Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview

Abstract

1. The Birth of a Novel Class of Composite Materials

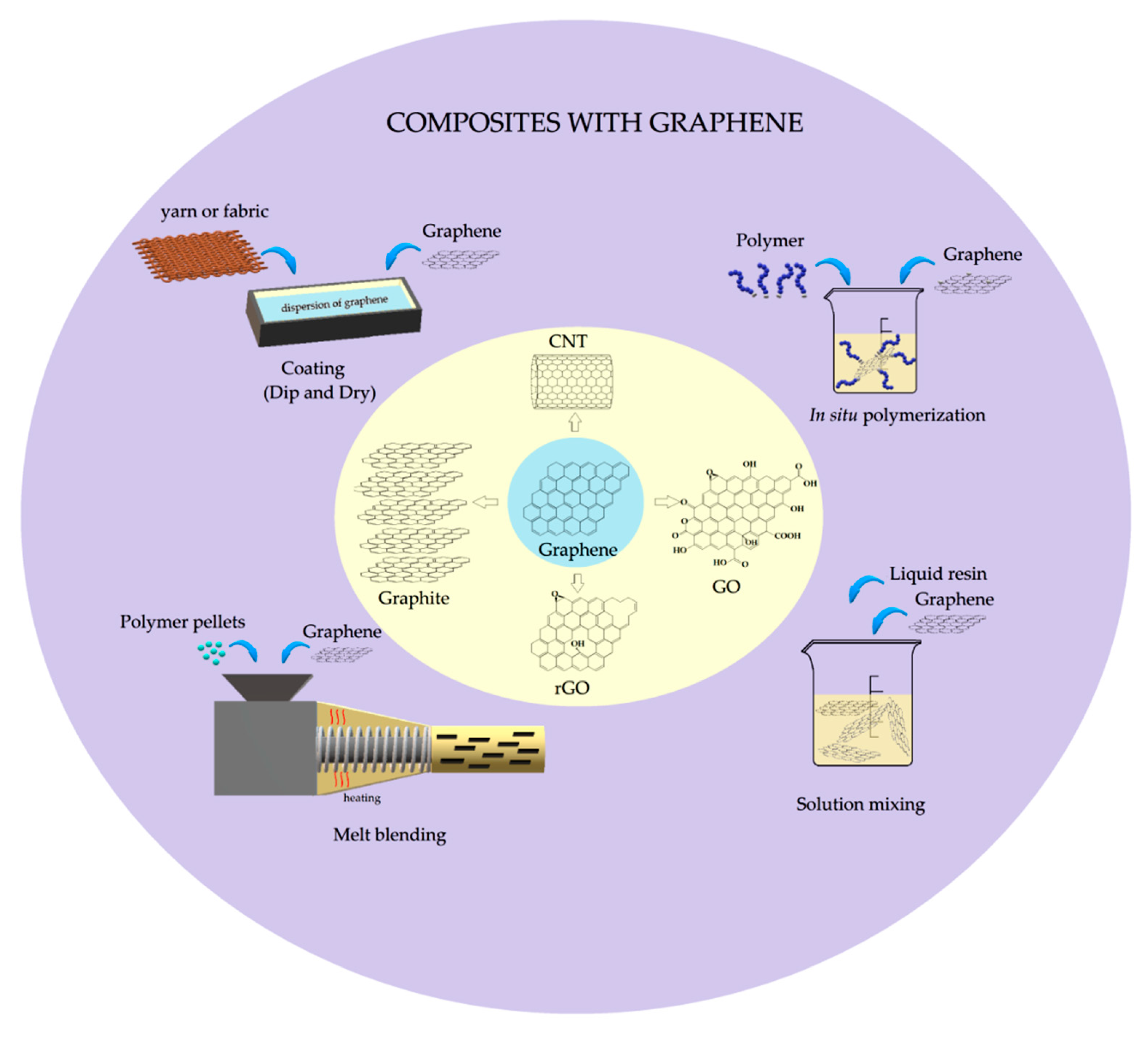

2. Graphene-Based Materials

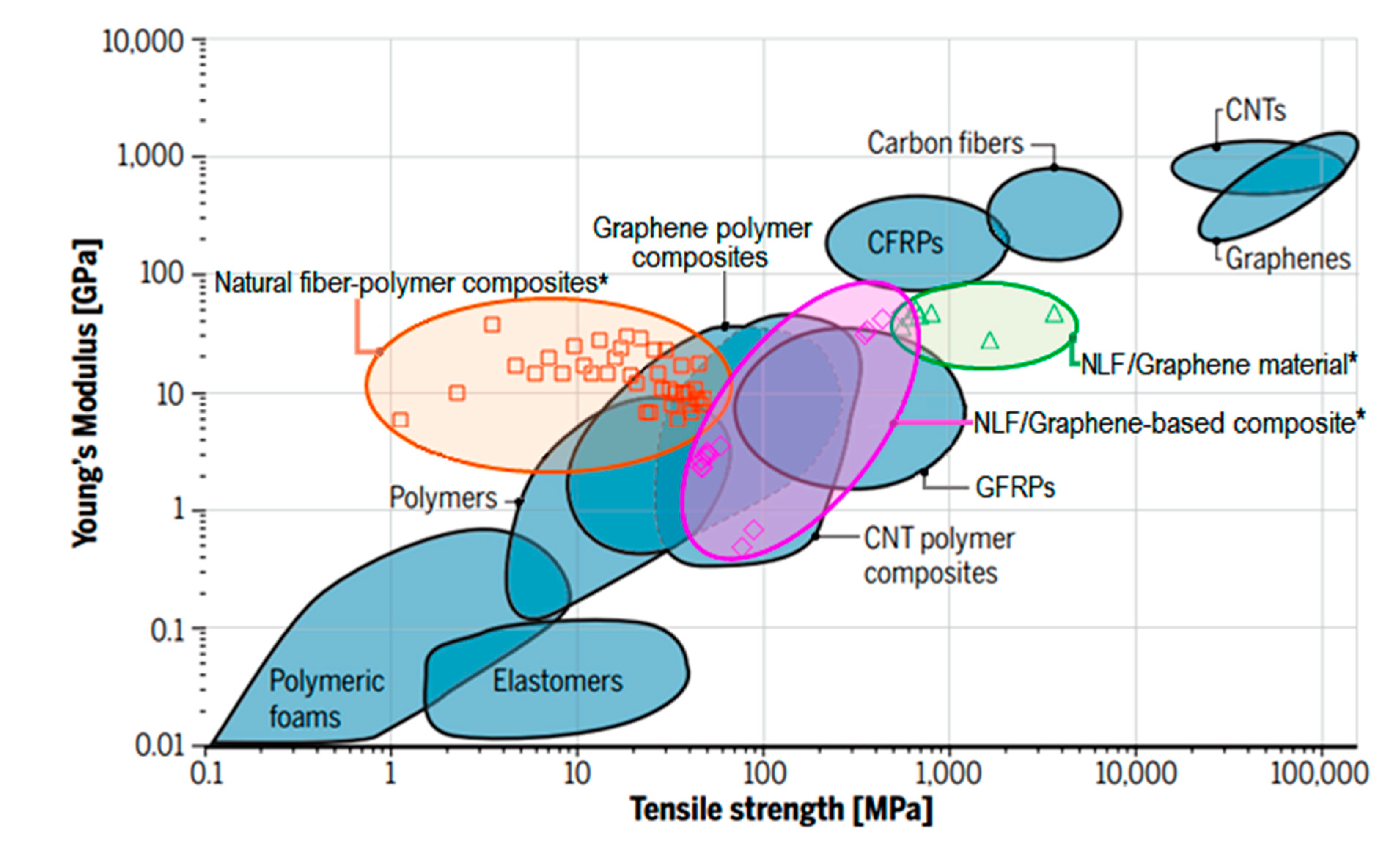

3. Composites with Graphene-Based Materials

4. Properties of Graphene Incorporated NLF Composites

4.1. Graphene as a Filler in Natural Fiber Polymer Composites

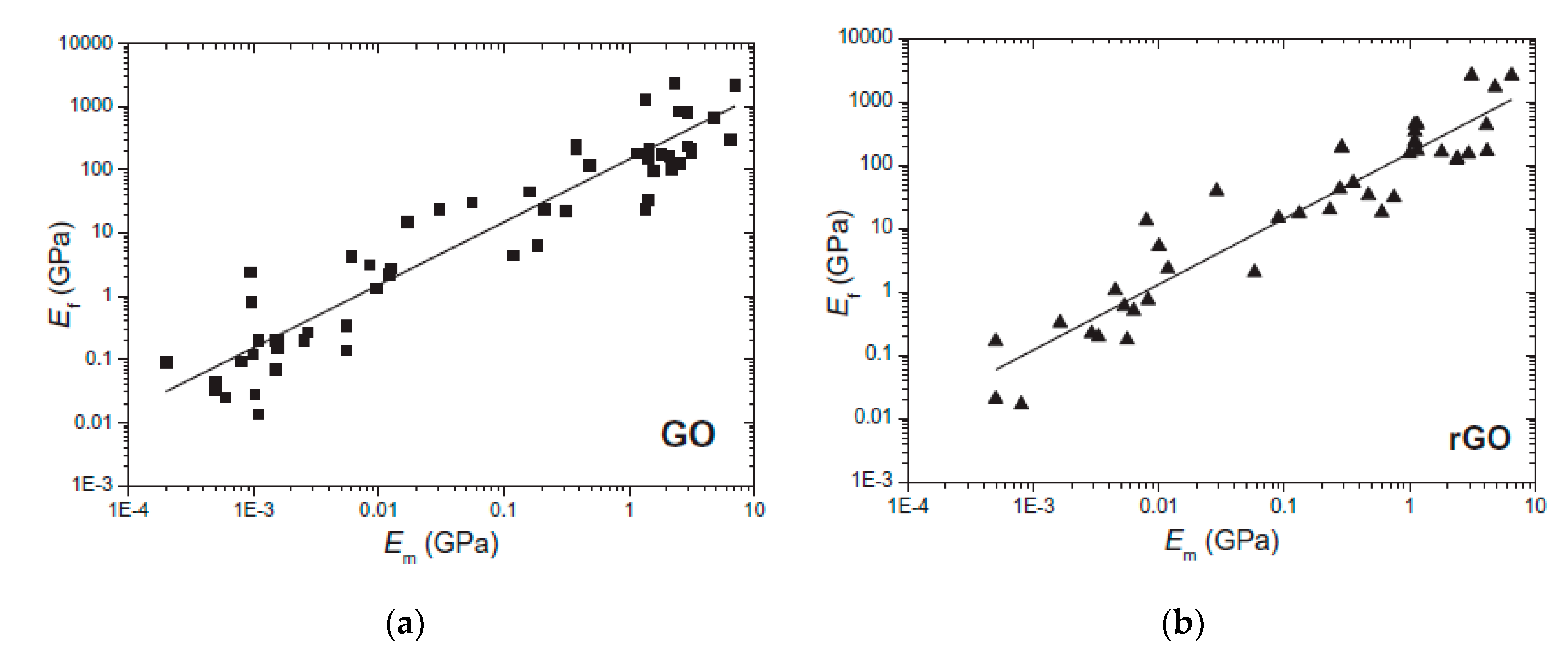

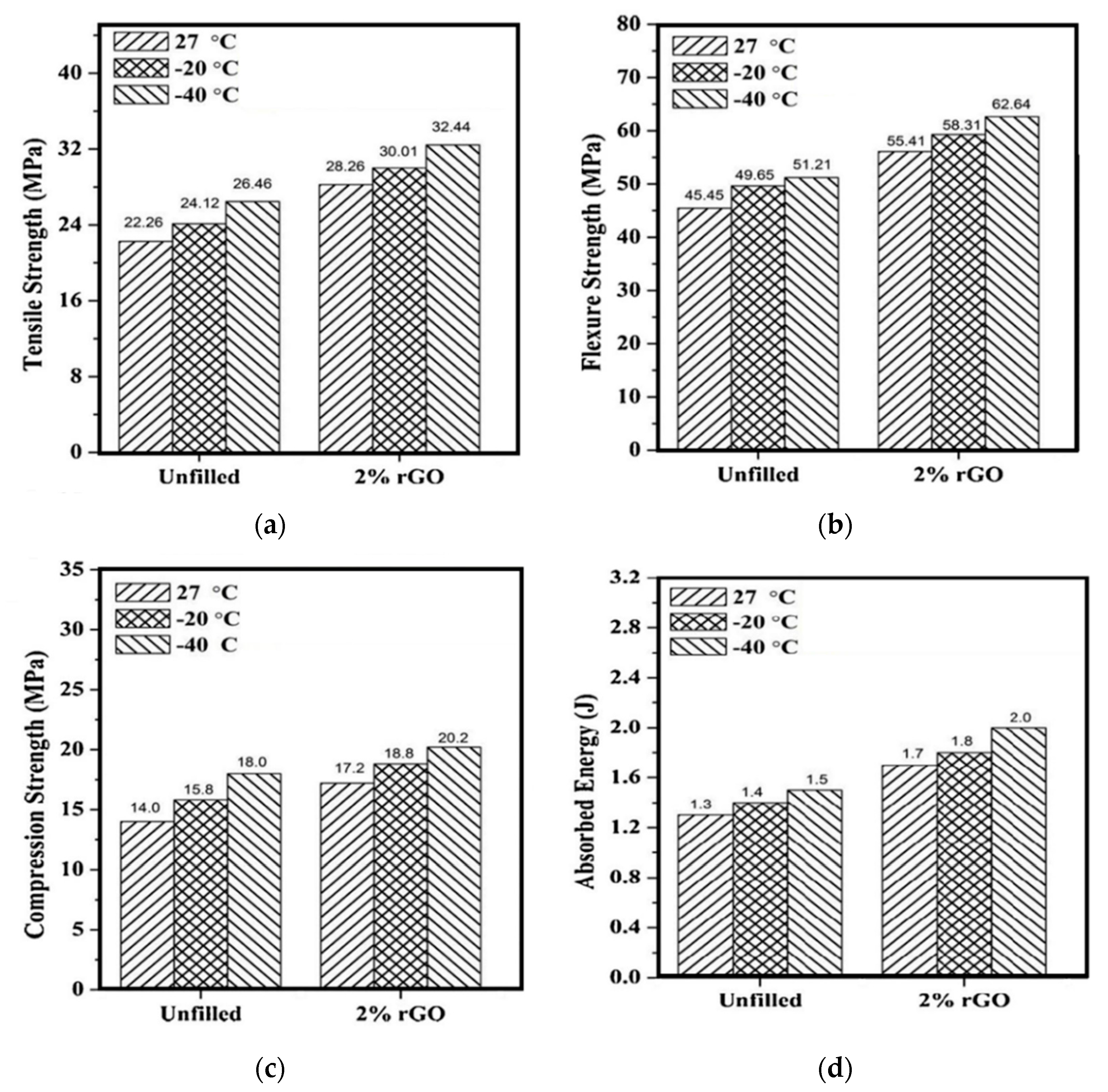

4.1.1. Mechanical Properties

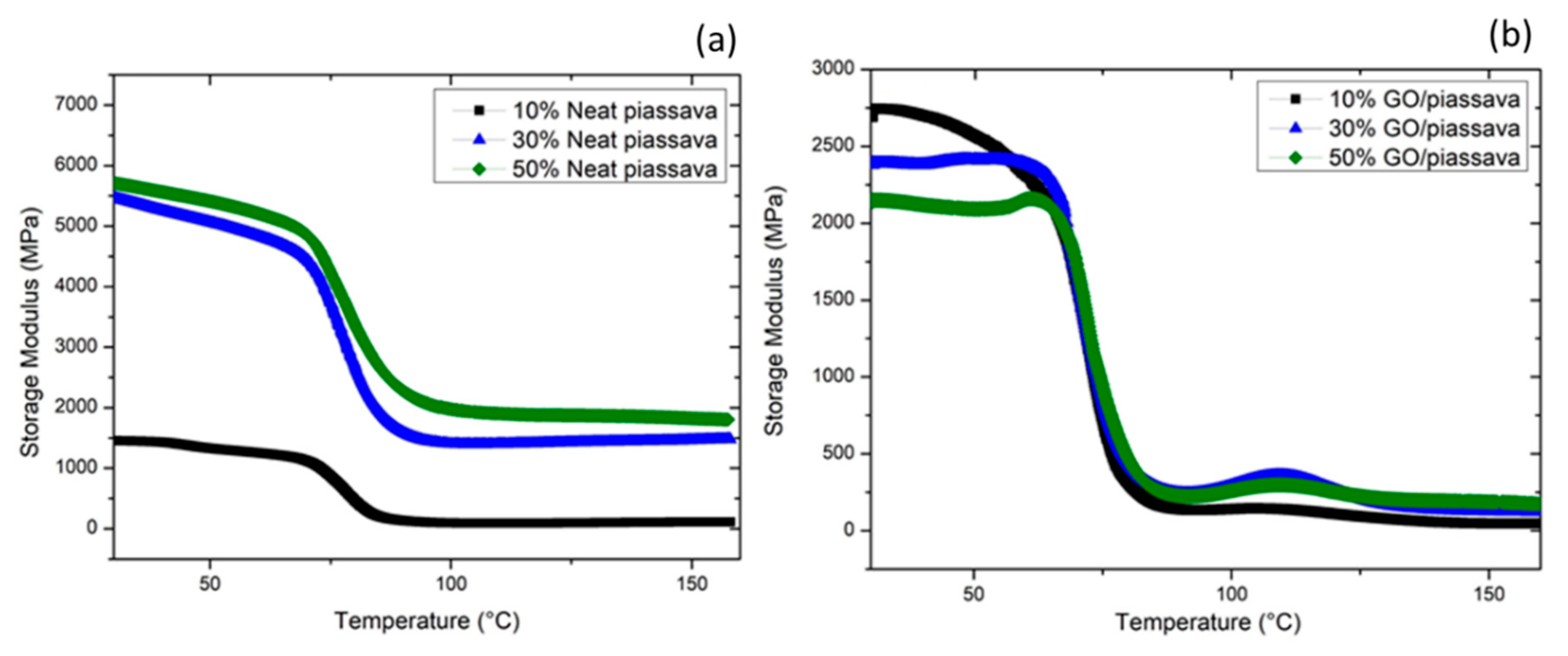

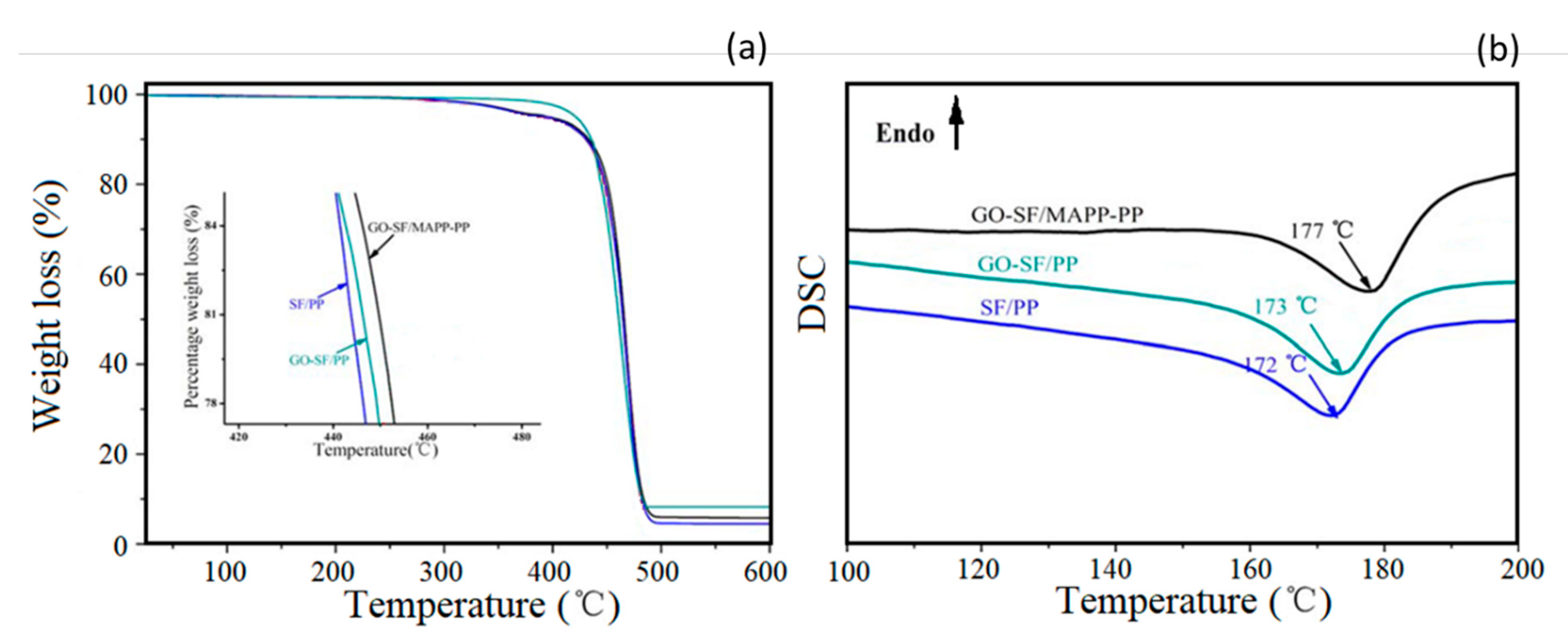

4.1.2. Thermal Properties

4.2. Natural Fibers Coated with Graphene as Reinforcement of Polymer Composites

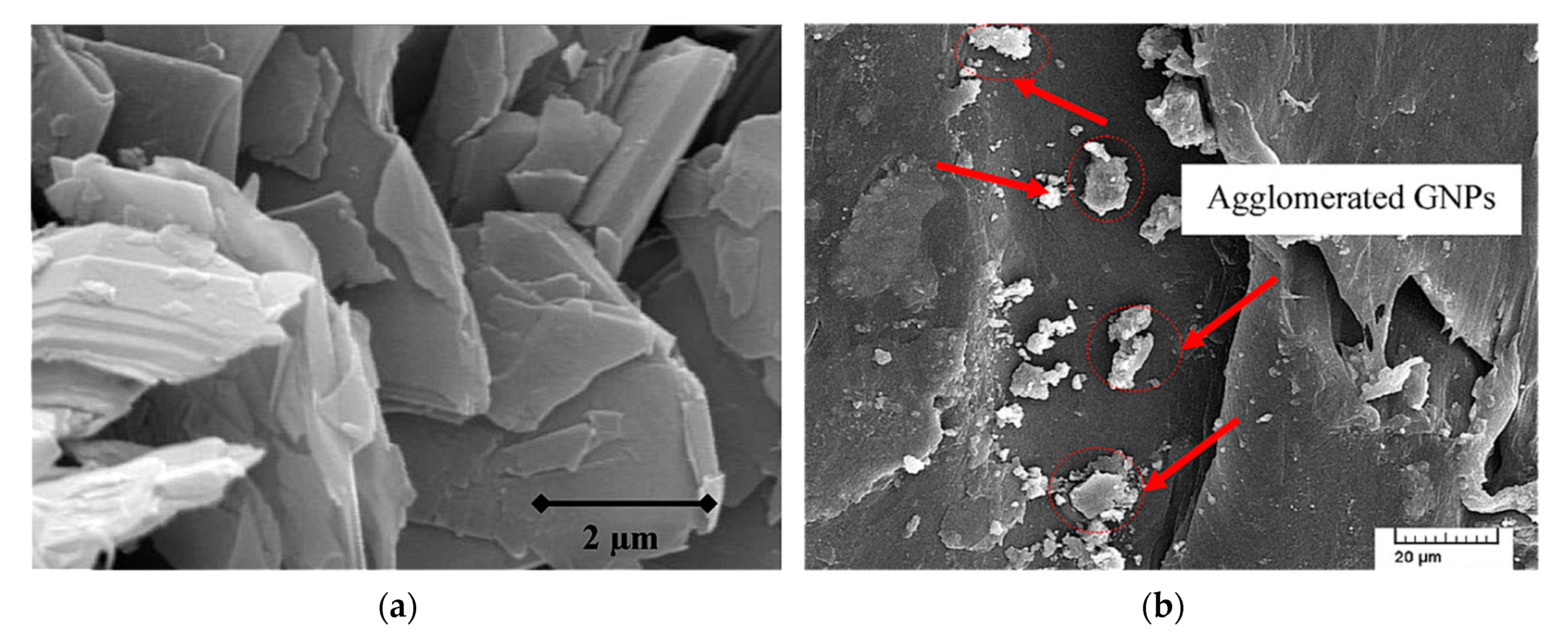

4.2.1. Mechanical Properties

- Strong adhesion between the GO and alkali treated fiber; and

- Interaction of GO treated jute fiber with the matrix. The oxygen containing functional groups present in GO could create strong bond with the alkali treated fibers to make them capable of carrying more load from the matrix.

4.2.2. Thermal Properties

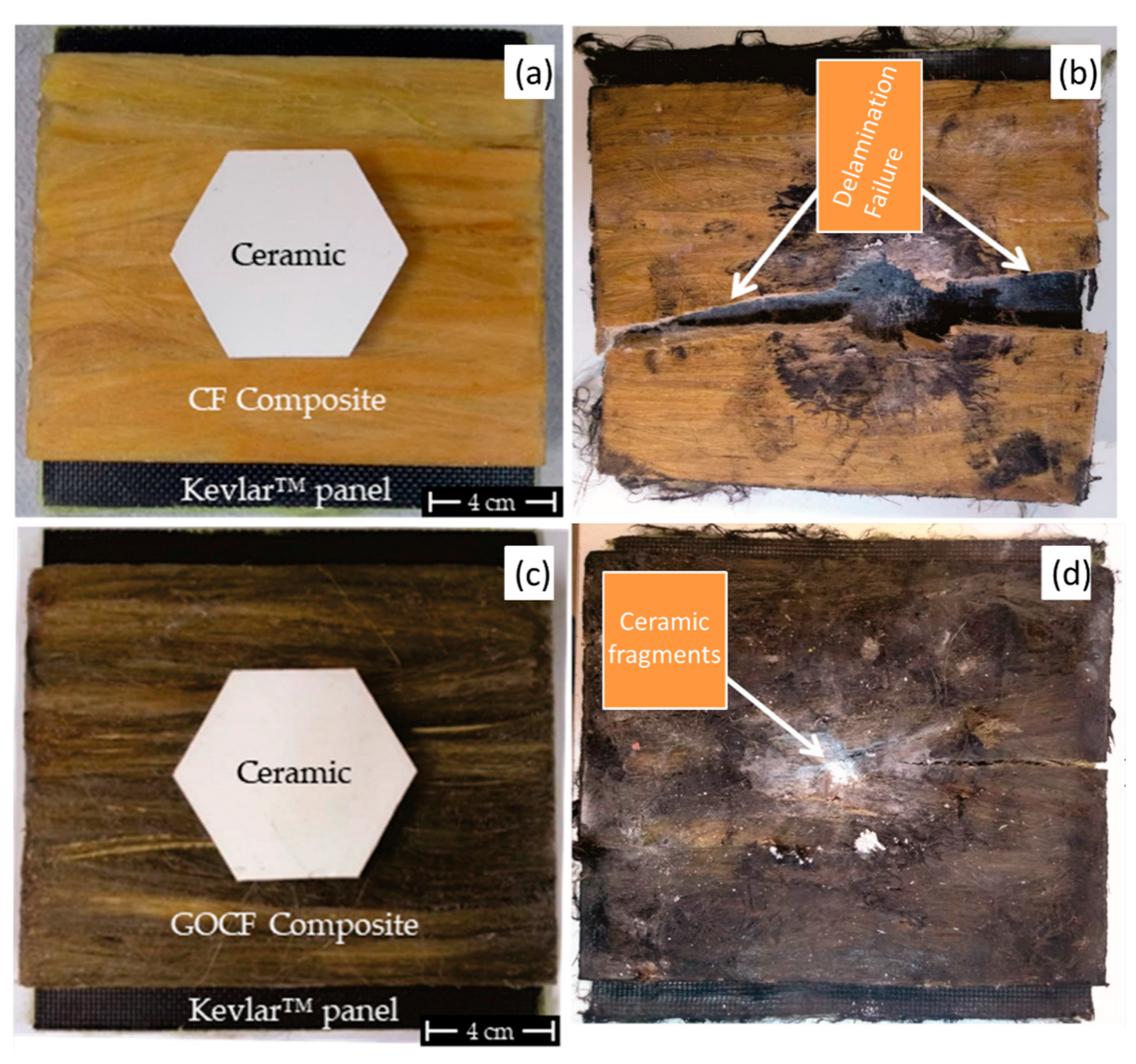

4.2.3. Ballistic Performance

4.2.4. Other Characteristics

5. Applications and Future Trends of Graphene Incorporated NLF Composites

5.1. Electronic Textiles

5.2. Gas Sensor

6. Final Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- GIATEC. Available online: https://www.giatecscientific.com/education/the-history-of-concrete/ (accessed on 13 June 2020).

