Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering

Abstract

:1. Introduction

- −

- The ability to customize products according to individual needs and requirements.

- −

- The ability to design and fabricate elements complex in shape, which are impossible or very difficult to produce using conventional processes.

- −

- The ability to combine many components into one single product to save assembly costs.

- −

- The characteristics of the input material (powders in the case of SLS).

- −

- The geometries of 3D printed objects (including the dimensional tolerances and surface topology).

- −

- The mechanical and rheological properties of 3D printed materials.

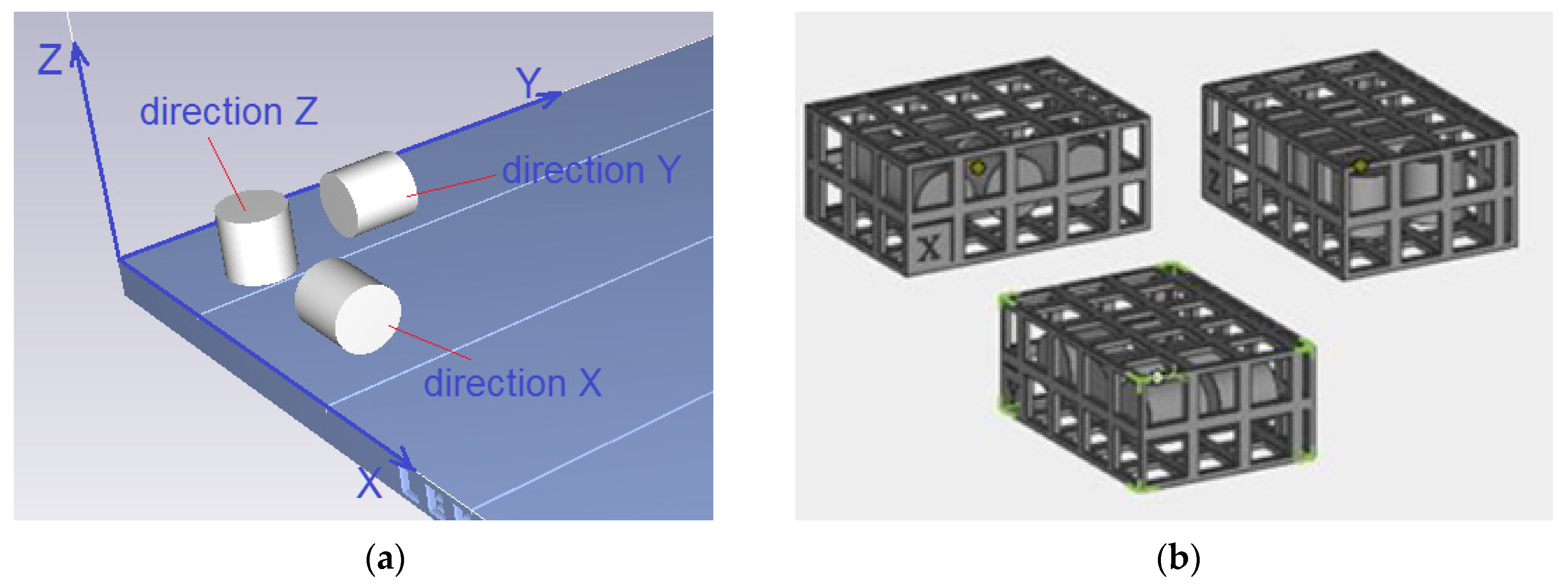

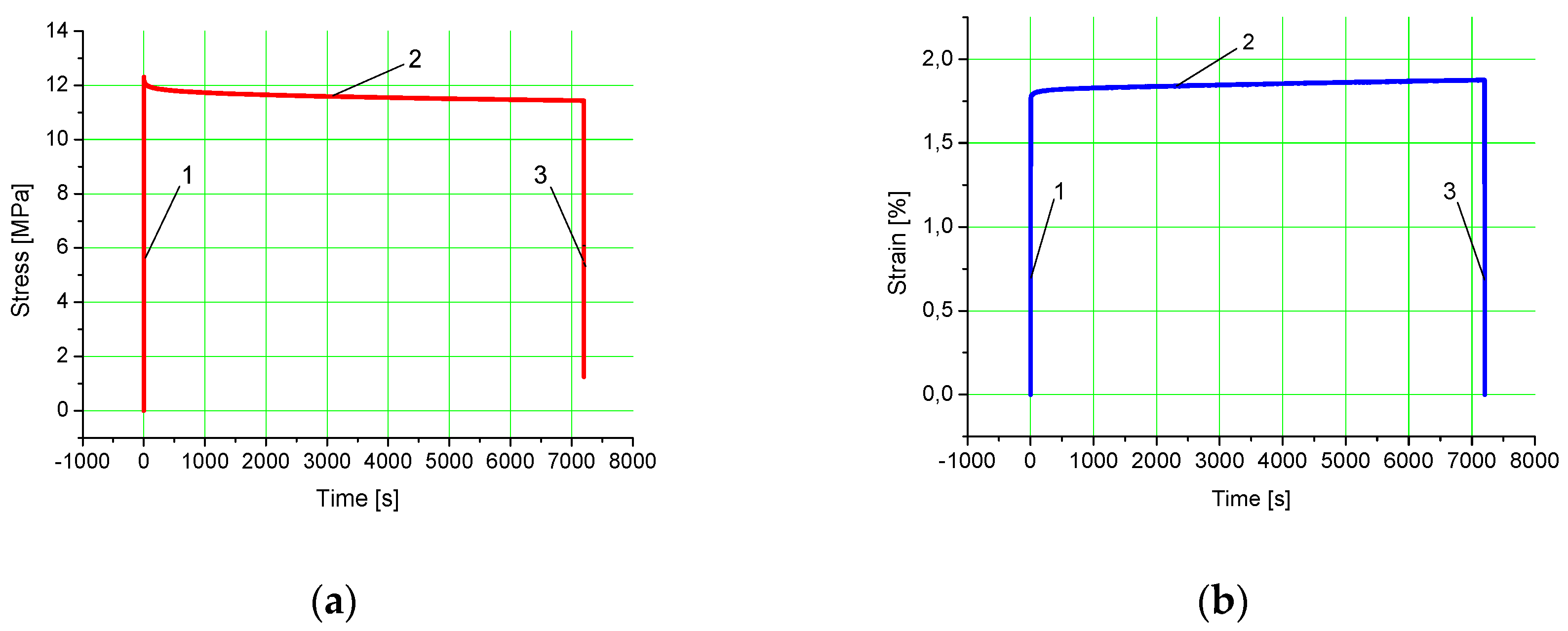

2. Methods and Materials

- −

- to achieve a displacement of 0.5 mm in stress relaxation tests;

- −

- to achieve a force of 300 N in creep tests.

