A Novel Acetylene-Functional/Silicon-Containing Benzoxazine Resin: Preparation, Curing Kinetics and Thermal Properties

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

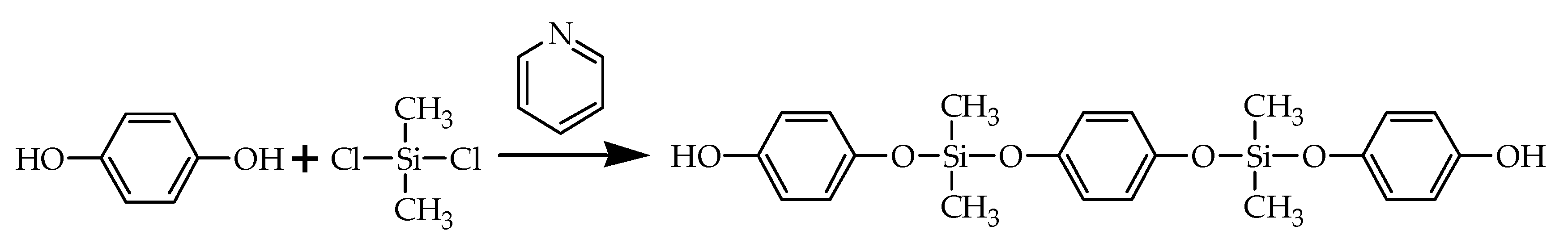

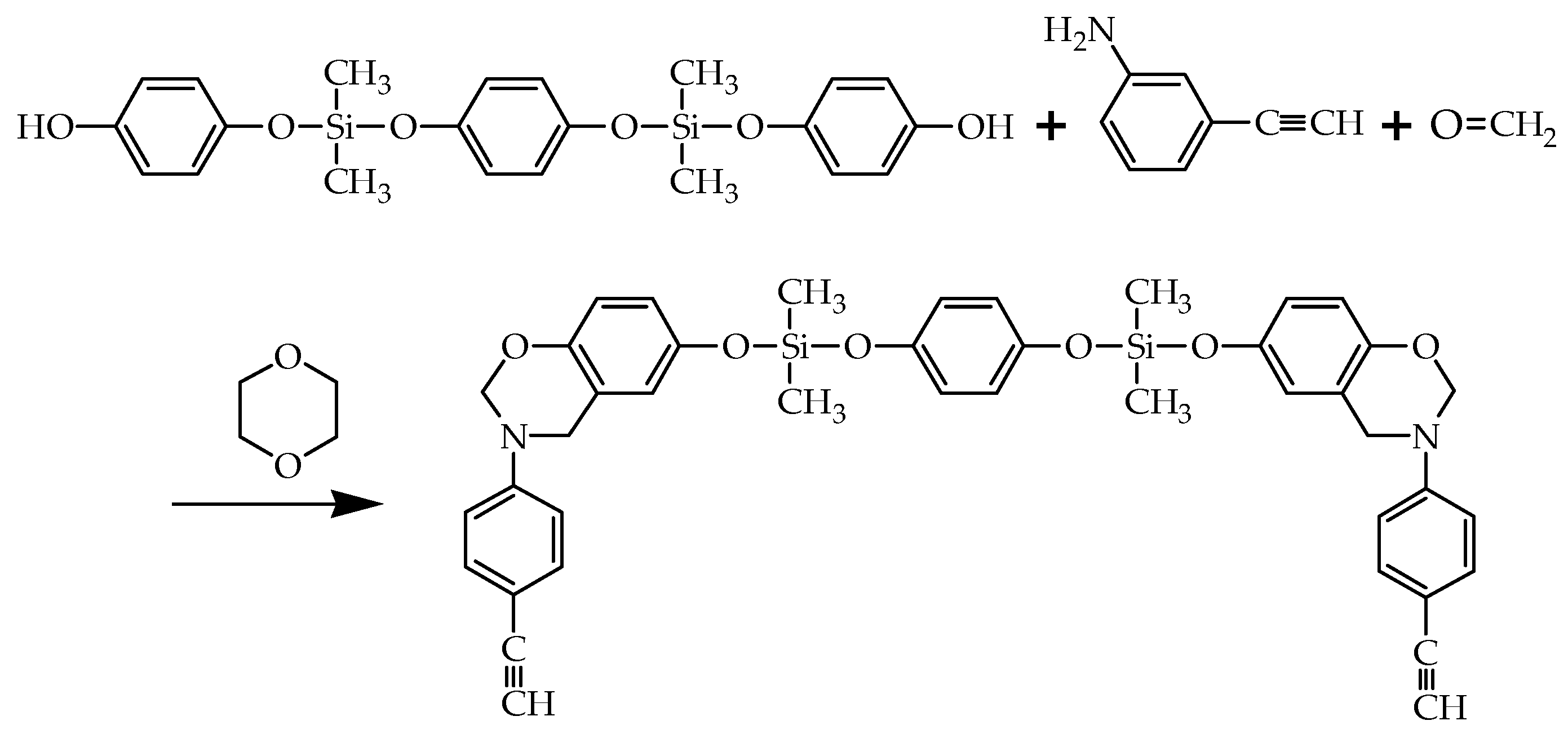

2.2. Synthesis of Phenolic Hydroxyl-Terminated Siloxane (PHS)

2.3. Synthesis of Acetylene-Functional/Silicon-Containing Benzoxazine Resin (ASB)

2.4. Preparation of Polybenzoxazines

2.5. Instruments

3. Results and Discussion

