Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene

Abstract

1. Introduction

2. Experimental

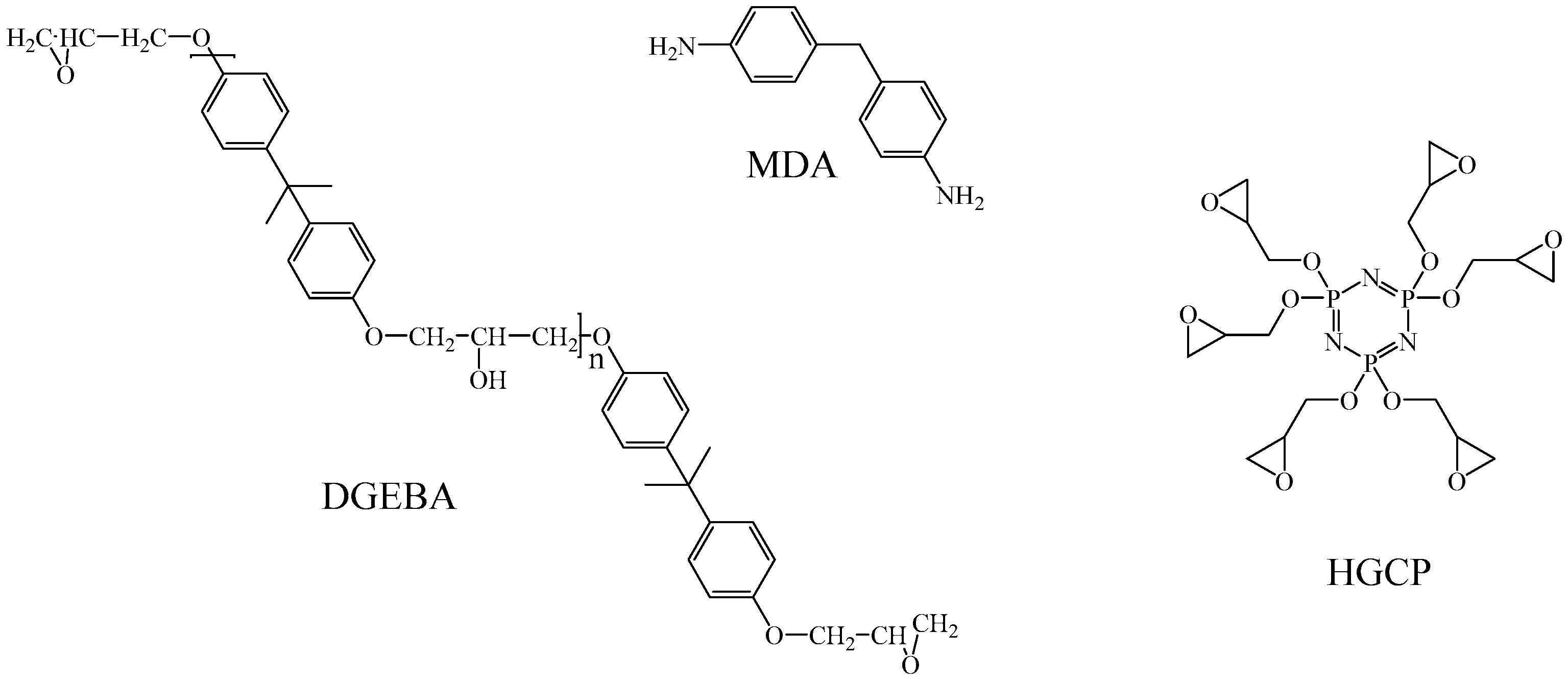

2.1. Materials and Methods

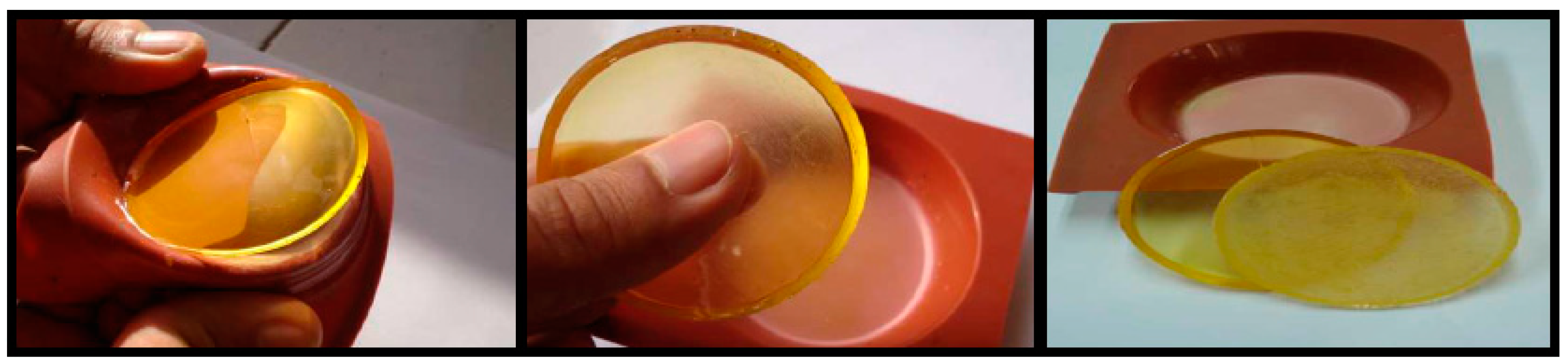

2.2. Sample Preparation

- One night at 70 °C

- 3 h at 100 °C

- 2 h at 120 °C

- 1 h at 140 °C

- 30 min at 150 °C

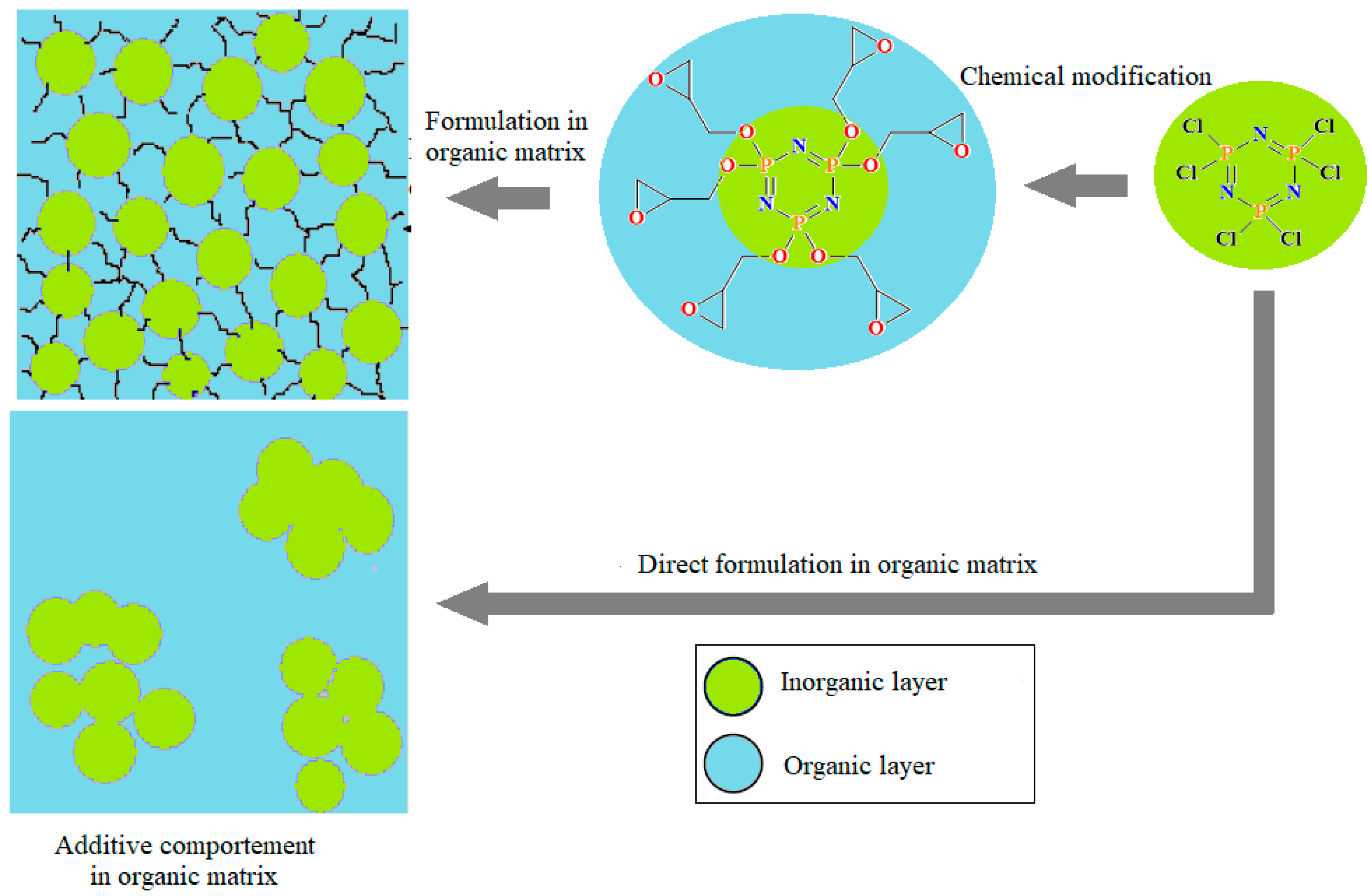

2.3. HGCP Dispersion Approach in a Polymer Matrix

2.4. Morphological Characterization

2.5. Rheological Measurement

2.6. Electrical Measurements

3. Results and Discussions