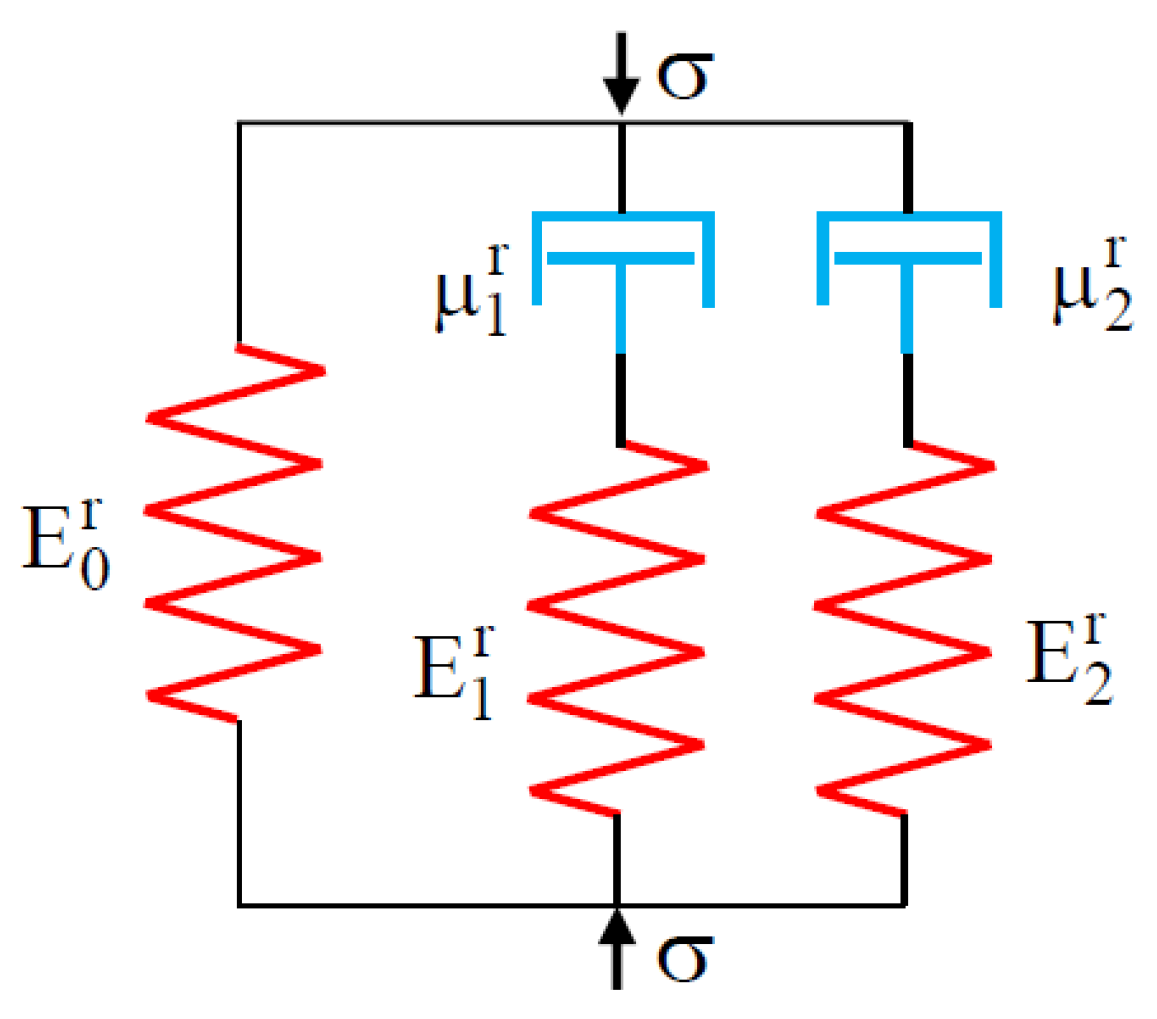

3. Mathematical Model

- stress relaxation

- and creep

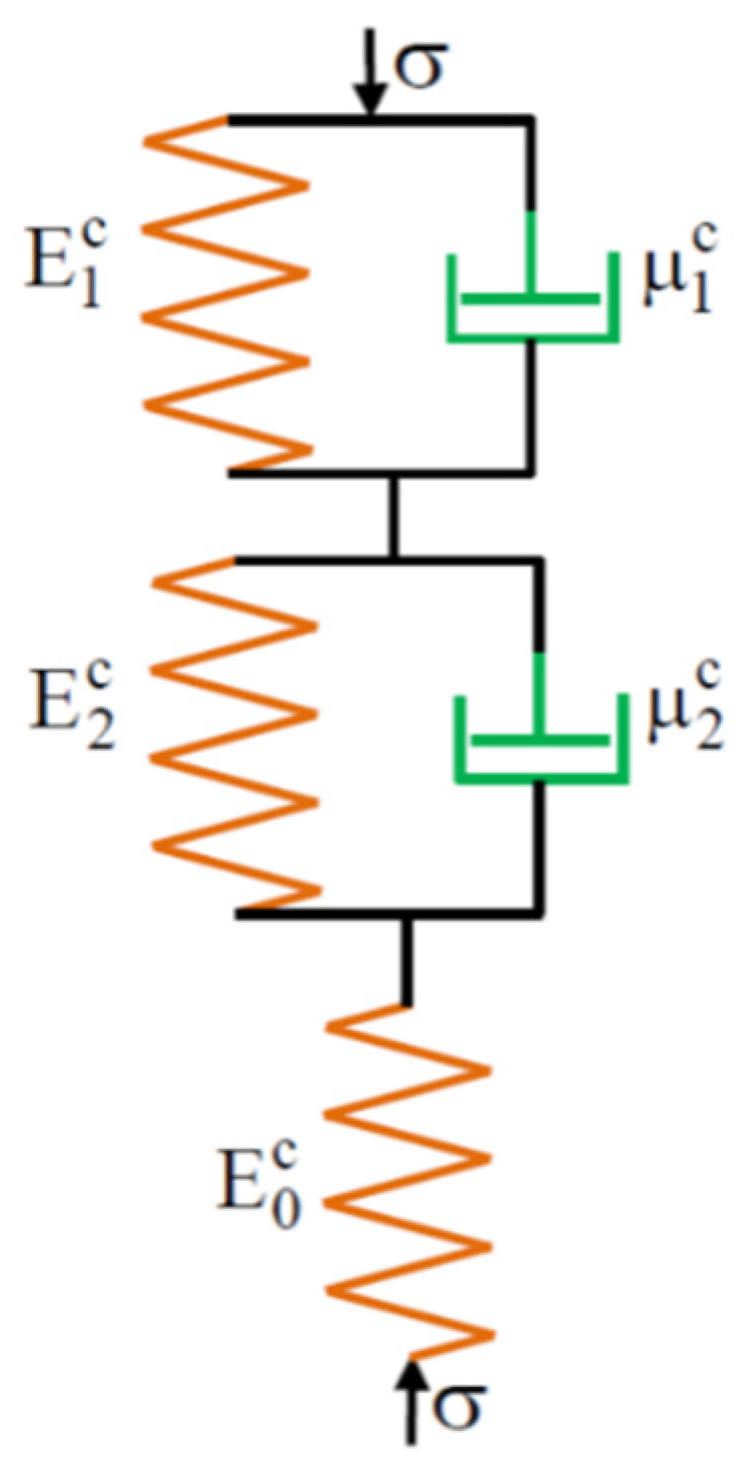

3.1. Maxwell–Wiechert Stress Relaxation Model

3.2. Kelvin–Voight Creep Model

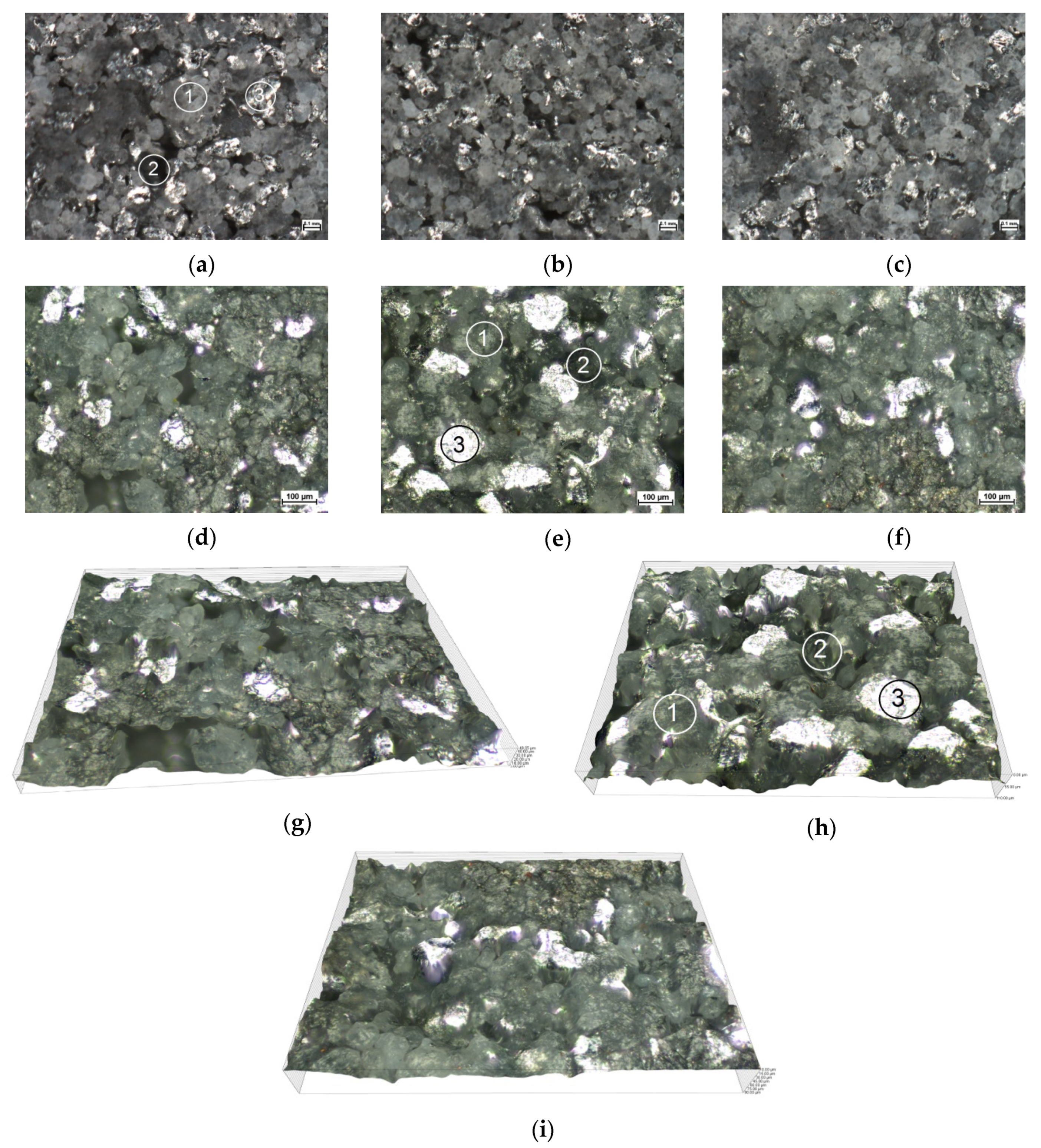

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| , , , , , , and | coefficients of the general equation, |

| , , , , and | coefficients of the stress relaxation equation, |

| , , , , and | coefficients of the creep equation, |

| D | specimen diameter, |

| , and | elastic moduli for the five-parameter Kelvin–Voight model, |

| equivalent elastic modulus for the Kelvin–Voight model, | |

| elastic modulus of the i-th model for creep, | |

| , and | elastic moduli for the five-parameter Maxwell–Wiechert model, |

| equivalent elastic modulus for the Maxwell–Wiechert model, | |

| elastic modulus of the i-th model for relaxation stress, | |

| H | specimen height, |

| Heaviside function, | |

| Dirac delta function, | |

| creep strain, | |

| and | strain for the five-parameter Kelvin–Voight model, |

| predetermined strain for stress relaxation, | |

| viscosity of the i-th model for creep, | |

| and | dynamic viscosities in the creep equation, |

| and | dynamic viscosities in the stress relaxation equation, |

| delay of elasticity of the i-th Kelvin model, | |

| and | retardation times, |

| and | relaxation times, |

| stress relaxation, | |

| constant stress for creep. |

References

- Maniruzzaman, M. Pharmaceutical applications of hot-melt extrusion: Continuous manufacturing, twin-screw granulations, and 3D printing. Pharmaceutics 2019, 11, 218. [Google Scholar] [CrossRef] [Green Version]

- Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. Advanced pharmaceutical applications of hot-melt extrusion coupled with fused deposition modelling (FDM) 3D printing for personalised drug delivery. Pharmaceutics 2018, 10, 203. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.; Tan, D.K.; Nokhodchi, A.; Maniruzzaman, M. Drop-on-powder 3D printing of tablets with an anti-cancer drug, 5-fluorouracil. Pharmaceutics 2019, 11, 150. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohd Javaid, A.H. Additive manufacturing applications in medical cases: A literature based review. Alexandria J. Med. 2018, 54, 411–422. [Google Scholar] [CrossRef] [Green Version]

- Sunil Sharma, S.A.G. Three-dimensional printing and its future in medical world. J. Med. Res. Innov. 2019, 3, e000141. [Google Scholar]

- Kozior, T.; Trabelsi, M.; Mamun, A.; Sabantina, L.; Ehrmann, A. Stabilization of electrospun nanofiber mats used for filters by 3D printing. Polymers (Basel) 2019, 11, 1618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Martin Wortmann, S.L.; Ehrmann, A. Electrospinning on 3D printed polymers for mechanically stabilized filter composites. Polymers (Basel) 2019, 11, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dhakshyani, R.; Nukman, Y.; Azuan, A.O.N. FDM models and FEA in dysplastic hip. Rapid Prototyp. J. 2012, 18, 215–221. [Google Scholar] [CrossRef]

- Omar Balderrama-Armendariz, C.; MacDonald, E.; Espalin, D.; Cortes-Saenz, D.; Wicker, R.; Maldonado-Macias, A. Torsion analysis of the anisotropic behavior of FDM technology. Int. J. Adv. Manuf. Technol. 2018, 96, 307–317. [Google Scholar] [CrossRef]

- Calise, G.J.; Seigel, A. Anisotropy and failure in octahedral lattice structure parts fabricated using the fdm technology. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2018; AMER SOC Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar]

- Bochnia, J.; Blasiak, S. Anisotrophy of mechanical properties of a material which is shaped incrementally using polyjet technology. In Proceedings of the 22nd International Conference, the Engineering Mechanics 2016, Svratka, Czech Republic, 9–12 May 2016; Zolotarev, I., Radolf, V., Eds.; ACAD SCI Czech Republic, Inst Thermomechanics: Prague, Czech Republic, 2016; pp. 74–77. [Google Scholar]

- Gay, P.; Blanco, D.; Pelayo, F.; Noriega, A.; Fernandez, P. Analysis of Factors Influencing the Mechanical Properties of Flat PolyJet Manufactured Parts. Procedia Eng. 2015, 132, 70–77. [Google Scholar] [CrossRef] [Green Version]

- Yamaguchi, K.; Thomas, A.G.; Busfield, J.J.C. Stress relaxation, creep and set recovery of elastomers. Int. J. Non. Linear. Mech. 2015, 68, 66–70. [Google Scholar] [CrossRef]

- Babaei, B.; Davarian, A.; Pryse, K.M.; Elson, E.L.; Genin, G.M. Efficient and optimized identification of generalized maxwell viscoelastic relaxation spectra. J. Mech. Behav. Biomed. Mater. 2016, 55, 32–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Renaud, F.; Dion, J.-L.; Chevallier, G.; Tawfiq, I.; Lemaire, R. A new identification method of viscoelastic behavior: Application to the generalized Maxwell model. Mech. Syst. Signal. Process. 2011, 25, 991–1010. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Zheng, Y.; Shen, Y.; Chen, X.; Zhang, X.; Lin, H.; Guo, Y.; Wang, T.; Chen, S. Analyzing and modeling rheological behavior of liver fibrosis in rats using shear viscoelastic moduli. J. Zhejiang Univ. B. 2014, 15, 375–381. [Google Scholar] [CrossRef]

- Chen, T. Determining a Prony Series for a Viscoelastic Material From Time Varing Strain Data, National Aeronautics and Space Administration; Langley Research Center: Hampton, VA, USA, 2000; 23681–2199. [Google Scholar]

- Bochnia, J. Evaluation of Relaxation Properties of Digital Materials Obtained by Means of PolyJet Matrix Technology. Bull. Pol. Acad. Sci. 2018, 66, 6. [Google Scholar]

- Bochnia, J.; Blasiak, S. Fractional Relaxation Model of Materials Obtained with Selective Laser Sintering Technology. RAPID Prototyp. J. 2019, 25, 76–86. [Google Scholar] [CrossRef]

