Caranan Fiber from Mauritiella armata Palm Tree as Novel Reinforcement for Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

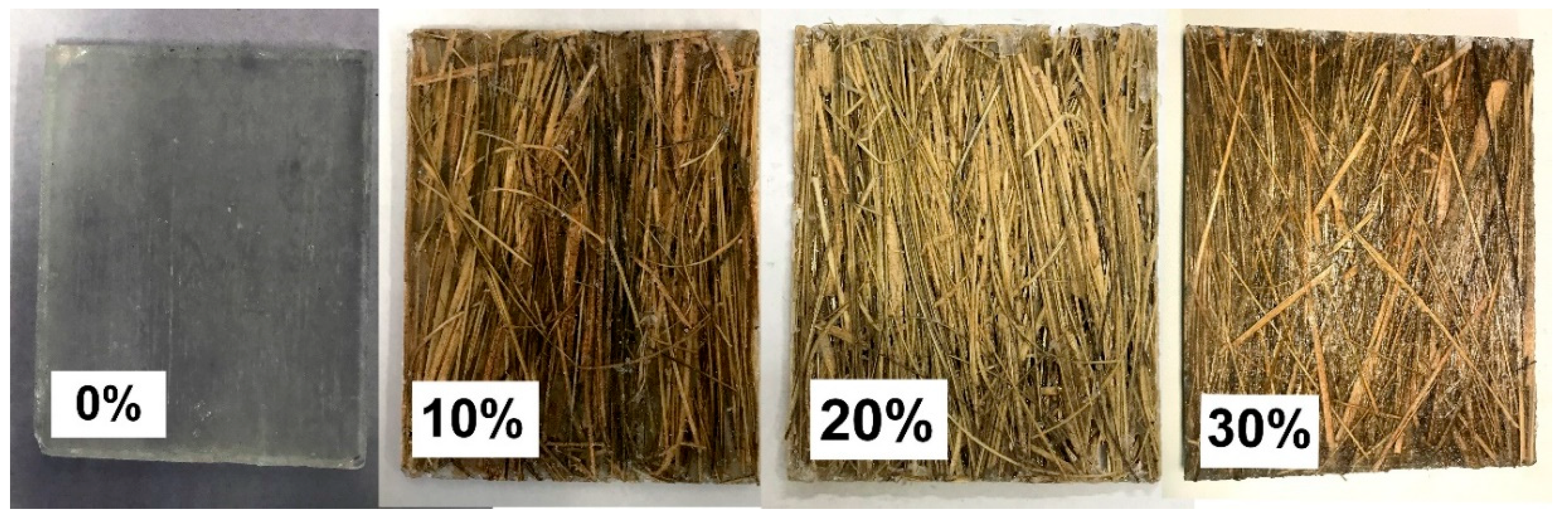

2.2. Composites Processing

2.3. Density and Porosity Measurements