- Oda, J. Optimization Procedure for material composition of composite material structure. In Proceedings of the International Symposium on Optimum Structural Design, Tucson, AZ, USA, 19–22 October 1918. [Google Scholar]

- Scopus. Available online: www.scopus.com/search/form.uri#basic (accessed on 13 June 2020).

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering, 8th ed.; John Wiley & Sons: New York, NY, USA, 2011; pp. 344–348. [Google Scholar]

- Arche, G. Fiber polymer composite flexible insulating materials. Plast. Electric. Insul. 1968, 173–182. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-0014364149&origin=resultslist&sort=plf-t&src=s&st1=%22polymer+composites%22+and+fiber&nlo=&nlr=&nls=&sid=b585d40bdf4b01c867519cc950dde139&sot=b&sdt=b&sl=45&s=TITLE-ABS-KEY%28%22polymer+composites%22+and+fiber%29&relpos=0&citeCnt=0&searchTerm= (accessed on 25 June 2020).

- National Research Council. High-Performance Synthetic Fibers for Composites; National Academy Press: Washington, DC, USA, 1992; pp. 9–20. [Google Scholar]

- Kumar, R.; Ul-Haq, M.I.; Raina, A.; Anand, A. Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. Int. J. Sustain. Eng. 2019, 12, 212–220. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- Güven, O.; Monteiro, S.N.; Moura, E.A.; Drelich, J.W. Re-emerging field of lignocellulosic fiber–polymer composites and ionizing radiation technology in their formulation. Polym. Rev. 2016, 56, 702–736. [Google Scholar] [CrossRef]

- Dunne, R.; Desai, D.; Sadiku, R.; Jayaramudu, J. A review of natural fibres, their sustainability and automotive applications. J. Reinf. Plast. Compos. 2016, 35, 1041–1050. [Google Scholar] [CrossRef]

