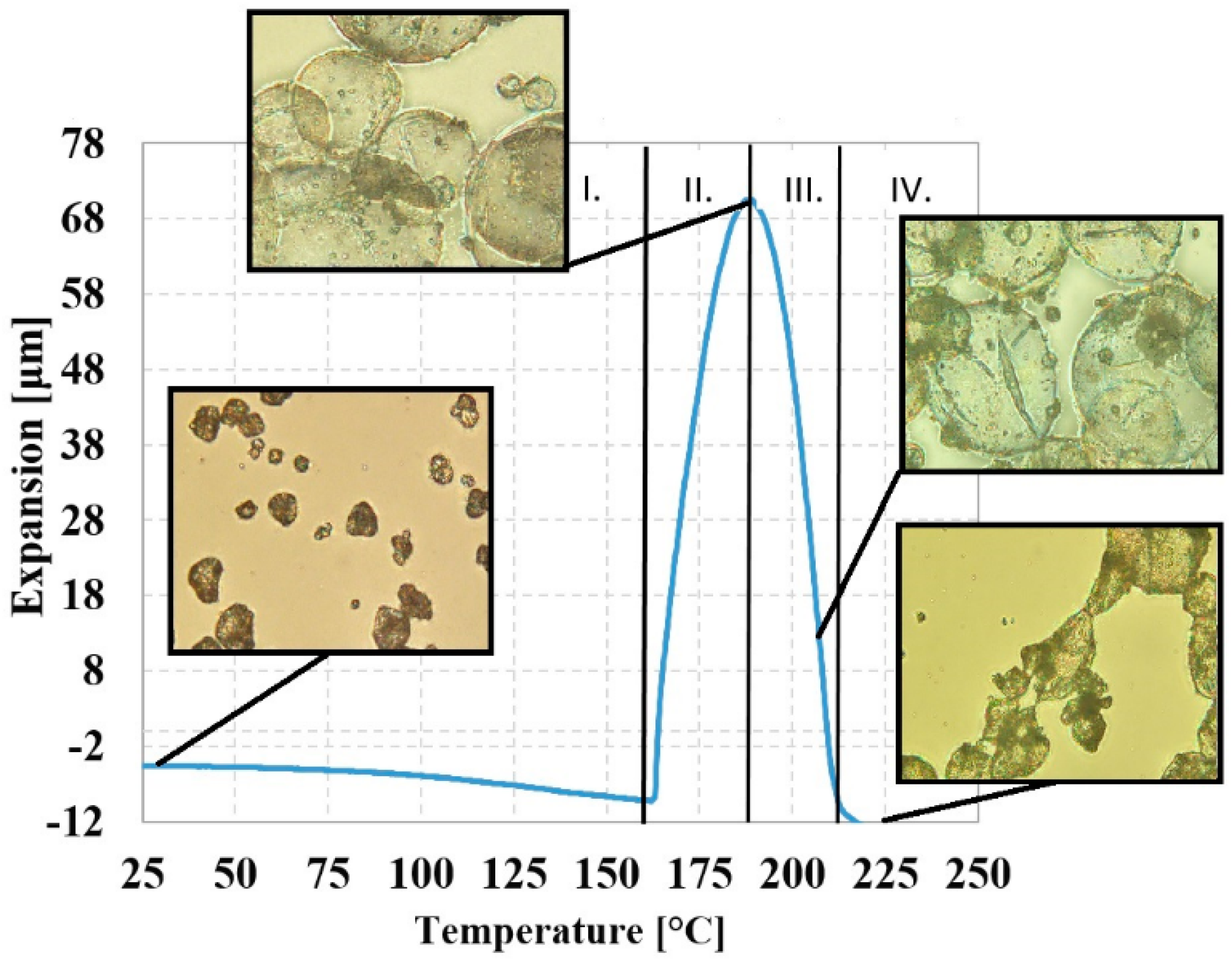

3.1.4. Thermomechanical Analysis of EMS

3.2. Extrusion Foaming of Polylactic Acid with Expandable Microspheres

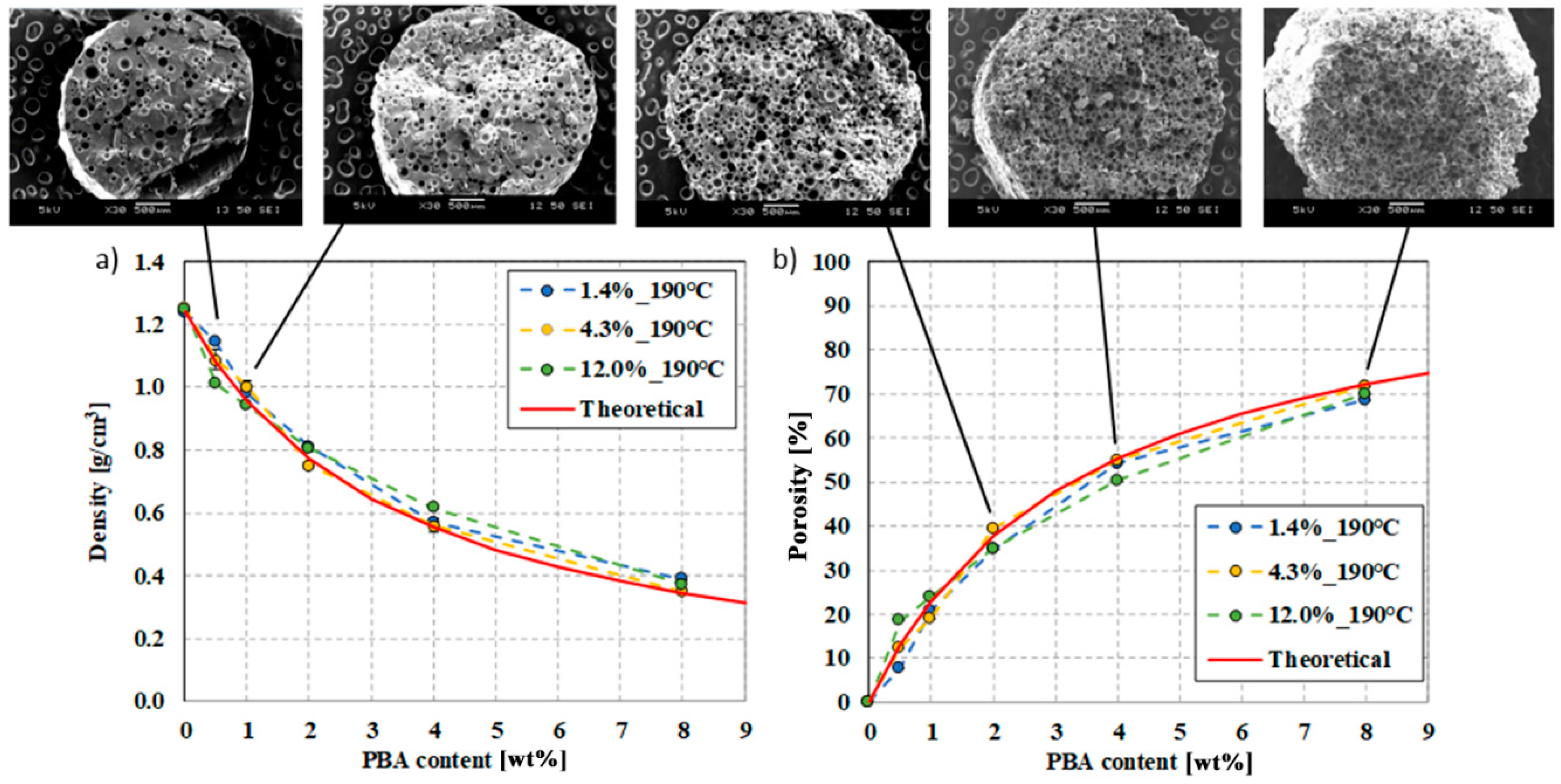

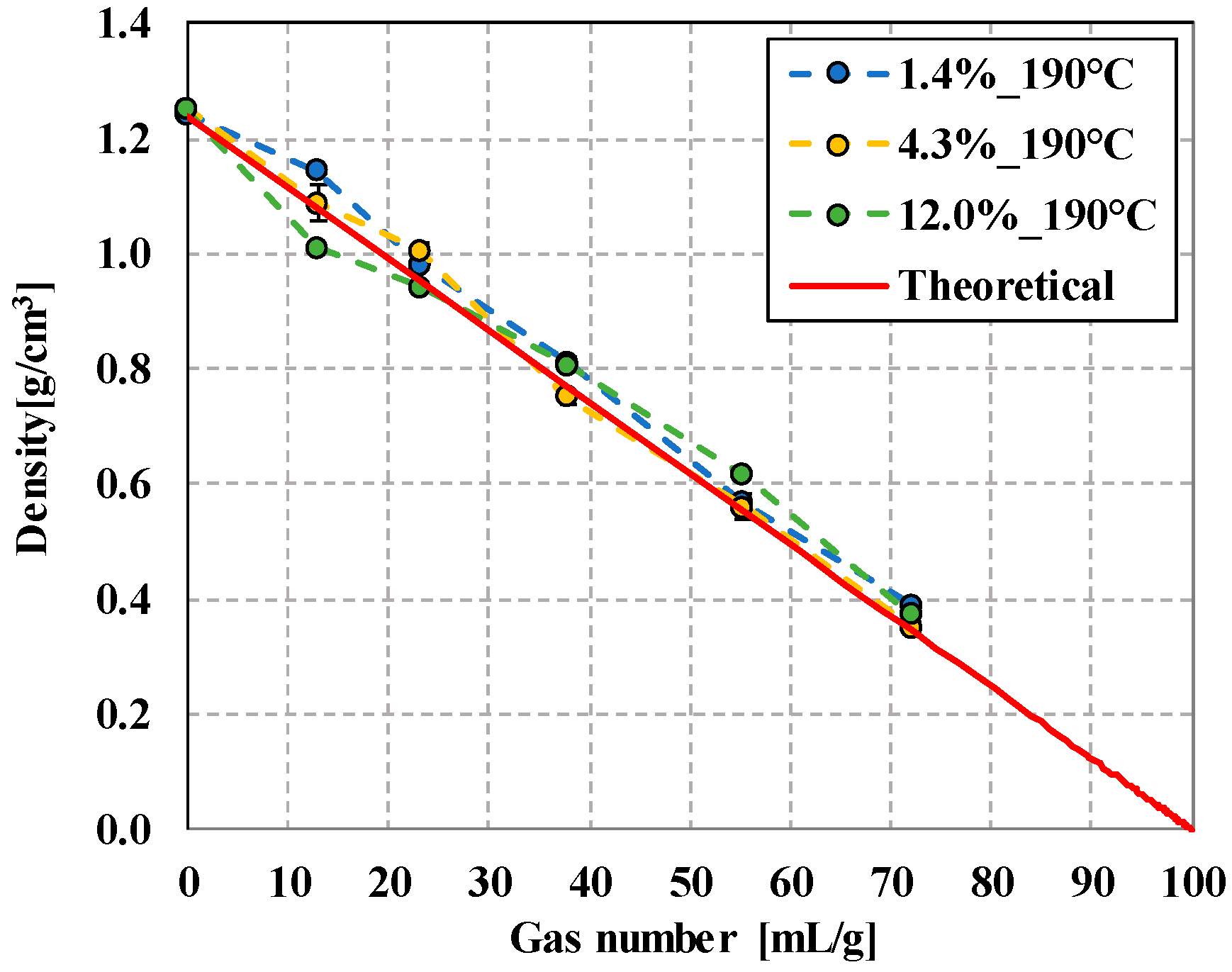

