Post-Processing of FDM 3D-Printed Polylactic Acid Parts by Laser Beam Cutting

Abstract

:1. Introduction

2. Experimental Design and Methodology

3. Experimental Work

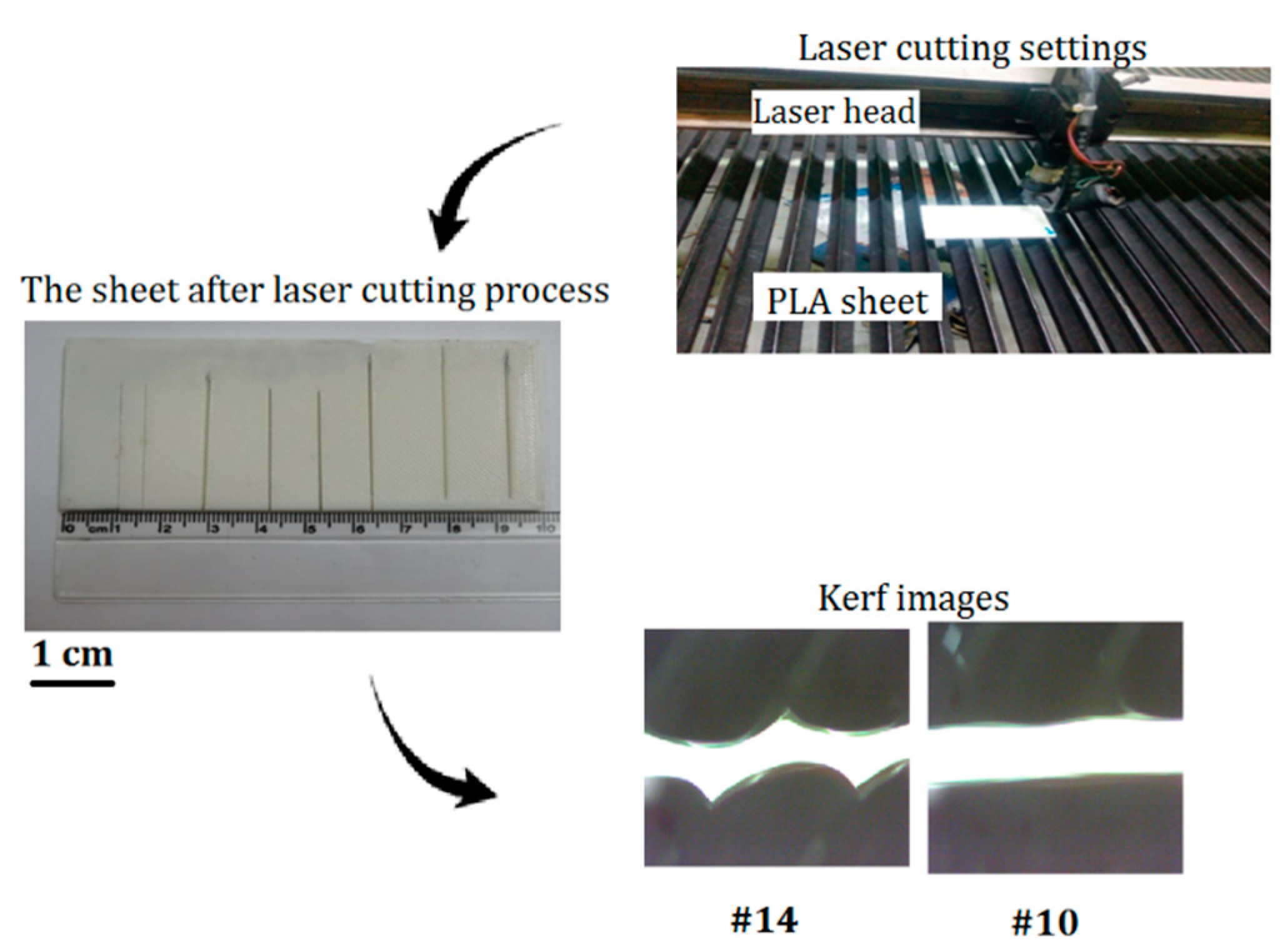

3.1. Polylactic Acid Sheet Fabricated by 3D Printing

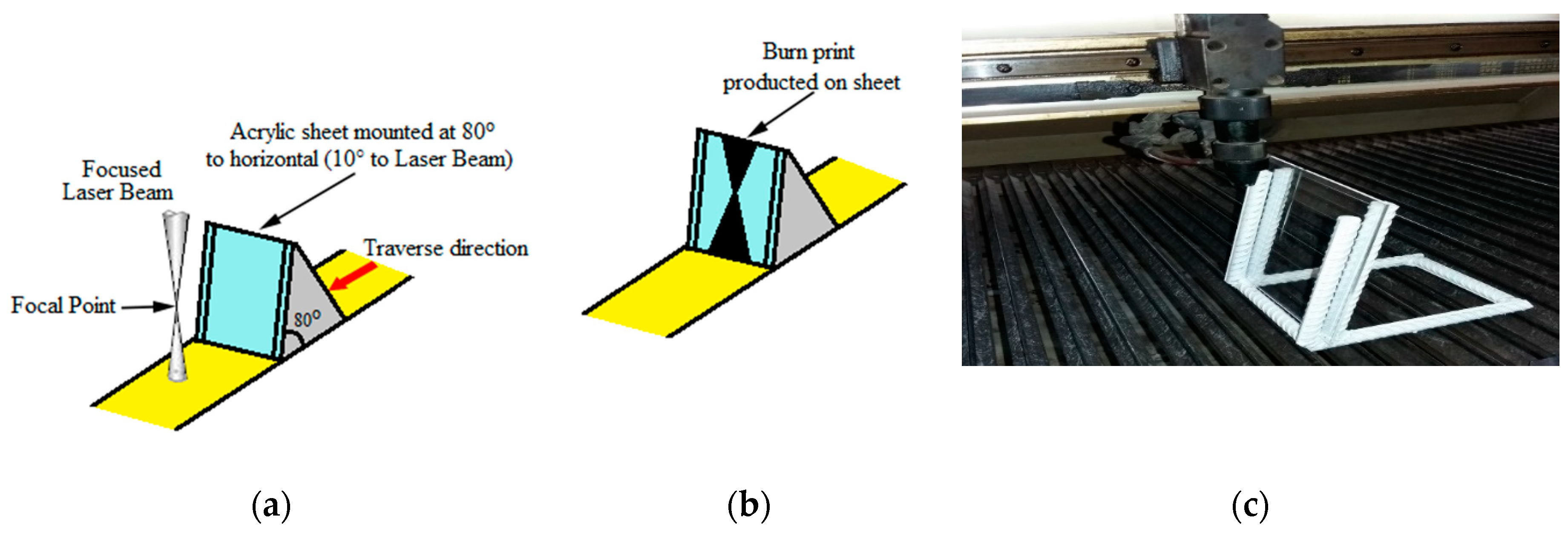

3.2. Laser Cutting Process

4. Results and Discussion

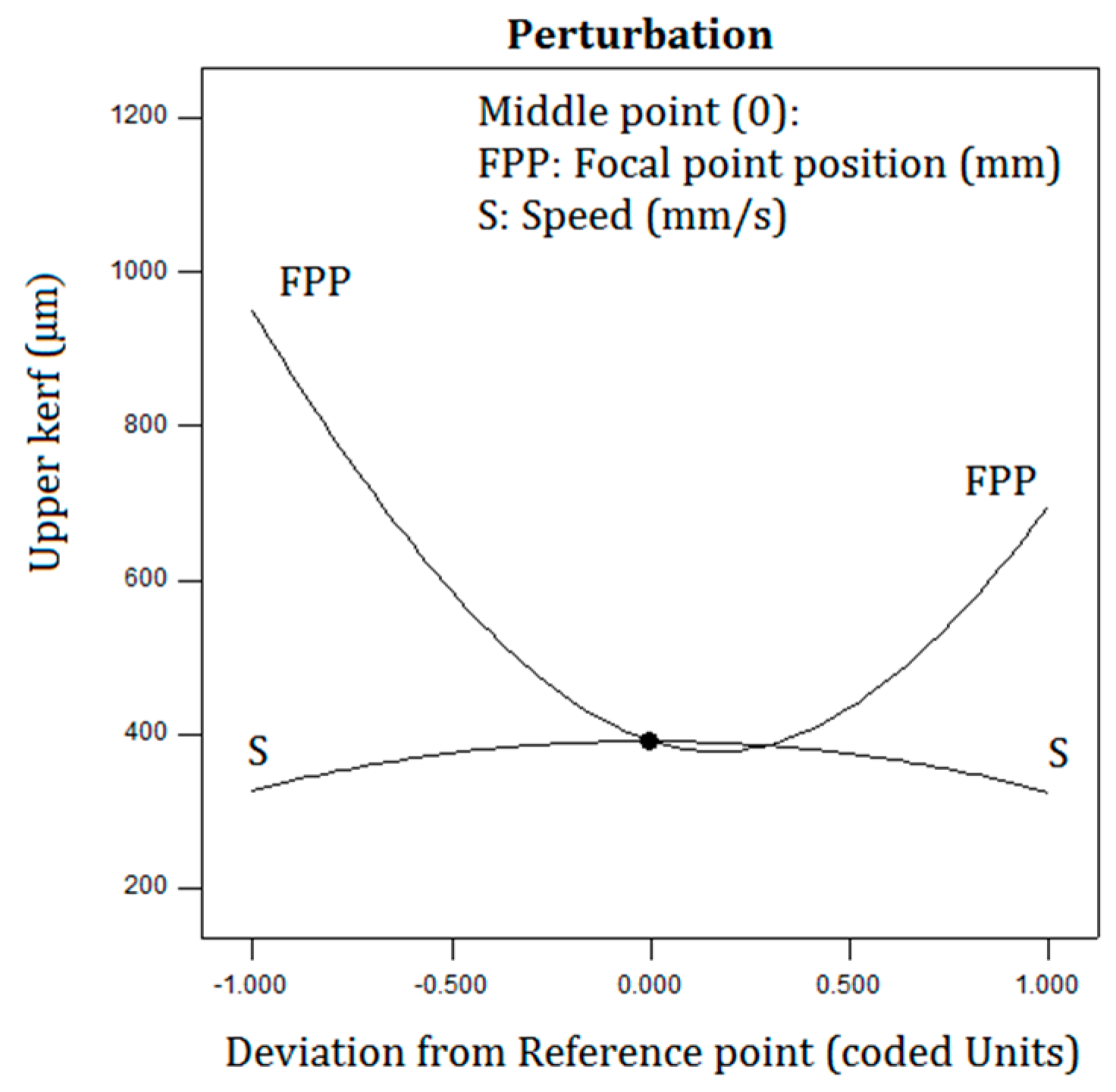

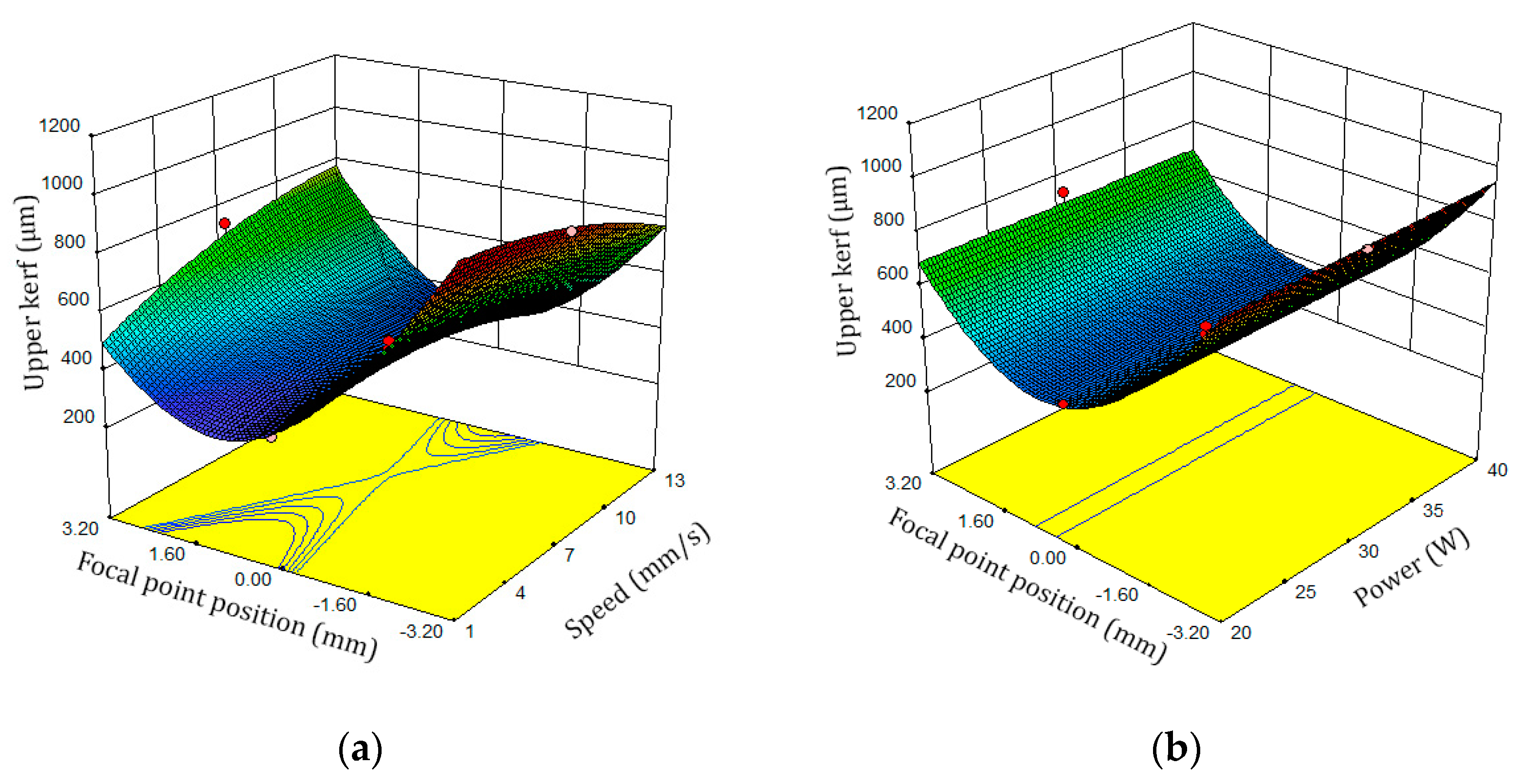

4.1. Top Kerf Width

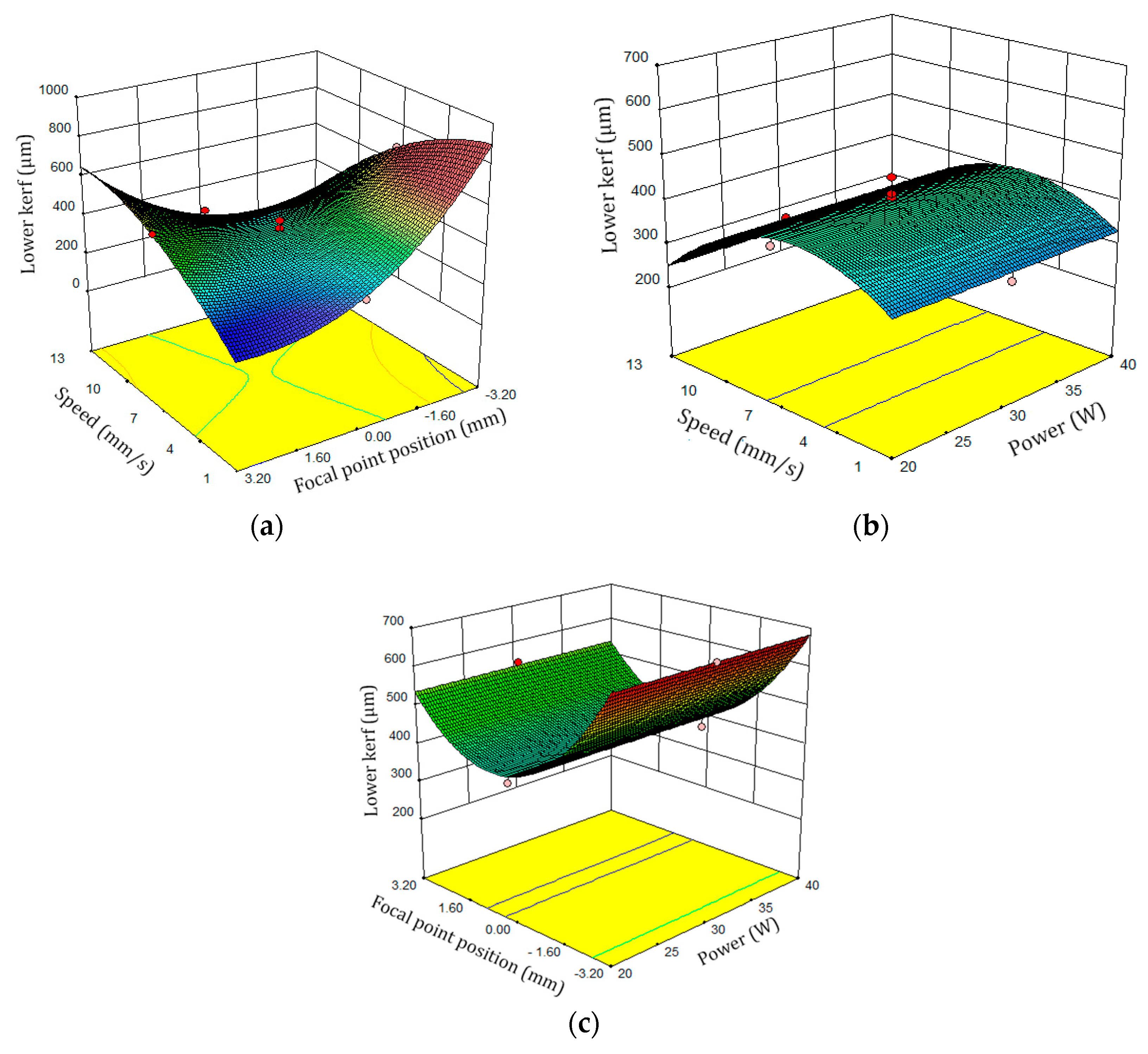

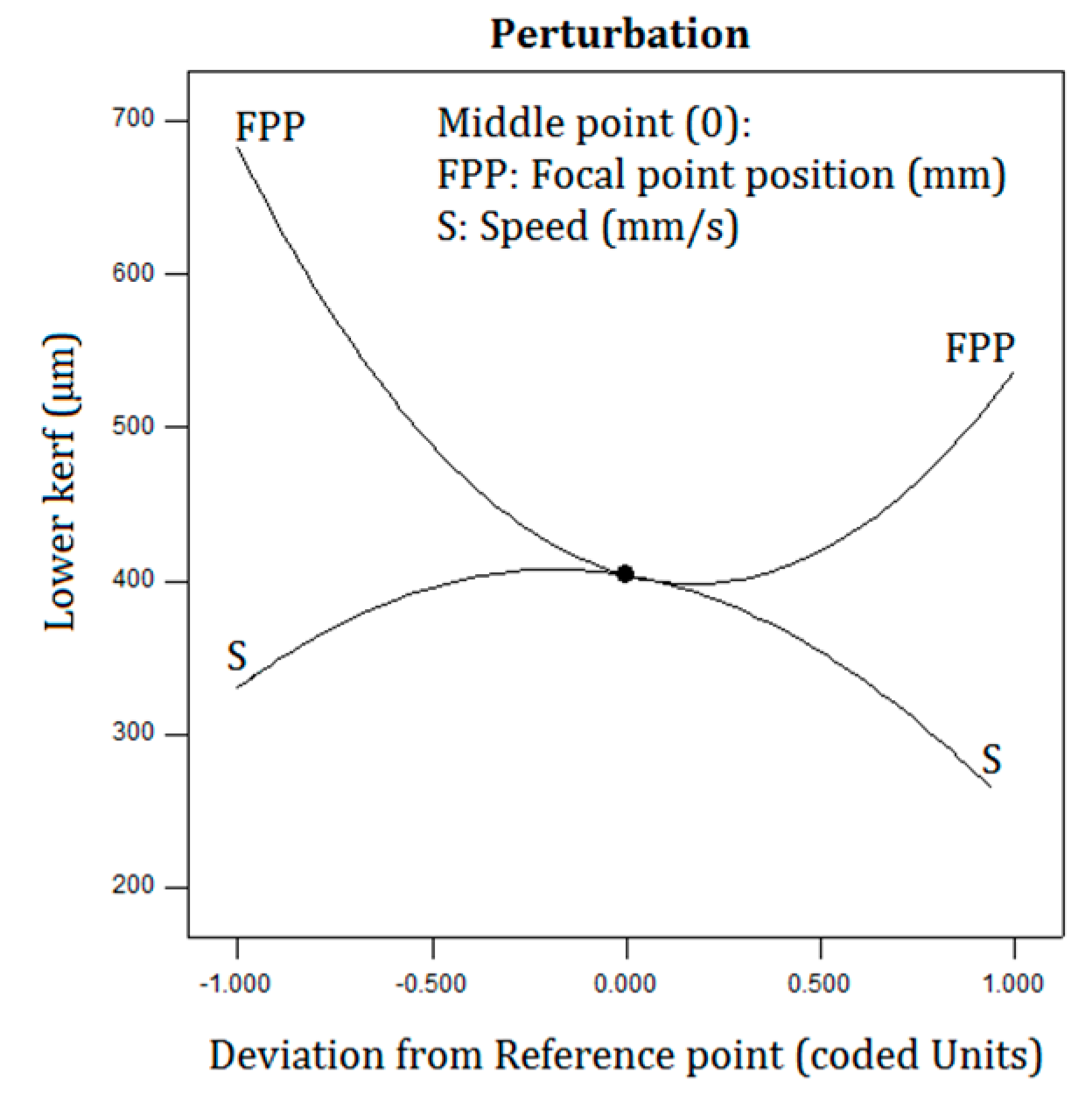

4.2. Bottom Kerf Width

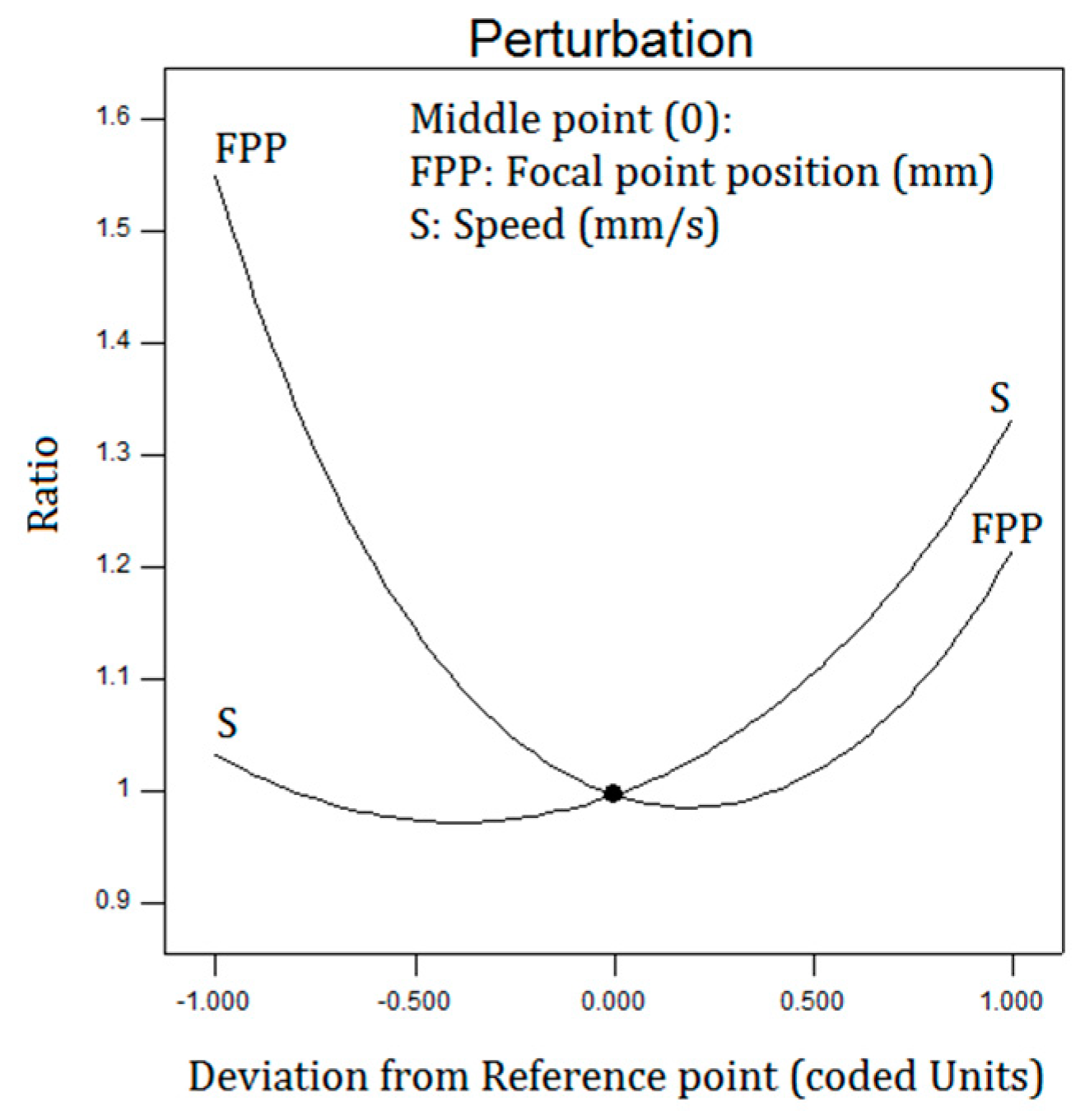

4.3. Ratio of the Top Kerf to Bottom Kerf

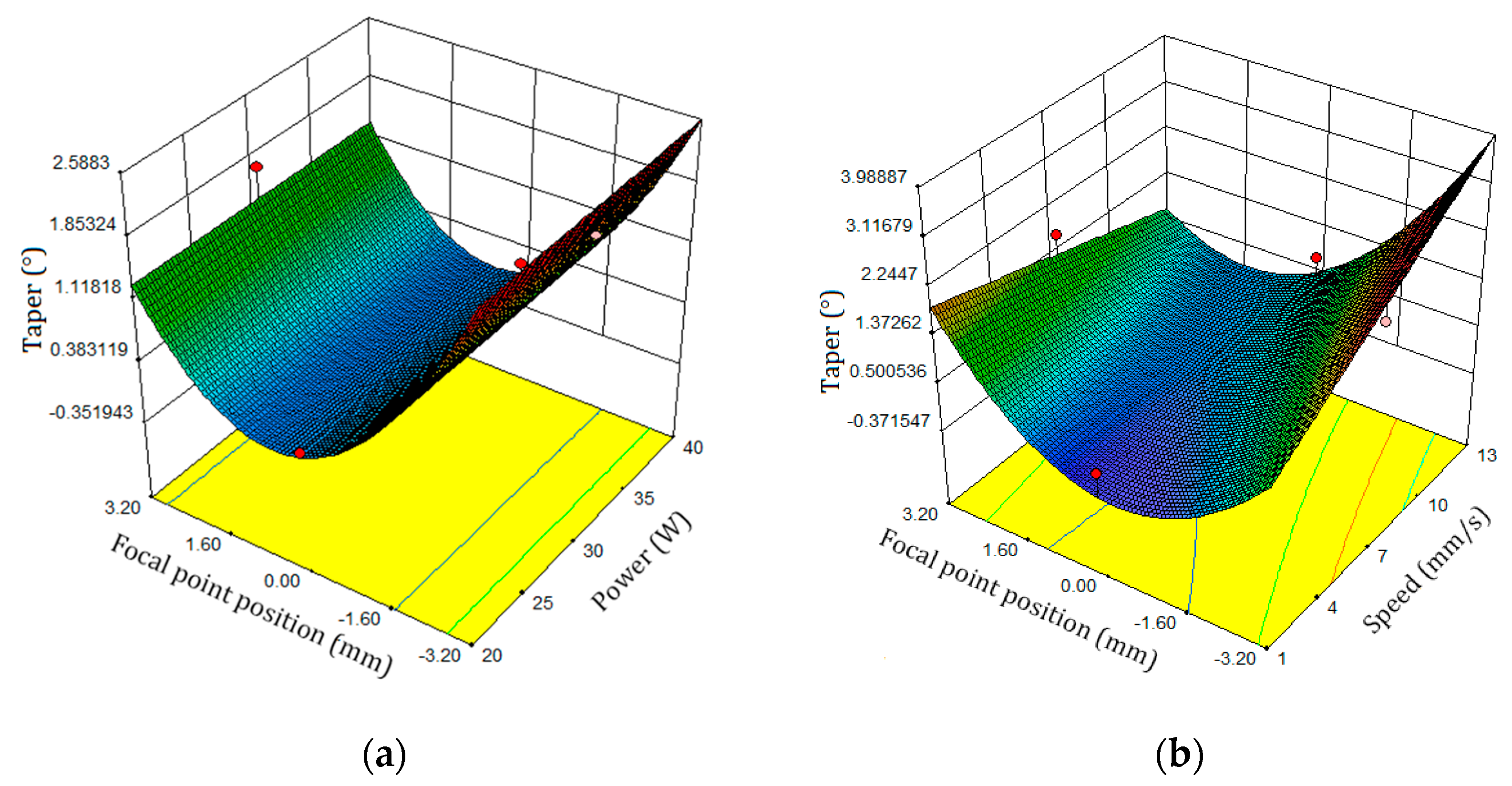

4.4. Taper

5. Optimization