- Thomas, N.; Paul, S.A.; Pothan, L.A.; Deepa, B. Natural fibers: Structure, properties and applications. In Cellulose Fibers: Bio-and Nano-Polymer Composites; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: Berlin, Germany, 2011; pp. 3–42. [Google Scholar]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Da Silva, I.L.A.; Da Costa, L.L. Natural lignocellulosic fibers as engineering materials—An overview. Met. Mater. Trans. A 2011, 42, 2963. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural-fiber polymer-matrix composites: Cheaper, tougher, and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, P.R.; Lin, S.; Chen, H.; Johnson, K.; Wang, R.; Borges, W.; Zhan, C.; Hsiao, B.S. Reinforcement of Natural Rubber Latex Using Jute Carboxycellulose Nanofibers Extracted Using Nitro-Oxidation Method. Nanomaterials 2020, 10, 706. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.C.; Nascimento, L.F.C.; da Luz, F.S.; da Silva, L.C.; dos Santos, J.L.; Garcia Filho, F.C.; de Assis, F.S.; Lima, E.P., Jr.; et al. Natural Fibers Reinforced Polymer Composites Applied in Ballistic Multilayered Armor for Personal Protection—An Overview. In Green Materials Engineering; Ikhmayies, S., Li, J., Vieira, C.M.F., Margem, J.I., de Oliviera, F.B., Eds.; Springer: Cham, Switzerland, 2019; pp. 33–47. [Google Scholar]

- Luz, F.S.; Lima, E.P., Jr.; Louro, L.H.L.; Monteiro, S.N. Ballistic Test of Multilayered Armor with Intermediate Epoxy Composite Reinforced with Jute Fabric. Mater. Res. 2015, 18, 170–177. [Google Scholar] [CrossRef]

