Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication and 3D Printing of ABS-TiO2 and ABS/ATO Nanocomposite Filaments

2.3. Compositional and Structural Characterization Methods

2.4. Thermal Properties

2.5. Tensile Tests

2.6. Flexural Tests

2.7. Micro-Hardness Tests

3. Results

3.1. Experimental Observations Regarding Filament and Specimens’ Fabrication

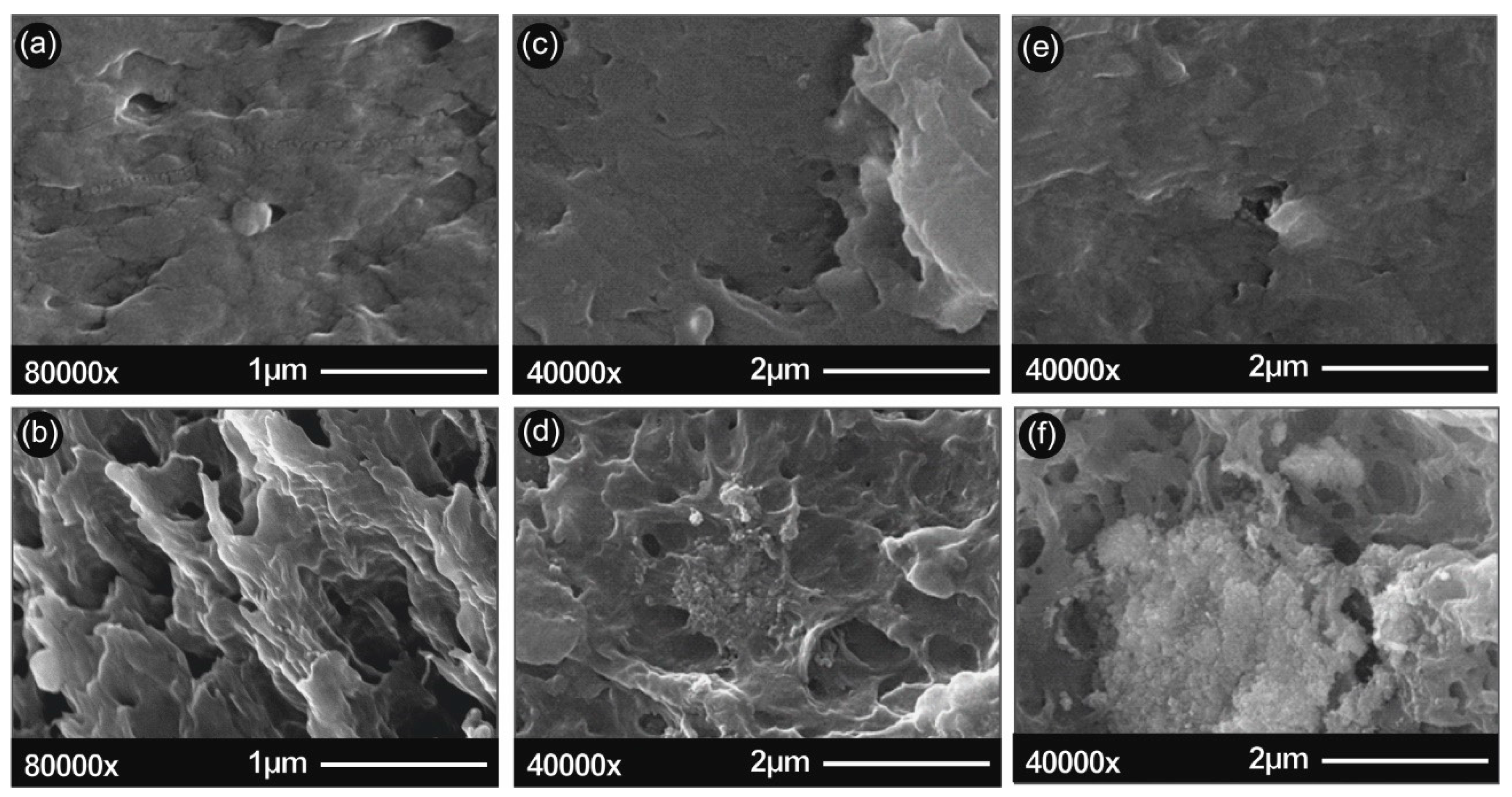

3.2. Microstructure Characterization

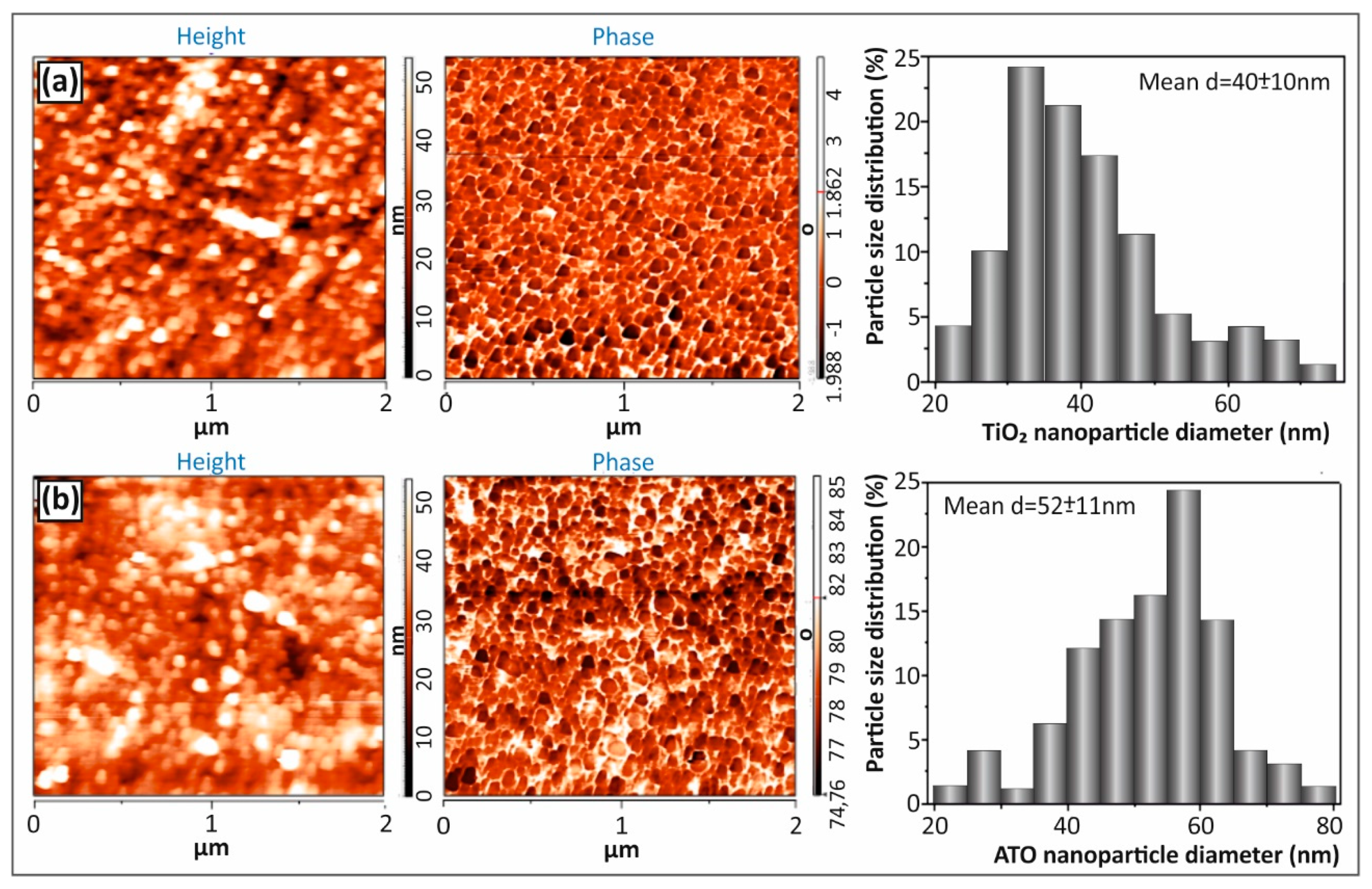

3.3. AFM Analysis of TiO2 and ATO Nnanoparticles’ Size

