1. Introduction

Synthetic fibers experienced exponential growth after the Second World War and became a successful class of engineering materials, mainly as reinforcement of polymer matrix composites. They have been applied in several technological fields of human interest, from surgical prostheses to aerospace components [

1,

2,

3]. However, at the end of the last century, concerns on the widespread pollution caused by non-degradable materials, such as common plastics, as well as climate changes resulting from carbon dioxide emissions, motivated a tendency to replace synthetic by natural fibers in composite materials. These fibers, naturally produced by living organisms, such as animals [

4] and plants [

5], consume less energy to be processed and rapidly degrade in natural environments, reducing disposal problems and contributing to the sustainability of the projects.

Cellulose-rich natural lignocellulosic fibers (NLFs) have been gaining considerable interest as possible substitutes for the reinforcement phase of polymer composites [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16], including totally biodegradable biocomposites [

17]. Indeed, as compared to synthetic fibers, the NLFs display better characteristics, such as lower density and cost, as well as superior specific strength and elastic modulus [

18,

19]. Such characteristics are motivating applications in automotive, packaging, civil construction, and aerospace industries associated with NLF composites [

20,

21,

22,

23,

24,

25,

26]. In particular, these composites are being considered for ballistic armors [

27,

28,

29,

30]. More recently, several researchers have been investigating the NLF waste as a source of nanocrystalline cellulose (NCC) [

31,

32,

33,

34,

35,

36], a strong nanomaterial, which can be used to produce several important products, such as nanocomposites, ion exchange membranes, films for electronics devices, and others [

36].

Despite all the advantages, NLFs present some drawbacks associated with their polar incompatibility towards a non-polar nature of polymeric matrices. In this case, poor interfacial adhesion between the reinforcement and matrix phases is created, impairing the mechanical properties [

6,

7,

8,

9,

10,

11,

12,

13,

14]. Another major limitation often encountered is thermal degradation. The decomposition reaction of the fiber components (cellulose, hemicellulose, and lignin) mainly occurs at low temperatures, around 200 °C, and imposes limitations to processing and application for the NLF-reinforced polymeric-matrix composites [

37]. In the case of less known NLFs, it is important to study the thermal behavior of related polymer composites, in order to assure better processing and properties [

38,

39]. Among the less known NLFs, the several types of sedge only recently begun to be investigated [

40,

41,

42,

43,

44,

45,

46,

47] but have still not been cited in the aforementioned specialized reviews dedicated to technical properties of NLF polymer composites.

Babu et al. [

40] evaluated polyester composites reinforced with

Cyperus pangorei fibers treated with benzoyl chloride. They studied the tribological properties of the composites aiming the application as vehicle brakes. Babu et al. [

41] investigated the mechanical and thermal properties of the

Cyperus esculentus fiber-reinforced polypropylene composites, with and without mercerization. The mercerized specimens presented the best properties, as well as the 30 vol.% fiber specimens. They obtained values as high as ~70 MPa of tensile strength, ~60 MPa of flexural strength, and 30 J/m impact strength. Rajini et al. [

42] studied the tribological properties of

Cyperus pangorei fiber-reinforced polyester composites, such as hardness, friction coefficient, and surface roughness. Kalimuthu et al. [

43] examined the mechanical properties and morphology of

Cyperus pangorei fiber-reinforced polyester composites. They evaluated several fiber lengths and percentages of fibers. The best performance was observed for the 40 mm length fiber and 40 vol.% fraction of fibers. The tensile strength was found as 57.7 MPa, and the flexural strength as 90.5 MPa. Vijay and Singaravelu [

44] investigated the influence of the sandwiching stacking sequence of

Cyperus pangorei fiber layers in the mechanical properties of laminated composites. They produced the specimens by stacking the