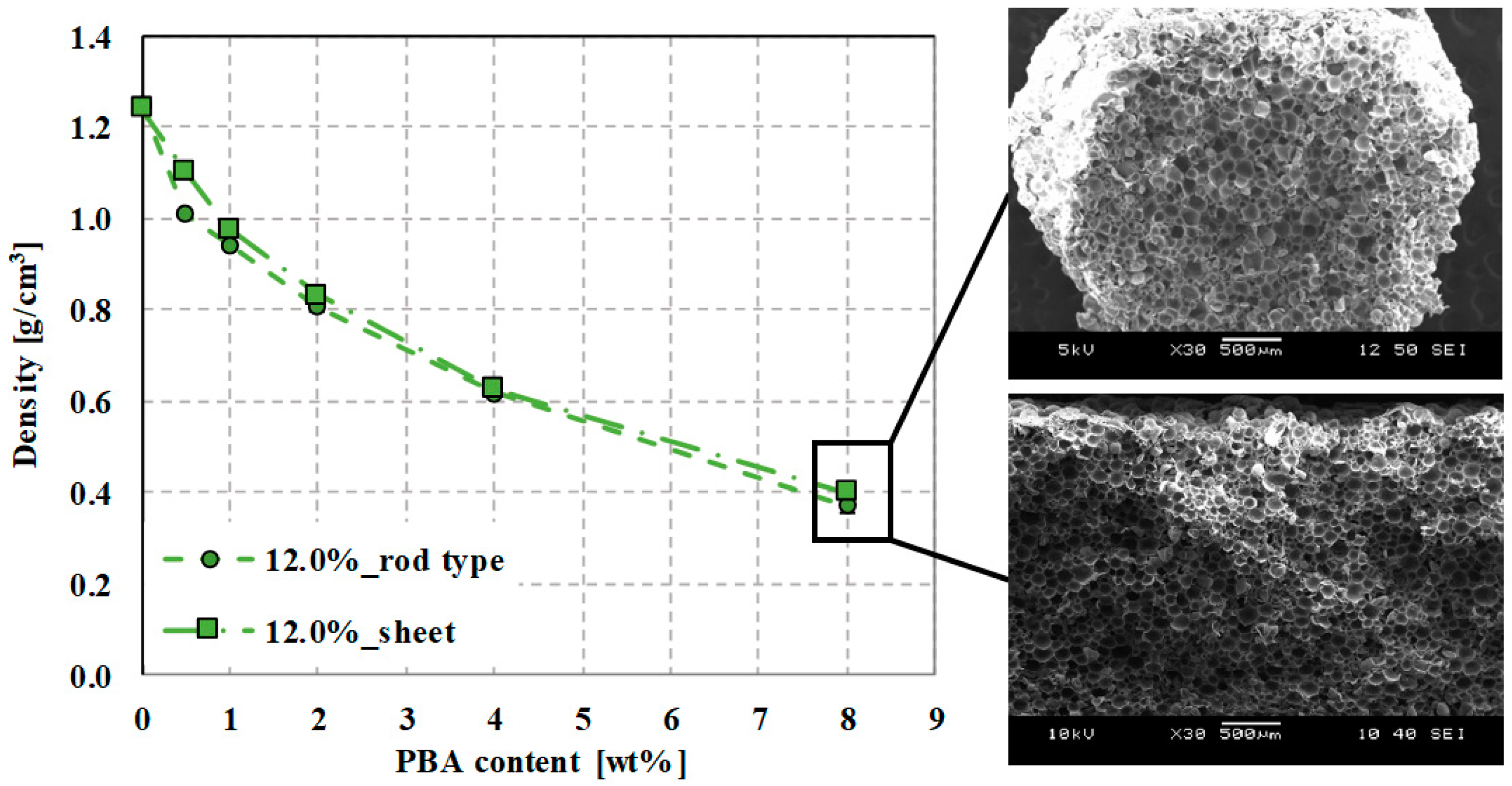

3.3. The Effect of EMS Amount

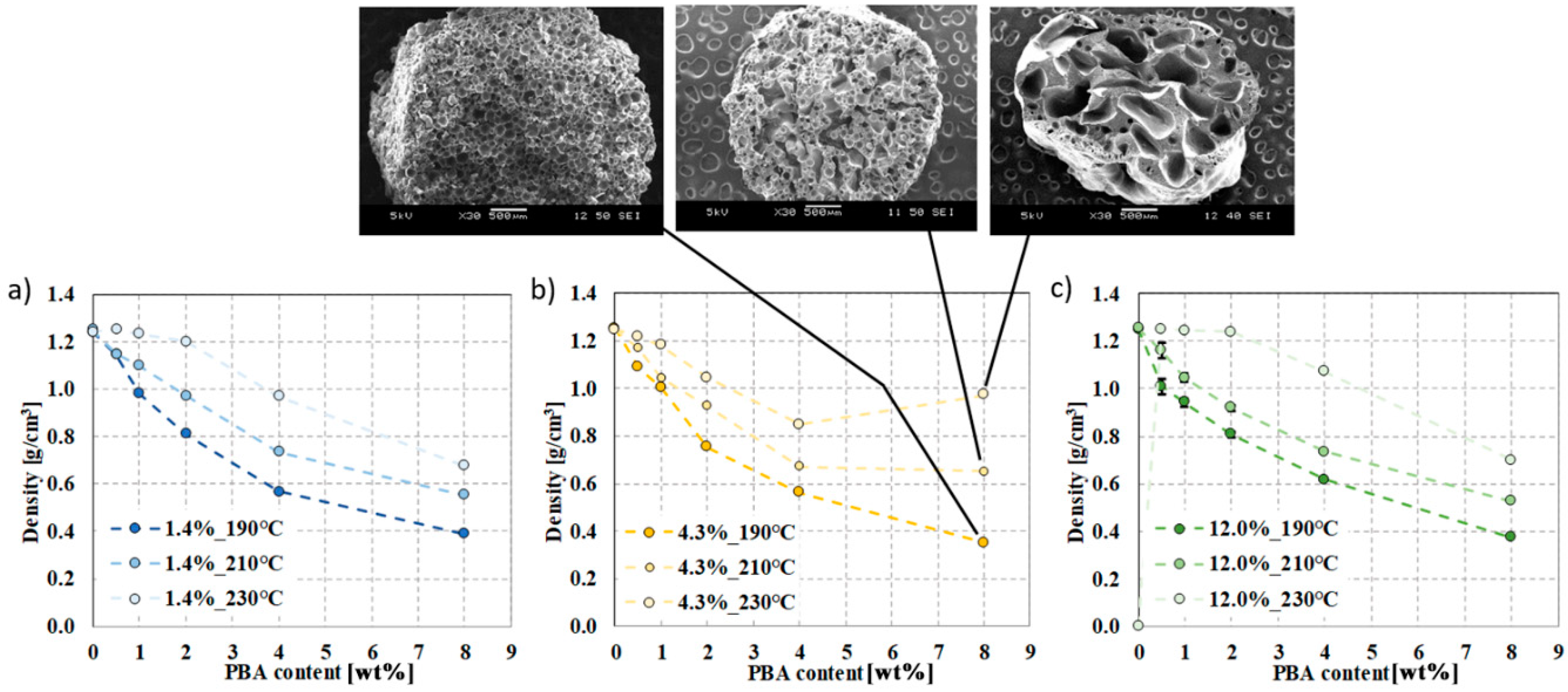

3.4. The Effect of Processing Temperature

3.5. The Effect of EMS Content and the d-Lactide Content of PLAs on Foam Morphology