- Assis, F.S.; Pereira, A.C.; Garcia Filho, F.C.; Lima, E.P., Jr.; Monteiro, S.N.; Weber, R.P. Performance of jute non-woven mat reinforced polyester matrix composite in multilayered armor. J. Mater. Res. Technol. 2018, 7, 535–540. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Louro, L.H.L.; Monteiro, S.N.; Lima, E.P., Jr.; Luz, F.S. Mallow Fiber-Reinforced Epoxy Composites in Multilayered Armor for Personal Ballistic Protection. JOM 2017, 69, 2052–2056. [Google Scholar] [CrossRef]

- Luz, F.S.; Monteiro, S.N.; Lima, E.S.; Lima, E.P.; Lima, E.P., Jr. Ballistic application of coir fiber reinforced epoxy composite in multilayered armor. Mater. Res. 2018, 20, 23–28. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Assis, F.S.; Ferreira, C.L.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Lopera, H.A.C.; Pereira, A.C. Fique Fabric: A promising reinforcement for polymer composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [PubMed]

- Braga, F.O.; Bolzan, L.T.; Ramos, F.J.H.T.V.; Monteiro, S.N.; Lima, E.P., Jr.; Silva, L.C. Ballistic efficiency of multilayered armor systems with sisal fiber polyester composites. Mater. Res. 2018, 20, 767–774. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Monteiro, S.N. Piassava Fiber as an Epoxy Matrix Composite Reinforcement for Ballistic Armor Applications. JOM 2019, 71, 801–808. [Google Scholar] [CrossRef]

- Sharma, P.R.; Sharma, S.K.; Antoine, R.; Hsiao, B.S. Efficient removal of arsenic using zinc oxide nanocrystal-decorated regenerated microfibrillated cellulose scaffolds. ACS Sustain. Chem. Eng. 2019, 7, 6140–6151. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Sharma, S.K.; Geng, L.; Amiralian, N.; Martin, D.; Hsiao, B.S. Nanocellulose from spinifex as an effective adsorbent to remove cadmium(II) from water. ACS Sustain. Chem. Eng. 2018, 6, 3279–3290. [Google Scholar] [CrossRef]

- Sharma, P.R.; Joshi, R.; Sharma, S.K.; Hsiao, B.S. A simple approach to prepare carboxycellulose nanofibers from untreated biomass. Biomacromolecules 2017, 18, 2333–2342. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Raw natural fiber–based polymer composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Franck, R.R. Bast and Other Plant Fibres; CRC Press: Boca Raton, FL, USA, 2005; pp. 1–385. [Google Scholar]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Godara, S.S. Effect of chemical modification of fiber surface on natural fiber composites: A review. Mater. Today Proc. 2019, 18, 3428–3434. [Google Scholar]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites: A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

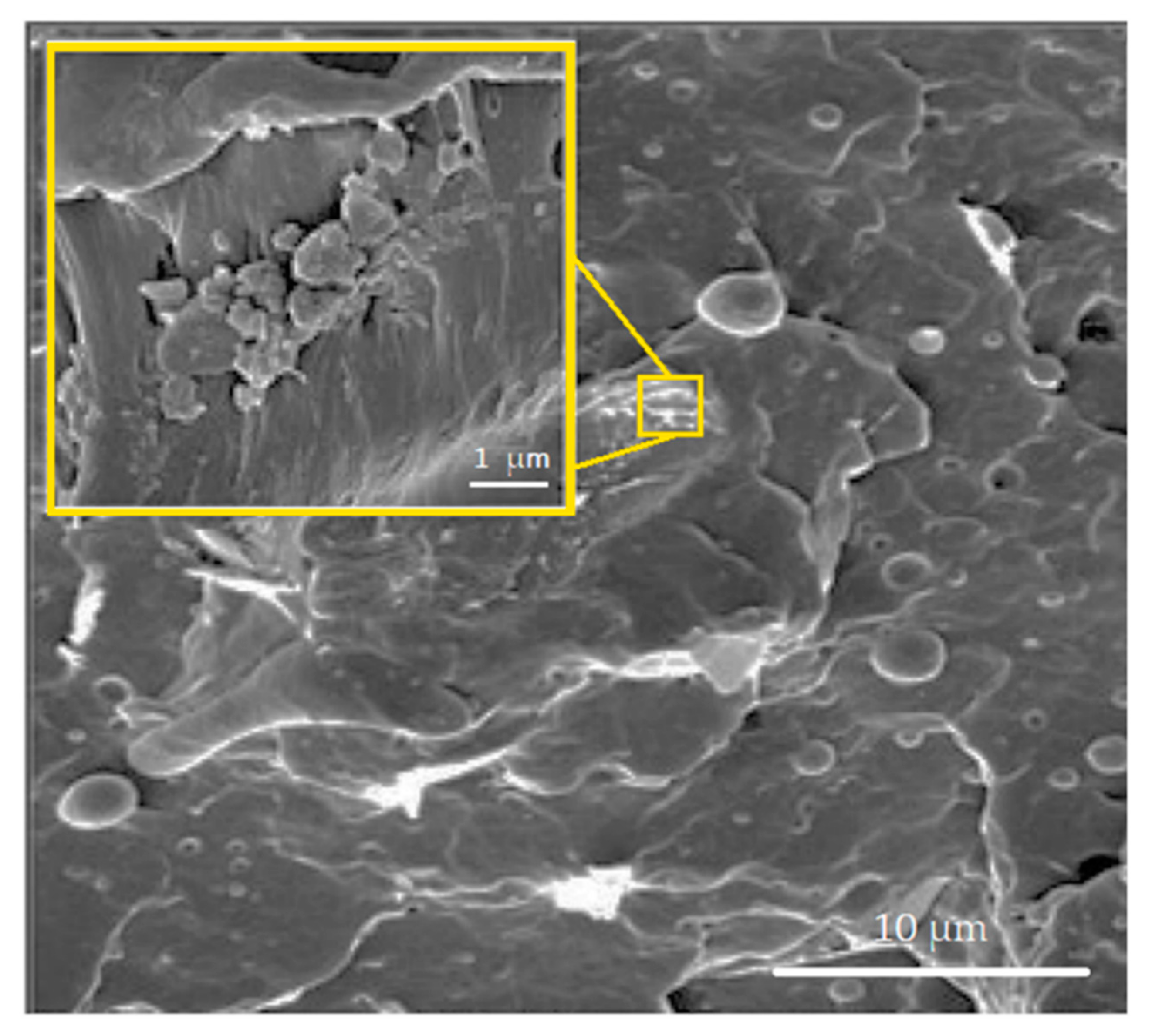

- Garcia Filho, F.C.; Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- Afroj, S.; Tan, S.; Abdelkader, A.M.; Novoselov, K.S.; Karim, N. Highly Conductive, Scalable, and Machine Washable Graphene-Based E-Textiles for Multifunctional Wearable Electronic Applications. Adv. Funct. Mater. 2020, 2000293. [Google Scholar] [CrossRef]

- Allahbakhsh, A. PVC/rice straw/SDBS-modified graphene oxide sustainable Nanocomposites: Melt mixing process and electrical insulation characteristics. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105902. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Liang, W.; Wang, J.; Chen, Y. Improved mechanical properties of the graphene oxide modified bamboo-fiber-reinforced polypropylene composites. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Saraswati, P.K.; Sahoo, S.; Parida, S.P.; Jena, P.C. Fabrication, characterization and drilling operation of natural fiber reinforced hybrid composite with filler (Fly-ash/graphene). Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1653–1659. [Google Scholar]

- Agarwal, C.; Singh, M.N.; Sharma, R.K.; Sagdeo, A.; Csóla, L. In situ green synthesis and functionalization of reduced graphene oxide on cellulose fibers by cannabis sativa L. extract. Mater. Perform. Charact. 2019, 8, 518–531. [Google Scholar] [CrossRef]

- Banapurmath, N.R.; Hallad, S.A.; Hunashyal, A.M.; Sajjan, A.M.; Shettar, A.S.; Ayachit, N.H.; Godi, M.T. Nanocomposites for structural and energy applications. In Handbook of Ecomaterials; Martinez, L.M.T., Ed.; Springer International Publishing: New York, NY, USA, 2019; Volume 2, pp. 854–883. [Google Scholar]

- Khalili, P.; Blinzler, B.; Kádár, R.; Bisschop, R.; Försth, M.; Blomqvist, P. Flammability, smoke, mechanical behaviours and morphology of flame retarded natural fibre/Elium® composite. Materials 2019, 12, 2648. [Google Scholar] [CrossRef]

- Zakaria, N.E.; Ahmad, I.; Busu, W.N.W.; Khalid, K.H.; Baharum, A. Effects of addition graphene nanoplatlet on the mechanical properties and thermal hybrid composite fibre Sansevieria natural rubber-high density polyethylene. Sains Malays. 2019, 48, 1121–1128. [Google Scholar] [CrossRef]

- Prasob, P.A.; Sasikumar, M. Viscoelastic and mechanical behaviour of reduced graphene oxide and zirconium dioxide filled jute/epoxy composites at different temperature conditions. Mater. Today Commun. 2019, 19, 252–261. [Google Scholar]

- Sarker, F.; Potluri, P.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Karim, N. Ultrahigh Performance of Nanoengineered Graphene-Based Natural Jute Fiber Composites. ACS Appl. Mater. Interfaces 2019, 11, 21166–21176. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Monteiro, S.N.; Luz, F.S.; Pinheiro, W.A.; Garcia Filho, F.C. Effect of graphene oxide coating on natural fiber composite for multilayered ballistic armor. Polymers 2019, 11, 1356. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-performance graphene-based natural fiber composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Lv, W.; Wang, C.C. Graphene oxide decorated sisal fiber/MAPP modified PP composites:Towards high-performance biocomposites. Polym. Compos. 2018, 39, e113–e121. [Google Scholar] [CrossRef]

- Mohan, V.B.; Jayaraman, K.; Bhattacharyya, D. Fabrication of highly conductive graphene particle-coated fiber yarns using polymeric binders through efficient coating techniques. Adv. Polym. Technol. 2018, 37, 3438–3447. [Google Scholar] [CrossRef]

- Veerapuram, S.; Nambi, M.; Thimmarayan, R. Experimental Investigation of Drilling Characteristics of Jute Fiber Reinforced Graphene Filled Epoxy Nanocomposites. Polymers 2018, 42, 603–609. [Google Scholar] [CrossRef]

- Hallad, S.A.; Banapurmath, N.R.; Patil, V.; Ajarekar, V.S.; Patil, A.; Godi, M.T.; Shettar, A.S. Graphene Reinforced Natural Fiber Nanocomposites for Structural Applications. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Advances in Manufacturing, Materials and Energy Engineeing, Karnataka, India, 2–3 March 2018; IOP Publishing Ltd.: Bristol, UK, 2018; p. 012072. [Google Scholar]

- Kumar, S.C.R.; Shivanand, H.K.; Vidayasagar, H.N.; Nagabhushan, V. Studies on mechanical properties of graphene based hybrid composites reinforced with kenaf/glass fiber. AIP Conf. Proc. 2018, 1943, 020115. [Google Scholar]

