Improved Energy Storage Performance of All-Organic Composite Dielectric via Constructing Sandwich Structure

Abstract

:1. Introduction

2. Experimental Section

2.1. Material and Methods

2.2. Microstructure and Properties Characterization

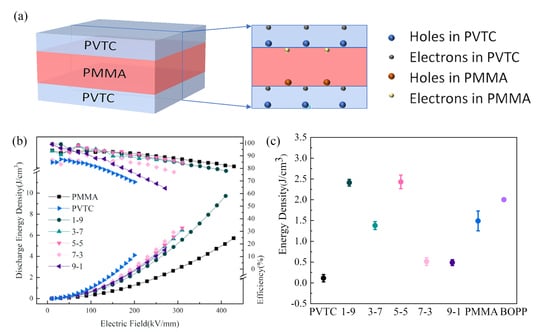

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tan, D.Q. The search for enhanced dielectric strength of polymer-based dielectrics: A focused review on polymer nanocomposites. J. Appl. Polym. Sci. 2020, 137, 49379. [Google Scholar] [CrossRef]

- Huang, X.; Sun, B.; Zhu, Y.; Li, S.; Jiang, P. High-k polymer nanocomposites with 1D filler for dielectric and energy storage applications. Prog. Mater. Sci. 2019, 100, 187–225. [Google Scholar] [CrossRef]

- Qi, L.; Petersson, L.; Liu, T. Review of Recent Activities on Dielectric Films for Capacitor Applications. J. Int. Counc. Electr. Eng. 2014, 4, 1–6. [Google Scholar] [CrossRef]

- Barshaw, E.J.; White, J.; Chait, M.J.; Cornette, J.B.; Bustamante, J.; Folli, F.; Biltchick, D.; Borelli, G.; Picci, G.; Rabuffi, M. High Energy Density (HED) Biaxially-Oriented Poly-Propylene (BOPP) Capacitors for Pulse Power Applications. IEEE Trans. Magn. 2006, 43, 223–225. [Google Scholar] [CrossRef]

- Hao, X. A review on the dielectric materials for high energy-storage application. J. Adv. Dielectr. 2013, 3, 1–14. [Google Scholar] [CrossRef]

- Huan, T.D.; Boggs, S.; Teyssedre, G.; Laurent, C.; Cakmak, M.; Kumar, S.; Ramprasad, R.; Tran, H.D. Advanced polymeric dielectrics for high energy density applications. Prog. Mater. Sci. 2016, 83, 236–269. [Google Scholar] [CrossRef]

- Fan, B.; Zhou, M.; Zhang, C.; He, D.; Bai, J. Polymer-based materials for achieving high energy density film capacitors. Prog. Polym. Sci. 2019, 97, 101143. [Google Scholar] [CrossRef]

- Bouharras, F.E.; Raihane, M.; Ameduri, B. Recent progress on core-shell structured BaTiO3@polymer/fluorinated polymers nanocomposites for high energy storage: Synthesis, dielectric properties and applications. Prog. Mater. Sci. 2020, 113, 100670. [Google Scholar] [CrossRef]

- Dang, Z.-M.; Yuan, J.; Yao, S.-H.; Liao, R.-J. Flexible Nanodielectric Materials with High Permittivity for Power Energy Storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef]

- Zhou, Z.; Carr, J.; Mackey, M.; Yin, K.; Schuele, D.; Zhu, L.; Baer, E. Interphase/interface modification on the dielectric properties of polycarbonate/poly(vinylidene fluoride-co-hexafluoropropylene) multilayer films for high-energy density capacitors. J. Polym. Sci. Part B 2013, 51, 978–991. [Google Scholar] [CrossRef]

- Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar]

- Wei, J.-J.; Zhu, L. Intrinsic polymer dielectrics for high energy density and low loss electric energy storage. Prog. Polym. Sci. 2020, 106, 101254. [Google Scholar] [CrossRef]

- Feng, M.; Zhang, T.; Zhou, G.; Zhang, T.; Feng, Y.; Chi, Q.; Lei, Q. Enhanced Energy Storage Characteristics in PVDF-Based Nanodielectrics with Core-Shell Structured and Optimized Shape Fillers. IEEE Access 2020, 8, 81542–81550. [Google Scholar] [CrossRef]

