Removal of Rhodamine B from Water Using a Solvent Impregnated Polymeric Dowex 5WX8 Resin: Statistical Optimization and Batch Adsorption Studies

Abstract

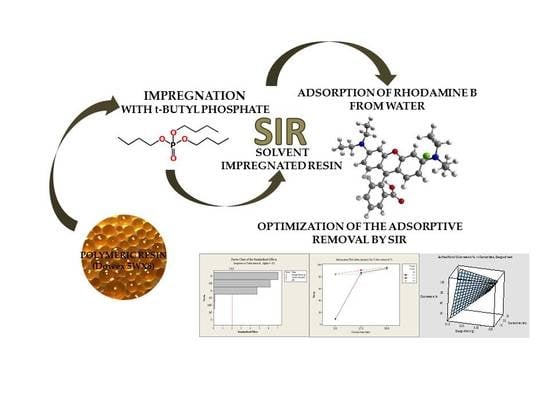

:1. Introduction

2. Experimental

2.1. Chemicals, Reagents, and Adsorbent

2.2. Synthesis of Solvent Impregnated Dowex 5WX8 Resin

2.3. Characterization of Solvent Impregnated Dowex 5WX8 Resin

2.4. Batch Scale Adsorption

2.5. Design of Experiments and Optimization of Parameters

2.6. Isotherm Modeling

3. Results and Discussion

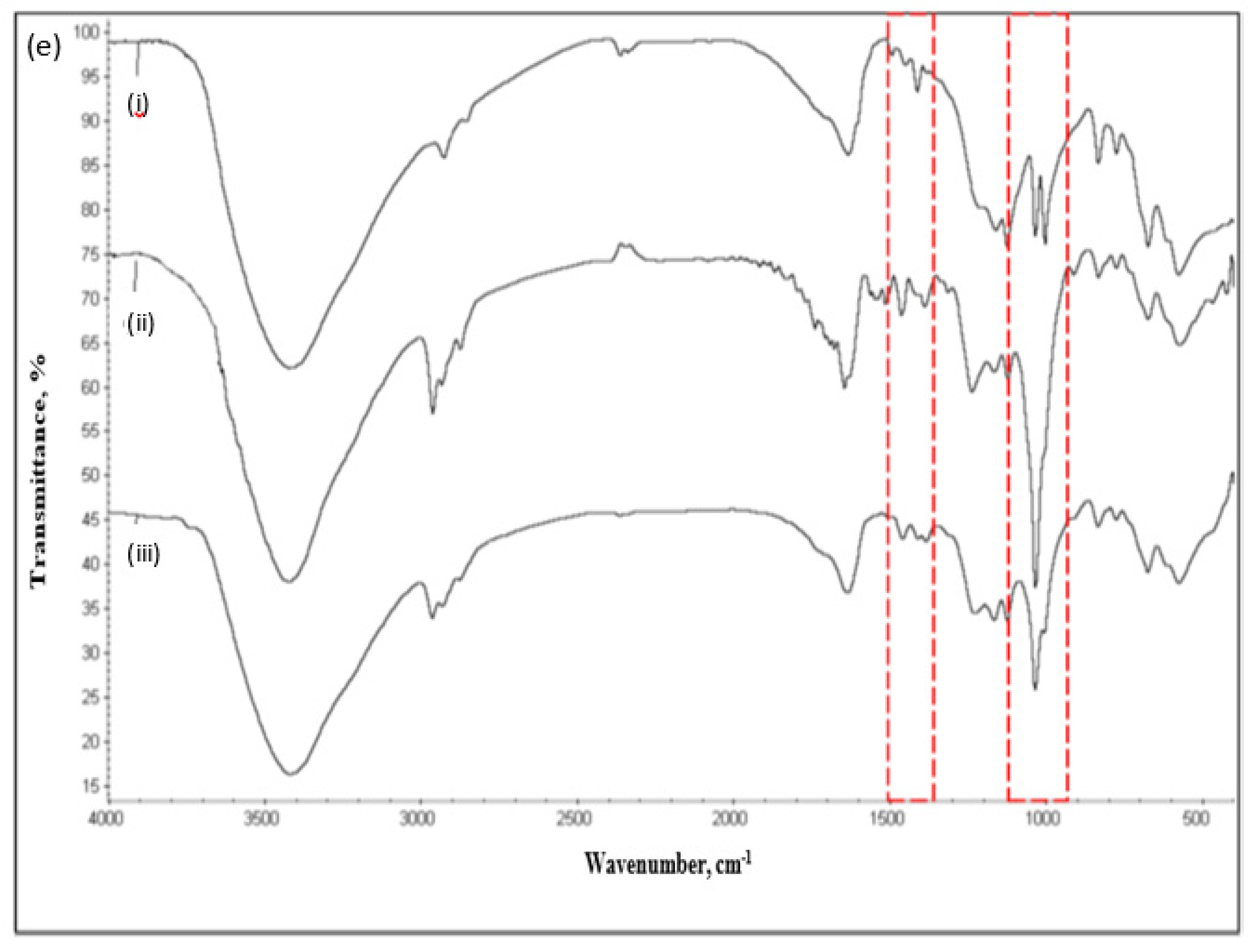

3.1. Pre and Post-Adsorption Characterization

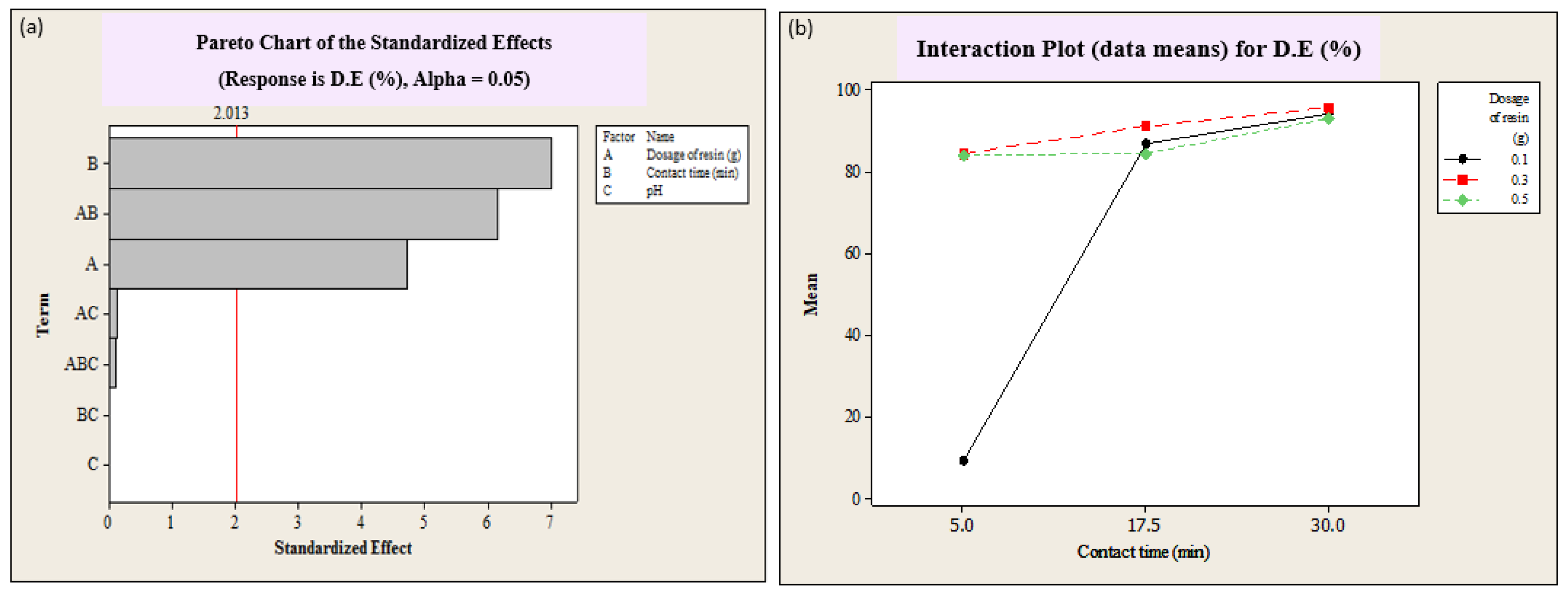

3.2. Screening of Process Independent Variables

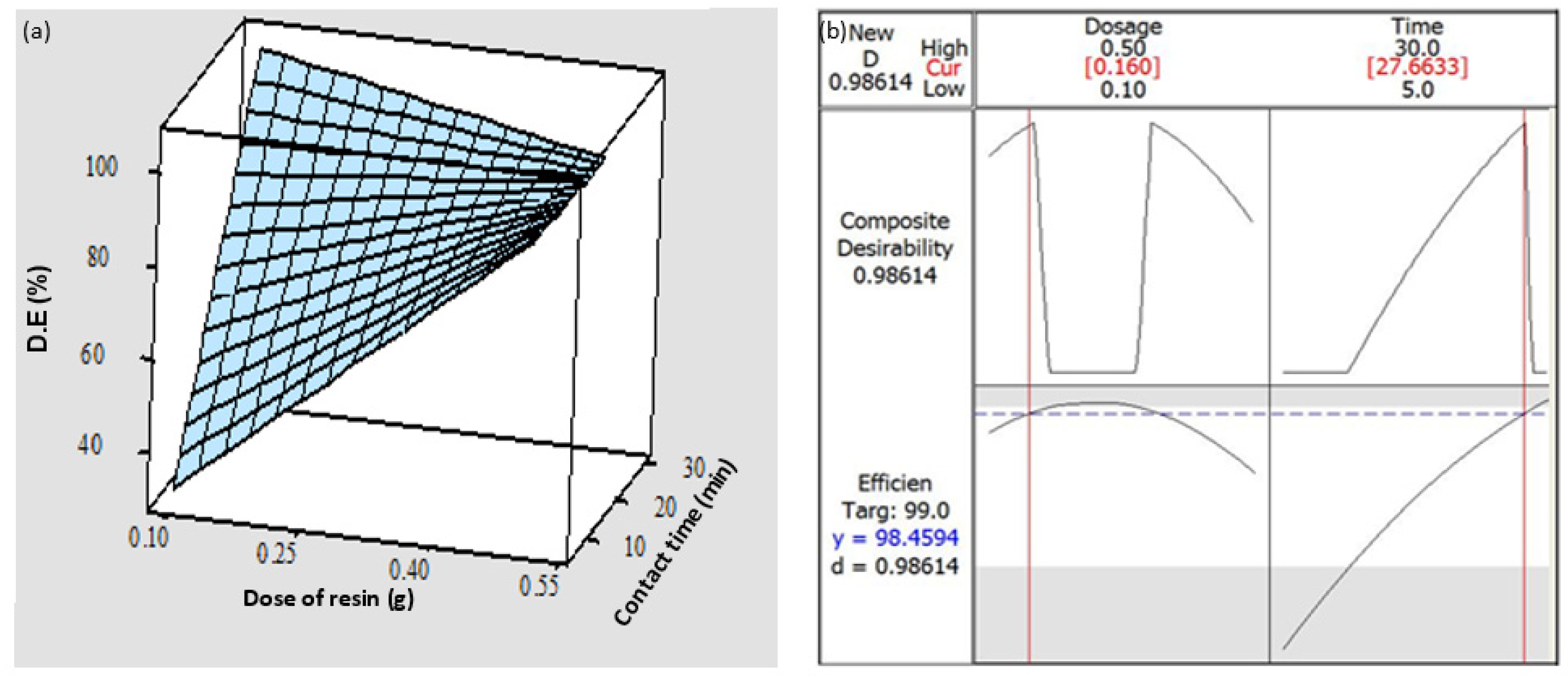

3.3. Optimization of Experiment

3.4. Adsorption Isotherm

3.5. Adsorption Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Verma, A.K.; Dash, R.R.; Bhunia, P. A review on chemical coagulation/flocculation technologies for removal of color from textile wastewaters. J. Environ. Manag. 2012, 293, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, J.; Sikder, J.; Chakraborty, S.; Curcio, S.; Drioli, E. Remediation of textile effluents by membrane based treatment techniques: A state of the art review. J. Environ. Manag. 2015, 147, 55–72. [Google Scholar] [CrossRef] [PubMed]