- Abdellaoui, H.; Raji, M.; Essabir, H.; Bouhfid, R.; Qaiss, A.E.K. Mechanical behavior of carbon/natural fiber-based hybrid composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid. Composites, 1st ed.; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 103–122. [Google Scholar]

- Jayaseelan, J.; Vijayakumar, K.R.; Ethiraj, N.; Sivabalan, T.; Andrew Nallayan, W. The effect of fibre loading and graphene on the mechanical properties of goat hair fibre epoxy composite. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Material Engineering and Advanced Technology, Busan, Korea, 25–27 August 2017; IOP Publishing Ltd.: Bristol, UK, 2017; p. 012018. [Google Scholar]

- Idumah, C.I.; Hassan, A. Hibiscus Cannabinus Fiber/PP based Nano-Biocomposites Reinforced with Graphene Nanoplatelets. J. Nat. Fibers 2017, 14, 691–706. [Google Scholar] [CrossRef]

- Chang, H.-C.; Yang, S.-H.; Liao, Y.-S.; Yen, C.C.C.; Yeh, S.-K. Improving the flame retardancy of polypropylene/rice husk composites using graphene nanoplatelets and metal hydroxide flame retardants. In Proceedings of the Annual Technical Conference—ANTEC, Anaheim, CA, USA, 8–10 May 2017; pp. 636–641. [Google Scholar]

- Abdelkader, A.M.; Karim, N.; Vallés, C.; Afroj, S.; Novoselov, K.S.; Yeates, S.G. Ultraflexible and Robust Graphene Supercapacitors Printed on Textiles for Wearable Electronics Applications. 2D Mater. 2017, 4, 035016. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Kong, I.; Yeoh, C.H. The effects of graphene and flame retardants on flammability and mechanical properties of natural fibre reinforced polymer composites. Key Eng. Mater. 2016, 701, 286–290. [Google Scholar] [CrossRef]

- Kolli, B.R.S.; Lakshmankumar, A. Effect of filler material in bamboo fiber reinforced polymer composites. J. Chem. Pharm. Sci. 2016, 9, 2975–2979. [Google Scholar]

- Tshai, K.Y.; Khalili, P.; Kong, I.; Yeoh, C.H.; Tshai, K.H. Synthesization of graphene and its incorporation into natural fiber reinforced thermosetting nanocomposite. ARPN J. Eng. Appl. Sci. 2016, 11, 121–127. [Google Scholar]

- Pottathara, Y.B.; Bobnar, V.; Gorgieva, S.; Grohens, Y.; Finšgar, M.; Thomas, S.; Kokol, V. Mechanically strong, flexible and thermally stable graphene oxide/nanocellulosic films with enhanced dielectric properties. RSC Adv. 2016, 6, 49138–49149. [Google Scholar]

- Idumah, C.I.; Hassan, A. Effect of exfoliated graphite nanoplatelets on thermal and heat deflection properties of kenaf polypropylene hybrid nanocomposites. J. Polym. Eng. 2016, 36, 877–889. [Google Scholar] [CrossRef]

- Sridharan, V.; Raja, T.; Muthukrishnan, N. Study of the effect of matrix, fibre treatment and graphene on delamination by drilling jute/epoxy nanohybrid composite. Arab. J. Sci. Eng. 2016, 41, 1883–1894. [Google Scholar] [CrossRef]

- Tissera, N.D.; Wijesena, R.N.; Perera, J.R.; de Silva, K.N.; Amaratunge, G.A. Hydrophobic cotton textile surfaces using an amphiphilic graphene oxide (GO) coating. Appl. Surf. Sci. 2015, 324, 455–463. [Google Scholar] [CrossRef]

- Tian, M.; Qu, L.; Zhang, X.; Zhang, K.; Zhu, S.; Guo, X.; Han, G.; Tang, X.; Sun, Y. Enhanced mechanical and thermal properties of regenerated cellulose/graphene composite fibers. Carbohydr. Polym. 2014, 111, 456–462. [Google Scholar] [CrossRef] [PubMed]

- Chaharmahali, M.; Hamzeh, Y.; Ebrahimi, G.; Ashori, A.; Ghasemi, I. Effects of nano-graphene on the physico-mechanical properties of bagasse/polypropylene composites. Polym. Bull. 2014, 71, 337–349. [Google Scholar] [CrossRef]

- Han, S.O.; Karevan, M.; Bhuiyan, M.A.; Park, J.H.; Kalaitzidou, K. Effect of exfoliated graphite nanoplatelets on the mechanical and viscoelastic properties of poly (lactic acid) biocomposites reinforced with kenaf fibers. J. Mater. Sci. 2014, 47, 3535–3543. [Google Scholar] [CrossRef]

- Sheshmani, S.; Ashori, A.; Fashapoyeh, M.A. Wood plastic composite using graphene nanoplatelets. Int. J. Biol. Macromol. 2013, 58, 1–6. [Google Scholar] [CrossRef]

- Yang, W.; Gong, Y.; Zhao, X.; Liu, T.; Zhang, Y.; Chen, F.; Fu, Q. Strong and highly conductive graphene composite film based on the nanocellulose-assisted dispersion of expanded graphite and incorporation of poly (ethylene oxide). ACS Sustain. Chem. Eng. 2019, 7, 5045–5056. [Google Scholar] [CrossRef]

- Liu, D.; Dong, Y.; Liu, Y.; Ma, N.; Sui, G. Cellulose Nanowhisker (CNW)/Graphene Nanoplatelet (GN) Composite Films with Simultaneously Enhanced Thermal, Electrical and Mechanical Properties. Front. Mater. 2019, 6, 235. [Google Scholar] [CrossRef]

- Wang, R.; Ma, Q.; Zhang, H.; Ma, Z.; Yang, R.; Zhu, J.Y. Producing conductive graphene–nanocellulose paper in one-pot. J. Polym. Environ. 2019, 27, 148–157. [Google Scholar] [CrossRef]

- Li, D.; Muller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G.G. Processable Aqueous Dispersions of Graphene Nanosheets. Nat. Nanotechnol. 2008, 3, 101–105. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; Rodgers, P., Ed.; Nature Publishing Group: London, UK, 2010; pp. 11–19. [Google Scholar]

- Bianco, A. Graphene: Safe or toxic? The two faces of the medal. Angew. Chem. Int. Ed. 2013, 52, 4986–4997. [Google Scholar] [CrossRef] [PubMed]

- Kumar, C.V.; Pattammattel, A. Introduction to Graphene: Chemical and Biochemical Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Kinloch, I.A.; Suhr, J.; Lou, J.; Young, R.J.; Ajayan, P.M. Composites with carbon nanotubes and graphene: An outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef]

- Brodie, B.C., XIII. On the atomic weight of graphite. Philos. Trans. R. Soc. Lond. 1859, 149, 249–259. [Google Scholar]

- Shapira, P.; Go, A.; Salehi, F. Graphene enterprise: Mapping innovation and business development in a strategic emerging technology. J. Nanoparticle Res. 2016, 18, 1–24. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar]

- Wick, P.; Louw-Gaume, A.E.; Kucki, M.; Krug, H.F.; Kostarelos, K.; Fadeel, B.; Dawson, K.A.; Salvati, A.; Vazquez, E.; Ballerini, L.; et al. Classification framework for graphene-based materials. Angew. Chem. Int. Ed. 2014, 53, 7714–7718. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611. [Google Scholar] [CrossRef]

- Shams, S.S.; Zhang, R.; Zhu, J. Graphene synthesis: A Review. Mater. Sci. Pol. 2015, 33, 566–578. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Rourke, J.P.; Pandey, P.A.; Moore, J.J.; Bates, M.; Kinloch, I.A.; Young, R.J.; Wilson, N.R. The real graphene oxide revealed: Stripping the oxidative debris from the graphene-like sheets. Angew. Chem. Int. Ed. 2010, 50, 3173–3177. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef] [PubMed]

- Guerrero-Contreras, J.; Caballero-Briones, F. Graphene oxide powders with different oxidation degree, prepared by synthesis variations of the Hummers method. Mater. Chem. Phys. 2015, 153, 209–220. [Google Scholar] [CrossRef]

- Chen, J.; Yao, B.; Li, C.; Shi, G. An Improved Hummers Method for Eco-Friendly Synthesis of Graphene Oxide. Carbon 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Dimiev, A.M.; Tour, J.M. Mechanism of graphene oxide formation. ACS Nano 2014, 8, 3060–3068. [Google Scholar] [CrossRef]

- Eigler, S.; Enzelberger-Heim, M.; Grimm, S.; Hofmann, P.; Kroener, W.; Geworski, A.; Dotzer, C.; Rockert, M.; Xiao, J.; Papp, C.; et al. Wet chemical synthesis of graphene. Adv. Mater. 2013, 25, 3583–3587. [Google Scholar] [CrossRef] [PubMed]

- Ray, S.C.; Jana, N.R. Applications of Graphene and Graphene Oxide Based Nanomaterials, 1st ed.; William Andrew Publishing: Oxford, UK, 2015. [Google Scholar]

- Elmarakbi, A.; Azoti, W. State of the art on graphene light weighting nanocomposites for automotive applications. In Experimental Characterization, Predictive Mechanical and Thermal Modeling of Nanostructures and their Polymer Composites; de Sciarra, F., Russo, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–23. [Google Scholar]

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Composites Part A Appl. Sci. Manuf. 2016, 87, 29–45. [Google Scholar] [CrossRef]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Panzavolta, S.; Bracci, B.; Gualandi, C.; Focarete, M.L.; Treossi, E.; Kouroupis-Agalou, K.; Rubini, K.; Bosia, F.; Berely, L.; Pugno, N.M.; et al. Structural reinforcement and failure analysis in composite nanofibers of graphene oxide and gelatin. Carbon 2014, 78, 566–577. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef]

- Monica Veca, L.; Meziani, M.J.; Wang, W.; Wang, X.; Fushen, L.; Zhang, P.; Yi, L.; Fee, R.; Connell, J.W.; Sun, Y.P. Carbon nanosheets for polymeric nanocomposites with high thermal conductivity. Adv. Mater. 2009, 21, 2088–2092. [Google Scholar] [CrossRef]

- Zhen, X.; Gao, C. In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Zhang, W.L.; Park, B.J.; Choi, H.J. Colloidal graphene oxide/polyaniline nanocomposite and its electrorheology. Chem. Commun. 2010, 46, 5596–5598. [Google Scholar] [CrossRef] [PubMed]

- Galpaya, D.; Wang, M.; Liu, M.; Motta, N.; Waclawik, E.R.; Yan, C. Recent advances in fabrication and characterization of graphene-polymer nanocomposites. Graphene 2012, 1, 30–49. [Google Scholar] [CrossRef]

- Hussain, S.; Yorucu, C.; Ahmed, I.; Hussain, R.; Chen, B.; Khan, M.B.; Siddique, N.A.; Rehman, I.U. Surface modification of aramid fibres by graphene oxide nano-sheets for multiscale polymer composites. Surf. Coat. Technol. 2014, 258, 458–466. [Google Scholar] [CrossRef]