- Guo, M.; Jiang, J.; Shen, Z.; Lin, Y.; Nan, C.-W.; Shen, Y. High-Energy-Density Ferroelectric Polymer Nanocomposites for Capacitive Energy Storage: Enhanced Breakdown Strength and Improved Discharge Efficiency. Mater. Today 2019, 29, 49–67. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, Y.; Zhang, T.; Zhang, C.; Zhang, Y.; Zhang, Y.; Chen, Q.; Chi, Q. Ultrahigh discharge efficiency and excellent energy density in oriented core-shell nanofiber-polyetherimide composites. Energy Storage Mater. 2020, 25, 180–192. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, T.; Feng, Y.; Zhang, Y.; Zhang, C.; Zhang, Y.; Wang, X.; Chi, Q.; Chen, Q.; Lei, Q. Sandwich-structured polymers with electrospun boron nitrides layers as high-temperature energy storage dielectrics. Chem. Eng. J. 2020, 389, 124443. [Google Scholar] [CrossRef]

- Kuang, D.; Li, R.; Pei, J. Polyamide 11/Poly(vinylidene fluoride)/Vinyl Acetate-Maleic Anhydride Copolymer as Novel Blends Flexible Materials for Capacitors. Polymers 2014, 6, 2146–2156. [Google Scholar] [CrossRef]

- Yang, B.; Qu, P.; Peng, X.; Liu, X. High breakdown strength and low loss of polystyrene-block-poly(methyl methacrylate)/Poly(vinylidene fluoride) composites for energy storage application. Polym. Plast. Technol. Mater. 2018, 58, 1245–1252. [Google Scholar] [CrossRef]

- Tseng, J.-K.; Yin, K.; Zhang, Z.; Mackey, M.; Baer, E.; Zhu, L. Morphological effects on dielectric properties of poly(vinylidene fluoride-co-hexafluoropropylene) blends and multilayer films. Polymers 2019, 172, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Meng, Q.; Li, W.; Zheng, Y.; Zhang, Z. Effect of poly(methyl methacrylate) addition on the dielectric and energy storage properties of poly(vinylidene fluoride). J. Appl. Polym. Sci. 2010, 116, 2674–2684. [Google Scholar] [CrossRef]

- Mohamadi, S.; Sharifi-Sanjani, N.; Foyouhi, A. Evaluation of graphene nanosheets influence on the physical properties of PVDF/PMMA blend. J. Polym. Res. 2012, 20. [Google Scholar] [CrossRef]

- Baer, E.; Zhu, L. 50th Anniversary Perspective: Dielectric Phenomena in Polymers and Multilayered Dielectric Films. Macromolecules 2017, 50, 2239–2256. [Google Scholar] [CrossRef]

- Chi, Q.; Zhou, Y.; Yin, C.; Zhang, Y.; Zhang, T.; Zhang, T.; Feng, Y.; Zhang, Y.; Chen, Q. A blended binary composite of poly(vinylidene fluoride) and poly(methyl methacrylate) exhibiting excellent energy storage performances. J. Mater. Chem. C 2019, 7, 14148–14158. [Google Scholar] [CrossRef]

- Wang, C.; Pilania, G.; Boggs, S.; Kumar, S.; Breneman, C.; Ramprasad, R. Computational strategies for polymer dielectrics design. Polymer 2014, 55, 979–988. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.; Zhang, D.; Bowen, C.R.; Wan, C. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef] [Green Version]

- Tseng, J.-K.; Tang, S.; Zhou, Z.; Mackey, M.; Carr, J.M.; Mu, R.; Flandin, L.; Schuele, D.E.; Baer, E.; Zhu, L. Interfacial polarization and layer thickness effect on electrical insulation in multilayered polysulfone/poly(vinylidene fluoride) films. Polymer 2014, 55, 8–14. [Google Scholar] [CrossRef]

- Zhang, L.; Shan, X.; Bass, P.; Tong, Y.; Rolin, T.D.; Hill, C.W.; Brewer, J.C.; Tucker, D.S.; Cheng, Z.-Y. Process and Microstructure to Achieve Ultra-high Dielectric Constant in Ceramic-Polymer Composites. Sci. Rep. 2016, 6, 35763. [Google Scholar] [CrossRef] [Green Version]