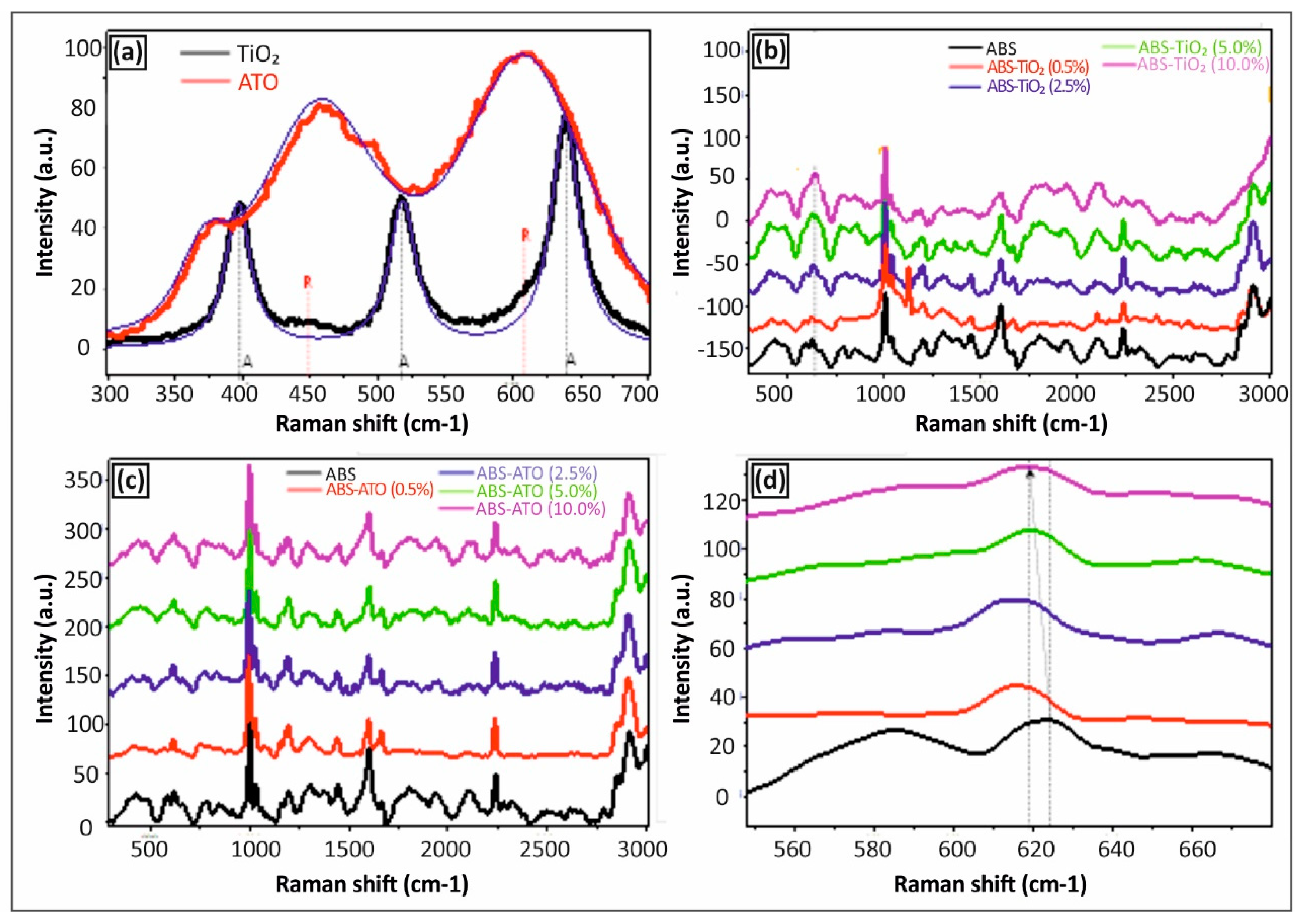

3.4. Raman Analysis

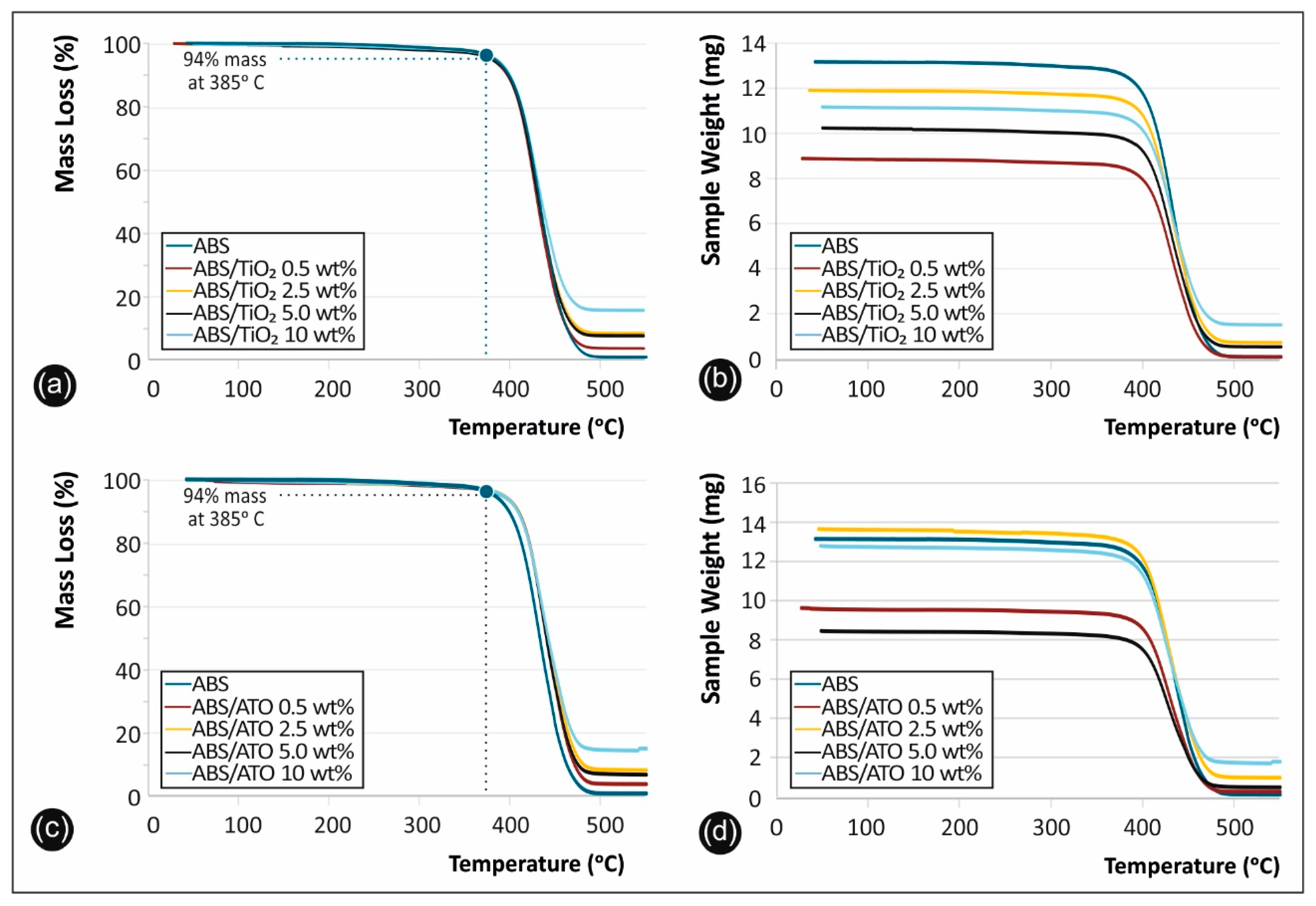

3.5. Thermal Analysis

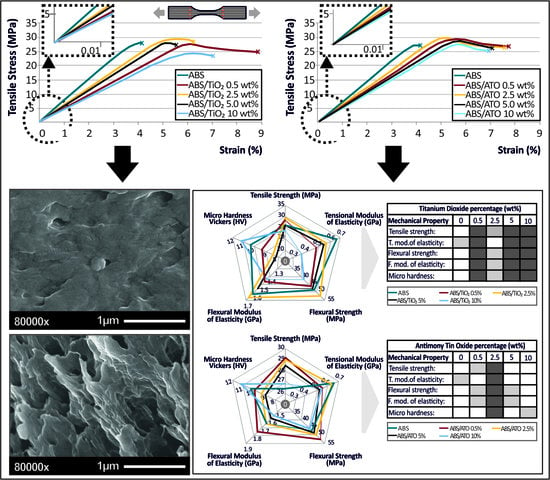

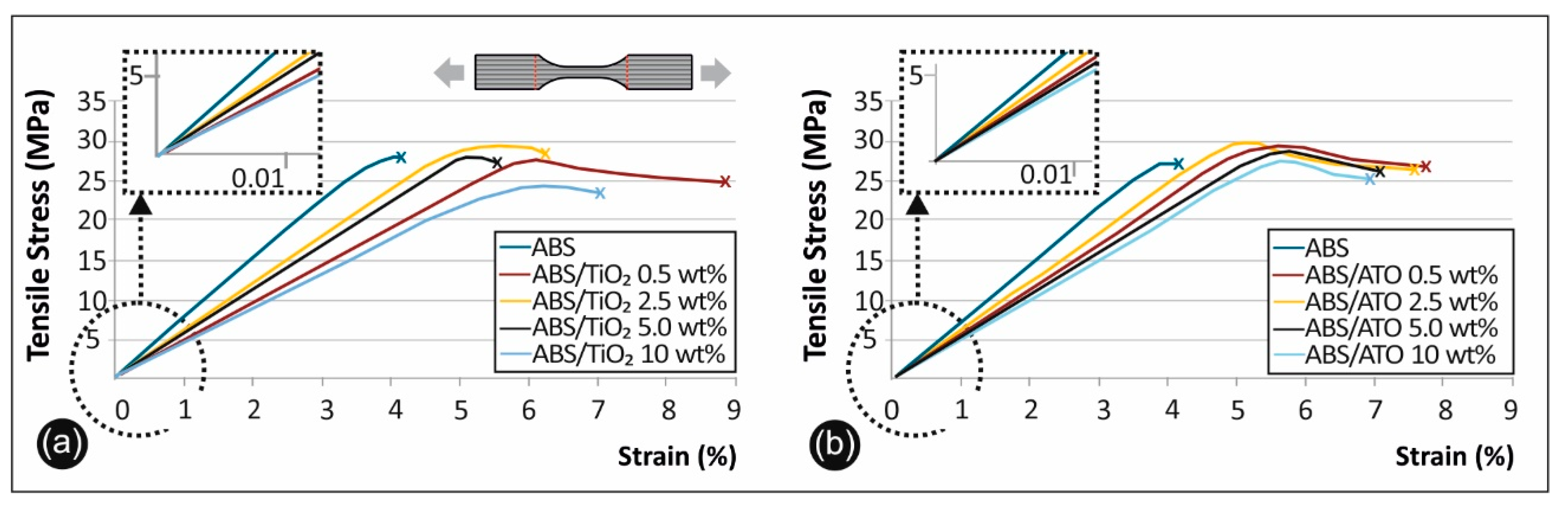

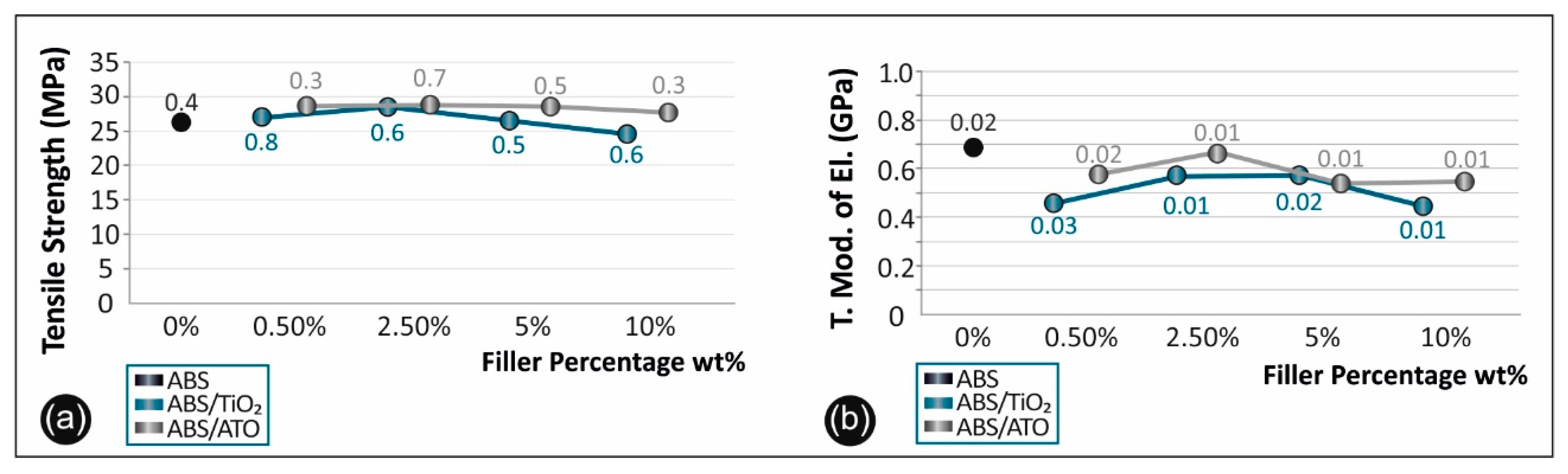

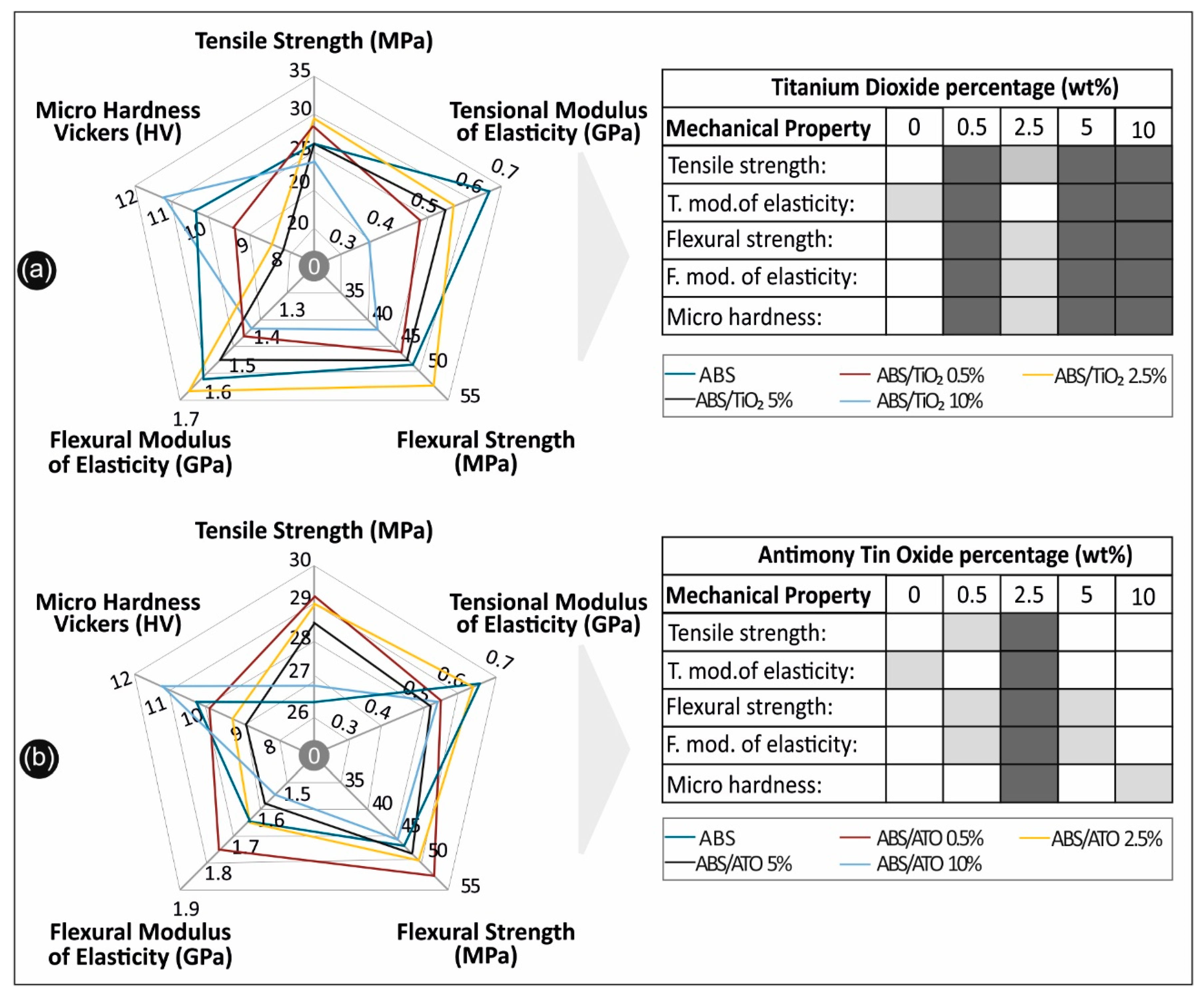