6. Conclusions

- (1)

- Dimensional accuracy of the FDM 3D-printed PLA parts can be improved by laser cutting as a post processing step. The laser can cut the samples easily, whereas the kerfs dimension quality has acceptable features.

- (2)

- Decreasing the FPP range from zero to −3 mm causes a decline in the top and bottom kerf width but decreasing more than −3 mm has an inverse effect.

- (3)

- Kerf taper is increased by changing the FPP. It should be mentioned that the laser cutting speed and FPP in the liner terms based on the ANOVA table of kerf taper has effective influence on kerf Taper amount.

- (4)

- The best optimum sample is achieved with 1.19 mm/s cutting speed, 36.49 W power and 0.53 mm. Focal plane position input parameters have good physical features after the laser cutting process when 276.9 μm top and 261.5 μm bottom kerf width is cut by laser.

- (5)

- The overall conclusion is that by locating the laser spot point in the profundity of the sheet, the laser cutting process results in the best quality.

Author Contributions

Funding

Conflicts of Interest

References

- Majumdar, J.D.; Manna, I. Laser material processing. Int. Mater. Rev. 2011, 56, 341–388. [Google Scholar] [CrossRef]

- Brasil, B.; Moura, L.; Neto, A. Non-Traditional machining: A review on methods employed in advanced materials treatment. J. Mechatron. Eng. 2019, 2, 8–34. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Karami Moghadam, M.; Shamsborhan, M. How the laser beam energy distribution effect on laser surface transformation hardening process, Diode and Nd: YAG lasers. Optik 2019, 204, 163991. [Google Scholar] [CrossRef]

- Sikora, A.; Coustillier, G.; Sarnet, T.; Sentis, M. Laser engraving optimization for achieving smooth sidewalls. Appl. Surf. Sci. 2019, 492, 382–391. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Moghadam, M.K.; Kazazi, M. Improved laser surface hardening of AISI 4130 low alloy steel with electrophoretically deposited carbon coating. Optik 2019, 178, 614–622. [Google Scholar] [CrossRef]

- Moradi, M.; Ghorbani, D.; Moghadam, M.K.; Kazazi, M.; Rouzbahani, F.; Karazi, S. Nd: YAG laser hardening of AISI 410 stainless steel: Microstructural evaluation, mechanical properties, and corrosion behavior. J. Alloy. Compd. 2019, 795, 213–222. [Google Scholar] [CrossRef]

- Marimuthu, S.; Antar, M.; Dunleavey, J. Characteristics of micro-hole formation during fibre laser drilling of aerospace superalloy. Precis. Eng. 2019, 55, 339–348. [Google Scholar] [CrossRef]

- Safari, M.; Joudaki, J. Prediction of bending angle for laser forming of tailor machined blanks by neural network. Iran. J. Mater. Form. 2018, 5, 47–57. [Google Scholar]

- Meiabadi, M.; Kazerooni, A.; Moradi, M.; Torkamany, M. Laser assisted joining of St12 to polycarbonate: Experimental study and numerical simulation. Optik Int. J. Light Electron Opt. 2020, 164151. [Google Scholar] [CrossRef]