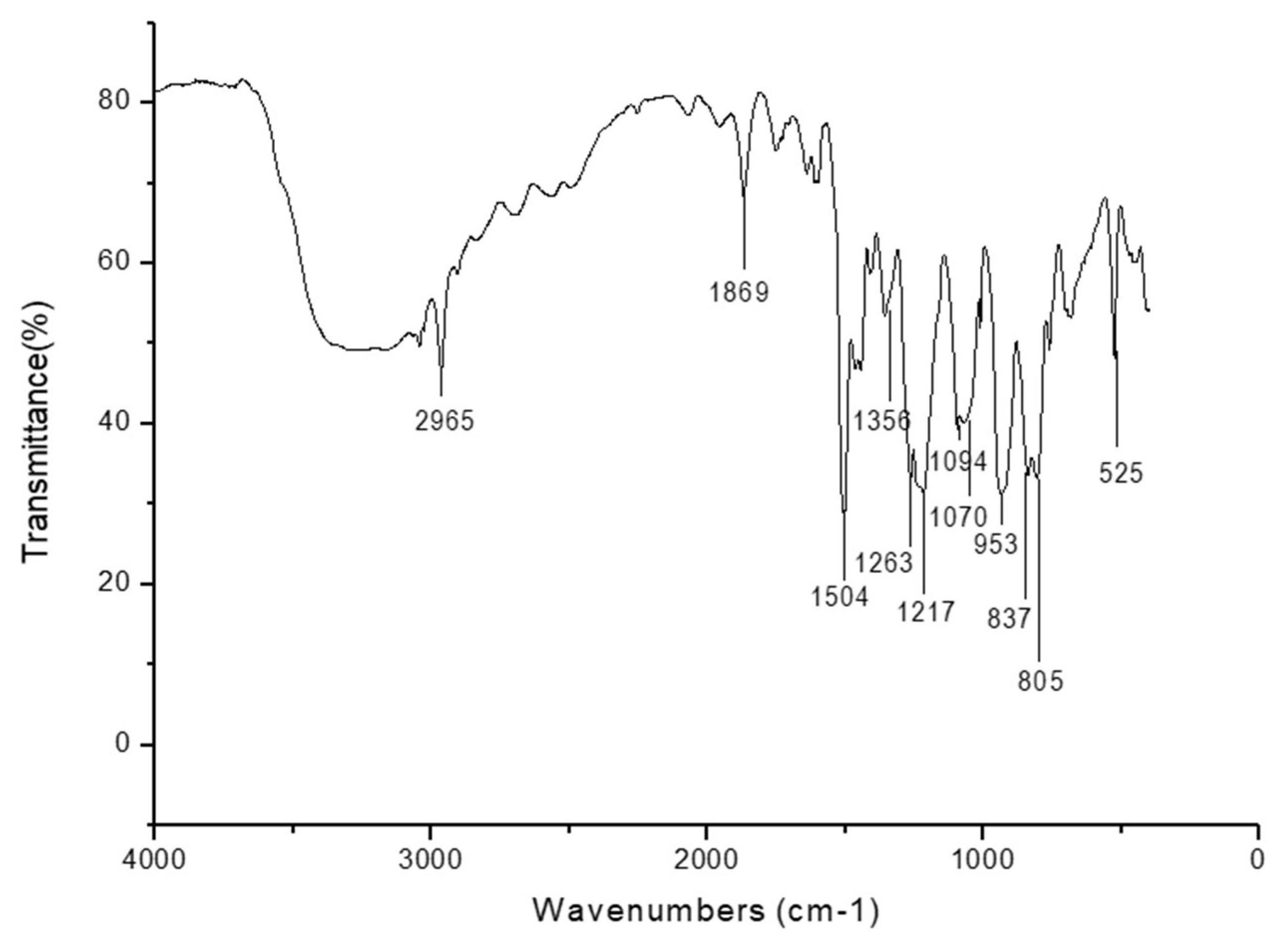

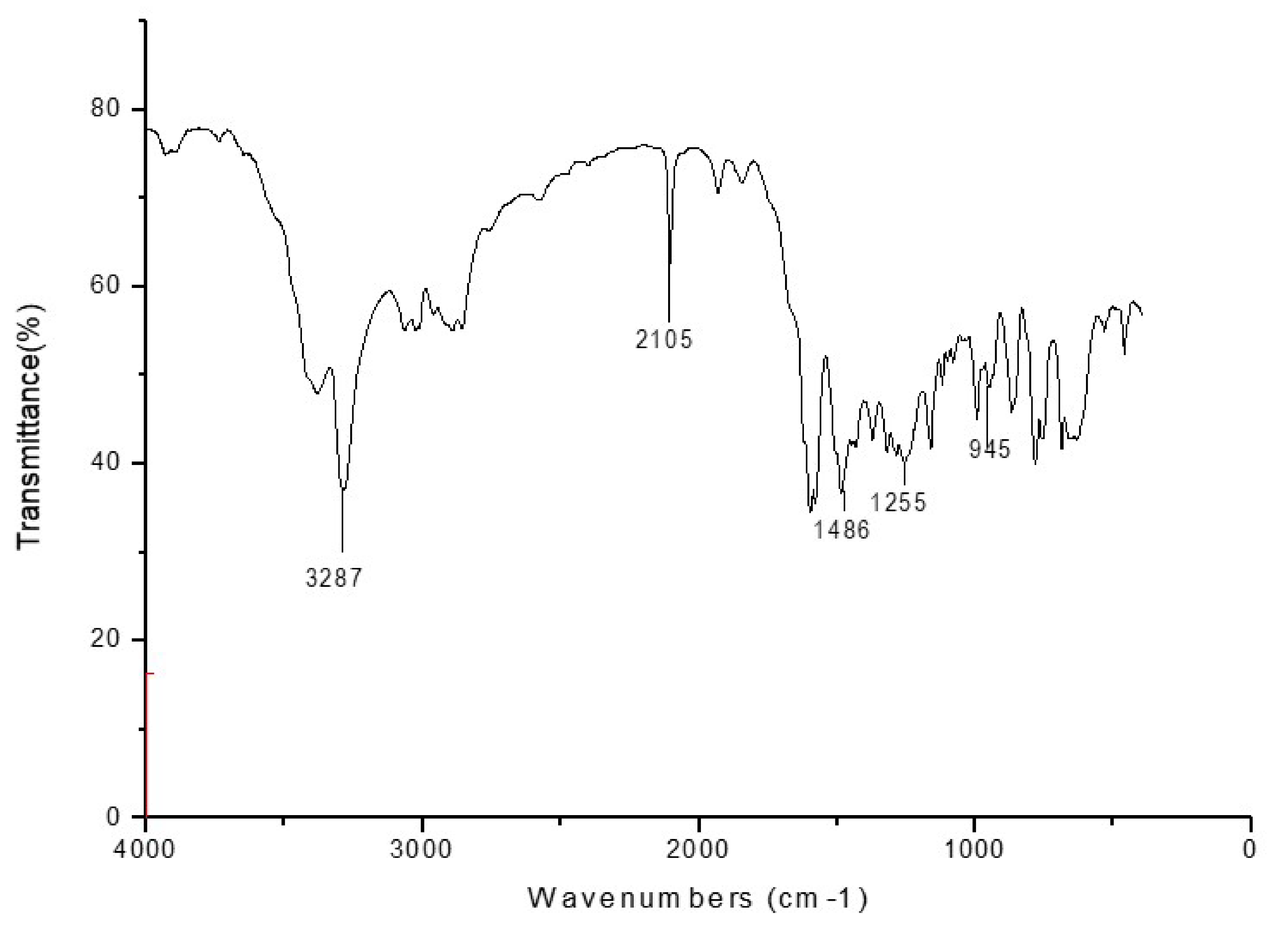

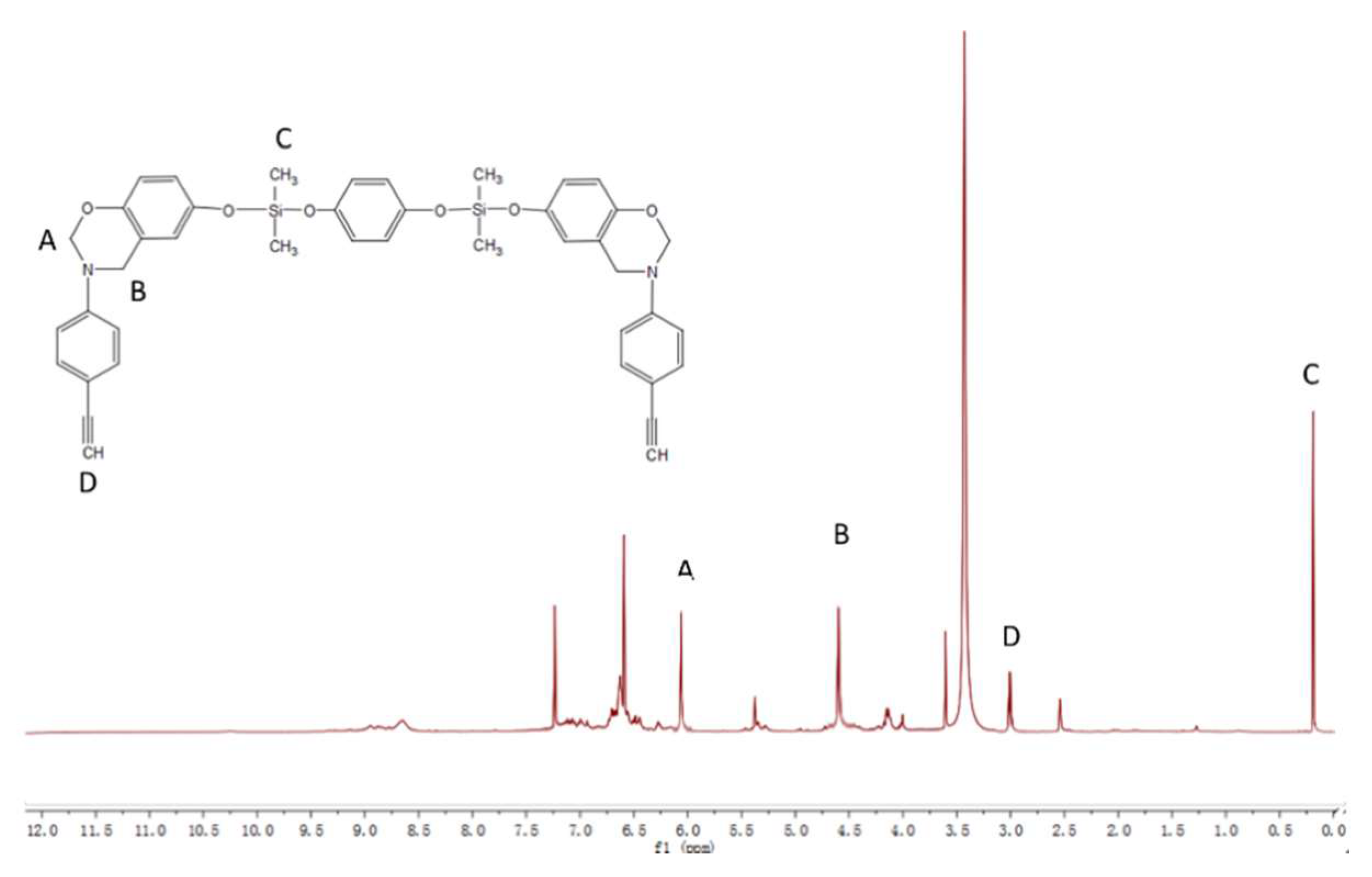

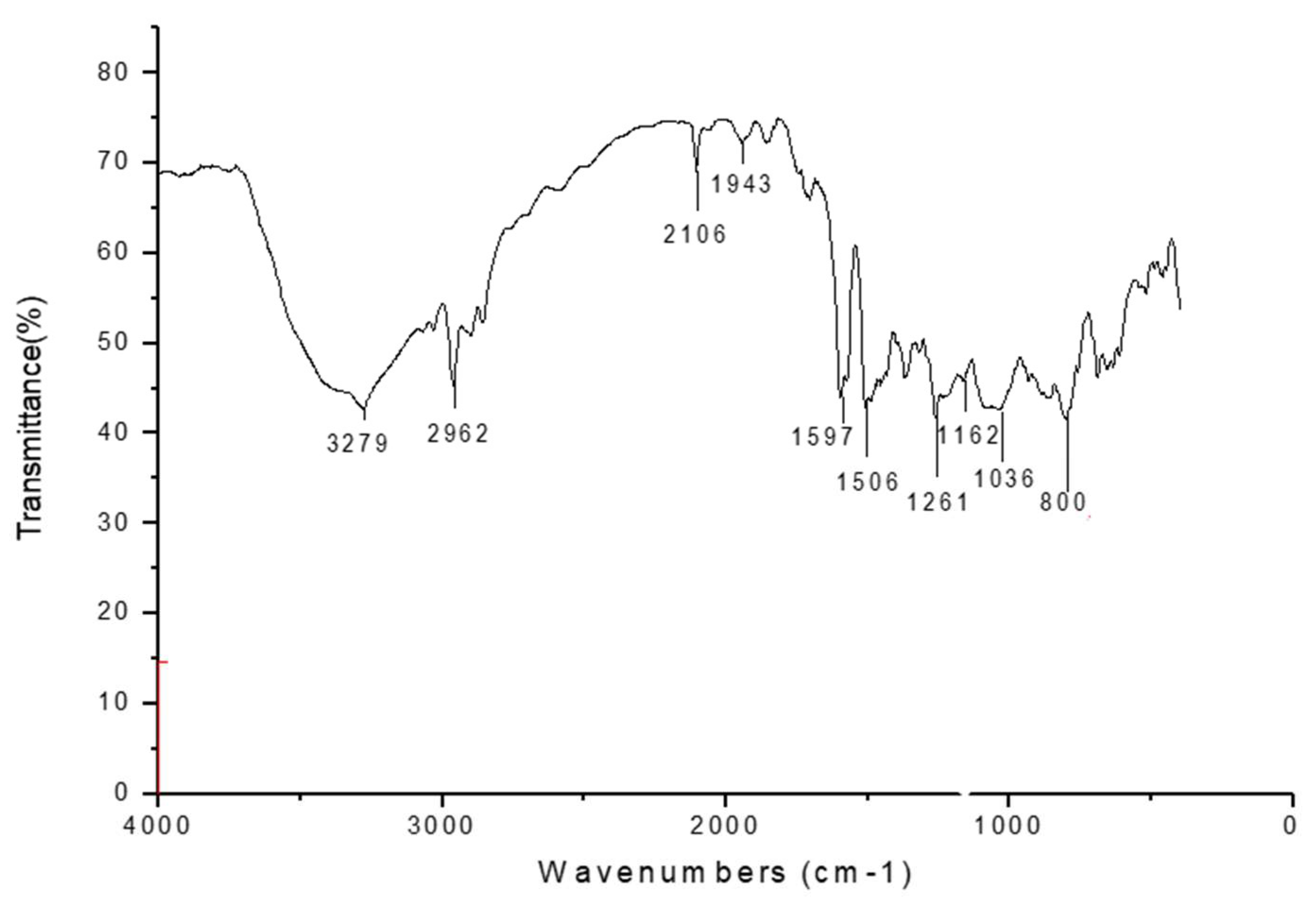

3.1. Synthesis of PHS, AB and ASB

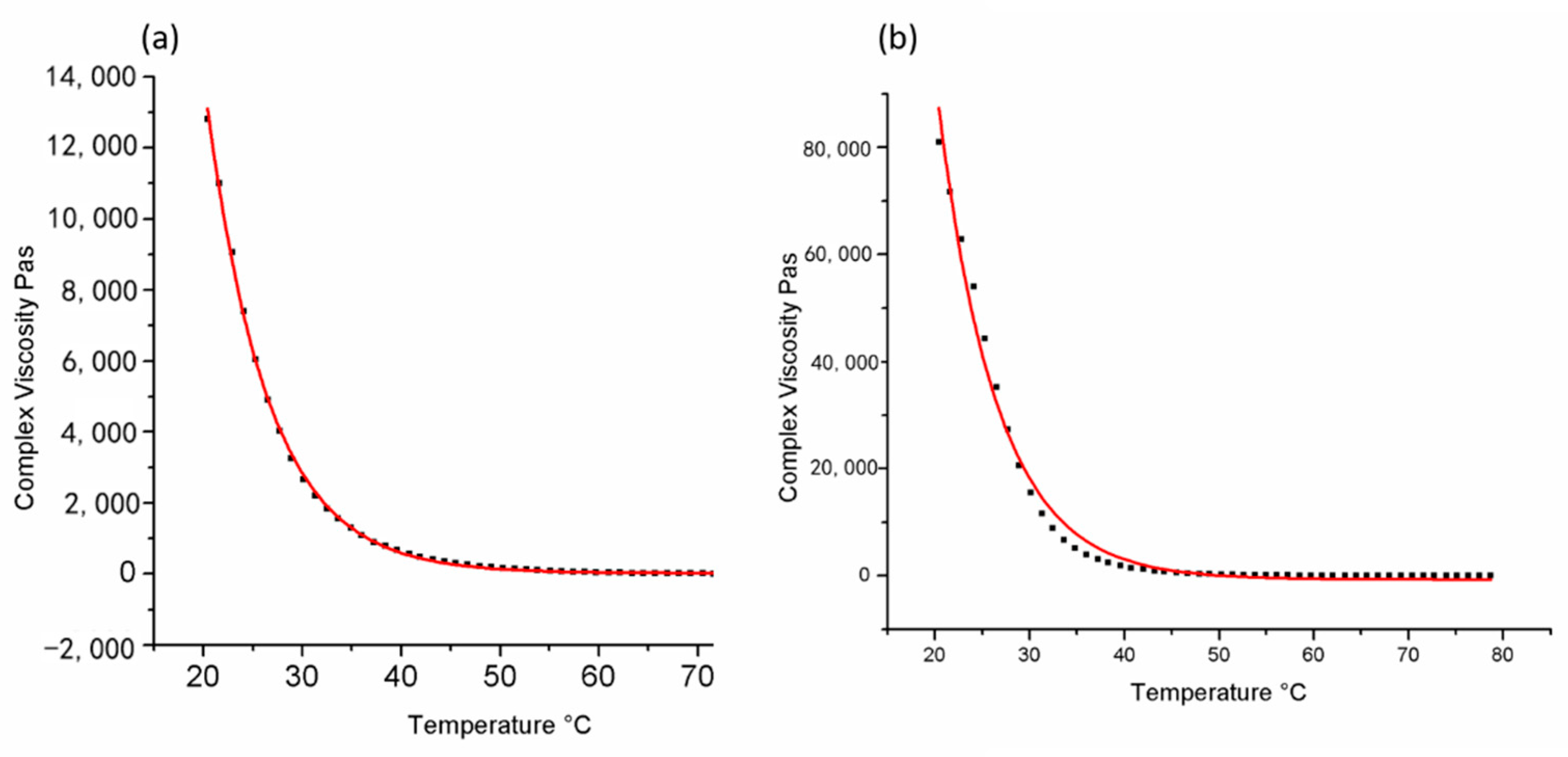

3.2. Rheological Analysis

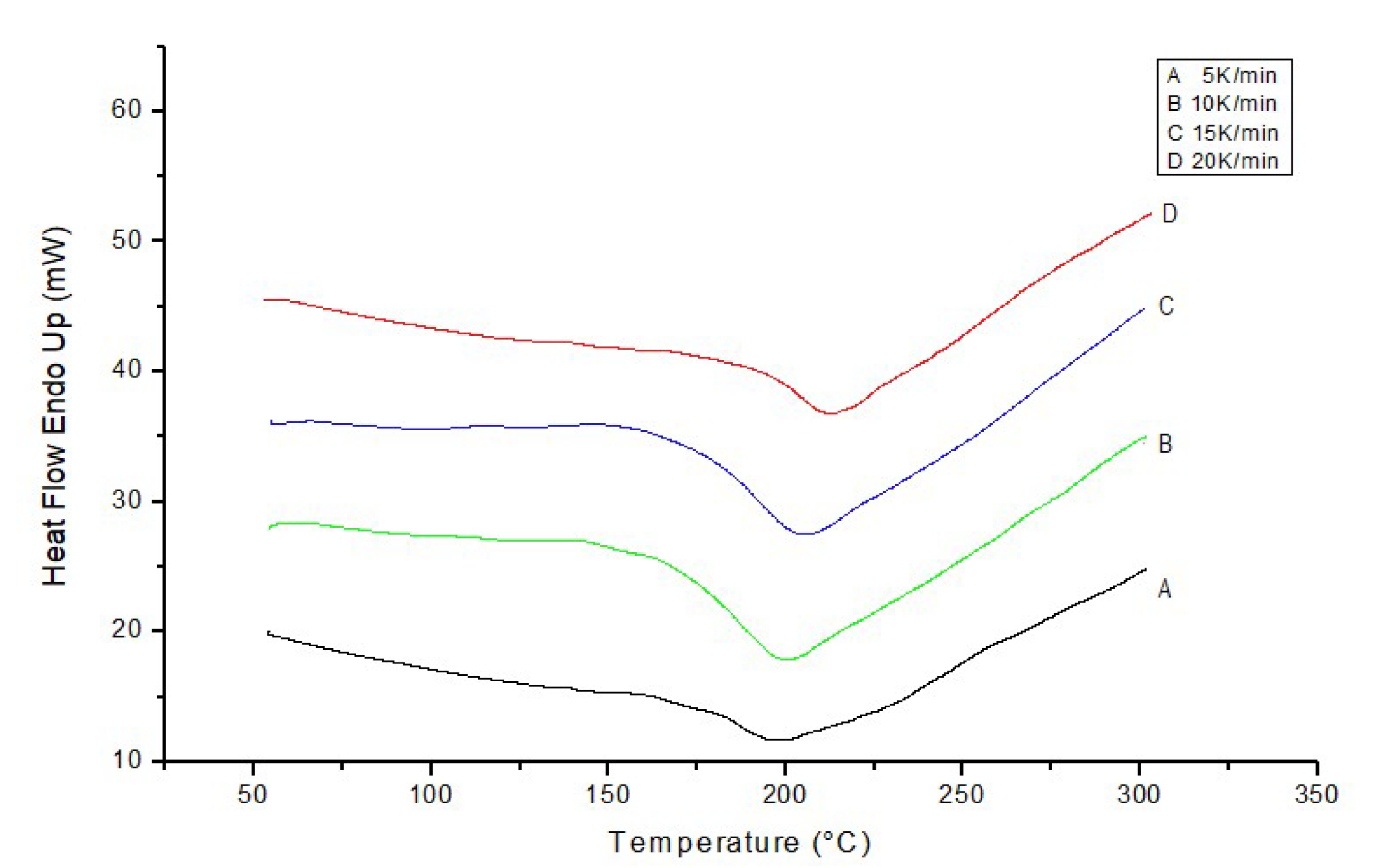

3.3. DSC Analysis

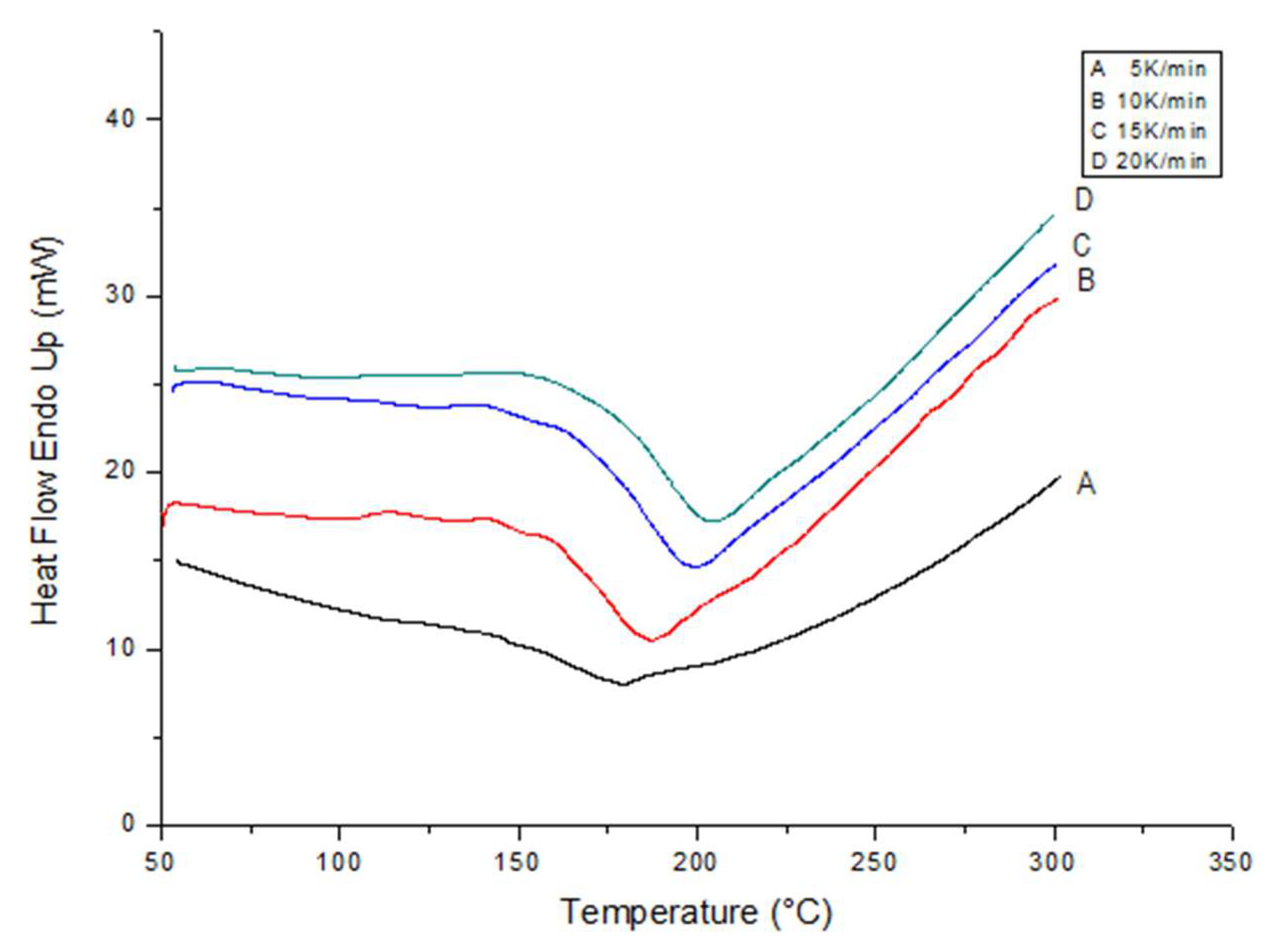

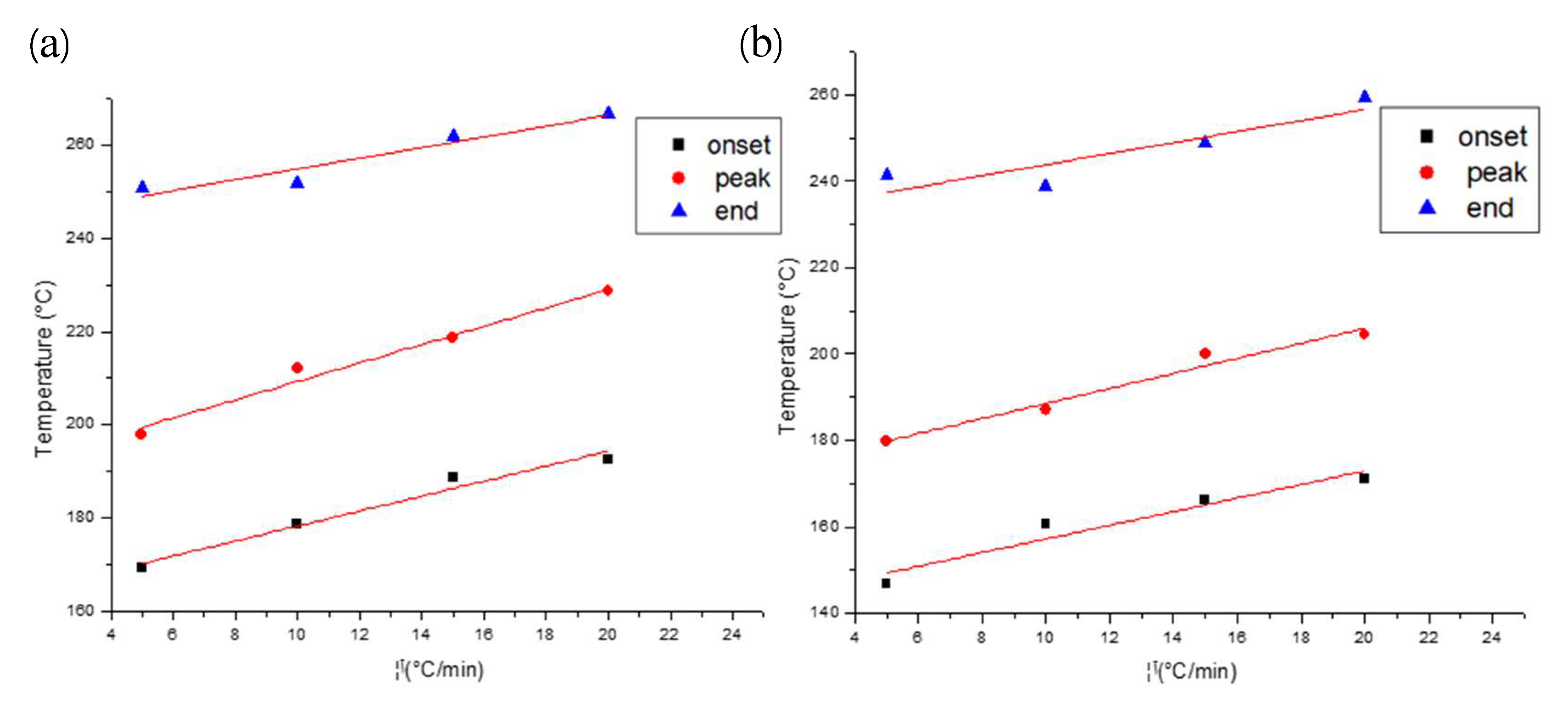

3.4. Research on Resin Curing Reaction Kinetics

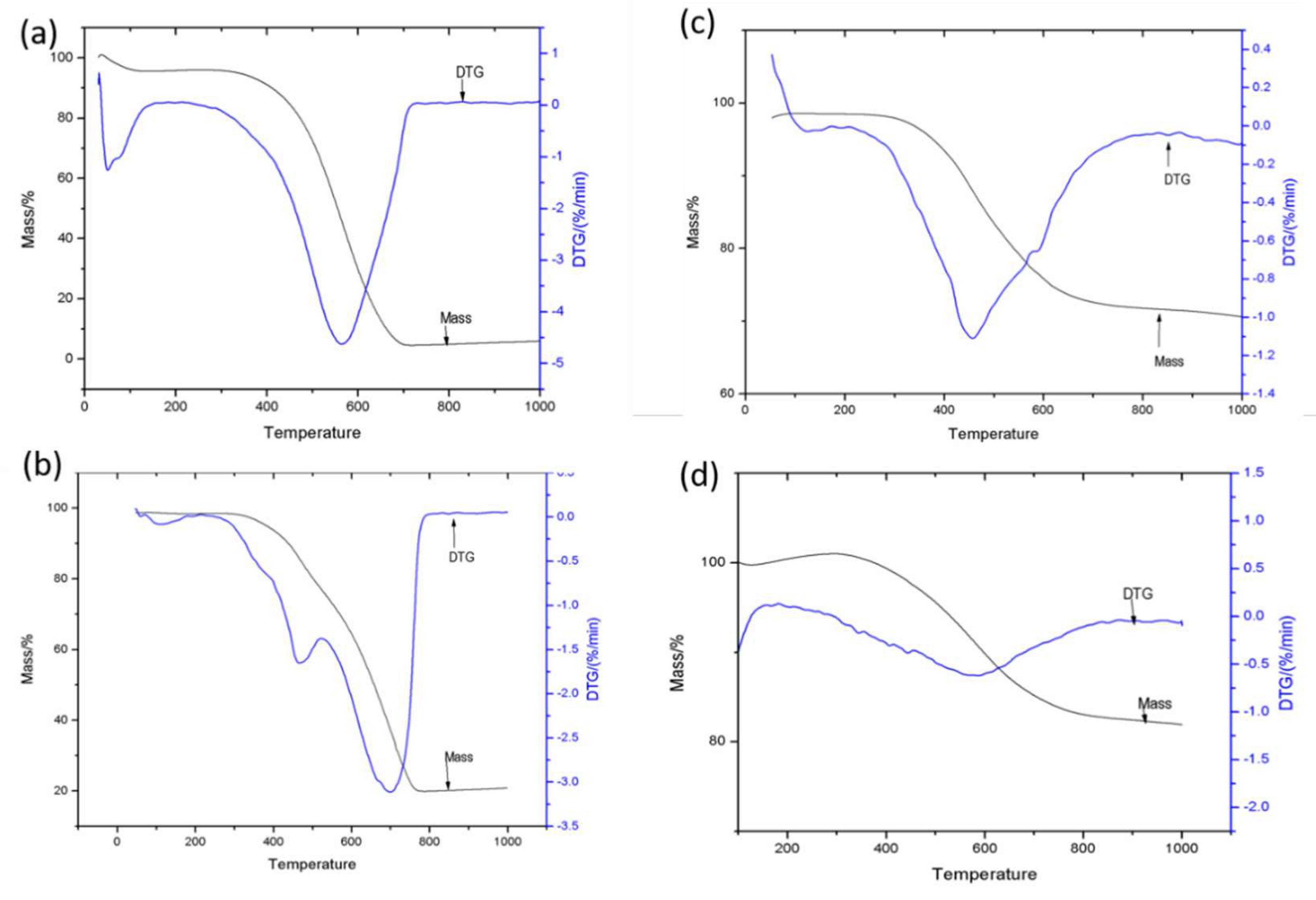