C. pangorei layers within external glass fabric layers either with kenaf, sisal, or jute core layers. The best results were obtained by the kenaf-cored laminates, which presented 51.5 MPa as tensile strength, 384.3 MPa as flexural strength, and 8.17 J as impact strength. Mayandi et al. [

45] performed a thorough characterization (mechanical, thermal, chemical, and structural) of the

Cyperus Pangorei fibers. The values 196 ± 56 MPa and 11.6 ± 2.6 GPa were obtained as tensile strength and elastic modulus for the fibers, respectively. They also found out that the fibers were semicrystalline (~41% crystallinity obtained by XRD) and were stable until 221 °C. The general characteristics of these fibers, according to the authors, make them promising to composite reinforcement. Govindasamy et al. [

46] evaluated the characteristics of the

Cyperus malaccensis (CM) fibers for papermaking purposes. Benazir et al. [

47] studied the chemical composition, structure, and some mechanical properties of mat sedge

Cyperus pangorei yarns. They found out that the fibers were composed mainly of alpha-cellulose (~42%), hemicellulose (~42%), lignin (~13%), and waxes (~2%).

In particular, the CM sedge fiber has not yet been investigated for possible composite reinforcement but only for papermaking [

46] or agricultural purpose [

48]. Therefore, the objective of this work was for the first time to investigate the mechanical and thermal behavior of the CM sedge fiber-reinforced composites. Tensile, Izod-impact, and ballistic impact tests were performed, as well as Fourier transform infrared (FT-IR) and thermal analysis of the fibers and composites.

3. Results and Discussion

The Fourier transform infrared (FT-IR) spectrum of the CM sedge fiber is shown in

Figure 2. In this spectrum, an absorption band appears at 3430 cm

−1, which is attributed to the axial vibration of hydroxyl groups (O-H) of the cellulose [

54]. The band found at 2923 cm

−1 refers to the vibration of CH

2 and CH

3 molecules of the organic structure of NLFs. The relatively small amplitude of this band in the CM sedge fiber might justify a low interaction with the polymer matrix during the eventual manufacture of composites [

54]. The band at 2361 cm

−1 is assigned to the bond between organic molecules. The band at 1648 cm

−1 is related to C=O aromatic groups, and the band at 1254 cm

−1 to the C–O and C–C bonds. The bands at 1030 and 446 cm

−1 are attributed to C–O and C–C deformation of the respective covalent bonds.

Table 1 presents the results for all Izod impact tests for the different composite materials. They showed a low energy absorption capacity when compared to other different composites reinforced with natural lignocellulosic fibers (NLFs) [

55,

56]. The tested specimens were completely fractured, as expected, which is required for the validity of the tests, as shown in the macrographs in

Figure 3.

The results in

Table 1 can be better visualized by the graph in

Figure 4. A tendency of increasing impact energy with increasing fiber fraction was observed, as already observed for other NFL polymer composites [

55,

56]. The effect of incorporating 30 vol.% fibers as reinforcement in composites was remarkable, producing a 181% increase when compared to the value obtained for the neat epoxy resin.

ANOVA was conducted to confirm if there is a significant difference between the Izod impact energy average results. According to

Table 2, the hypothesis that the averages are equal was rejected, with a level of significance of 5%, since the calculated F (statistical parameter of ANOVA) was higher than the critical F

c (tabulated). Therefore, it was confirmed that there was indeed a significant difference between the impact energy for the different materials.

Table 3 shows the results of the Tukey’s honestly significant difference (HSD) test. The calculated HSD was 16.32 J/m, and thus the differences above the HSD were considered significant. These values are marked in bold in

Table 3 and showed that the impact strength of the 30 vol.% sedge fiber composites was better than all other tested specimens.

The impact test results were now compared to the results for the other fibers of the

Cyperus family, investigated as possible reinforcement to polymers, as presented in

Table 4 [

41,

43]. The composites of the present work displayed better impact strength when compared to the other composites with related sedge fibers.