- Jozwiak, B.; Orczykowska, M.; Dziubinski, M. Fractional Generalizations of Maxwell and Kelvin-Voigt Models for Biopolymer Characterization. PLoS ONE 2015, 10, e0143090. [Google Scholar] [CrossRef]

- Oman, S.; Nagode, M. Observation of the Relation Between Uniaxial Creep and Stress Relaxation of Filled Rubber. Mater. Des. 2014, 60, 451–457. [Google Scholar] [CrossRef]

- Bihari, B.K.; Rao, N.P.N.; Gupta, M.; Murthy, K.P.S. A Study on Creep Behavior of Composite Solid Propellants Using the Kelvin-Voigt Model. Cent. Eur. J. Energ. Mater. 2017, 14, 742–756. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; ISBN 9781441911193. [Google Scholar]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D Microstructures by Direct 3D Printing of Polymer/Carbon Nanotube Nanocomposites Via Liquid Deposition Modeling. Compos. Part. A Appl. Sci. Manuf. 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. Selective Laser Sintering (SLS) 3D Printing of Medicines. Int. J. Pharm. 2017, 529, 285–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stoia, D.I.; Linul, E.; Marsavina, L. Influence of Manufacturing Parameters on Mechanical Properties of Porous Materials by Selective Laser Sintering. Material (Basel, Switzerland) 2019, 12, 871. [Google Scholar] [CrossRef] [PubMed] [Green Version]