3.5. TGA Analysis

3.6. Mechanical Property Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, S.R.; Dhanasekaran, J.; Mohan, S.K. Epoxy benzoxazine based ternary systems of improved thermo-mechanical behavior for structural composite applications. RSC Adv. 2015, 5, 3709–3719. [Google Scholar] [CrossRef]

- Sandomierski, M.; Strzemiecka, B.; Koczorowski, W.; Barczewski, M.; Kasperkowiak, M.; Pokora, M.; Borek, B.; Chehimi, M.M.; Voelkel, A. Mechanically robust and thermally stable abrasive tools from phenolic resins reinforced with diazonium-modified zeolites. Polym. Compos. 2019, 40, 3209–3219. [Google Scholar] [CrossRef]

- Seena, J.; Sreekala, M.S.; Sabu, T. Effect of chemical modifications on the thermal stability and degradation of banana fiber and banana fiber-reinforced phenol formaldehyde composites. J. Appl. Polym. Sci. 2008, 110, 2305–2314. [Google Scholar]

- Yusuf, Y.; Baris, K.; Narendra, N.G. Recent advancement on polybenzoxazine-A newly developed high performance thermoset. J. Polym. Sci. Part A Polym. Chem. 2009, 47, 5565–5575. [Google Scholar]

- Durukan, C.; Kiskan, B.; Yagci, Y. One-Pot Synthesis of Amide-Functional Main-Chain Polybenzoxazine Precursors. Polymers 2019, 11, 679. [Google Scholar] [CrossRef]

- Ghosh, N.N.; Kiskan, B.; Yagci, Y. Polybenzoxazines-New high performance thermosetting resins: Synthesis and properties. Prog. Polym. Sci. 2007, 32, 1344–1391. [Google Scholar] [CrossRef]