- Wabaidur, S.M.; Khan, M.A.; Siddiqui, M.R.; Alothman, Z.A.; Al-Ghamdi, M.S.; Al-Sohami, H.I. Dodecyl sulfate chain anchored bio-char to sequester triaryl methane dyes: Equilibrium, kinetics, and adsorption mechanism. Desal. Water Treat. 2017, 67, 357–370. [Google Scholar] [CrossRef]

- Ahmad, T.; Rafatullah, M.; Ghazali, A.; Sulaiman, O.; Hashim, R. Oil palm biomass-Based adsorbents for the removal of water pollutants—A review. J. Environ. Sci. Health Part C 2011, 29, 177–222. [Google Scholar] [CrossRef]

- Rafatullah, M.; Sulaiman, O.; Hashim, R.; Ahmad, A. Adsorption of methylene blue on low-cost adsorbents: A review. J. Hazard. Mater. 2010, 177, 70–80. [Google Scholar] [CrossRef]

- Momina, M.; Isamil, S. Regeneration performance of clay-based adsorbents for the removal of industrial dyes: A review. RSC Adv. 2018, 8, 24571–24587. [Google Scholar] [CrossRef]

- Rafatullah, M.; Ismail, S.; Ahmad, A. Optimization study for the desorption of methylene blue dye from clay based adsorbent coating. Water 2019, 11, 1304. [Google Scholar]

- Rafatullah, M.; Ahmad, T.; Ghazali, A.; Sulaiman, O.; Danish, M.; Hashim, R. Oil palm biomass as a precursor of activated carbons: A review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 1117–1161. [Google Scholar] [CrossRef]

- El-Refaie, K.; Ghfar, A.A.; Wabaidur, S.M.; Khan, M.A.; Siddiqui, M.R.; Alothman, Z.A.; Alqadami, A.A. Muhammad, Cetyltrimethylammonium bromide intercalated and branched polyhydroxystyrene functionalized montmorillonite clay to sequester cationic dyes. J. Environ. Manag. 2018, 219, 285–293. [Google Scholar]

- Aldawsari, A.; Khan, M.A.; Hameed, B.H.; Yaseen, A.; Alothman, Z.A.; Siddiqui, M.R. Development of activated carbon from Phoenix dactylifera fruit pits: Process optimization, characterization, and methylene blue adsorption. Desal. Water Treat. 2017, 62, 273–281. [Google Scholar] [CrossRef]

- Das, R. Introduction. In Polymeric materials for clean water. Springer Series on Polymer and Composite Materials; Das, R., Ed.; Springer Publishing: New York, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Karimi-Maleh, H.; Shafieizadeh, M.; Taher, M.A.; Rezapour, M.; Orooji, Y. The role of magnetite/graphene oxide nano-composite as a high-efficiency adsorbent for removal of phenazopyridine residues from water samples, an experimental/theoretical investigation. J. Mol. Liq. 2020, 298, 112040. [Google Scholar] [CrossRef]

- Orooji, Y.; Liang, F.; Razmjou, A.; Liu, G.; Jin, W. Preparation of anti-adhesion and bacterial destructive polymeric ultrafiltration membranes using modified mesoporous carbon. Sep. Purif. Technol. 2018, 205, 273–283. [Google Scholar] [CrossRef]

- Orooji, Y.; Ghasali, E.; Emami, N.; Noorisafa, F.; Razmjou., A. ANOVA design for the optimization of TiO2 coating on polyether sulfone membranes. Molecules 2019, 24, 2924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Razmjou, A.; Eshaghi, G.; Orooji, Y.; Hosseini, E.; Korayem, A.H.; Mohagheghian, F.; Boroumand, Y.; Noorbakhsh, A.; Asadnia, M.; Chen, V. Lithium ion-selective membrane with 2D subnanometer channels. Water Res. 2019, 159, 313–323. [Google Scholar] [CrossRef] [PubMed]

- Razmjou, A.; Asadnia, M.; Hosseini, E.; Habibnejad Korayem, A.; Chen, V. Design principles of ion selective nanostructured membranes for the extraction of lithium ions. Nat. Commun. 2019, 10, 5793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Greluk, M.; Hubicki, Z. Evaluation of polystyrene anion exchange resin for removal of reactive dyes from aqueous solutions. Chem. Eng. Res. Des. 2013, 91, 1343–1351. [Google Scholar] [CrossRef]