3.6. Tensile Properties

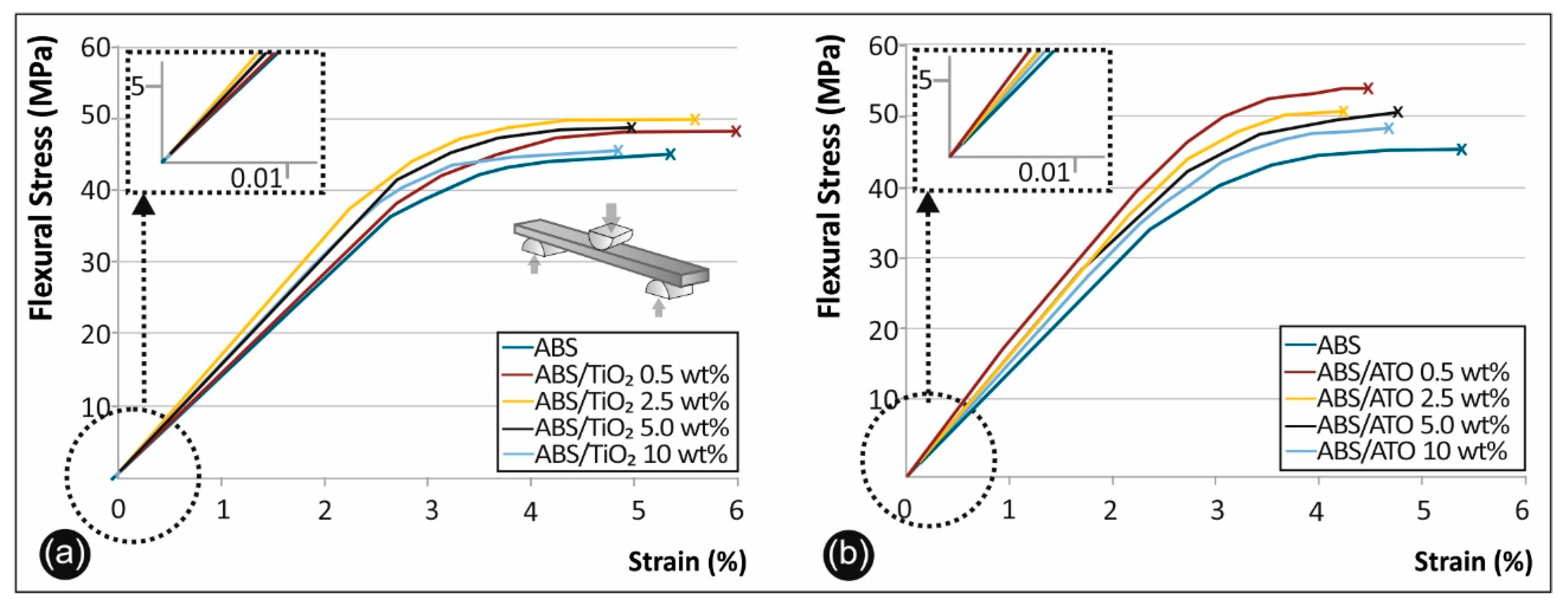

3.7. Flexural Properties

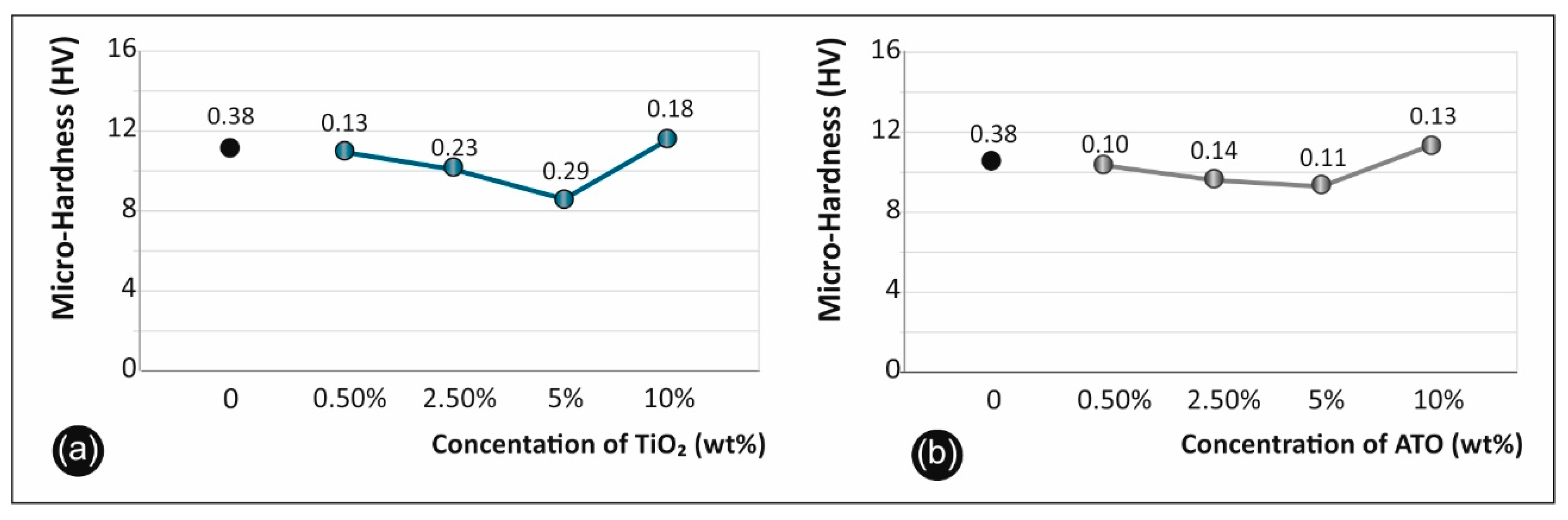

3.8. Micro-Hardness Results

4. Discussion

4.1. Structural and Compositional Characterization

4.2. AFM Nanoparticle Size Analysis

4.3. Raman Analysis

4.4. Thermal Analysis

4.5. Tensile Test Results

4.6. Flexural Test Results

4.7. Micro-Hardness Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Tech. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Ivanova, O.; Williams, C.; Campbell, T. Additive manufacturing (AM) and nanotechnology promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Miller, J.S.; Stevens, K.R.; Yang, M.T. Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues. Nat. Mater. 2012, 11, 768–774. [Google Scholar] [CrossRef] [PubMed]