- Fan, Q.; Liu, M.; Ma, C.; Wang, L.; Ren, S.; Lu, L.; Lou, X.; Jia, C.-L. Significantly enhanced energy storage density with superior thermal stability by optimizing Ba(Zr0.15Ti0.85)O3/Ba(Zr0.35Ti0.65)O3 multilayer structure. Nano Energy 2018, 51, 539–545. [Google Scholar] [CrossRef]

- Lean, M.H.; Chu, W.-P.L. Dynamic charge mapping in layered polymer films. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1319–1329. [Google Scholar] [CrossRef]

- Mackey, M.; Flandin, L.; Hiltner, A.; Baer, E. Confined crystallization of PVDF and a PVDF-TFE copolymer in nanolayered films. J. Polym. Sci. Part B 2011, 49, 1750–1761. [Google Scholar] [CrossRef]

- Mackey, M.; Schuele, D.E.; Zhu, L.; Baer, E. Layer confinement effect on charge migration in polycarbonate/poly(vinylidene fluorid-co-hexafluoropropylene) multilayered films. J. Appl. Phys. 2012, 111, 113702. [Google Scholar] [CrossRef] [Green Version]

- Mackey, M.; Schuele, D.E.; Zhu, L.; Flandin, L.; Wolak, M.A.; Shirk, J.S.; Hiltner, A.; Baer, E. Reduction of Dielectric Hysteresis in Multilayered Films via Nanoconfinement. Macromolecules 2012, 45, 1954–1962. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, D.; Wang, L.; Chen, C.; Zhou, J.; Zhou, K. Highly enhanced dielectric strength and energy storage density in hydantoin@BaTiO3–P(VDF-HFP) composites with a sandwich-structure. RSC Adv. 2015, 5, 52809–52816. [Google Scholar] [CrossRef]

- Li, Q.; Liu, F.; Yang, T.; Gadinski, M.R.; Zhang, G.; Chen, L.-Q.; Wang, Q. Sandwich-structured polymer nanocomposites with high energy density and great charge-discharge efficiency at elevated temperatures. Proc. Natl. Acad. Sci. USA 2016, 113, 9995–10000. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Wang, J.; Mao, F.; Yang, C.; Zhang, C.; Fan, R. Significantly improved dielectric performances of sandwich-structured polymer composites induced by alternating positive-k and negative-k layers. J. Mater. Chem. A 2017, 5, 14575–14582. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, Y.; Deng, Y. Effects of interfaces between adjacent layers on breakdown strength and energy density in sandwich-structured polymer composites. Compos. Sci. Technol. 2017, 145, 71–77. [Google Scholar] [CrossRef]

- Cui, Y.; Zhang, T.; Feng, Y.; Zhang, C.; Chi, Q.; Zhang, Y.; Chen, Q.; Wang, X.; Lei, Q. Excellent energy storage density and efficiency in blend polymer-based composites by design of core-shell structured inorganic fibers and sandwich structured films. Compos. Part B 2019, 177, 107429. [Google Scholar] [CrossRef]

- Pei, J.-Y.; Zha, J.-W.; Zhou, W.; Wang, S.-J.; Zhong, S.-L.; Yin, L.-J.; Zheng, M.-S.; Cai, H.-W.; Dang, Z.-M. Enhancement of breakdown strength of multilayer polymer film through electric field redistribution and defect modification. Appl. Phys. Lett. 2019, 114, 103702. [Google Scholar] [CrossRef]

- Zhang, Y.; Chi, Q.; Liu, L.; Zhang, T.; Chen, C.; Wang, X.; Lei, Q. Enhanced electric polarization and breakdown strength in the all-organic sandwich-structured poly(vinylidene fluoride)-based dielectric film for high energy density capacitor. APL Mater. 2017, 5, 076109. [Google Scholar] [CrossRef]

- Lu, X.; Shen, J.; Zhang, L.; Xu, Z.; Cheng, Z.-Y. Dielectric property and ac conductivity of P(VDF-CTFE)-PLZST polymer-ceramic composite films. Ceram. Int. 2019, 45, 8979–8987. [Google Scholar] [CrossRef]

- Lu, X.; Zou, X.; Shen, J.; Zhang, L.; Jin, L.; Cheng, Z.-Y. High energy density with ultrahigh discharging efficiency obtained in ceramic-polymer nanocomposites using a non-ferroelectric polar polymer as matrix. Nano Energy 2020, 70, 104551. [Google Scholar] [CrossRef]