- Shrestha, R.; Shamsaei, N.; Seifi, M.; Phand, N. An investigation into specimen property to part performance relationships for laser beam powder bed fusion additive manufacturing. Addit. Manuf. 2019, 29, 100807. [Google Scholar] [CrossRef]

- El Aoud, B.; Boujelbene, M.; Bayraktar, E.; Ben Salem, S. Optimization of kerf quality during CO2 laser cutting of titanium alloy sheet Ti-6Al-4V and pure titanium Ti mechanics of composite. Hybrid Multifunct. Mater. 2019, 5, 213–219. [Google Scholar]

- Tamrin, K.F.; Nukman, Y.; Choudhury, I.A.; Shirley, S. Multiple-Objective optimization in precision laser cutting of different thermoplastics. Opt. Lasers Eng. 2015, 67, 57–65. [Google Scholar] [CrossRef]

- Marimuthu, S.; Dunleavey, J.; Liu, Y.; Antar, M.; Smith, B. Laser cutting of aluminium-alumina metal matrix composite. Opt. Laser Technol. 2019, 117, 251–259. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Rossini, N.S.; Dassisti, M.; Alrashed, K.; Aldaham, T.A.; Benyounis, K.Y.; Olabi, A.G. Evalaution and optimization of laser cutting parameters for plywood materials. Opt. Lasers Eng. 2013, 51, 1029–1043. [Google Scholar] [CrossRef] [Green Version]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef] [Green Version]

- Culmone, C.; Smit, G.; Breedveld, P. Additive manufacturing of medical instruments: A state-of-the-art review. Addit. Manuf. 2019, 27, 461–473. [Google Scholar] [CrossRef]

- Katkar, R.A.; Taft, R.M.; Grant, G.T. 3D Volume rendering and 3D printing (additive manufacturing). Dent. Clin. N. Am. 2018, 62, 393–402. [Google Scholar] [CrossRef]

- Gloriaa, F.; Miguel, L.; Armenio, C.; Massimo, M.; Jorge, F.J.; Coelho, A.; Fonseca, C.; Domingos, M. The influence of poly (ester amide) on the structural and functional features of 3D additive manufactured poly (ε-caprolactone) scaffolds. Mater. Sci. Eng. 2019, 98, 994–1004. [Google Scholar] [CrossRef] [Green Version]

- Mahadik, A.; Masel, D. Implementation of additive manufacturing cost estimation tool (AMCET) using break-down approach. Procedia Manuf. 2018, 17, 70–77. [Google Scholar] [CrossRef]

- Ding, W.; Chen, G.; Qin, M.; He, Y.; Qu, X. Low-cost Ti powders for additive manufacturing treated by fluidized bed. Powder Technol. 2019, 350, 117–122. [Google Scholar] [CrossRef]

- Correa-Pacheco, Z.N.; Black-Solís, J.D.; Ortega-Gudiño, P.; Sabino-Gutiérrez, M.A.; Benítez-Jiménez, J.J.; Barajas-Cervantes, A.; Bautista-Baños, S.; Hurtado-Colmenares, L.B. Preparation and characterization of bio-based PLA/PBAT and cinnamon essential oil polymer fibers and life-cycle assessment from hydrolytic degradation. Polymers 2020, 12, 38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Song, K.; Chen, Y.; Wang, Y.; Shi, F.; Nie, Y.; Liu, T. Design and biophysical characterization of poly (l-lactic) acid microcarriers with and without modification of Chitosan and Nanohydroxyapatite. Polymers 2018, 10, 1061. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Denis, P.; Wrzecionek, M.; Gadomska-Gajadhur, A.; Sajkiewicz, P. Poly (glycerol sebacate)-poly (l-lactide) nonwovens: Towards attractive electrospun material for tissue engineering. Polymers 2019, 11, 2113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perić, M.; Putz, R.; Paulik, C. Influence of nanofibrillated cellulose on the mechanical and thermal properties of poly (lactic acid). Eur. Polym. J. 2019, 114, 426–433. [Google Scholar] [CrossRef]

- Djukić-Vuković, A.; Mladenović, D.; Ivanović, J.; Pejin, J.; Mojović, L. Towards sustainability of lactic acid and poly-lactic acid polymers production. Renew. Sustain. Energy Rev. 2019, 108, 238–252. [Google Scholar] [CrossRef]

- Sayadi, T.R.; Neitzert, G.; Clifton, C. Influence of poly-lactic acid on the properties of perlite concrete. Constr. Build. Mater. 2018, 189, 660–675. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef]

- Onder, C.; Nazeer, M.A.; Yilgör, E.; Yilgör, I. Spontaneous formation of microporous poly (lactic acid) coatings. Prog. Org. Coat. 2018, 125, 249–256. [Google Scholar] [CrossRef]

- Moradi, M.; Karami Moghadam, M.; Shamsborhan, M.; Bodaghi, M. The synergic effects of FDM 3D printing parameters on mechanical behaviors of bronze poly lactic acid composites. J. Compos. Sci. 2020, 4, 17. [Google Scholar] [CrossRef] [Green Version]

- Bodaghi, M.; Liao, W.H. 4D printed tunable mechanical metamaterials with shape memory operations. Smart Mater. Struct. 2019, 28, 045019. [Google Scholar] [CrossRef] [Green Version]

- Bodaghi, M.; Noroozi, R.; Zolfagharian, A.; Fotouhi, M.; Norouzi, S. 4D printing self-morphing structures. Materials 2019, 12, 1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiajun, J.; Peng, X.; Huang, K.; Li, L.; Liu, X.; Chitrakar, C.; Chang, L.; Gu, Z.; Kuang, T. High-Performance porous PLLA-based scaffolds for bone tissue engineering: Preparation, characterization, and In Vitro and in vivo evaluation. Polymer 2019, 180, 121707. [Google Scholar]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Erratum: Effect of porosity and crystallinity on 3D printed PLA properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choudhury, I.A.; Chuan, P.C. Experimental evaluation of laser cut quality of glass fiber reinforced plastic composite. Opt. Lasers Eng. 2013, 51, 1125–1132. [Google Scholar] [CrossRef]

- Caiazzo, F.; Curcio, F.; Daurelio, G.; Minutolo, F.M.C. LASER cutting of different polymeric plastics (PE, PP and PC) by a CO2 LASER beam. J. Mater. Process. Technol. 2005, 159, 279–285. [Google Scholar] [CrossRef]

- Zho, B.H.; Mahdavian, S.M. Experimental and theoretical analyses of cutting nonmetallic materials by low power CO2—Laser. J. Mater. Process. Technol. 2004, 146, 188–192. [Google Scholar] [CrossRef]