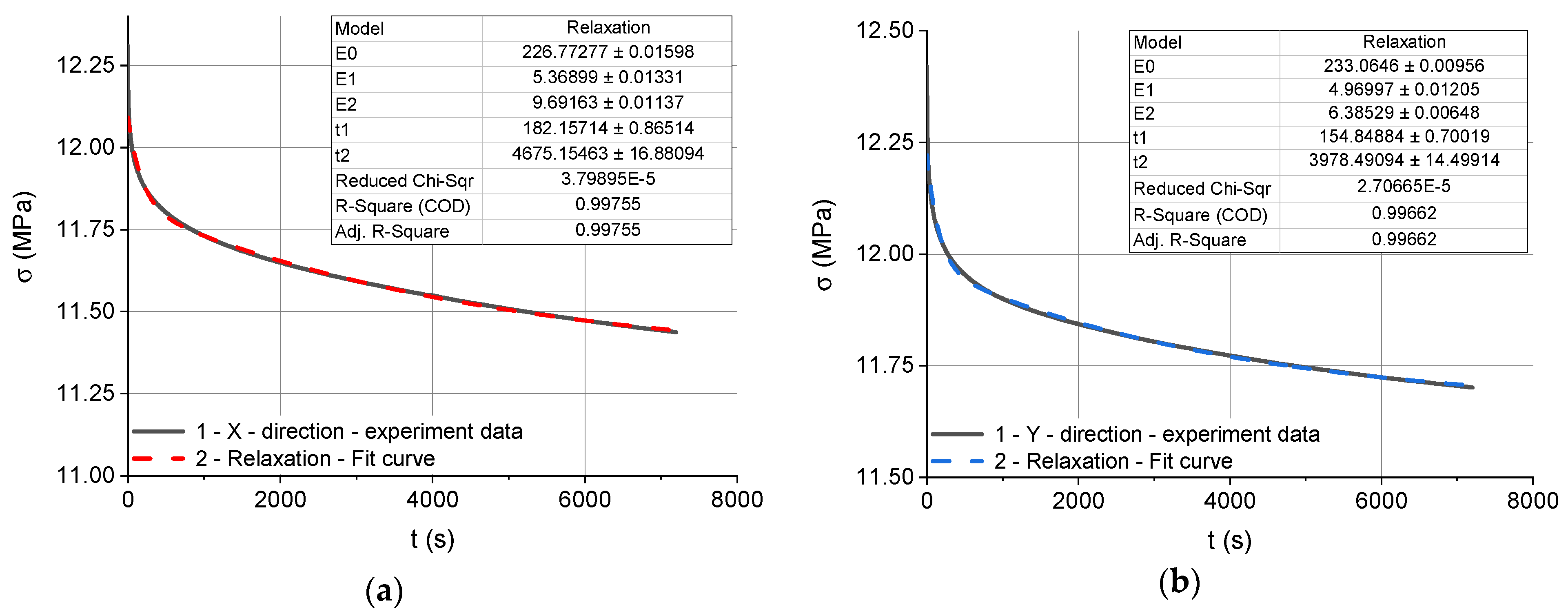

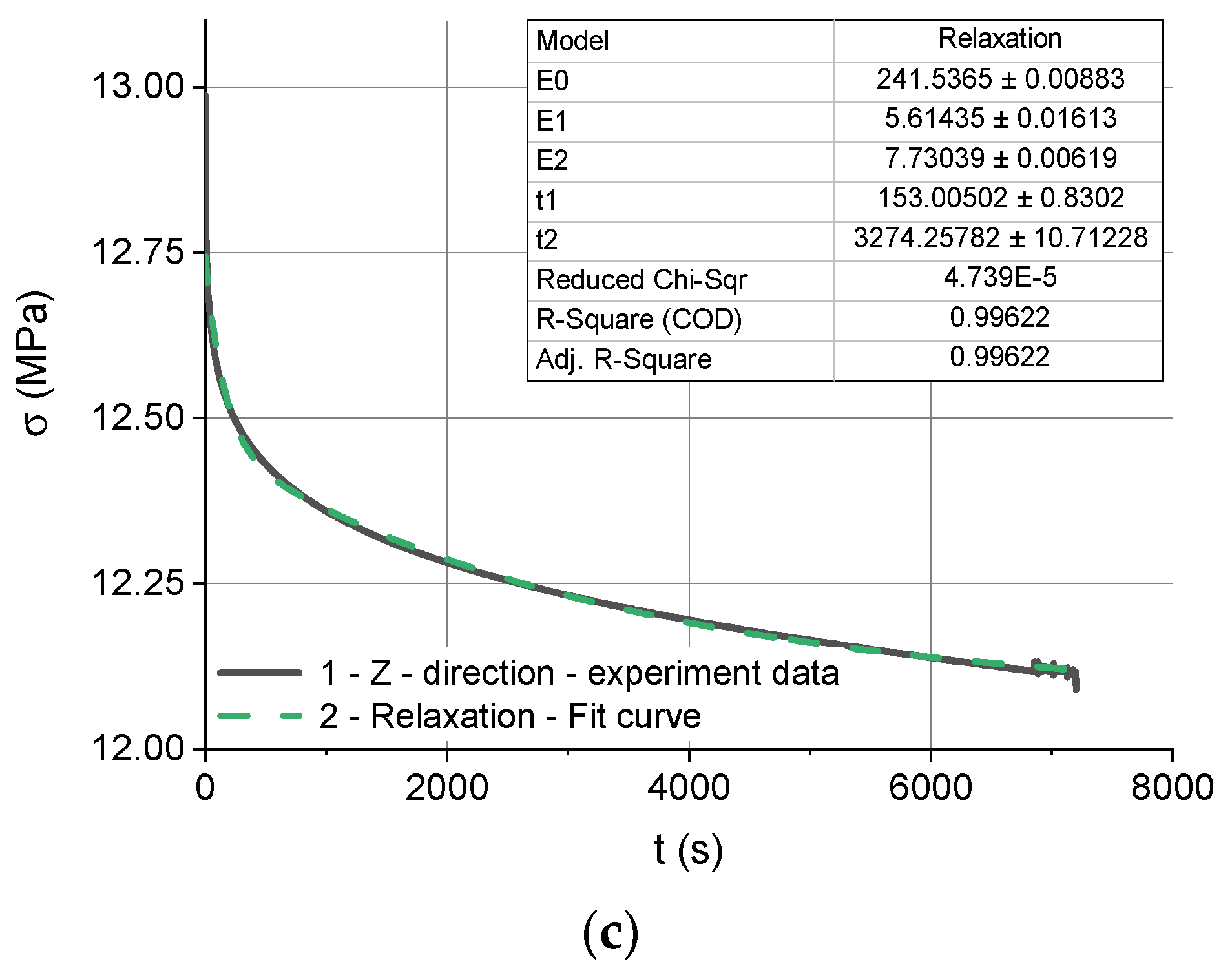

| Build Direction | (MPa) | (MPa) | (MPa) | (s) | (s) |

|---|---|---|---|---|---|

| X | 226.77 | 5.37 | 9.69 | 182 | 4675 |

| Y | 233.06 | 4.97 | 6.39 | 154 | 3978 |

| Z | 241.54 | 5.61 | 7.73 | 153 | 3274 |

| Build Direction | (MPa) | (MPa) | (MPa) |

|---|---|---|---|

| X | 241.83 | 12.09 | 11.34 |

| Y | 244.42 | 12.22 | 11.65 |

| Z | 254.88 | 12.74 | 12.08 |

| Build Direction | (MPa∙s) | (MPa∙s) |

|---|---|---|

| X | 977 | 45,300 |

| Y | 765 | 25,419 |

| Z | 858 | 25,419 |

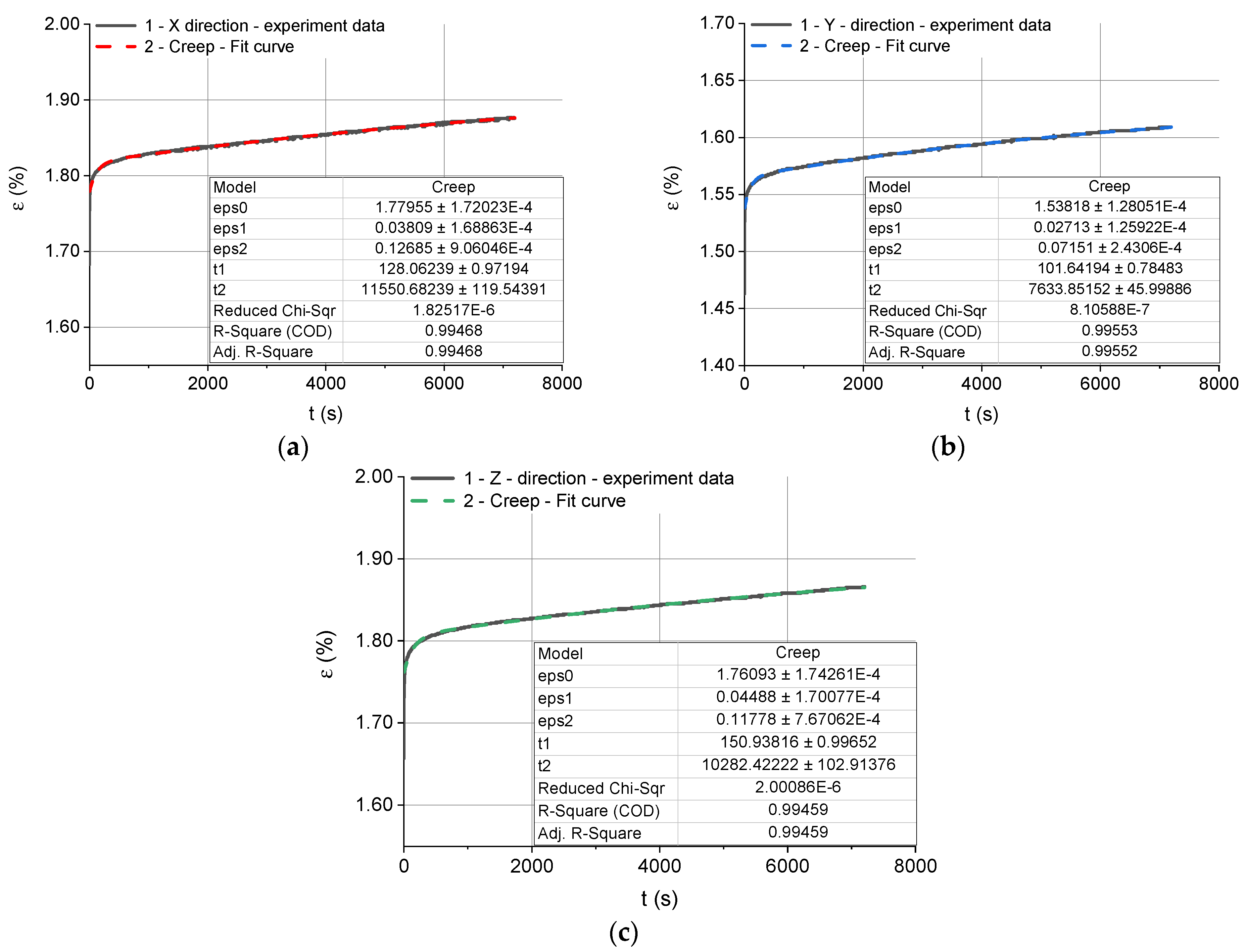