- Liu, S.; Xue, S.; Zhang, W.; Zhai, J.; Chen, G. Significantly enhanced dielectric property in PVDF nanocomposites flexible films through a small loading of surface-hydroxylated Ba0.6Sr0.4TiO3nanotubes. J. Mater. Chem. A 2014, 2, 18040–18046. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Wang, X.; Lei, Q. Energy storage enhancement of P(VDF-TrFE-CFE)-based composites with double-shell structured BZCT nanofibers of parallel and orthogonal configurations. Nano Energy 2019, 66, 104195. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Li, G.; Cui, Y.; Wang, X.; et al. Excellent energy storage performance and thermal property of polymer-based composite induced by multifunctional one-dimensional nanofibers oriented in-plane direction. Nano Energy 2019, 56, 138–150. [Google Scholar] [CrossRef]

- Elashmawi, I.; Hakeem, N. Effect of PMMA addition on characterization and morphology of PVDF. Polym. Eng. Sci. 2008, 48, 895–901. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, H.; Yao, Z.; Hao, H.; Yu, Z.; Cao, M. Effect of layered structure on dielectric properties and energy storage density in xBa0.7Sr0.3TiO3-SrTiO3 multilayer ceramics. Ceram. Int. 2017, 43, 8418–8423. [Google Scholar] [CrossRef]

- Chen, X.; Tseng, J.K.; Treufeld, I.; Mackey, M.; Schuele, D.E.; Li, R.; Fukuto, M.; Baer, E.; Zhu, L. Enhanced dielectric properties due to space charge-induced interfacial polarization in multilayer polymer films. J. Mater. Chem. C 2017, 5, 10417–10426. [Google Scholar] [CrossRef]

- Zhu, L. Exploring Strategies for High Dielectric Constant and Low Loss Polymer Dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef]

- Chi, Q.; Ma, T.; Zhang, Y.; Cui, Y.; Zhang, T.; Lin, J.; Wang, X.; Lei, Q. Significantly enhanced energy storage density for poly(vinylidene fluoride) composites by induced PDA-coated 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 nanofibers. J. Mater. Chem. A 2017, 5, 16757–16766. [Google Scholar] [CrossRef]

- Zhu, J.; Shen, J.; Guo, S.; Sue, H. Confined distribution of conductive particles in polyvinylidene fluoride-based multilayered dielectrics: Toward high permittivity and breakdown strength. Carbon 2015, 84, 355–364. [Google Scholar] [CrossRef]

- Wu, L.; Wu, K.; Liu, D.; Huang, R.; Huo, J.; Chen, F.; Fu, Q. Largely enhanced energy storage density of poly(vinylidene fluoride) nanocomposites based on surface hydroxylation of boron nitride nanosheets. J. Mater. Chem. A 2018, 6, 7573–7584. [Google Scholar] [CrossRef]

- Shen, Y.; Luo, S.; Yu, S.-H.; Sun, R.; Wong, C. Surface-modified barium titanate by MEEAA for high-energy storage application of polymer composites. High Volt. 2016, 1, 175–180. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, G.; Liu, F.; Han, K.; Gadinski, M.R.; Xiong, C.; Wang, Q. Solution-processed ferroelectric terpolymer nanocomposites with high breakdown strength and energy density utilizing boron nitride nanosheets. Energy Environ. Sci. 2015, 8, 922–931. [Google Scholar] [CrossRef]

- Marwat, M.A.; Yasar, M.; Ma, W.; Fan, P.; Liu, K.; Lu, D.; Tian, Y.; Samart, C.; Ye, B.; Zhangaf, H. Significant Energy Density of Discharge and Charge–Discharge Efficiency in Ag@BNN Nanofillers-Modified Heterogeneous Sandwich Structure Nanocomposites. ACS Appl. Energy Mater. 2020. [Google Scholar] [CrossRef]

- Zhang, H.; Marwat, M.A.; Xie, B.; Ashtar, M.; Liu, K.; Zhu, Y.; Zhang, L.; Fan, P.; Samart, C.; Ye, Z.-G. Polymer Matrix Nanocomposites with 1D Ceramic Nanofillers for Energy Storage Capacitor Applications. ACS Appl. Mater. Interfaces 2019, 12, 1–37. [Google Scholar] [CrossRef]