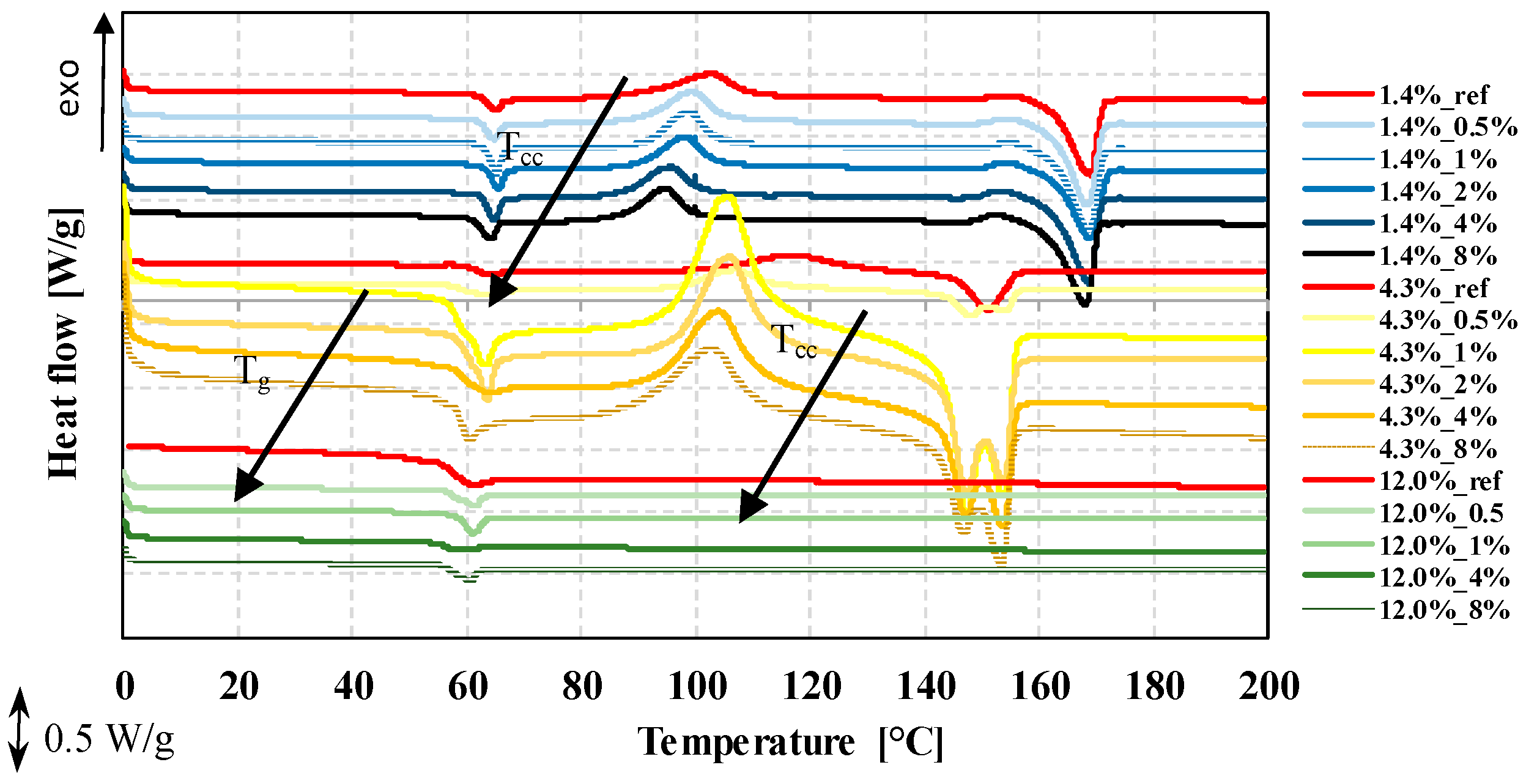

3.6. Adapting Previous Results to Produce Foamed Sheet PLA Specimens

3.7. Mechanical Properties of Foams

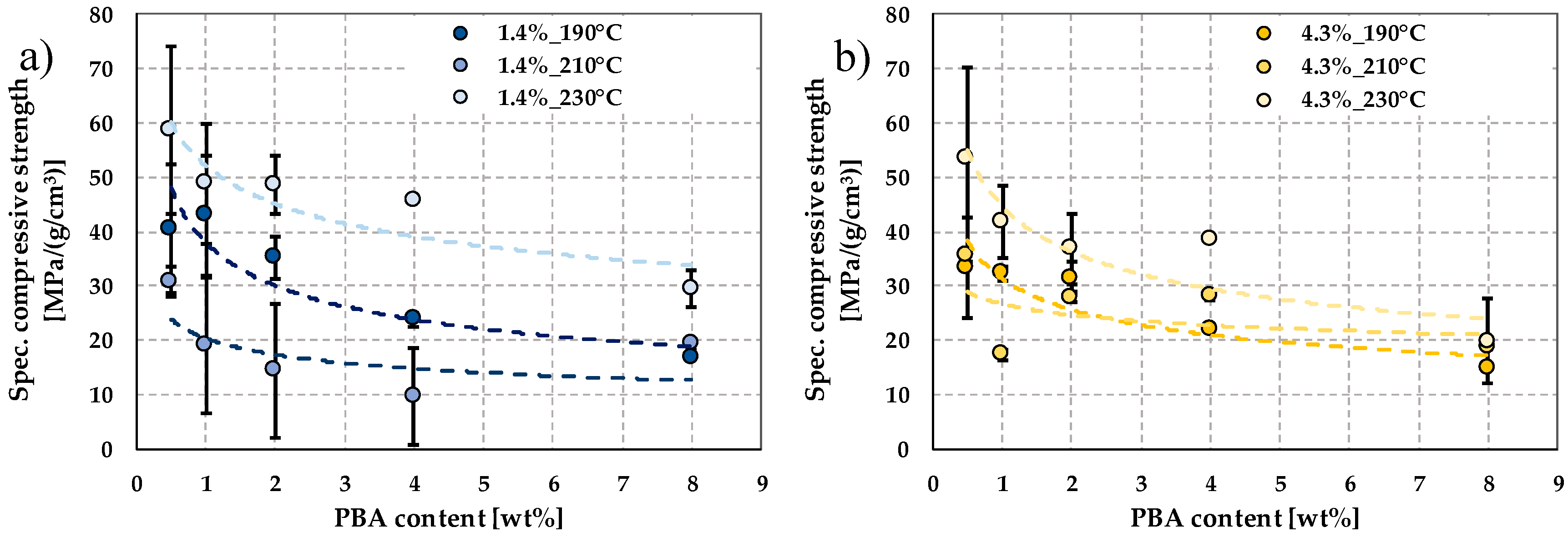

3.7.1. Compression Properties of Foam Structures

3.7.2. Dynamic Mechanical Properties of Foam Structures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kmetty, Á.; Litauszki, K.; Réti, D. Characterization of different chemical blowing agents and their applicability to produce poly(lactic acid) foams by extrusion. Appl. Sci. 2018, 8, 1960. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.T.; Ramesh, N.S. Polymeric foams - Mechanisms and Materials; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Szabó, V.A.; Dogossy, G. Investigation of Flame Retardant rPET Foam. Period. Polytech. Mech. Eng. 2020, 64, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Research, Z.M. Polymer Foam Market. Revenue to Ascend to US$ 161 Billion by 2021; Zion Market Research: New York, NY, USA, 2018. [Google Scholar]