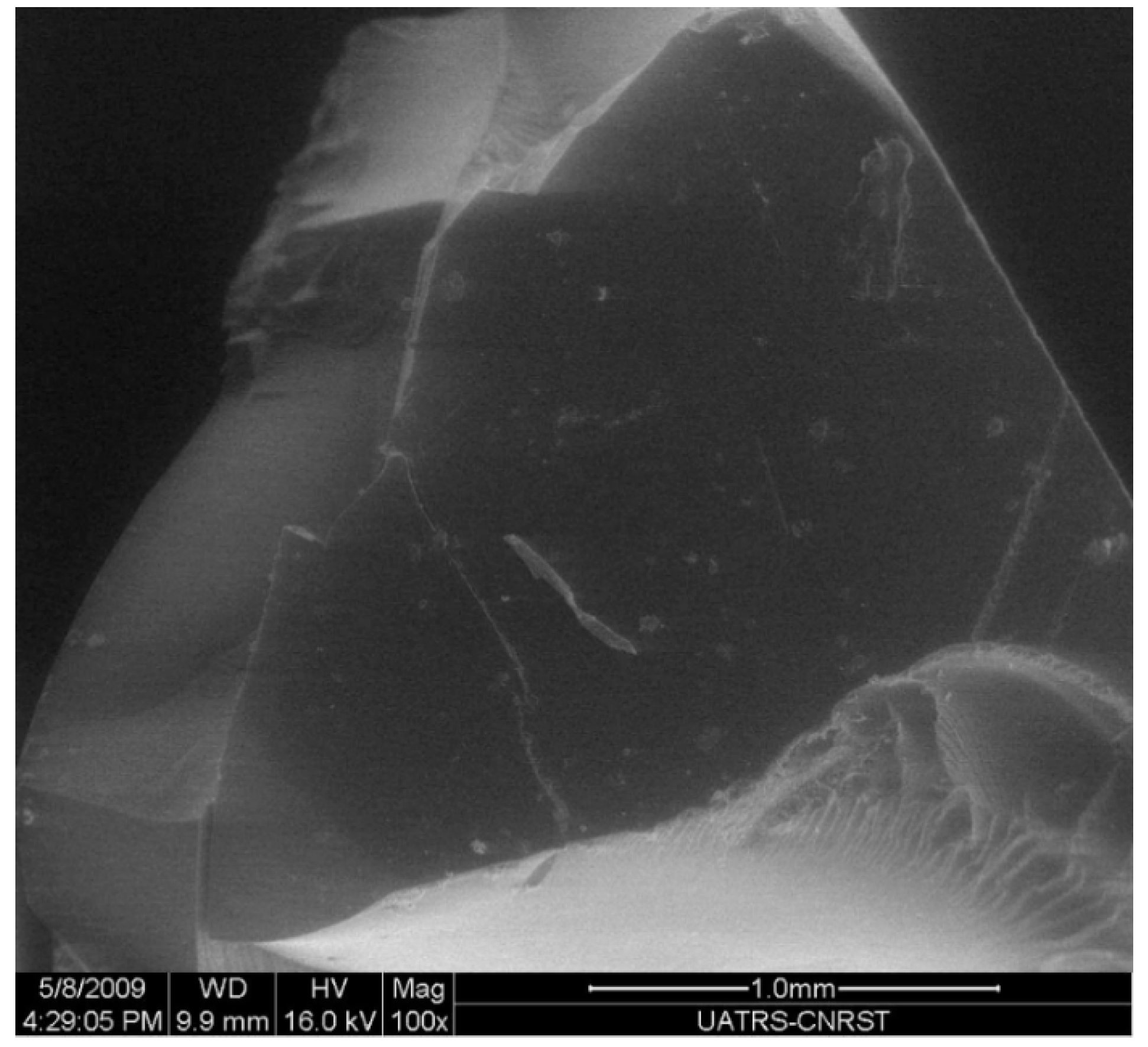

3.1. Morphology Study

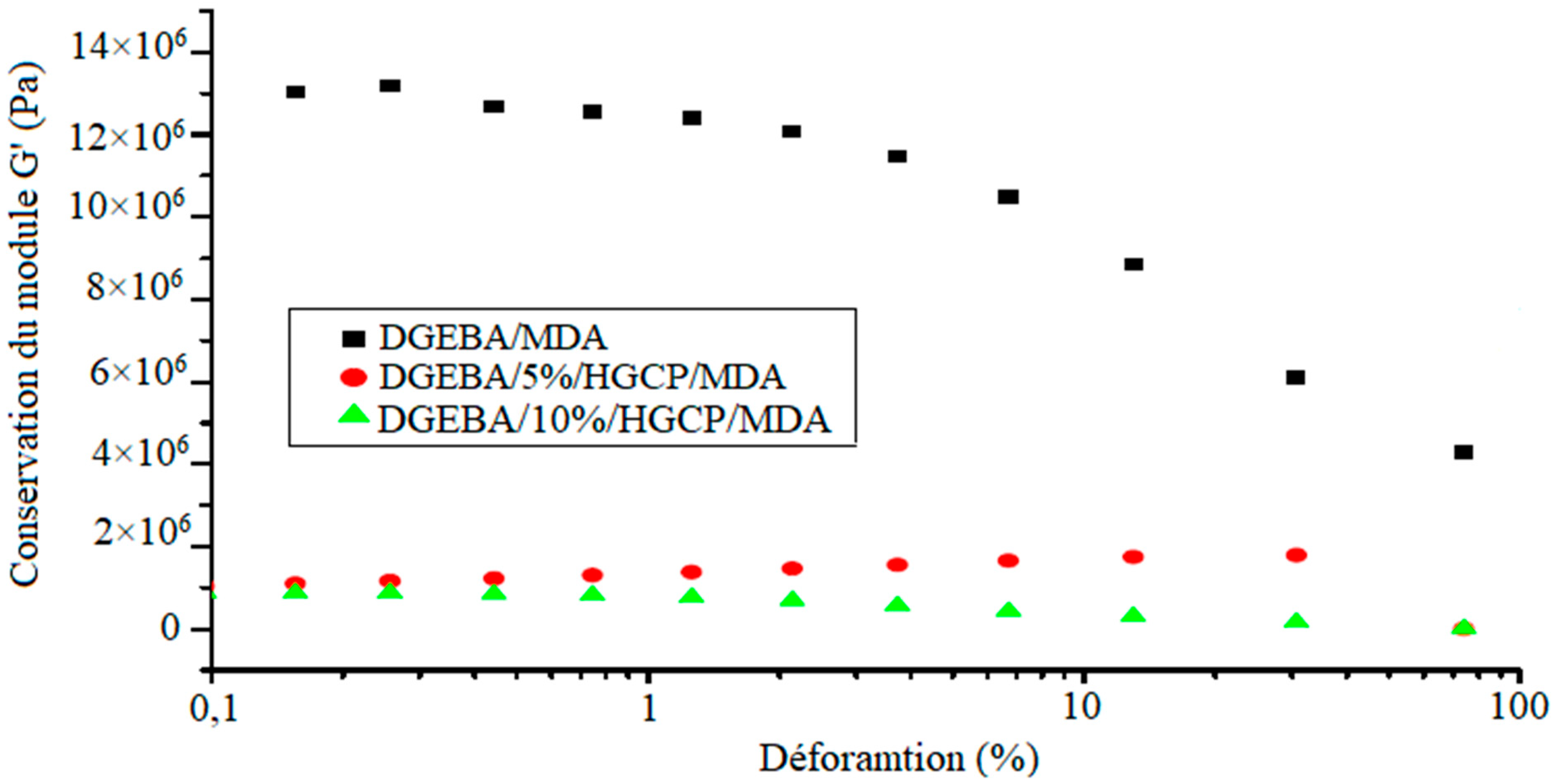

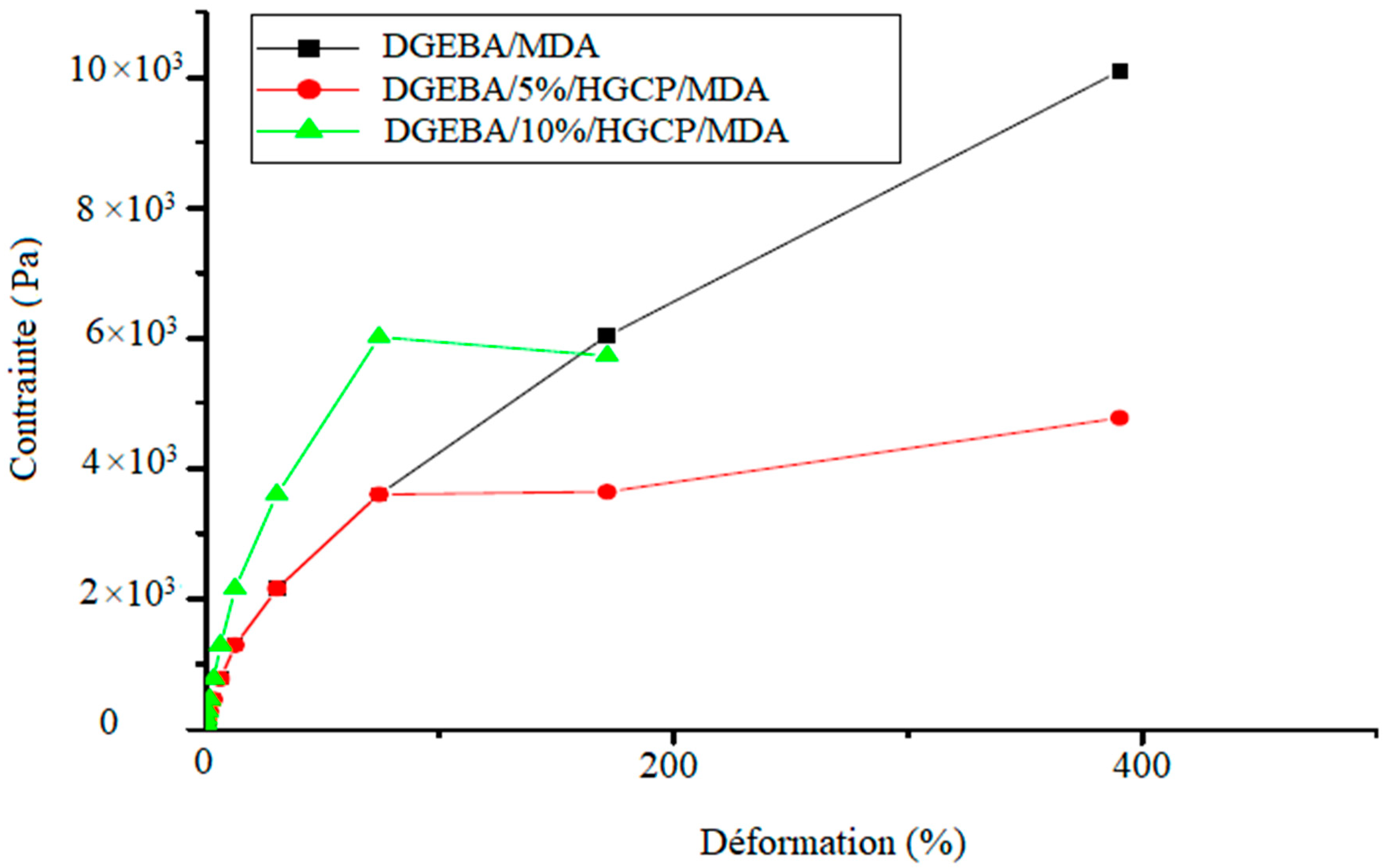

3.2. Dynamic Viscoelastic Analyzes

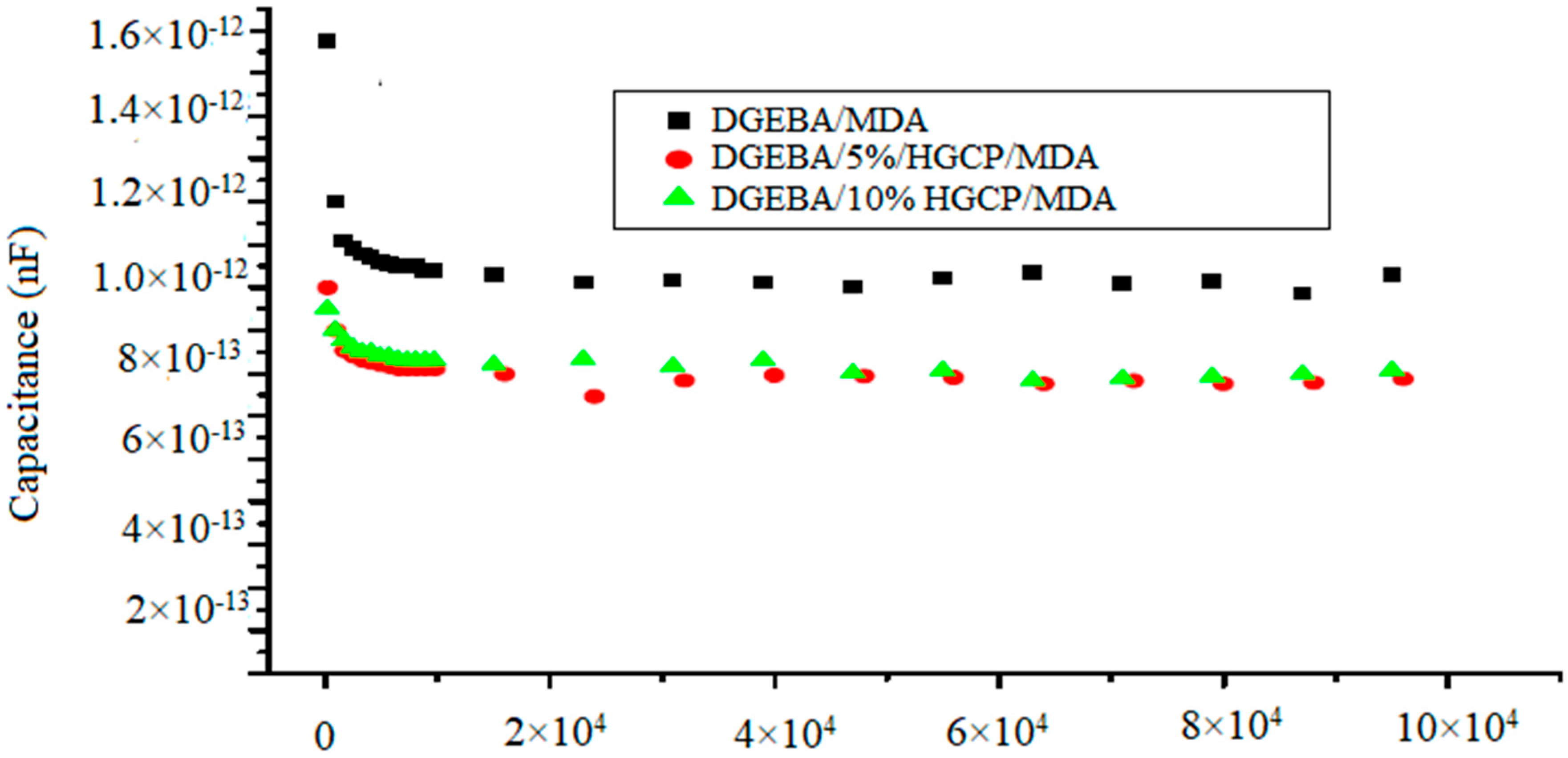

3.3. Electric Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saeb, M.R.; Rastin, H.; Nonahal, M.; Paran, S.M.R.; Khonakdar, H.A.; Puglia, D. Cure kinetics of epoxy/chicken eggshell biowaste composites: Isothermal calorimetric and chemorheological analyses. Prog. Org. Coat. 2018, 114, 208–215. [Google Scholar] [CrossRef]