- Liu, C.; Shen, D.; Sebastián, R.M.A.; Marquet, J.; Schönfeld, R. Mechanistic studies on ring-opening polymerization of benzoxazines: A mechanistically based catalyst design. Macromolecules 2011, 44, 4616–4622. [Google Scholar] [CrossRef]

- Wang, M.W.; Jeng, R.J.; Lin, C.H. Study on the Ring-Opening Polymerization of Benzoxazine through Multisubstituted Polybenzoxazine Precursors. Macromolecules 2015, 48, 530–535. [Google Scholar] [CrossRef]

- Onysko, P.P.; Zamulko, K.A.; Kyselyova, O.I.; Syzonenko, Y.A. Novel 2H-1,3-benzoxazine ring formation by intramolecular heterocyclization of N-(alpha-aryloxyalkyl)imidoyl chlorides. Heterocycl. Commun. 2017, 23, 421–428. [Google Scholar]

- Su, H.; Liu, Z. The structure and thermal properties of novel DOPO-containing 1,3-benzoxazines. J. Therm. Anal. Calorim. 2013, 114, 1207–1215. [Google Scholar] [CrossRef]

- Huang, J.; Du, W.; Zhang, J.; Huang, F.; Du, L. Study on the copolymers of silicon-containing arylacetylene resin and acetylene-functional benzoxazine. Polym. Bull. 2009, 62, 127–138. [Google Scholar] [CrossRef]