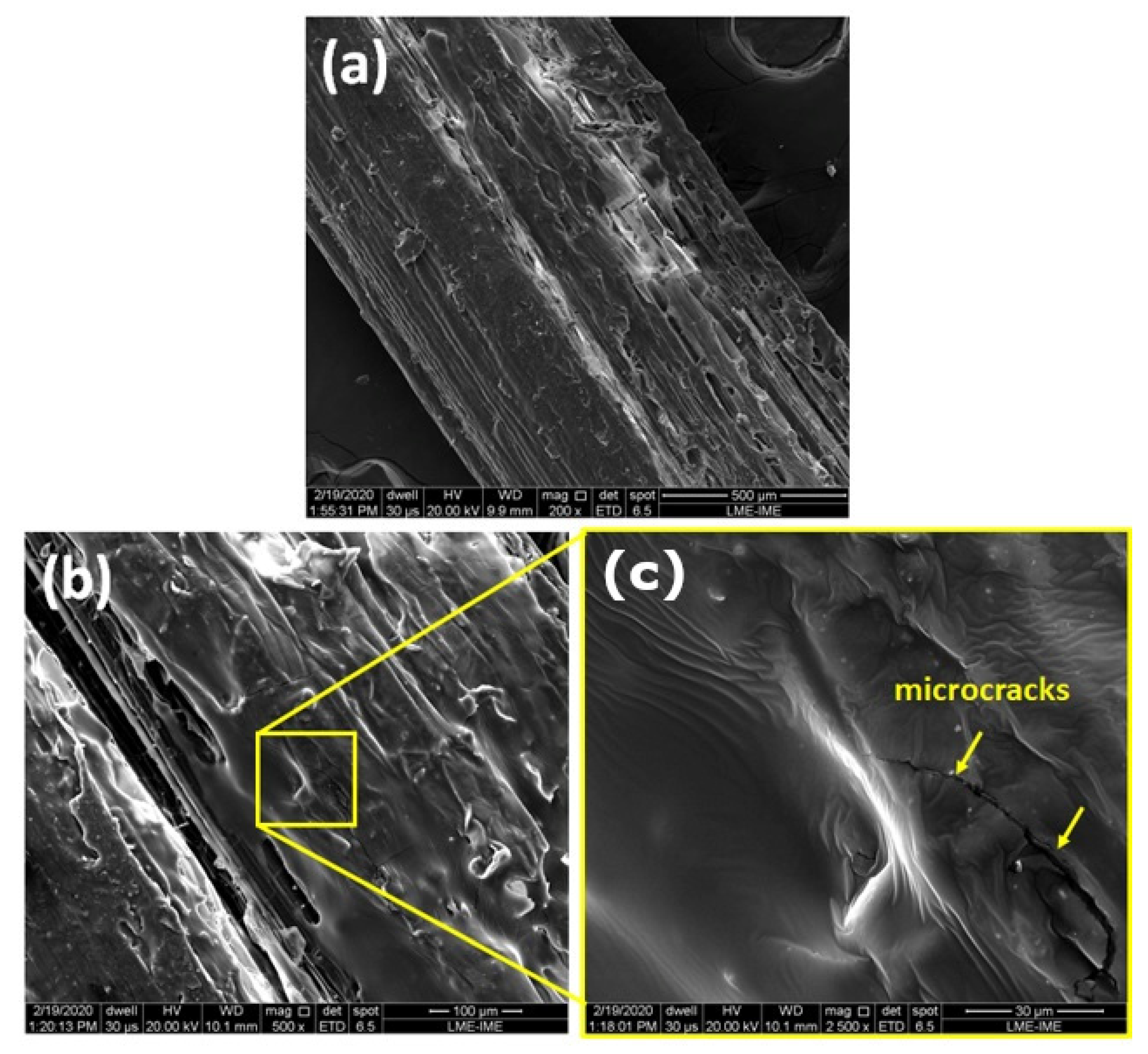

SEM observations of the surface aspects of the fibers are shown in

Figure 5. A relatively rough fiber surface can be noticed (

Figure 5a), which is generally considered a good feature for composite materials, since it might improve the adhesion between fiber and matrix by mechanical interlocking in the fiber-matrix interface. However, higher magnification images showed inhomogeneities, such as the rougher regions contrasting to the smoother regions in

Figure 5b. Microcracks can be observed (arrows) in the inset of

Figure 5b, which might be attributed to degradation by the SEM electron beam power.