- Davim, J.P.; Oliveira, C.; Barricas, N.; Conceição, M. Evaluation of cutting quality of PMMA using CO2 lasers. Int J. Adv. Manuf. Technol. 2008, 35, 875–879. [Google Scholar] [CrossRef]

- Karimzad Ghavidel, T.; Azdast, M.R.; Shabgard, A.; Navidfar, S.; Mamaghani, S. Effect of carbon nanotubes on laser cutting of multi-walled carbon nanotubes/poly methyl methacrylate Nano composites. Opt. Laser Technol. 2015, 67, 119–124. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Olabi, A.G.; Benyounis, K.Y. Effect of process parameters and optimization of CO2 laser cutting of ultrahigh-performance polyethylene. Mater. Des. 2010, 31, 4029–4038. [Google Scholar] [CrossRef] [Green Version]

- Assarzadeh, S.; Ghoreishi, M. Statistical investigation into the effects of electro-discharge machining parameters on WC/6%Co composite-part 1: Modeling through response surface methodology (RSM). Adv. Mater. Manuf. Charact. 2013, 3. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, J.; Lee, Y.; Hsieh, W.; Yang, A. Determination of melt pool dimensions using DOE-FEM and RSM with process window during SLM of Ti6Al4V powder. Opt. Laser Technol. 2018, 103, 59–76. [Google Scholar] [CrossRef]

- Sagar, M.; Baligidad, U.; Chandrasekhar, K.; Elangovan, S. RSM optimization of parameters influencing mechanical properties in selective inhibition sintering. Mater. Today Proc. 2018, 5, 4903–4910. [Google Scholar]

- Moradi, M.; Karami Moghadam, M. High power diode laser surface hardening of AISI 4130: Statistical modelling and optimization. Opt. Laser Technol. 2019, 111, 554–570. [Google Scholar] [CrossRef]

- Nagaraju, U.; Harinath Gowd, G.; Vishnu Vardan, T. An integrated approach for optimization of pulsed ND: YAG laser beam welding process. Mater. Today Proc. 2018, 5, 7991–8000. [Google Scholar] [CrossRef]

- Singh, A.; Garg, H.; Lall, A.K. Optical polishing process: Analysis and optimization using response surface methodology (RSM) for large diameter fused silica flat substrates. J. Manuf. Process. 2017, 30, 439–451. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Azdast, T.; Benyounis, K.Y. Enhancement of low power CO2 laser cutting process for injection molded polycarbonate. Opt. Laser Technol. 2017, 96, 208–218. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Bagci, E.; Demirer, H. Dimensional analyses and surface quality of the laser cutting process for engineering plastics. Int. J. Adv. Manuf. Technol. 2008, 41, 259–267. [Google Scholar] [CrossRef]

- Goeke, A.; Emmelmann, C. Influence of laser cutting parameters on CFRP part quality. Phys. Procedia 2010, 5, 253–258. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Abdollahi, H. Statistical modelling and optimization of the laser percussion microdrilling of thin sheet stainless steel. Lasers Eng. 2018, 40, 375–393. [Google Scholar]

- Haddadi, E.; Moradi, M.; Ghavidel, A.K.; Ghavidel, A.K.; Meiabadi, S. Experimental and parametric evaluation of cut quality characteristics in CO2 laser cutting of polystyrene. Optik 2019, 184, 103–114. [Google Scholar] [CrossRef]

- Casalino, G.; Moradi, M.; Moghadam, M.K.; Khorram, A.; Perulli, P. Experimental and Numerical Study of AISI 4130 Steel Surface Hardening by Pulsed Nd:YAG Laser. Materials 2019, 12, 3136. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moradi, M.; Arabi, H.; Moghadam, M.K.; Benyounis, K.Y. Enhancement of surface hardness and metallurgical properties of AISI 410 by laser hardening process; diode and Nd: YAG lasers. Optik 2019, 188, 277–286. [Google Scholar] [CrossRef]

| Variable | Symbol | Unit | −2 | −1 | 0 | +1 | +2 |

|---|---|---|---|---|---|---|---|

| Scanning speed | S | mm/s | 1 | 4 | 7 | 10 | 13 |

| Laser power | P | W | 20 | 25 | 30 | 35 | 40 |

| Focal plane position | FPP | mm | −3.2 | −1.6 | 0 | 1.6 | 3.2 |

| Sample No. | Input Variables | Output Responses | |||||

|---|---|---|---|---|---|---|---|

| P (W) | S (mm/s) | FPP (mm) | Top Kerf Width (μm) | Bottom Kerf Width (μm) | Ratio | Taper (°) | |

| 1 | 35 | 4 | −1.6 | 631.30 | 576.950 | 1.0942 | 0.4865 |

| 2 | 30 | 13 | 0 | 358.62 | 273.490 | 1.311 | 0.7620 |

| 3 | 30 | 7 | 0 | 387.93 | 406.890 | 0.953 | −0.1697 |

| 4 | 30 | 7 | 0 | 400 | 415.517 | 0.962 | −0.1342 |

| 5 | 30 | 7 | −3.2 | 934.60 | 681.230 | 1.372 | 2.267 |

| 6 | 30 | 7 | 3.2 | 732.75 | 543.670 | 1.347 | 1.692 |

| 7 | 25 | 10 | 1.6 | 413.79 | 386.630 | 1.070 | 0.2431 |

| 8 | 25 | 10 | −1.6 | 472.41 | 332.720 | 1.419 | 1.250 |

| 9 | 25 | 4 | 1.6 | 332.75 | 303.500 | 1.096 | 0.2618 |

| 10 | 25 | 4 | −1.6 | 608.62 | 546.670 | 1.113 | 0.5545 |

| 11 | 35 | 10 | −1.6 | 582.75 | 383.390 | 1.519 | 1.784 |

| 12 | 30 | 7 | 0 | 429.31 | 453.870 | 0.945 | −0.2198 |

| 13 | 40 | 7 | 0 | 385.34 | 364.780 | 1.056 | 0.1840 |

| 14 | 35 | 10 | 1.6 | 429.31 | 453.870 | 0.945 | −0.2198 |

| 15 | 30 | 1 | 0 | 320.04 | 310.210 | 1.031 | 0.0880 |

| 16 | 20 | 7 | 0 | 401.72 | 387.500 | 1.036 | 0.1273 |

| 17 | 35 | 4 | 1.6 | 381.03 | 403.440 | 0.944 | −0.2006 |

| Device Parameters | Parameter Range |

|---|---|

| Type of printer | FDM Sizan Model 3 |

| Print size | 20 × 20 × 20 cm |

| Laying accuracy | 30 μm |

| Temperature of plate | 110 °C |

| Nozzle diameter | 0.5 mm |

| Temperature of nozzle | 260 °C |

| Speed of printer | 300 mm/s |

| Feature | Amount |

|---|---|

| Name | Polylactic acid (PLA) |

| Crystallinity | 37% |

| Chemical formula | (C3H4O2)n |

| Tensile modulus | 2.7–16 GPa |

| Density | 1.210–1.430 g·cm−3 |

| Melting point | 150 to 160 °C (302 to 320 °F) |

| Glass transition | 60–65 °C |

| Injection mold temperature | 178 to 240 °C (353 to 464 °F) |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 76,260,000 | 5 | 15,250,000 | 65.71 | <0.0001 |