- Avalle, M.; Belingardi, G.; Montanini, R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int. J. Impact Eng. 2001, 25, 455–472. [Google Scholar] [CrossRef]

- Duranceau, C.M.; Winslow, G.R.; Saha, P. Recycling of Automotive Seat Foam: Acoustics of Post Consumer Rebond Seat Foam For Carpet Underlayment Application. SAE Tech. Paper 1998, 980094. [Google Scholar]

- Liu, S.; Duvigneau, J.; Vancso, G.J. Nanocellular polymer foams as promising high performance thermal insulation materials. Eur. Polym. J. 2015, 65, 33–45. [Google Scholar] [CrossRef]

- Heidari, A.; Fasihi, M. Cell structure-impact property relationship of polypropylene/thermoplastic elastomer blend foams. Express Polym. Lett. 2019, 13, 429–442. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Dai, X.R.; Zou, L.; Wen, S.B.; Sinha, T.K.; Li, H. A developed, eco-friendly, and flexible thermoplastic elastomeric foam from SEBS for footwear application. Express Polym. Lett. 2019, 13, 948–958. [Google Scholar] [CrossRef]

- Szabó, V.A.; Dogossy, G. Recycling of Mineral Water Bottles with Chemical Foaming. Acta Tech. Jaurinensis 2017, 10, 157–167. [Google Scholar] [CrossRef] [Green Version]

- Szabó, V.A.; Dogossy, G. Structure and properties of closed-cell foam prepared from rPET. IOP Conference Series: Mater. Sci. Eng. 2018, 426, 1–8. [Google Scholar] [CrossRef]

- Di, Y.; Iannace, S.; Di Maio, E.; Nicolais, L. Reactively modified poly(lactic acid): Properties and foam processing. Macromol. Mater. Eng. 2005, 290, 1083–1090. [Google Scholar] [CrossRef]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 820–852. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, W.; Zhang, H.; Park, C.B. Continuous processing of low-density, microcellular poly(lactic acid) foams with controlled cell morphology and crystallinity. Chem. Eng. Sci. 2012, 75, 390–399. [Google Scholar] [CrossRef]

- Vadas, D.; Igricz, T.; Sarazin, J.; Bourbigot, S.; Marosi, G.; Bocz, K. Flame retardancy of microcellular poly(lactic acid) foams prepared by supercritical CO2-assisted extrusion. Polym. Degrad. Stab. 2018, 153, 100–108. [Google Scholar] [CrossRef] [Green Version]

- Ludwiczak, J.; Kozlowski, M. Foaming of Polylactide in the Presence of Chain Extender. J. Polym. Environ. 2015, 23, 137–142. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Ma, P.; Xu, P.; Wang, R.; Dong, W.; Chen, M.; Joziass, E.C. The crystallization behavior of poly(lactic acid) with different types of nucleating agents. Int. J. Biol. Macromol. 2018, 106, 955–962. [Google Scholar] [CrossRef]

- Tábi, T.; Wache, A.F.; Hajba, S. Effect of D-lactide content of annealed poly(lactic acid) on its thermal, mechanical, heat deflection temperature, and creep properties. J. Appl. Polym. Sci. 2018, 136, 47103. [Google Scholar] [CrossRef]

- Chauvet, M.; Sauceau, M.; Baillon, F.; Fages, J. Mastering the structure of PLA foams made with extrusion assisted by supercritical CO2. J. Appl. Polym. Sci. 2017, 28, 45067. [Google Scholar] [CrossRef] [Green Version]

- Soares, F.A.; Bohrz Nachtigall, S.M. Effect of chemical and physical foaming additives on the properties of PP/wood flour composites. Polym. Test. 2013, 2013, 640–646. [Google Scholar] [CrossRef]

- Petrossian, G.; Hohimer, C.J.; Ameli, A. Highly-Loaded Thermoplastic Polyurethane/Lead Zirconate Titanate Composite Foams with Low Permittivity Fabricated using Expandable Microspheres. Polymers 2019, 11, 280. [Google Scholar] [CrossRef] [Green Version]

- Garbacz, T.; Jachowicz, T.; Tor-Świątek, A. The effect of blowing agents on the effectiveness of poly(vinyl chloride) extrusion. Adv. Sci. Technol. Res. J. 2016, 10, 217–223. [Google Scholar] [CrossRef] [Green Version]

- Pak, A.R.; Park, J.H.; Lee, S.G. Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules. Polymers 2019, 11, 1652. [Google Scholar] [CrossRef] [Green Version]