- Dastorian Jamnani, B.; Hosseini, S.; Rahmanian, S.; Abdul Rashid, S.; Keshan Balavandy, S. Grafting carbon nanotubes on glass fiber by dip coating technique to enhance tensile and interfacial shear strength. J. Nanomater. 2015, 2015. [Google Scholar] [CrossRef]

- Pegoretti, A.; Mahmood, H.; Pedrazzoli, D.; Kalaitzidou, K. Improving fiber/matrix interfacial strength through graphene and graphene-oxide nano platelets. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 37th Riso International Symposium on Material Science, Riso, Denmark, 5–8 September 2016; IOP Publishing Ltd.: Bristol, UK, 2016; Volume 139, p. 012004. [Google Scholar] [CrossRef]

- Fan, J.; Shi, Z.; Zhang, L.; Wang, J.; Yin, J. Aramid nanofiber-functionalized graphene nanosheets for polymer reinforcement. Nanoscale 2012, 4, 7046–7055. [Google Scholar] [CrossRef] [PubMed]

- Du, S.S.; Li, F.; Xiao, H.M.; Li, Y.Q.; Hu, N.; Fu, S.Y. Tensile and flexural properties of graphene oxide coated-short glass fiber reinforced polyethersulfone composites. Compos. Part B Eng. 2016, 99, 407–415. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A.; Kalaitzidou, K. Synergistic effect of graphite nanoplatelets and glass fibers in polypropylene composites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Z.; Zhai, H.; Chen, X.; Sun, R.; Lyu, S.; Fan, Y.; Yi, Y.; Chen, Z.; Jin, L.; et al. Moisture-Resilient Graphene-Dyed Wool Fabric for Strain Sensing. ACS Appl. Mater. Interfaces 2020, 12, 13265–13274. [Google Scholar] [CrossRef]

- Liu, W.W.; Yan, X.B.; Lang, J.W.; Peng, C.; Xue, Q.J. Flexible and conductive nanocomposite electrode based on graphene sheets and cotton cloth for supercapacitor. J. Mater. Chem. 2012, 22, 17245–17253. [Google Scholar] [CrossRef]

- Le, M.T.; Pickering, K.L. The potential of harakeke fibre as reinforcement in polymer matrix composites including modelling of long harakeke fibre composite strength. Compos. Part A 2015, 76, 44–53. [Google Scholar] [CrossRef]

- Madsen, B.; Lilholt, H. Physical and mechanical properties of unidirectional plant fibre composites—An evaluation of the influence of porosity. Compos. Sci. Technol. 2003, 63, 1265–1272. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos. Part A 2010, 41, 596–603. [Google Scholar] [CrossRef]

- Carpenter, J.E.P.; Miao, M.H.; Brorens, P. Deformation behaviour of composites reinforced with four different linen flax yarn structures. In Advanced Materials and Processing IV; Zhang, D., Pickering, K., Gabbitas, B., Cao, P., Langdon, A., Torrens, R., Eds.; Trans Tech Publications: Stafa-Zurich, Switzerland, 2007; pp. 263–266. [Google Scholar]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanen, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Angelov, I.; Wiedmer, S.; Evstatiev, M.; Friedrich, K.; Mennig, G. Pultrusion of a flax/polypropylene yarn. Compos. Part A 2007, 38, 1431–1438. [Google Scholar] [CrossRef]

- Rodriguez, E.; Petrucci, R.; Puglia, D.; Kenny, J.M.; Vazquez, A. Characterization of composites based on natural and glass fibers obtained by vacuum infusion. J. Compos. Mater. 2005, 39, 265–282. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Effect of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites. Compos. Struct. 2003, 62, 443–448. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Manufacture and characterisation of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos. Part A 2013, 50, 93–101. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Technol. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Hughes, M.; Carpenter, J.; Hill, C. Deformation and fracture behaviour of flax fibre reinforced thermosetting polymer matrix composites. J. Mater. Sci. 2007, 42, 2499–2511. [Google Scholar] [CrossRef]

- Oksman, K. High quality flax fibre composites manufactured by the resin transfer moulding process. J. Reinf. Plast. Compos. 2001, 20, 621–627. [Google Scholar] [CrossRef]

- Phillips, S.; Baets, J.; Lessard, L.; Hubert, P.; Verpoest, I. Characterization of flax/epoxy prepregs before and after cure. J. Reinf. Plast. Compos. 2013, 32, 777–785. [Google Scholar] [CrossRef]

- Graupner, N.; Mussig, J. A comparison of the mechanical characteristics of kenaf and lyocell fibre reinforced poly(lactic acid) (PLA) and poly(3-hydroxybutyrate) (PHB) composites. Compos. Part A 2011, 42, 2010–2019. [Google Scholar] [CrossRef]

- Newman, R.H.; Le Guen, M.J.; Battley, M.A.; Carpenter, J.E.P. Failure mechanisms in composites reinforced with unidirectional Phormium leaf fibre. Compos. Part A 2010, 41, 353–359. [Google Scholar] [CrossRef]

- Oksman, K.; Wallstrom, L.; Berglund, L.A.; Toledo, R.D. Morphology and mechanical properties of unidirectional sisal-epoxy composites. J. Appl. Polym. Sci. 2002, 84, 2358–2365. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali fiber treatment and fiber processing on the mechanical properties of hemp/epoxy composites. J. Appl. Polym. Sci. 2011, 119, 3696–3707. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of flax fibre based textile reinforcements for composite applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Oksman, K. Mechanical properties of natural fibre mat reinforced thermoplastic. Appl. Compos. Mater. 2000, 7, 403–414. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Cardinali, M.; Valentini, L.; Kennya, J.M.; Mutlay, I. Graphene based composites prepared through exfoliation of graphite patelets in methyl mathacrylate/poly(methylmathacrylate). Polym. Int. 2012, 61, 1079–1083. [Google Scholar] [CrossRef]

- Valorosi, F.; Meo, E.; Blanco-Varela, T.; Martorana, B.; Veca, A.; Pugno, N.; Kinloch, I.A.; Anagnostopoulos, G.; Galiotis, C.; Bertocchi, F.; et al. Graphene and related materials in hierarchical fiber composites: Production techniques and key industrial benefits. Compos. Sci. Technol. 2020, 185, 107848. [Google Scholar] [CrossRef]

- Shen, X.; Jia, J.; Chen, C.; Li, Y.; Kim, J. Enhancement of mechanical properties of natural fiber composites via carbon nanotube addition. J. Mater. Sci. 2014, 49, 3225–3233. [Google Scholar] [CrossRef]

- Wulan, P.P.D.K.; Saputra, A.H.; Purwanto, W.W. Mechanical reinforcements of composites made from fiber of fruit bunch palm oil by adding carbon nanotube. Int. J. Sci. Technol. Res. 2014, 3, 377–382. [Google Scholar]

- Lima, A.M.; Pino, G.G.; Rivera, J.L.V.; Chong, K.B.; Macêdo Neto, J.C.; Valenzuela, M.G.S.; Dehaini, J.; Díaz, F.V. Characterization of polyester resin nanocomposite with curauá fibers and graphene oxide. Rev. Cienc. Tec. Agropecu. 2019, 28, 1–10. [Google Scholar]

- Barcelos, M.A.; Simonassi, N.T.; Margem, F.M.; Braga, F.O.; Monteiro, S.N. Under pressure processed polyester composites with high amount of curaua fibers for improved tensile properties. Mater. Sci. Forum 2016, 869, 255–259. [Google Scholar] [CrossRef]

- Layek, R.K.; Nandi, A.K. A review on synthesis and properties of polymer functionalized graphene. Polymer 2013, 54, 5087–5103. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Garcia Filho, F.C.; Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either the epoxy matrix or the curaua fiber reinforcement. J. Mater. Res. Technol. Submitted.

- Yavari, F.; Rafiee, M.; Rafiee, J.; Yu, Z.Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef]

- Wong, K.H.; Syed Mohammed, D.; Pickering, S.J.; Brooks, R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos. Sci. Technol. 2012, 72, 835–844. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. A review of flammability of natural fibre reinforced polymeric composites. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Demosthenes, L.C.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; Garcia Filho, F.C.; Luz, F.S.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and structural characterization of buriti fibers and their relevance in fabric reinforced composites. J. Mater. Res. Technol. 2020, 9, 115–123. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Luz, F.S.; Demosthenes, L.C.C.; Pereira, A.C.; Colorado, H.A.; Nascimento, L.F.C.; Monteiro, S.N. Evaluation of dynamics mechanical properties of fique fabric/epoxy composites. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Luz, F.S.; Candido, V.S.; Silva, A.C.R.; Monteiro, S.N. Thermal behavior of polyester composites reinforced with green sugarcane bagasse fiber. JOM 2018, 70, 1965–1971. [Google Scholar] [CrossRef]

- Luz, F.S.; Monteiro, S.N.; Tommasini, F.J. Evaluation of dynamic mechanical properties of PALF and coir fiber reinforcing epoxy composites. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.M.A.; Margem, F.M.; Rodriguez, R.J.S. Thermogravimetric stability behavior of less common lignocellulosic fibers—A review. J. Mater. Res. Technol. 2012, 1, 189–199. [Google Scholar] [CrossRef]

- Premkumar, T.; Siva, I.; Munde, Y.; Rajesh, S.; Amico, S.C. Basalt fiber hybridization effects on the thermal degradation properties of curaua fiber composites. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mat. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Pereira, A.C.; Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Demosthenes, L.C.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mat. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Pereira, A.C.; Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Lima, E.S.; Lopera, H.A.C.; Monteiro, S.N. Evaluation of the projectile’s loss of energy in polyester composite reinforced with fique fiber and fabric. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Pereira, A.C.; Nunes, L.F.; Luz, F.S.; Braga, F.O.; Colorado, H.A.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the Weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Braga, F.O.; Bolzan, L.T.; Luz, F.S.; Lopes, P.H.L.M.; Lima, E.P., Jr.; Monteiro, S.N. High energy ballistic and fracture comparison between multilayered armor systems using non-woven curaua fabric composites and aramid laminates. J. Mater. Res. Technol. 2017, 6, 417–422. [Google Scholar] [CrossRef]

- National Criminal Justice Reference Service. Available online: https://www.ncjrs.gov (accessed on 6 June 2020).