| Build Direction | (%) | (%) | (%) | (s) | (s) |

|---|---|---|---|---|---|

| X | 1.78 | 0.04 | 0.13 | 128 | 11,550 |

| Y | 1.54 | 0.03 | 0.07 | 101 | 7633 |

| Z | 1.76 | 0.05 | 0.12 | 150 | 10,282 |

| Build Direction | (MPa) | (MPa) | (MPa) | (MPa∙s) | (MPa∙s) |

|---|---|---|---|---|---|

| X | 214.59 | 9549 | 2938 | 1,222,272 | 33,933,900 |

| Y | 248.03 | 12,732 | 5456 | 1,285,932 | 41,645,648 |

| Z | 217.03 | 7639 | 3183 | 1,145,850 | 11,781,629,700 |

| Build Direction | (MPa) | (%) | (%) |

|---|---|---|---|

| X | 195.88 | 1.78 | 1.95 |

| Y | 232.90 | 1.54 | 1.64 |

| Z | 197.91 | 1.76 | 1.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bochnia, J.; Blasiak, S. Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering. Polymers 2020, 12, 830. https://doi.org/10.3390/polym12040830

Bochnia J, Blasiak S. Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering. Polymers. 2020; 12(4):830. https://doi.org/10.3390/polym12040830

Chicago/Turabian StyleBochnia, Jerzy, and Slawomir Blasiak. 2020. "Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering" Polymers 12, no. 4: 830. https://doi.org/10.3390/polym12040830

APA StyleBochnia, J., & Blasiak, S. (2020). Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering. Polymers, 12(4), 830. https://doi.org/10.3390/polym12040830