- Xue, B.; Zhang, J.; Bao, Y. Acoustically and thermally insulating epoxy foams prepared by non-traditional expandable microspheres. Polym. Eng. Sci. 2019, 59, 799–806. [Google Scholar] [CrossRef]

- Yua, J.-F.; Gan, L.; Liu, C.-H.; Ma, X.-Z.; Wang, D.; Huang, J. Heat-counteracted strategy for tailoring the cell structure and properties of sustainable poly(butylene succinate) foams. Polymer 2018, 155, 50–57. [Google Scholar] [CrossRef]

- Standau, T.; Zhao, C.; Murillo Castellón, S.; Bonten, C.; Altstädt, V. Chemical Modification and Foam Processing of Polylactide (PLA). Polymers 2019, 11, 306. [Google Scholar] [CrossRef] [Green Version]

- Technical Data Sheet Ingeo Biopolymer 2003D, 4032D and 4060D; NatureWorks LLC.: Minnetonka, MN, USA, 2019.

- Litauszki, K.; Kmetty, Á. Extrusion foaming of poly(lactic acid) with thermally expandable microsphers. In Proceedings of the SPE Foams 2019 Conference, Valladolid, Spain, 2–3 October 2019; pp. 1–5. [Google Scholar]

- Cox, W.P.; Merz, E.H. Correlation of dynamic and steady flow viscosities. J. Polym. Sci. 1958, 28, 619–622. [Google Scholar] [CrossRef]

- Hajba, S.; Tábi, T. Cross Effect of Natural Rubber and Annealing on the Properties of Poly(Lactic Acid). Period. Polytech. Mech. Eng. 2019, 63, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Park, C.B.; Xu, D.; Pop-Iliev, R. Effects of Die Geometry on Cell Nucleation of PS Foams Blown with CO2. Polym. Eng. Sci. 2003, 43, 1378–1390. [Google Scholar] [CrossRef]

- Frisch, K.C.; Klempner, D. Advances in Urethane: Science & Technology; Technomic Publishing Company, Inc.: Lancaster, PA, USA, 1993; Volume 12. [Google Scholar]

- Collier, J.R.; Petrovan, S.; Patil, P. Temperature shifting of convergent flow measured effective elongational viscosity. J. Appl. Polym. Sci. 2003, 87, 1387–1396. [Google Scholar] [CrossRef]

- Jonsson, M.; Nordin, O.; Kron, A.L.; Malmström, E. Thermally Expandable Microspheres with ExcellentExpansion Characteristics at High Temperature. J. Appl. Polym. Sci. 2010, 117, 384–392. [Google Scholar]

- Abu-Zahra, N.; Alian, A.M. Density and cell morphology of rigid foam PVC-clay nanocomposites. Polym.-Plast. Technol. Eng. 2010, 49, 237–243. [Google Scholar] [CrossRef]

| Zone Temperatures | Screw Rotation Speed | Notation | ||||

|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Z5 | n | - |

| °C | °C | °C | °C | °C | 1/min | - |

| 155 | 160 | 175 | 190 | 190 | 10 | T1 |

| 175 | 180 | 195 | 210 | 210 | 10 | T2 |

| 195 | 200 | 215 | 230 | 230 | 10 | T3 |

| Sample_Temp | wt=10 min | wt=23 min |

|---|---|---|

| % | % | |

| Tracel G 6800_190 °C | 88.8 | 86.3 |

| Tracel G 6800_210 °C | 87.6 | 85.2 |

| Tracel G 6800_230 °C | 83.8 | 82.3 |

| Unit | 12.0%_ref | 12.0%_G6800_4wt% | 12.0%_G6800_8wt% | |

|---|---|---|---|---|

| T(tanδMAX) | °C | 53.8 | 52.1 | 51.2 |

| Storage modulus (at 25°C) | MPa | 2476 | 812 | 384 |

| Storage modulus (at Tg+10°C) | MPa | 8.5 | 7.9 | 10.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kmetty, Á.; Litauszki, K. Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres. Polymers 2020, 12, 463. https://doi.org/10.3390/polym12020463

Kmetty Á, Litauszki K. Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres. Polymers. 2020; 12(2):463. https://doi.org/10.3390/polym12020463

Chicago/Turabian StyleKmetty, Ákos, and Katalin Litauszki. 2020. "Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres" Polymers 12, no. 2: 463. https://doi.org/10.3390/polym12020463

APA StyleKmetty, Á., & Litauszki, K. (2020). Development of Poly (Lactide Acid) Foams with Thermally Expandable Microspheres. Polymers, 12(2), 463. https://doi.org/10.3390/polym12020463