- Qu, L.; Tian, M.; Hu, X.; Wang, Y.; Zhu, S.; Guo, X.; Han, G.; Zhang, X.; Sun, K.; Tang, X. Functionalization of cotton fabric at low graphene nanoplate content for ultra-strong ultraviolet blocking. Carbon 2014, 80, 565–574. [Google Scholar] [CrossRef]

- Shateri-Khalilabad, M.; Yazdanshenas, M.E. Fabricating electroconductive cotton textiles using graphene. Carbohydr. Polym. 2013, 96, 190–195. [Google Scholar] [CrossRef]

- Weng, Z.; Su, Y.; Wang, D.W.; Li, F.; Du, J.; Cheng, H.M. Graphene-cellulose paper flexible supercapacitors. Adv. Energy Mater. 2011, 1, 917–922. [Google Scholar] [CrossRef]

- Kang, Y.R.; Li, Y.L.; Hou, F.; Wen, Y.Y.; Su, D. Fabrication of electric papers of graphene nanosheet shelled cellulose fibres by dispersion and infiltration as flexible electrodes for energy storage. Nanoscale 2012, 4, 3248–3253. [Google Scholar] [CrossRef]

- Xing, J.; Tao, P.; Wu, Z.; Xing, C.; Liao, X.; Nie, S. Nanocellulose-graphene composites: A promising nanomaterial for flexible supercapacitors. Carbohydr. Polym. 2019, 207, 447–459. [Google Scholar] [CrossRef] [PubMed]

- Van Lam, D.; Jo, K.; Kim, C.H.; Won, S.; Hwangbo, Y.; Kim, J.H.; Lee, H.J.; Lee, S.M. Calligraphic ink enabling washable conductive textile electrodes for supercapacitors. J. Mater. Chem. A 2016, 4, 4082–4088. [Google Scholar] [CrossRef]

- Digital Trends. Available online: www.digitaltrends.com/features/real-graphene-battery-interview-samuel-gong-ces-2020/ (accessed on 6 June 2020).

- Lund, A.; van der Velden, N.M.; Persson, N.K.; Hamedi, M.M.; Müller, C. Electrically conducting fibres for e-textiles: An open playground for conjugated polymers and carbon nanomaterials. Mat. Sci. Eng. R 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Afroj, S.; Karim, N.; Wang, Z.; Tan, S.; He, P.; Holwill, M.; Ghazaryan, D.; Fernando, A.; Novoselov, K.S. Engineering graphene flakes for wearable textile sensors via highly scalable and ultrafast yarn dyeing technique. ACS Nano 2019, 13, 3847–3857. [Google Scholar] [CrossRef]

- Stylios, G.K. Novel Smart Textiles. Materials 2020, 13, 950. [Google Scholar] [CrossRef] [PubMed]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Tan, S.; He, P.; Fernando, A.; Carr, C.; Novoselov, K.S. Scalable production of graphene-based wearable e-textiles. ACS Nano 2017, 11, 12266–12275. [Google Scholar] [CrossRef]

- Ren, J.; Wang, C.; Zhang, X.; Carey, T.; Chen, K.; Yin, Y.; Torrisi, F. Environmentally friendly conductive cotton fabric as flexible strain sensor based on hot press reduced graphene oxide. Carbon 2017, 111, 622–630. [Google Scholar] [CrossRef]

- Liu, Y.; Tao, L.Q.; Wang, D.Y.; Zhang, T.Y.; Yang, Y.; Ren, T.L. Flexible, highly sensitive pressure sensor with a wide range based on graphene-silk network structure. Appl. Phys. Lett. 2017, 110, 123508. [Google Scholar] [CrossRef]

- Souri, H.; Bhattacharyya, D. Wearable strain sensors based on electrically conductive natural fiber yarns. Mater. Des. 2018, 154, 217–227. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y.; Dai, K.; Wang, Y.; Zheng, G.; Liu, C.; Shen, C. A highly stretchable and stable strain sensor based on hybrid carbon nanofillers/polydimethylsiloxane conductive composites for large human motions monitoring. Compos. Sci. Technol. 2018, 156, 276–286. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Y.; Zhao, Y.; Mao, L.; Gao, L.; Pan, W.; Zhang, Y.; Liu, P. Highly stretchable strain sensor based on SWCNTs/CB synergistic conductive network for wearable human-activity monitoring and recognition. Smart Mater. Struct. 2017, 26, 095017. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E. Conductive fiber_based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- You, X.; He, J.; Nan, N.; Sun, X.; Qi, K.; Zhou, Y.; Shao, W.; Liu, F.; Cui, S. Stretchable capacitive fabric electronic skin woven by electrospun nanofiber coated yarns for detecting tactile and multimodal mechanical stimuli. J. Mater. Chem. C 2018, 6, 12981–12991. [Google Scholar] [CrossRef]

- Yang, Z.; Pang, Y.; Han, X.L.; Yang, Y.; Ling, J.; Jian, M.; Zhang, Y.; Yang, Y.; Ren, T.L. Graphene Textile Strain Sensor with Negative Resistance Variation for Human Motion Detection. ACS Nano 2018, 12, 9134–9141. [Google Scholar] [CrossRef] [PubMed]

- Cataldi, P.; Ceseracciu, L.; Athanassiou, A.; Bayer, I.S. Healable Cotton.Graphene Nanocomposite Conductor for Wearable Electronics. ACS Appl. Mater. Interfaces 2017, 9, 13825–13830. [Google Scholar] [CrossRef]

- Lee, H.; Glasper, M.J.; Li, X.; Nychka, J.A.; Batcheller, J.; Chung, H.-J.; Chen, Y. Preparation of fabric strain sensor based on graphene for human motion monitoring. J. Mater. Sci. 2018, 53, 9026–9033. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, T.; Lao, J.; Zhang, R.; Zhang, Y.; Zhu, M.; Li, X.; Zang, X.; Wang, K.; Yu, W. Ultra-sensitive graphene strain sensor for sound signal acquisition and recognition. Nano Res. 2015, 8, 1627–1636. [Google Scholar] [CrossRef]

- Singh, E.; Meyyappan, M.; Nalwa, H.S. Flexible graphene-based wearable gas and chemical sensors. ACS Appl. Mater. Interfaces 2017, 9, 34544–34586. [Google Scholar] [CrossRef]

- Yun, Y.J.; Hong, W.G.; Choi, N.J.; Kim, B.H.; Jun, Y.; Lee, H.K. Ultrasensitive and highly selective graphene-based single yarn for use in wearable gas sensor. Sci. Rep. 2015, 5, 10904. [Google Scholar] [CrossRef]

- Jung, W.T.; Jeon, J.W.; Jang, H.S.; Lee, H.K.; Kim, B.H. Commercial silk-based electronic textiles for NO2 sensing. Sens. Actuators B Chem. 2020, 307, 127596. [Google Scholar] [CrossRef]

- Kumar, S.; Kaushik, S.; Pratap, R.; Raghavan, S. Graphene on paper: A simple, low-cost chemical sensing platform. ACS Appl. Mater. Interfaces 2015, 7, 2189–2194. [Google Scholar] [CrossRef] [PubMed]