- Puglia, D.; Rastin, H.; Saeb, M.R.; Shojaei, B.; Formela, K. Cure kinetics of epoxy/MWCNTs nanocomposites: Isothermal calorimetric and rheological analyses. Prog. Org. Coat. 2017, 108, 75–83. [Google Scholar]

- Duan, H.; Chen, Y.; Ji, S.; Hu, R.; Ma, H. A novel phosphorus/nitrogen-containing polycarboxylic acid endowing epoxy resin with excellent flame retardance and mechanical properties. Chem. Eng. J. 2019, 375, 121916. [Google Scholar] [CrossRef]

- Guo, X.; Wang, H.; Ma, D.; He, J.; Lei, Z. Synthesis of a novel, multifunctional inorganic curing agent and its effect on the flame-retardant and mechanical properties of intrinsically flame retardant epoxy resin. J. Appl. Polym. Sci. 2018, 135, 46410. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, X.; Lu, C.; Zhang, X.; Ji, Y.; Bai, C.; Qiao, Y. Studies on curing kinetics and tensile properties of silica-filled phenolic amine/epoxy resin nanocomposite. Polymers 2019, 11, 680. [Google Scholar] [CrossRef]

- Rudawska, A. The impact of the seasoning conditions on mechanical properties of modified and unmodified epoxy adhesive compounds. Polymers 2019, 11, 804. [Google Scholar] [CrossRef]

- Wang, T.; Song, B.; Wang, L. A New filler for epoxy resin: Study on the properties of graphite carbon nitride (g-C3N4) reinforced epoxy resin composites. Polymers 2020, 12, 76. [Google Scholar] [CrossRef]

- Bao, Q.; Wang, B.; Liu, Y.; Wang, Q.; Yang, Z. Epoxy resin flame retarded and toughed via flexible siloxane chain containing phosphaphenanthrene. Polym. Degrad. Stab. 2020, 172, 109055. [Google Scholar] [CrossRef]

- Chistyakov, E.M.; Panfilova, D.V.; Kireev, V.V.; Volkov, V.V.; Bobrov, M.F. Synthesis and properties of hexakis-(β-carboxyethenylphenoxy) cyclotriphosphazene. J. Mol. Struct. 2017, 1148, 1–6. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, G.; Yang, S.; Yang, L.; Cao, J.; Yang, K. The synthesis, curing kinetics, thermal properties and flame rertardancy of cyclotriphosphazene-containing multifunctional epoxy resin. Thermochim. Acta 2019, 680, 178348. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, J.; Yang, S.; Zhang, Q.; Hu, Y.; Ding, G.; Huo, S. Aminobenzothiazole-substituted cyclotriphosphazene derivative as reactive flame retardant for epoxy resin. React. Funct. Polym. 2020, 146, 104412. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, J.; Yang, S.; Zhang, Q.; Huo, S.; Zhang, Q.; Ding, G. Benzimidazolyl-substituted cyclotriphosphazene derivative as latent flame-retardant curing agent for one-component epoxy resin system with excellent comprehensive performance. Compos. Part B Eng. 2019, 177, 107440. [Google Scholar] [CrossRef]