- Chen, C.; Xing, J.; Cui, Y.; Zhang, T.; Feng, Y.; Zhang, Y.; Zhang, T.; Chi, Q.; Wang, X.; Lei, Q. Designing of Ferroelectric/Linear Dielectric Bilayer Films: An Effective Way to Improve the Energy Storage Performances of Polymer-Based Capacitors. J. Phys. Chem. C 2020, 124, 5920–5927. [Google Scholar] [CrossRef]

- Sun, L.; Shi, Z.; Liang, L.; Wei, S.; Wang, H.; Dastan, D.; Sun, K.; Fan, R. Layer-structured BaTiO3/P(VDF-HFP) composites with concurrently improved dielectric permittivity and breakdown strength toward capacitive energy-storage applications. J. Mater. Chem. C 2020, 8, 10257–10265. [Google Scholar] [CrossRef]

- Lu, H.; Du, J.; Yu, C.; Wang, X.; Gao, Y.; Xu, W.; Liu, A.; Lu, X.; Chen, Y. Ultrahigh Energy Storage Capacitance and High Breakdown Strength in Biaxially Oriented Poly(vinylidene fluoride) Using a High-Electric-Induced Technique. Macromol. Res. 2020, 28, 573–579. [Google Scholar] [CrossRef]

- Wang, L.; Luo, H.; Zhou, X.; Yuan, X.; Zhou, K.; Zhang, D. Sandwich-structured all-organic composites with high breakdown strength and high dielectric constant for film capacitor. Compos. Part A 2019, 117, 369–376. [Google Scholar] [CrossRef]

| VPVTC:VPMMA | VPVTC for First Layer /mL | VPMMA for Second Layer /mL | VPVTC for Third Layer /mL |

|---|---|---|---|

| 1:9 | 0.3125 | 1.125 | 0.3125 |

| 3:7 | 0.9360 | 0.875 | 0.9360 |

| 5:5 | 1.5625 | 0.625 | 1.5625 |

| 7:3 | 2.1875 | 0.375 | 2.1875 |

| 9:1 | 2.8125 | 0.125 | 2.8125 |

| Sample | Discharge Energy Density(J/cm3) @ 90% Efficiency | Reference |

|---|---|---|

| 1 vol % PDA-SiO2@BT NPs/PVDF | 2.1 | [13] |

| PVDF/PS-b-PMMA composite | 1 | [18] |

| BCZT + Ag@Al2O3/PMMA/PVDF | 0.8 | [37] |

| 5 vol % BZT-BCT NFs/PVDF composite | 0.9 | [49] |

| P(VDF-TrFE-CFE)/PI bilayer films | 1 | [56] |

| 15 vol % 4L BT/P(VDF-HFP) composites | 1 | [57] |

| BOPVDF films | 2 | [58] |

| 25 vol % sandwich-structured PVDF/P(VDF-TrFE-CTFE)/PVDF | 1 | [59] |

| 1-9 Sandwich Structure PVTC/PMMA composite | 2.569 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, M.; Zhang, T.; Song, C.; Zhang, C.; Zhang, Y.; Feng, Y.; Chi, Q.; Chen, Q.; Lei, Q. Improved Energy Storage Performance of All-Organic Composite Dielectric via Constructing Sandwich Structure. Polymers 2020, 12, 1972. https://doi.org/10.3390/polym12091972

Feng M, Zhang T, Song C, Zhang C, Zhang Y, Feng Y, Chi Q, Chen Q, Lei Q. Improved Energy Storage Performance of All-Organic Composite Dielectric via Constructing Sandwich Structure. Polymers. 2020; 12(9):1972. https://doi.org/10.3390/polym12091972

Chicago/Turabian StyleFeng, Mengjia, Tiandong Zhang, Chunhui Song, Changhai Zhang, Yue Zhang, Yu Feng, Qingguo Chi, Qingguo Chen, and Qingquan Lei. 2020. "Improved Energy Storage Performance of All-Organic Composite Dielectric via Constructing Sandwich Structure" Polymers 12, no. 9: 1972. https://doi.org/10.3390/polym12091972

APA StyleFeng, M., Zhang, T., Song, C., Zhang, C., Zhang, Y., Feng, Y., Chi, Q., Chen, Q., & Lei, Q. (2020). Improved Energy Storage Performance of All-Organic Composite Dielectric via Constructing Sandwich Structure. Polymers, 12(9), 1972. https://doi.org/10.3390/polym12091972