| Material | Manufacturing Process | Reference |

|---|---|---|

| Natural fiber | ||

| 1 wt % GO-Curaua | Coating | [51] |

| Jute | Coating | [52] |

| 0.25 wt % GO-Jute | ||

| 0.5 wt % GO-Jute | ||

| 0.75 wt % GO-Jute | ||

| 1 wt % GO-Jute | ||

| 1 wt % G-Jute | ||

| 10 wt % G-Jute | ||

| Natural fiber-based composite | ||

| Piassava/epoxy | Fiber: Coating; Composite: Compression molding | [40] |

| GO-10 vol% Piassava/epoxy | ||

| GO-30 vol% Piassava/epoxy | ||

| GO-50 vol% Piassava/epoxy | ||

| Jute/epoxy | Fiber: Coating; Composite: Vacuum infusion | [50] |

| 0.25 wt % GO-Jute/epoxy | ||

| 0.5 wt % GO-Jute/epoxy | ||

| 0.75 wt % GO-Jute/epoxy | ||

| 1 wt % GO-Jute/epoxy | ||

| PP | Fiber: Coating; Composite: Melt blending | [53] |

| 7.5 wt % Sisal/PP | ||

| GO-7.5 wt % Sisal/PP | ||

| GO-7.5 wt % Sisal/MAPP-PP | ||

| 15 wt % bagasse flour-0.1 wt % NG/PP | Melt blending | [71] |

| 15 wt % bagasse flour-0.25 wt % NG/PP | ||

| 15 wt % bagasse flour-0.5 wt % NG/PP | ||

| 15 wt % bagasse flour-0.75 wt % NG/PP | ||

| 15 wt % bagasse flour-1 wt % NG/PP | ||

| 30 wt % bagasse flour-0.1 wt % NG/PP | ||

| 30 wt % bagasse flour-0.25 wt % NG/PP | ||

| 30 wt % bagasse flour-0.5 wt % NG/PP | ||

| 30 wt % bagasse flour-0.75 wt % NG/PP | ||

| 30 wt % bagasse flour-1 wt % NG/PP | ||

| PLA | Fiber: Coating; Composite: Melt blending | [72] |

| 5 wt % GNP/PLA | ||

| 40 wt % Kenaf/PLA | ||

| 40 wt % Kenaf-1 wt % GNP/PLA | ||

| 40 wt % Kenaf-3 wt % GNP/PLA | ||

| 40 wt % Kenaf-5 wt % GNP/PLA | ||

| Synthetic fiber | ||

| Aramid fiber | Coating | [108] |

| GO (ph6)-Aramid fiber | ||

| GO (ph9)-Aramid fiber | ||

| Glass fiber | Coating | [109] |

| 0.4 mg/mL CNT-glass fiber | ||

| 1 mg/mL CNT-glass fiber | ||

| 1.6 mg/mL CNT-glass fiber | ||

| 2 mg/mL CNT-glass fiber | ||

| Synthetic fiber-based composite | ||

| Epoxy | Solution mixing | [110] |

| 5 wt % GNP/Epoxy | ||

| 10 wt % Glass fiber-5 wt % GNP/Epoxy | ||

| 15 wt % Glass fiber-5 wt % GNP/Epoxy | ||

| PMMA | Solution mixing | [111] |

| 0.3 wt % rGO/PMMA | ||

| 1 wt % Aramid fiber/PMMA | ||

| 0.7 wt % Aramid fiber-GO/PMMA | ||

| Glass fiber/PES | Fiber: Coating; Composite: Melt blending | [112] |

| 0.1 wt % GO-Glass fiber/PES | ||

| 0.2 wt % GO-Glass fiber/PES | ||

| 0.5 wt % GO-Glass fiber/PES | ||

| 1 wt % GO-Glass fiber/PES | ||

| PP | Fiber: Coating; Composite: Melt blending | [113] |

| 10 wt % Glass fiber/PP | ||

| 1 wt % GNP-10 wt % Glass fiber/PP | ||

| 3 wt % GNP-10 wt % Glass fiber/PP | ||

| 5 wt % GNP-10 wt % Glass fiber/PP | ||

| 7 wt % GNP-10 wt % Glass fiber/PP |

| Material | Tensile Strength (MPa) | Young’s Modulus (GPa) | Reference |

|---|---|---|---|

| Natural Fiber/Polymer composite | |||

| ~50 wt % Harakeke/Epoxy | 223 | 17 | [117] |

| 72 wt % Flax (yarn)/PP | 321 | 29 | [118] |

| 73 wt % Sisal (alkali treated)/Epoxy | 410 | 6 | [119] |

| 77 wt % Sisal (aligned)/Epoxy | 330 | 10 | |

| 30 wt % Hemp (carded)/PLA | 83 | 11 | [120] |

| ~46 wt % Flax (sliver)/Epoxy | 200 | 17 | [121] |

| 30 wt % Hemp (aligned)/PLA | 77 | 10 | [122] |

| 30 wt % Flax (yarn)/PP | 89 | 7 | [123] |

| 35 wt % Jute (woven)/UP | 50 | 8 | [124] |

| 39 wt % Flax (aligned)/PP | 212 | 23 | [125] |

| 44 wt % Flax (sliver)/PP | 146 | 15 | [126] |

| 46 wt % Hemp (aligned)/PP | 127 | 11 | |

| 45 wt % Hemp/PLA | 62 | 7 | [127] |

| 45 wt % Flax (yarn)/Epoxy | 133 | 28 | [128] |

| 37 wt % Flax (yarn)/Epoxy | 132 | 15 | |

| ~58 wt % Flax (sliver)/UP | 304 | 30 | [129] |

| 46 wt % Flax (aligned)/Epoxy | 280 | 39 | [130] |

| 50 wt % Flax (woven)/Epoxy | 104 | 10 | [131] |

| 40 wt % Kenaf (aligned)/PLA | 82 | 8 | [132] |

| 40 wt % Kenaf (aligned)/PHB | 70 | 6 | |

| 52 wt % Harakeke/Epoxy | 211 | 15 | [133] |

| 48 wt % Sisal (aligned)/Epoxy | 211 | 20 | [134] |

| 37 wt % Sisal (aligned)/Epoxy | 183 | 15 | |

| 37 wt % Flax (aligned)/Epoxy | 132 | 15 | |

| 65 wt % Hemp (aligned)/Epoxy | 165 | 17 | [135] |

| 65 wt % Hemp (DSF)/Epoxy | 113 | 18 | |

| ~31 wt % Flax (yarn)/Epoxy | 160 | 15 | [136] |

| ~28 wt % Flax/Epoxy | 182 | 20 | |

| ~24 wt % Flax (yarn)/VE | 248 | 24 | |

| ~34 wt % Flax (yarn)/UP | 143 | 14 | |

| 50 wt % Flax (aligned)/PP | 40 | 7 | [137] |

| ~80 wt % Kenaf (selected)/PLA | 223 | 23 | [138] |

| 45 wt % Harakeke/Epoxy | 136 | 11 | [15] |

| 50 wt % Hemp/Epoxy | 105 | 9 | |

| 30 wt % Harakeke/PLA | 102 | 8 | |

| 25 wt % Hemp/PLA | 87 | 9 | |

| NLF/Graphene material | |||

| 0.25 wt % GO-Jute | 394 | 37 | [52] |

| 0.5 wt % GO-Jute | 436 | 44 | |

| 0.75 wt % GO-Jute | 501 | 46 | |

| 1 wt % GO-Jute | 575 | 48 | |

| 1 wt % G-Jute | 380 | 44 | |

| 10 wt % G-Jute | 474 | 52 | |

| 1 wt % GO-Curaua | 1834 | 38 | [51] |

| Graphene/NLF/Polymer composite | |||

| 7.5 wt % Sisal/PP | 55 | 0.5 | [53] |

| GO-7.5 wt % Sisal/PP | 60 | 0.6 | |

| GO-7.5 wt % Sisal/MAPP-PP | 69 | 0.7 | |

| 0.25 wt % GO-Jute/epoxy | 295 | 36.9 | [50] |

| 0.5 wt % GO-Jute/epoxy | 337 | 42.8 | |

| 0.75 wt % GO-Jute/epoxy | 379 | 44.6 | |

| 1 wt % GO-Jute/epoxy | 292.7 | 37.8 | |

| 1 wt % G-Jute/epoxy | 290 | 35.8 | |

| 10 wt % G-Jute/epoxy | 294 | 38.1 | |

| 15 wt % bagasse flour-0.1 wt % NG/PP | 41 | 3.1 | [71] |

| 15 wt % bagasse flour-0.25 wt % NG/PP | 37 | 2.4 | |

| 15 wt % bagasse flour-0.5 wt % NG/PP | 38 | 2.4 | |

| 15 wt % bagasse flour-0.75 wt % NG/PP | 37 | 2.6 | |

| 15 wt % bagasse flour-1 wt % NG/PP | 37 | 2.7 | |

| 30 wt % bagasse flour-0.1 wt % NG/PP | 47 | 3.6 | |

| 30 wt % bagasse flour-0.25 wt % NG/PP | 41 | 3 | |

| 30 wt % bagasse flour-0.5 wt % NG/PP | 40 | 3.2 | |

| 30 wt % bagasse flour-0.75 wt % NG/PP | 39 | 3 | |

| 30 wt % bagasse flour-1 wt % NG/PP | 39 | 3 | |

| 40 wt % Kenaf-1 wt % GNP/PLA | 106 | ~7.5 | [72] |

| 40 wt % Kenaf-3 wt % GNP/PLA | 114 | ~7.6 | |

| 40 wt % Kenaf-5 wt % GNP/PLA | 109 | ~8.8 | |

| Material | Property | Reference |

|---|---|---|

| Interfacial Shear Strength (MPa) | ||

| Jute | 295 | [52] |

| 0.25 wt % GO-Jute | 394 | |

| 0.5 wt % GO-Jute | 436 | |

| 0.75 wt % GO-Jute | 501 | |

| 1 wt % GO-Jute | 575 | |

| 1 wt % G-Jute | 380 | |

| 10 wt % G-Jute | 474 | |

| Tensile strength (MPa) | ||

| Jute/epoxy | 180 | |

| 0.25 wt % GO-Jute/epoxy | 295 | |

| 0.5 wt % GO-Jute/epoxy | 337 | [50] |

| 0.75 wt % GO-Jute/epoxy | 379 | |

| 1 wt % GO-Jute/epoxy | 293 | |

| 2.5 wt % Sisal/PP | 50.4 | [53] |

| 5 wt % Sisal/PP | 53.6 | |

| 7.5 wt % Sisal/PP | 55.2 | |

| 10 wt % Sisal/PP | 52.9 | |

| GO-2.5 wt % Sisal/PP | 54.7 | |

| GO-5 wt % Sisal/PP | 57.4 | |

| GO-7.5 wt % Sisal/PP | 59.8 | |

| GO-10 wt % Sisal/PP | 55.6 | |

| GO-2.5 wt % Sisal/MAPP-PP | 61.2 | |

| GO-5 wt % Sisal/MAPP-PP | 67.6 | |

| GO-7.5 wt % Sisal/MAPP-PP | 69.1 | |

| GO-10 wt % Sisal/MAPP-PP | 63.6 | |

| 15 wt % bagasse flour-0.1 wt % NG/PP | 41 | [71] |

| 15 wt % bagasse flour-0.25 wt % NG/PP | 37 | |

| 15 wt % bagasse flour-0.5 wt % NG/PP | 38 | |

| 15 wt % bagasse flour-0.75 wt % NG/PP | 37 | |

| 15 wt % bagasse flour-1 wt % NG/PP | 37 | |

| 30 wt % bagasse flour-0.1 wt % NG/PP | 47 | |

| 30 wt % bagasse flour-0.25 wt % NG/PP | 41 | |

| 30 wt % bagasse flour-0.5 wt % NG/PP | 40 | |

| 30 wt % bagasse flour-0.75 wt % NG/PP | 39 | |

| 30 wt % bagasse flour-1 wt % NG/PP | 39 | |

| PLA | 102 | [72] |

| 5 wt % GNP/PLA | 102 | |

| 40 wt % Kenaf/PLA | 97 | |

| 40 wt % Kenaf-1 wt % GNP/PLA | 106 | |

| 40 wt % Kenaf-3 wt % GNP/PLA | 114 | |

| 40 wt % Kenaf-5 wt % GNP/PLA | 109 | |

| Young’s Modulus (GPa) | ||

| Jute | 10 | [50] |

| 0.25 wt % GO-Jute | 36.9 | |

| 0.5 wt % GO-Jute | 42.8 | |

| 0.75 wt % GO-Jute | 44.4 | |

| 1 wt % GO-Jute | 37.8 | |

| 1 wt % G-Jute | 35.8 | |

| 10 wt % G-Jute | 37.9 | |

| 2.5 wt % Sisal/PP | 0.51 | [53] |

| 5 wt % Sisal/PP | 0.57 | |

| 7.5 wt % Sisal/PP | 0.65 | |

| 10 wt % Sisal/PP | 0.55 | |

| GO-2.5 wt % Sisal/PP | 0.53 | |

| GO-5 wt % Sisal/PP | 0.61 | |

| GO-7.5 wt % Sisal/PP | 0.68 | |

| GO-10 wt % Sisal/PP | 0.58 | |

| GO-2.5 wt % Sisal/MAPP-PP | 0.56 | |

| GO-5 wt % Sisal/MAPP-PP | 0.66 | |

| GO-7.5 wt % Sisal/MAPP-PP | 0.73 | |

| GO-10 wt % Sisal/MAPP-PP | 0.64 | |

| Composite | Reinforcement Architecture | Penetration Depth (mm) | Physical Integrity | Reference |

|---|---|---|---|---|

| GO-incorporated composite | ||||

| GO-Curaua/epoxy | Long aligned fibers | 27.4 ± 0.3 | Yes | [51] |

| Untreated composites | ||||

| Jute/polyester | Non-woven fabric | 24 ± 7 | Yes | [24] |

| Mallow/epoxy | Long aligned fibers | 22 ± 1 | No | [25] |

| Sisal/polyester | Long aligned fibers | 22 ± 3 | No | [28] |

| Piassava/epoxy | Long aligned fibers | 20 ± 4 | No | [29] |

| Curaua/epoxy | Long aligned fibers | 25.6 ± 0.2 | No | [51] |

| Fique/polyester | Long aligned fibers | 17 ± 2 | No | [159] |

| Fique/epoxy | Bidimensional fabric | 22 ± 2 | Yes | [161] |

| Curaua/epoxy | Non-woven fabric | 28 ± 3 | Yes | [162] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Luz, F.S.; Garcia Filho, F.d.C.; del-Río, M.T.G.; Nascimento, L.F.C.; Pinheiro, W.A.; Monteiro, S.N. Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview. Polymers 2020, 12, 1601. https://doi.org/10.3390/polym12071601

da Luz FS, Garcia Filho FdC, del-Río MTG, Nascimento LFC, Pinheiro WA, Monteiro SN. Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview. Polymers. 2020; 12(7):1601. https://doi.org/10.3390/polym12071601

Chicago/Turabian Styleda Luz, Fernanda Santos, Fabio da Costa Garcia Filho, Maria Teresa Gómez del-Río, Lucio Fabio Cassiano Nascimento, Wagner Anacleto Pinheiro, and Sergio Neves Monteiro. 2020. "Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview" Polymers 12, no. 7: 1601. https://doi.org/10.3390/polym12071601

APA Styleda Luz, F. S., Garcia Filho, F. d. C., del-Río, M. T. G., Nascimento, L. F. C., Pinheiro, W. A., & Monteiro, S. N. (2020). Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview. Polymers, 12(7), 1601. https://doi.org/10.3390/polym12071601