- Dagdag, O.; El Harfi, A.; El Gouri, M.; Safi, Z.; Jalgham, R.T.; Wazzan, N.; Kumar, U.P. Anticorrosive properties of Hexa (3-methoxy propan-1, 2-diol) cyclotri-phosphazene compound for carbon steel in 3% NaCl medium: Gravimetric, electrochemical, DFT and Monte Carlo simulation studies. Heliyon 2019, 5, e01340. [Google Scholar] [CrossRef] [PubMed]

- Shariati, A.; Peters, C.J. Recent developments in particle design using supercritical fluids. Curr. Opin. Solid State Materi. Sci. 2003, 7, 371–383. [Google Scholar] [CrossRef]

- Quede, A.; Mutel, B.; Supiot, P.; Jama, C.; Dessaux, O.; Delobel, R. Characterization of organosilicon films synthesized by N2-PACVD. Application to fire retardant properties of coated polymers. Surf. Coat. Technol. 2004, 180, 265–270. [Google Scholar] [CrossRef]

- El Gouri, M.; El Bachiri, A.; Hegazi, S.E.; Rafik, M.; El Harfi, A. Thermal degradation of a reactive flame retardant based on cyclotriphosphazene and its blend with DGEBA epoxy resin. Polym. Degrad. Stab. 2009, 94, 2101–2106. [Google Scholar] [CrossRef]

- Levan, Q. Thèse de Docteur-Ingénieur; INP Toulouse: Toulouse, France, 1981. [Google Scholar]

- El Gouri, M.; El Bachiri, A.; Hegazi, S.E.; Ziraoui, R.; Rafik, M.; El Harfi, A. A phosphazene compound multipurpose application-Composite material precursor and reactive flame retardant for epoxy resin materials. J. Mater. Environ. Sci. 2011, 2, 319–334. [Google Scholar]

- Lertwimolnun, W.; Vergnes, B. Influence of compatibilizer and processing conditions on the dispersion of nanoclay in a polypropylene matrix. Polymer 2005, 46, 3462–3471. [Google Scholar] [CrossRef]

- Cassagnau, P.; Melis, F. Non-linear viscoelastic behaviour and modulus recovery in silica filled polymers. Polymer 2003, 44, 6607–6615. [Google Scholar] [CrossRef]

- Treece, M.A.; Oberhauser, J.P. Soft glassy dynamics in polypropylene–clay nanocomposites. Macromolecules 2007, 40, 571–582. [Google Scholar] [CrossRef]

- Aoki, Y.; Hatano, A.; Watanabe, H. Rheology of carbon black suspensions. I. Three types of viscoelastic behavior. Rheol. Acta 2003, 42, 209–216. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Li, S. A novel phosphorus− silicon containing epoxy resin with enhanced thermal stability, flame retardancy and mechanical properties. Polym. Degrad. Stab. 2019, 164, 36–45. [Google Scholar] [CrossRef]

- Misra, S.C.K.; Chandra, S. Electronic applications of semiconducting polymers. Indian J. Chem. 1994, 33A, 583–594. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dagdag, O.; El Gouri, M.; El Mansouri, A.; Outzourhit, A.; El Harfi, A.; Cherkaoui, O.; El Bachiri, A.; Hamed, O.; Jodeh, S.; Hanbali, G.; et al. Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene. Polymers 2020, 12, 921. https://doi.org/10.3390/polym12040921

Dagdag O, El Gouri M, El Mansouri A, Outzourhit A, El Harfi A, Cherkaoui O, El Bachiri A, Hamed O, Jodeh S, Hanbali G, et al. Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene. Polymers. 2020; 12(4):921. https://doi.org/10.3390/polym12040921

Chicago/Turabian StyleDagdag, O., M. El Gouri, A. El Mansouri, A. Outzourhit, A. El Harfi, O. Cherkaoui, A. El Bachiri, O. Hamed, S. Jodeh, G. Hanbali, and et al. 2020. "Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene" Polymers 12, no. 4: 921. https://doi.org/10.3390/polym12040921

APA StyleDagdag, O., El Gouri, M., El Mansouri, A., Outzourhit, A., El Harfi, A., Cherkaoui, O., El Bachiri, A., Hamed, O., Jodeh, S., Hanbali, G., & Khalaf, B. (2020). Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene. Polymers, 12(4), 921. https://doi.org/10.3390/polym12040921