- El-Ashtoukhy, E.S.; Fouad, Y. Liquid-liquid extraction of methylene blue dye from aqueous solutions using sodium dodecylbenzenesulfonate as an extractant. Alex. Eng. J. 2015, 54, 77–81. [Google Scholar] [CrossRef] [Green Version]

- Bokhove, J.; Schuur, B.; DeHaan, A. Resin screening for the removal of pyridine-derivatives from waste-water by solvent impregnated resin technology. React. Funct. Polym. 2013, 73, 595–605. [Google Scholar] [CrossRef]

- Helaly, O.S.; El-Ghany, M.S.A.; Moustafa, M.I.; Abuzaid, A.H.; El-monem, N.M.A.; Ismail, I.M. Extraction of cerium (IV) using tributyl phosphate impregnated resin from nitric acid medium. Trans. Nonferr. Met. Soc. China 2012, 22, 206–214. [Google Scholar] [CrossRef]

- Oyekanmi, A.A.; Ahmad, A.; Hossain, K.; Rafatullah, M. Adsorption of Rhodamine B dye from aqueous solution onto acid treated banana peel: Response surface methodology, kinetics and isotherm studies. PLoS ONE 2019, 14, e0216878. [Google Scholar] [CrossRef]

- Kabay, N.; Cortina, J.L.; Trochimczuk, A.; Streat, M. Solvent-impregnated resins (SIRs)-methods of preparation and their applications. React. Funct. Polym. 2010, 70, 484–496. [Google Scholar] [CrossRef]

- Arami, M.; Limaee, N.Y.; Mahmoodi, N.M.; Tabrizi, N.S. Equilibrium and kinetics studies for the adsorption of direct and acid dyes from aqueous solution by soy meal hull. J. Hazard. Mater. 2006, 135, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Fitzpatrick, F. Solvent Impregnated Resins for the Recovery of Gold from Gold (I) Thiourea Solutions. MSc. Thesis, Dublin City University, Dublin, Ireland, 1997; p. 51. [Google Scholar]

- Low, L.W.; Teng, T.T.; Alkarkhi, A.F.M.; Ahmad, A.; Morad, N. Optimization of the adsorption conditions for the decolorization and COD reduction of methylene blue aqueous solution using low-cost adsorbent. Water Air Soil Pollut. 2011, 214, 185–195. [Google Scholar] [CrossRef]

- Anouzla, A.; Abrouki, Y.; Souabi, S.; Safi, M.; Rhbal, H. Colour and COD removal of disperse dye solution by a novel coagulant: Application of statistical design for the optimization and regression analysis. J. Hazard. Mater. 2009, 166, 1302–1306. [Google Scholar] [CrossRef] [PubMed]

- Annadurai, G.; Juang, R.-S.; Lee, D.-J. Use of cellulose-based wastes for adsorption of dyes from aqueous solutions. J. Hazard. Mater. 2002, 92, 263–274. [Google Scholar] [CrossRef]

- Namasivayam, C.; Muniaswamy, N.; Gayatri, K.; Rani, M.; Ranganathan, K. Removal of dyes from aqueous solutions by cellulosic waste orange peel. Bioresour. Technol. 1996, 57, 37–43. [Google Scholar] [CrossRef]

- Belkhouche, N.E.; Didi, M.A. Extraction of Bi (III) from nitrate medium by D2EHPA impregnated onto Amberlite XAD-1180. Hydrometallurgy 2010, 103, 60–67. [Google Scholar] [CrossRef]

- Şölener, M.; Tunali, S.; Ozcan, A.S.; Ozcan, A.; Gedikbey, T. Adsorption characteristics of lead (II) ions onto the clay/poly (methoxyethyl) acrylamide (PMEA) composite from aqueous solutions. Desalination 2008, 223, 308–322. [Google Scholar] [CrossRef]

- Oyekanmi, A.A.; Ahmad, A.; Hossain, K.; Rafatullah, M. Statistical optimization for adsorption of Rhodamine B dye from aqueous solutions. J. Mol. Liq. 2019, 281, 48–58. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Gao, X.; Liu, C.; Guo, L.; Zhang, S.; Liu, X.; Liu, C. Adsorption behavior of indium (III) on modified solvent impregnated resins (MSIRs) containing sec-octylphenoxy acetic acid. Hydrometallurgy 2012, 121, 60–67. [Google Scholar] [CrossRef]