Table 5 shows the average results for the tensile strength of the CM sedge fiber-reinforced composites.

Table 5 also shows literature values for the tensile strength of the same neat epoxy resin [

57]. The results displayed comparatively poor tensile properties for the CM sedge-reinforced composites. In fact, the values of tensile strength for all composites were lower than that for the neat epoxy resin. This indicated that the fibers did not act as reinforcement when tensile loads were applied to the material. In this case, the fibers probably acted as defects in the material’s structure, and the tensile properties of the fiber-matrix interface were impaired. This was consistent with the small 2923 cm

−1 band found in the FT-IR spectrum in

Figure 2 for the CM sedge fiber.

The results in

Table 5 can be better visualized by the graph in

Figure 6. Although there is a tendency of increasing tensile strength with the fiber fraction, as already mentioned, the values were significantly lower when compared to the neat epoxy resin. An apparent contradiction is a fact that the sedge fibers improve the impact properties of the material. However, as observed before [

56], the low interface strength resulted in a greater fracture surface. Consequently, it might provide better impact properties to the material, even though the tensile strength was lower.

Table 6 shows the ANOVA for the tensile strength of the composites. According to

Table 6, the hypothesis that the averages are equal was rejected, with a level of significance of 5%, since the calculated F was higher than the critical F

c (tabulated). Therefore, it was confirmed that there was a significant difference between the tensile strength for the different CM sedge fiber composites.

Table 7 shows the results of the Tukey’s honestly significant difference (HSD) test for the tensile strength. The calculated HSD was 5.46 MPa, and thus the differences above the HSD were considered significant. These values are marked in bold in

Table 7 and showed that the tensile strength of the 30 vol.% CM sedge fiber composites was better than all other tested specimens.

Furthermore, through the data obtained by the tensile test, it was possible to calculate the elastic modulus of the composites and their total strain. The results are presented in

Table 8 and

Figure 7 and

Figure 8.

According to

Table 8 and

Figure 8, it is possible to observe a clear tendency of increasing the elastic modulus of the composites as the volumetric fraction of fibers increases, probably because of the higher stiffness of the fibers. Comparing to literature data for the same epoxy resin [

58], only the 30 vol.% CM fiber-reinforced composite showed higher modulus, probably due to difficulties in load transfer in the fiber-matrix interface. On the other hand, the total strain graph,

Figure 7, did not show any significant variation between the different materials, within the standard deviation.

Preliminary tensile results for the CM sedge fiber indicated a maximum strength of 164 MPa, an elastic modulus of 4.4 GPa, and a total strain of 4.1%. In particular, the CM sedge fiber maximum strength was significantly higher than the epoxy matrix, 34.3 MPa, in

Table 5. However, the aforementioned low fiber/epoxy interfacial strength was responsible for the inferior strength of the composites in

Figure 6, in spite of the higher impact energy,

Figure 4, and elastic modulus,

Figure 8, reinforcement effect. CM sedge fiber treatment, especially as has been done for other NFLs with graphene oxide [

59], is expected to substantially improve the composites’ tensile strength.