- Goto, M.; Miyagi, Y.; Minami, M.; Sanda, F. Synthesis and crosslinking reaction of polyacetylenes substituted with benzoxazine rings: Thermally highly stable benzoxazine resins. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 1884–1893. [Google Scholar] [CrossRef]

- Hsieh, C.Y.; Su, W.C.; Wu, C.S.; Lin, L.K.; Hsu, K.Y.; Liu, Y.L. Benzoxazine-containing branched polysiloxanes: Highly efficient reactive-type flame retardants and property enhancement agents for polymers. Polymer 2013, 54, 2945–2951. [Google Scholar] [CrossRef]

- Zhang, H.C.; Li, M.; Deng, Y.Y.; Zhang, C.X.; Ran, Q.C.; Gu, Y. A novel polybenzoxazine containing styrylpyridine structure via the Knoevenagel reaction. J. Appl. Polym. Sci. 2014, 131, 40823. [Google Scholar] [CrossRef]

- Kim, H.J.; Brunovska, Z.; Ishida, H. Synthesis and thermal characterization of polybenzoxazines based on acetylene-functional monomer. Polymer 1999, 40, 6565–6573. [Google Scholar] [CrossRef]

- Kim, H.J.; Brunovska, Z.; Ishida, H. Molecular characterization of the polymerization of acetylene-functional benzoxazine resins. Polymer 1999, 40, 1815–1822. [Google Scholar]

- Zhang, J.; Huang, J.X.; Du, W.; Huang, F.R.; Du, L. Thermal stability of the copolymers of silicon-containing arylacetylene resin and acetylene-functional benzoxazine. Polym. Degrad. Stab. 2011, 96, 2276–2283. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, J.; Ran, Q.C.; Gu, Y. Greatly improved thermal properties of polybenzoxazine via modification by acetylene/aldehyde groups. Polymer 2017, 123, 232–239. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zheng, S.X. Inorganic-organic nanocomposites of polybenzoxazine with octa(propylglycidyl ether) polyhedral oligomeric silsesquioxane. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 1168–1181. [Google Scholar] [CrossRef]

- Huang, J.M.; Kuo, S.W.; Huang, H.J.; Wang, Y.X.; Chen, Y.T. Preparation of VB-a/POSS hybrid monomer and its polymerization of polybenzoxazine/POSS hybrid nanocomposites. J. Appl. Polym. Sci. 2009, 111, 628–634. [Google Scholar] [CrossRef]

- Lin, C.H.; Cai, S.X.; Leu, T.S.; Hwang, T.Y.; Lee, H.H. Synthesis and properties of flame-retardant benzoxazines by three approaches. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 106–114. [Google Scholar] [CrossRef]

- Spontón, M.; Ronda, J.C.; Galià, M.; Cádiz, V. Development of flame retardant phosphorus- and silicon-containing polybenzoxazines. Polym. Degrad. Stab. 2009, 94, 145–150. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, Y.; Huang, F.R.; Du, L. Preparation and properties of silicon-containing arylacetylene resin/benzoxazines blends. High Perform. Polym. 2013, 25, 445–453. [Google Scholar] [CrossRef]

- Zeng, K.; Li, H.; Shi, H.; Xu, J.; Li, Y.; Zhao, C. Synthesis and thermal properties of silicon-containing benzoxazine. High Perform. Polym. 2019, 32, 59–64. [Google Scholar] [CrossRef]

- Li, G.; Luo, Z.; Han, W. Preparation and properties of novel hybrid resins based on acetylene-functional benzoxazine and polyvinylsilazane. J. Appl. Polym. Sci. 2013, 130, 3794–3799. [Google Scholar] [CrossRef]

| Heating Rate (°C/min) | Initial (°C) | Peak (°C) | End (°C) |

|---|---|---|---|

| 5 | 169.2 | 197.9 | 250.8 |

| 10 | 178.6 | 211.9 | 251.7 |

| 15 | 188.8 | 218.6 | 261.7 |

| 20 | 192.5 | 228.6 | 266.7 |

| Heating Rate (°C/min) | Initial (°C) | Peak (°C) | End (°C) |

|---|---|---|---|

| 5 | 146.6 | 179.9 | 241.2 |

| 10 | 161.8 | 187.1 | 238.8 |

| 15 | 166.2 | 200.0 | 248.6 |

| 20 | 171.1 | 204.6 | 259.2 |

| Resin | In Air | In Nitrogen | ||

|---|---|---|---|---|

| Td5/°C | Yc at 1000 °C | Td5/°C | Yc at 1000 °C | |

| AB | 360 | 2% | 436 | 72% |

| ASB | 380 | 21% | 485 | 80% |

| Mechanical Property | AB | ASB |

|---|---|---|

| Tensile Strength/MPa | 76.8 ± 2.85 | 78.2 ± 1.85 |

| Flexural Strength/MPa | 141.8 ± 5.87 | 149.3 ± 4.56 |

| Impact Strength/kJ/m2 | 24.2 ± 2.17 | 32.8 ± 2.89 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, Q.; Wang, H.; Tong, D.; Song, J.; Huang, Z. A Novel Acetylene-Functional/Silicon-Containing Benzoxazine Resin: Preparation, Curing Kinetics and Thermal Properties. Polymers 2020, 12, 999. https://doi.org/10.3390/polym12050999

Mei Q, Wang H, Tong D, Song J, Huang Z. A Novel Acetylene-Functional/Silicon-Containing Benzoxazine Resin: Preparation, Curing Kinetics and Thermal Properties. Polymers. 2020; 12(5):999. https://doi.org/10.3390/polym12050999

Chicago/Turabian StyleMei, Qilin, Honghua Wang, Danliao Tong, Jiuqiang Song, and Zhixiong Huang. 2020. "A Novel Acetylene-Functional/Silicon-Containing Benzoxazine Resin: Preparation, Curing Kinetics and Thermal Properties" Polymers 12, no. 5: 999. https://doi.org/10.3390/polym12050999

APA StyleMei, Q., Wang, H., Tong, D., Song, J., & Huang, Z. (2020). A Novel Acetylene-Functional/Silicon-Containing Benzoxazine Resin: Preparation, Curing Kinetics and Thermal Properties. Polymers, 12(5), 999. https://doi.org/10.3390/polym12050999