| S | 539 | 1 | 539 | 0.002322 | 0.9624 |

| FPP | 14,970,000 | 1 | 14,970,000 | 64.50 | <0.0001 |

| S × FPP | 1,946,000 | 1 | 1,946,000 | 8.38 | 0.0146 |

| S2 | 768,000 | 1 | 768,000 | 3.31 | 0.0962 |

| FPP2 | 50,300,000 | 1 | 5,030,000 | 216.70 | <0.0001 |

| Residual | 2,553,000 | 11 | 232,100 | ||

| Lack of Fit | 2,426,000 | 9 | 269,500 | 4.23 | 0.2057 |

| Pure Error | 127,300 | 2 | 63,673.87 | ||

| Total | 78,810,000 | 16 | |||

| R-squared = 96.76% | R-squared (Adj) = 95.29% | ||||

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 12,718.65 | 5 | 2543.73 | 22.69 | <0.0001 |

| S | 564.87 | 1 | 564.87 | 5.04 | 0.0463 |

| FPP | 1411.01 | 1 | 1411.01 | 12.59 | 0.0046 |

| S× FPP | 2768.24 | 1 | 2768.24 | 24.69 | 0.0004 |

| S2 | 1531.34 | 1 | 1531.34 | 13.66 | 0.0035 |

| FPP2 | 4344.45 | 1 | 4344.45 | 38.75 | 0.0001 |

| Residual | 1233.26 | 11 | 112.11 | ||

| Lack of fit | 1138.58 | 9 | 126.51 | 2.67 | 0.3019 not |

| Pure error | 94.68 | 2 | 47.34 | ||

| Total | 13,951.91 | 16 | |||

| R-Squared = 91.16% | R-Squared (Adj) = 87.14% | ||||

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.002530 | 5 | 0.0005060 | 8.52 | 0.0016 |

| S | 0.0005163 | 1 | 0.0005163 | 8.69 | 0.0132 |

| FPP | 0.0004497 | 1 | 0.0004497 | 7.57 | 0.0188 |

| S × FPP | 0.0003422 | 1 | 0.0003422 | 5.76 | 0.0352 |

| S2 | 0.0003033 | 1 | 0.0003033 | 5.11 | 0.0451 |

| FPP2 | 0.001156 | 1 | 0.001156 | 19.47 | 0.001 |

| Residual | 0.0006532 | 11 | 0.00005938 | ||

| Lack of Fit | 0.0006519 | 9 | 0.00007243 | 111.44 | 0.0089 |

| Pure Error | 0.0000013 | 2 | 0.0000006499 | ||

| Total | 0.003183 | 16 | |||

| R-Squared = 79.48% | R-Squared (Adj) = 70.16% | ||||

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8.83 | 4 | 2.21 | 19.18 | <0.0001 |

| S | 0.72 | 1 | 0.72 | 6.22 | 0.0282 |

| FPP | 1.73 | 1 | 1.73 | 15.06 | 0.0022 |

| S × P | 0.54 | 1 | 0.54 | 4.74 | 0.0502 |

| FPP2 | 5.84 | 1 | 5.84 | 50.72 | <0.0001 |

| Residual | 1.38 | 12 | 0.12 | ||

| Lack of fit | 1.38 | 10 | 0.14 | 70.47 | 0.0141 |

| Pure error | 0.003908 | 2 | 0.001954 | ||

| Total | 10.21 | 16 | |||

| R-Squared = 86.48% | R-Squared (Adj) = 81.97% | ||||

| Solution | Input Parameters Optimum | Output Results | |||||

|---|---|---|---|---|---|---|---|

| 1 | S (mm/s) | P (W) | FPP (mm) | Top Kerf (μm) | Bottom Kerf (μm) | Ratio | |

| 1.4 | 30.18 | 0.53 | Actual | 327.07 | 307.69 | 1.052 | |

| Predicted | 287.056 | 289.735 | 0.945 | ||||

| Error% | 13.9 | 6.19 | 11.32 | ||||

| 2 | 7.97 | 24.27 | 0.98 | Actual | 406 | 392 | 1.035 |

| Predicted | 394.29 | 404.895 | 0.97 | ||||

| Error% | 2.96 | −3.18 | 6.7 | ||||

| 3 | 3.04 | 27.64 | 0.45 | Actual | 387.6 | 370 | 1.047 |

| Predicted | 333.659 | 351.065 | 0.95 | ||||

| Error% | 16.1 | 5.9 | 10.21 | ||||

| 4 | 2.42 | 36.57 | 0.47 | Actual | 400 | 364.6 | 1.09 |

| Predicted | 320.037 | 333.159 | 0.952 | ||||

| Error% | 24.8 | 9.4 | 14.4 | ||||

| 5 | 1.19 | 36.49 | 0.53 | Actual | 276.9 | 261.5 | 1.05 |

| Predicted | 287.077 | 289.752 | 0.945 | ||||

| Error% | −3.5 | −9.7 | 11.11 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moradi, M.; Karami Moghadam, M.; Shamsborhan, M.; Bodaghi, M.; Falavandi, H. Post-Processing of FDM 3D-Printed Polylactic Acid Parts by Laser Beam Cutting. Polymers 2020, 12, 550. https://doi.org/10.3390/polym12030550

Moradi M, Karami Moghadam M, Shamsborhan M, Bodaghi M, Falavandi H. Post-Processing of FDM 3D-Printed Polylactic Acid Parts by Laser Beam Cutting. Polymers. 2020; 12(3):550. https://doi.org/10.3390/polym12030550

Chicago/Turabian StyleMoradi, Mahmoud, Mojtaba Karami Moghadam, Mahmoud Shamsborhan, Mahdi Bodaghi, and Hamid Falavandi. 2020. "Post-Processing of FDM 3D-Printed Polylactic Acid Parts by Laser Beam Cutting" Polymers 12, no. 3: 550. https://doi.org/10.3390/polym12030550

APA StyleMoradi, M., Karami Moghadam, M., Shamsborhan, M., Bodaghi, M., & Falavandi, H. (2020). Post-Processing of FDM 3D-Printed Polylactic Acid Parts by Laser Beam Cutting. Polymers, 12(3), 550. https://doi.org/10.3390/polym12030550