- Skorski, M.; Esenther, J.; Ahmed, Z.; Miller, A.; Hartings, M. The chemical, mechanical, and physical properties of 3D printed materials composed of TiO2-ABS nanocomposites. Sci. Technol. Adv. Mater. 2016, 89, 89–97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Klein, J.; Stern, M.; Franchin, G. Additive Manufacturing of Optically Transparent Glass. 3D Print. Addit. Manuf. 2015, 2, 92–105. [Google Scholar] [CrossRef]

- Lewis, G.K.; Schlienger, E. Practical considerations and capabilities for laser assisted direct metal deposition. Mater. Des. 2000, 21, 417–423. [Google Scholar] [CrossRef]

- Yadoji, P.; Peelamedu, R.; Agrawal, D.; Roy, R. Microwave sintering of Ni-Zn ferrites: Comparison with conventional sintering. Mat. Sci. Eng. B-Solid State Mater. Adv. Tech. 2003, 98, 269–278. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Vidakis, N.; Vairis, A.; Petousis, M.; Savvakis, K.; Kechagias, J. Fused Deposition Modelling Parts Tensile Strength Characterisation. Acad. J. Manuf. Eng. 2016, 14, 87–94. [Google Scholar]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Experimental investigation and empirical modeling of FDM process for compressive strength improvement. J. Adv. Res. 2012, 3, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Rodrõ, Â.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Experimental investigation. Rapid Prototyp. J. 2001, 7, 148–158. [Google Scholar]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modelling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Koudoumas, E.; Kenanakis, G. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile–Butadiene–Styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020, 29, 1909–1918. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A Parametric Determination of Bending and Charpy’s impact strength of ABS and ABS-plus Fused Deposition Modeling Specimens. Prog. Addit. Manuf. J. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. On the compressive behavior of an FDM steward platform part. J. Comput. Des. Eng. 2017, 4, 339–346. [Google Scholar] [CrossRef]

- Vairis, A.; Petousis, M.; Vidakis, N.; Savvakis, K. On the Strain Rate Sensitivity of Abs and Abs Plus Fused Deposition Modelling Parts. J. Mater. Eng. Perform. 2016, 25, 3558–3565. [Google Scholar] [CrossRef]

- Magallón-Cacho, L.; Pérez-Bueno, J.J.; Meas-Vong, Y.; Stremsdoerfer, G.; Espinoza-Beltrán, F.J. Surface modification of acrylonitrile-butadiene-styrene (ABS) with heterogeneous photocatalysis (TiO2) for the substitution of the etching stage in the electroless process. Surf. Coat. Technol. 2011, 206, 1410–1415. [Google Scholar] [CrossRef]

- Salahuddin, N.; Abdelwahab, M.; Gaber, M.; Elneanaey, S. Synthesis and Design of Norfloxacin drug delivery system based on PLA/TiO2 nanocomposites: Antibacterial and antitumor activities. Mater. Sci. Eng. C 2020, 108, 110337. [Google Scholar] [CrossRef]

- Li, G.; Gray, K.A. Preparation of mixed-phase titanium dioxide nanocomposites via solvothermal processing. Chem. Mater. 2007, 19, 1143–1146. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO2 grafted flax fibers. Mater. Des. 2016, 106, 295–304. [Google Scholar] [CrossRef]

- Evora, V.M.F.; Shukla, A. Fabrication, characterization, and dynamic behavior of polyester/TiO2 nanocomposites. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 361, 358–366. [Google Scholar] [CrossRef]

- Torrado, P.A.; Roberson, D.; Wicker, R. Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Kim, J.; Van der Bruggen, B. The use of nanoparticles in polymeric and ceramic membrane structures: Review of manufacturing procedures and performance improvement for water treatment. Environ. Pollut. 2010, 158, 2335–2349. [Google Scholar] [CrossRef] [PubMed]

- Nussbaumer, R.J.; Caseri, W.R.; Smith, P.; Tervoort, T. Polymer-TiO2 nanocomposites: A route towards visually ransparent broadband UV filters and high refractive index materials. Macromol. Mater. Eng. 2003, 288, 44–49. [Google Scholar] [CrossRef]

- Luo, Y.B.; Li, W.D.; Wang, X.L.; Xu, D.Y.; Wang, Y.Z. Preparation and properties of nanocomposites based on poly(lactic acid) and functionalized TiO2. Acta Mater. 2009, 57, 3182–3191. [Google Scholar] [CrossRef]

- Viskadourakis, Z.; Sevastaki, M.; Kenanakis, G. 3D structured nanocomposites by FDM process: A novel approach for large-scale photocatalytic applications. Appl. Phys. A Mater. Sci. Process. 2018, 124, 1–8. [Google Scholar] [CrossRef]