- Liu, J.; Gao, X.; Liu, C.; Guo, L.; Zhang, S.; Liu, X.; Li, H.; Liu, C.; Jin, R. Adsorption properties and mechanism for Fe (III) with solvent impregnated resins containing HEHEHP. Hydrometallurgy 2013, 137, 140–147. [Google Scholar] [CrossRef]

| Terms | Factors | Levels | ||

|---|---|---|---|---|

| –1 | 0 | +1 | ||

| A | SIR dose (g) | 0.1 | 0.3 | 0.5 |

| B | Contact time (min) | 5 | 17.5 | 30 |

| C | Initial pH of RhB solution | 2 | 5 | 8 |

| Term | Coefficient | SE Coefficient | T-value | P-value |

|---|---|---|---|---|

| Constant | 71.78 | 0.9575 | 74.97 | 0.000 |

| A | 18.90 | 0.9575 | 19.74 | 0.000 |

| B | 21.53 | 0.9575 | 22.48 | 0.000 |

| C | –1.08 | 0.9575 | –1.13 | 0.341 |

| AB | –20.93 | 0.9575 | –21.86 | 0.000 |

| BC | 0.07 | 0.9575 | 0.08 | 0.943 |

| AC | 0.24 | 0.9575 | 0.25 | 0.817 |

| ABC | 0.99 | 0.9575 | 1.03 | 0.378 |

| Term | Coefficient | SE Coefficient | T-value | P-value |

|---|---|---|---|---|

| Constant | 91.374 | 5.156 | 17.722 | 0.000 |

| A | 11.215 | 5.069 | 2.212 | 0.063 |

| B | 17.214 | 5.069 | 3.396 | 0.012 |

| A2 | –12.117 | 7.472 | –1.622 | 0.149 |

| B2 | –6.863 | 7.472 | –0.918 | 0.389 |

| AB | –20.055 | 6.209 | –3.230 | 0.014 |

| Source | Degree of Freedom | Sum of Squares | Mean Squares | F-value | P-value |

|---|---|---|---|---|---|

| Regression | 5 | 4972.66 | 994.53 | 6.45 | 0.015 |

| A | 1 | 754.69 | 754.69 | 4.89 | 0.063 |

| B | 1 | 1777.96 | 1777.96 | 11.53 | 0.012 |

| A2 | 1 | 701.09 | 405.48 | 2.63 | 0.149 |

| B2 | 1 | 130.08 | 130.08 | 0.84 | 0.389 |

| AB | 1 | 1608.84 | 1608.84 | 10.43 | 0.014 |

| Residual error | 7 | 1079.36 | 154.19 | ||

| Lack of fit | 3 | 1052.53 | 350.84 | 52.30 | 0.001 |

| Pure error | 4 | 26.83 | 6.71 | ||

| Total | 12 | 6052.02 | |||

| r2 = 82.17% r2 (adjusted) = 69.43% | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali Khan, M.; Momina, <.; Siddiqui, M.R.; Otero, M.; Alshareef, S.A.; Rafatullah, M. Removal of Rhodamine B from Water Using a Solvent Impregnated Polymeric Dowex 5WX8 Resin: Statistical Optimization and Batch Adsorption Studies. Polymers 2020, 12, 500. https://doi.org/10.3390/polym12020500

Ali Khan M, Momina <, Siddiqui MR, Otero M, Alshareef SA, Rafatullah M. Removal of Rhodamine B from Water Using a Solvent Impregnated Polymeric Dowex 5WX8 Resin: Statistical Optimization and Batch Adsorption Studies. Polymers. 2020; 12(2):500. https://doi.org/10.3390/polym12020500

Chicago/Turabian Style

Ali Khan, Moonis,

Ali Khan, M., Momina, <., Siddiqui, M. R., Otero, M., Alshareef, S. A., & Rafatullah, M. (2020). Removal of Rhodamine B from Water Using a Solvent Impregnated Polymeric Dowex 5WX8 Resin: Statistical Optimization and Batch Adsorption Studies. Polymers, 12(2), 500. https://doi.org/10.3390/polym12020500