The tensile test results were also compared to the results for the other fibers of the

Cyperus family (

Table 9), investigated by [

41,

43]. It is important to mention that these authors performed the tests according to the ASTM D638 standard [

60]; besides, the polymeric matrices are also different, so the results might not be directly comparable to the present results. However, comparing the properties, it is worth to have some idea of the property values for similar materials. According to

Table 9, the

Cyperus malaccensis composites presented similar mechanical properties when compared to those of

Cyperus esculentus and

C. pangorei composites.

Table 10 shows the results of the ballistic tests. Values of absorbed energy during the impact of the projectile with the materials (E

abs) and the calculated limit velocity (V

L) are presented. All the specimens were perforated during the tests, so their residual velocities could be successfully measured. It is expected that the higher the absorbed energy, the better is the ballistic performance. From the data obtained, it was not shown any significant variation between the different materials.

Table 11 presents the ANOVA for the absorbed energy in the ballistic test. According to

Table 11, since F calculated was smaller than F

c (tabulated), the hypothesis that the averages are equal was accepted (with a level of significance of 5%). Therefore, it was confirmed that there was no significant difference between the absorbed energy of the different materials.

Figure 9 and

Figure 10 show the thermogravimetric (TG) and its derivative (DTG) curves, respectively, for the neat epoxy resin and the composites reinforced with 10, 20, and 30 vol.% of CM sedge fibers. The curves for the different materials presented similar features. Observing the TG curves in

Figure 9, there was a small mass loss (<5%) at low temperatures (until 200 °C), which was attributed to moisture desorption. For the neat epoxy resin, for example, the mass loss was extremely low, 1.64%, due to its hydrophobic nature (little water absorption). For the composites, the mass loss in this stage was slightly higher, ranging from 3 to 4.2%, due to the higher moisture absorption capacity of the sedge fibers that are now present in the structure.

At higher temperatures, degradation and rupture of the polymeric chains occurred, with severe mass loss. This occurred at T

onset = 345 °C for the neat epoxy resin, with a maximum rate at 389 °C (

Figure 10), resulting in a 70.59% mass loss in

Figure 9. A third stage occurring at temperatures ranging from 455 to 600 °C resulted in a final formation of ash corresponding to about 19.6% of the initial mass, also shown in

Figure 9. For the composites, the degradation occurred at lower temperatures, as previously reported [

39,

61], at T

onset = 292 °C for the 10 vol.% fiber-composites, T

onset = 287 °C for the 20 vol.% fiber-composites, and T

onset = 301 °C for the 30 vol.% CM fiber-composites. These temperatures could be considered as a first limit for the thermal stability of the CM sedge fiber-reinforced composites. Another difference between the epoxy resin and the composites was related to the temperature corresponding to the maximum rate of degradation, shown in the DTG curves in

Figure 10, where the composites had a temperature ranging from 334 to 362 °C, which was slightly lower than 389 °C registered for the neat epoxy resin.

Table 12 presents the main thermogravimetric parameters, temperatures, and mass loss for the neat epoxy, 0% fiber, and CM sedge fiber-reinforced composites.

Lignin is the first structural component of NLFs to begin its degradation process at lower temperatures from 220 °C and continues above 440 °C [

39]. Thus, the degradation of lignin is directly responsible for the thermal stability limit of a composite reinforced with NLFs.

Figure 11 shows the DSC curves for the neat epoxy resin and for the sedge fibers-reinforced composites. The curve for the epoxy resin showed an endothermic peak at 81.1 °C, which was associated with the glass transition temperature (Tg). Regarding the curves representing the composites, endothermic peaks ranging between 66.8 and 81.1 °C could be observed, also associated with the Tg. Changes in the baseline on temperatures ranging from 119 to 122.9 °C might be related to a post-curing process, as evidenced in the isolated DSC curve for the 30 vol% CM sedge fiber composite in

Figure 12 [

62,

63]. The decrease in Tg for the composites, as compared to the neat epoxy, was due to the interference of CM sedge fiber with the 3D organization of the polymer macromolecules. This is a common event for NLF composites [

39], which does not compromise the thermal stability for the usual engineering application since stiffness and hardness are not significantly changed.