- Hoflund, G.B.; Cox, D.F.; Woodson, G.L.; Laitinen, H.A. Surface characteristics of antimony-doped tin oxide films. Thin Solid Films 1981, 78, 357–363. [Google Scholar] [CrossRef]

- Egdell, R.G.; Flavell, W.R.; Tavener, P. Antimony-doped tin (IV) oxide: Surface composition and electronic structure. J. Solid State Chem. 1984, 51, 345–354. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Pan, W.; Zou, H. Characterization of PAN/ATO nanocomposites prepared by solution blending. Bull. Mater. Sci. 2008, 31, 807–811. [Google Scholar] [CrossRef]

- Pan, W.; He, X.; Chen, Y. Preparation and characterization of poly (vinyl alcohol)/antimony-doped tin oxide nanocomposites. Int. J. Polym. Mater. Polym. Biomater. 2011, 60, 223–232. [Google Scholar]

- ASTM D638-02a. Standard Test. Method for Tensile Properties of Plastics; American Society for Testing and Materials International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM D790-10. Standard Test. Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; American Society for Testing and Materials International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM D384-11. Standard Test. Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; American Society for Testing and Materials International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Hirata, T.; Ishioka, K.; Kitajima, M.; Doi, H. Concentration dependence of optical phonons in the in the TiO2-SnO2 system. Phys. Rev. B 1996, 53, 8442–8448. [Google Scholar] [CrossRef]

- Costa, I.M.; Colmenares, Y.N.; Pizani, P.S.; Leite, E.R.; Chiquito, A.J. Sb doping of VLS synthesized SnO2 nanowires probed by Raman and XPS spectroscopy. Chem. Phys. Lett. 2018, 695, 125–130. [Google Scholar] [CrossRef]

- Stroppa, D.G.; Montoro, L.A.; Beltrán, A.; Conti, T.G.; da Silva, R.O.; Andrés, J.; Longo, E.; Leite, E.R.; Ramirez, A.J. Unveiling the Chemical and Morphological Features of Sb−SnO2 Nanocrystals by the Combined Use of High-Resolution Transmission Electron Microscopy and ab Initio Surface Energy Calculations. J. Am. Chem. Soc. 2009, 131, 14544–14548. [Google Scholar] [CrossRef]

- Jyoti, J.; Babal, A.S.; Sharma, S.; Dhakate, S.R.; Singh, B.P. Significant improvement in static and dynamic mechanical properties of graphene oxide–carbon nanotube acrylonitrile butadiene styrene hybrid composites. J. Mater. Sci. 2018, 53, 2520–2536. [Google Scholar] [CrossRef]

- Soundararajan, R.; Jayasuriya, N.; Vishnu, R.G.G.; Prassad, B.G.; Pradeep, C. Appraisal of mechanical and tribological properties on PA6-TiO2 composites through fused deposition modelling. Mater. Today Proc. 2019, 18, 2394–2402. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Mascolo, I.; Modano, M. On the applicability of composite PA6-TiO2 filaments for the rapid prototyping of innovative materials and structures. Compos. Part. B Eng. 2018, 143, 132–140. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Hamming, L.M.; Qiao, R.; Messersmith, P.B.; Brinson, L.C. Effects of dispersion and interfacial modification on the macroscale properties of TiO2 polymer matrix nanocomposites. Compos. Sci Tech. 2009, 69, 1880–1886. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Kenanakis, G.; Romanitan, C.; Tutunaru, O.; Suchea, M.; Kechagias, J. The Mechanical and Physical Properties of 3D-Printed Materials Composed of ABS-ZnO Nanocomposites and ABS-ZnO Microcomposites. Micromachines 2020, 11, 615. [Google Scholar] [CrossRef] [PubMed]

- Maniadi, A.; Vidakis, N.; Petousis, M.; Vamvakaki, M.; Suchea, M.; Koudoumas, E. Graphene based polymer nanocomposites for electrical power systems. In Proceedings of the 3rd Autumn School on Physics of Advanced Materials (PAMS-3), Heraklion, Crete, Greece, 22–28 September 2018. [Google Scholar]

- Maniadi, A.; Vidakis, N.; Petousis, M.; Kenanakis, G.; Vamvakaki, M.; Pachiu, C.; Popescu, M.; Suchea, M.; Koudoumas, E. Graphite nanoplatelets/polymer nanocomposites: Basic characteristics and functional behavior of low density polyethylene. In Proceedings of the 12th International Conference on Physics of Advanced Materials (ICPAM-12), Crete, Greece, 22–28 September 2018. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers 2020, 12, 1589. https://doi.org/10.3390/polym12071589

Vidakis N, Petousis M, Maniadi A, Koudoumas E, Liebscher M, Tzounis L. Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers. 2020; 12(7):1589. https://doi.org/10.3390/polym12071589

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Athena Maniadi, Emmanuel Koudoumas, Marco Liebscher, and Lazaros Tzounis. 2020. "Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites" Polymers 12, no. 7: 1589. https://doi.org/10.3390/polym12071589

APA StyleVidakis, N., Petousis, M., Maniadi, A., Koudoumas, E., Liebscher, M., & Tzounis, L. (2020). Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers, 12(7), 1589. https://doi.org/10.3390/polym12071589