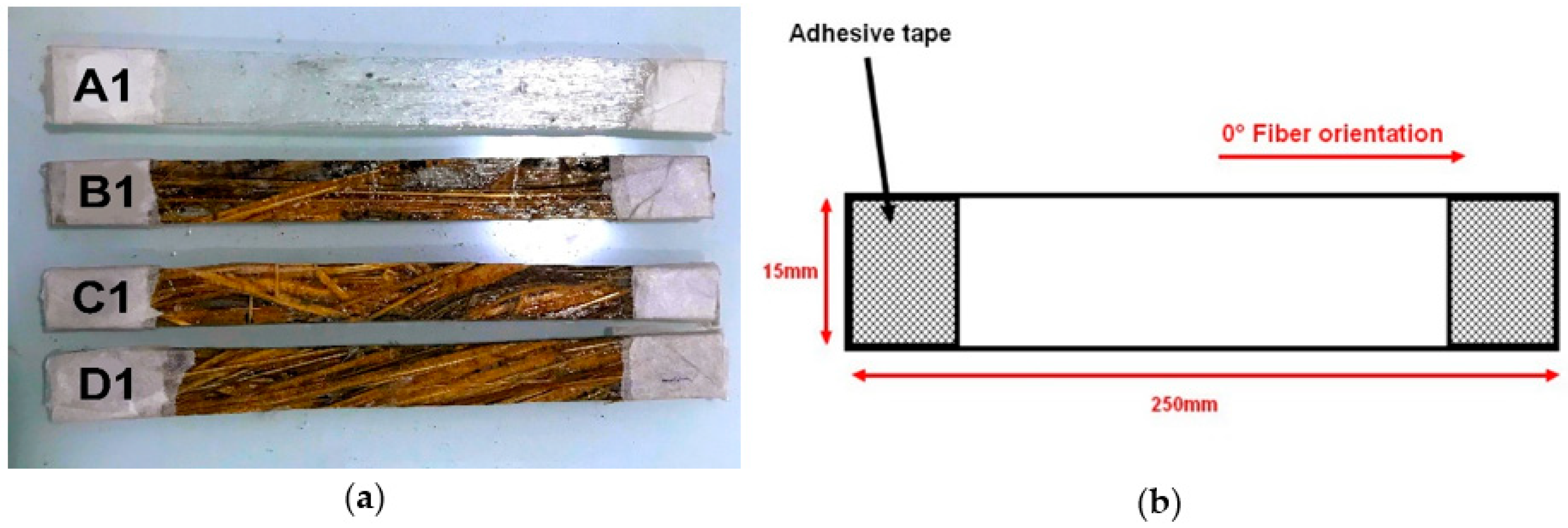

2.4. Tensile Tests

2.5. Thermal Analysis

2.6. Micrography Analysis

2.7. Dynamic Mechanical Analysis

3. Results and Discussions

3.1. Materials Basic Characterization

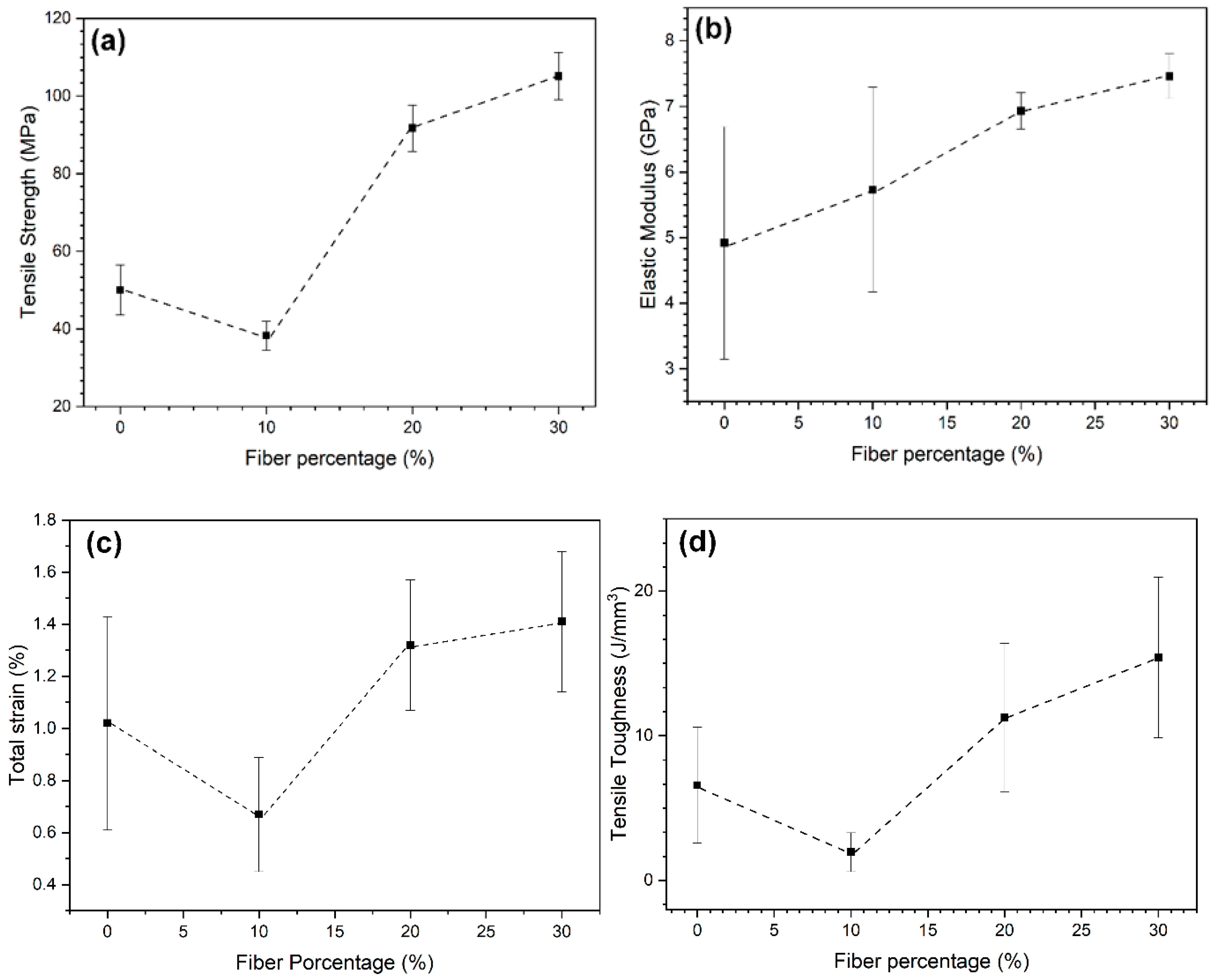

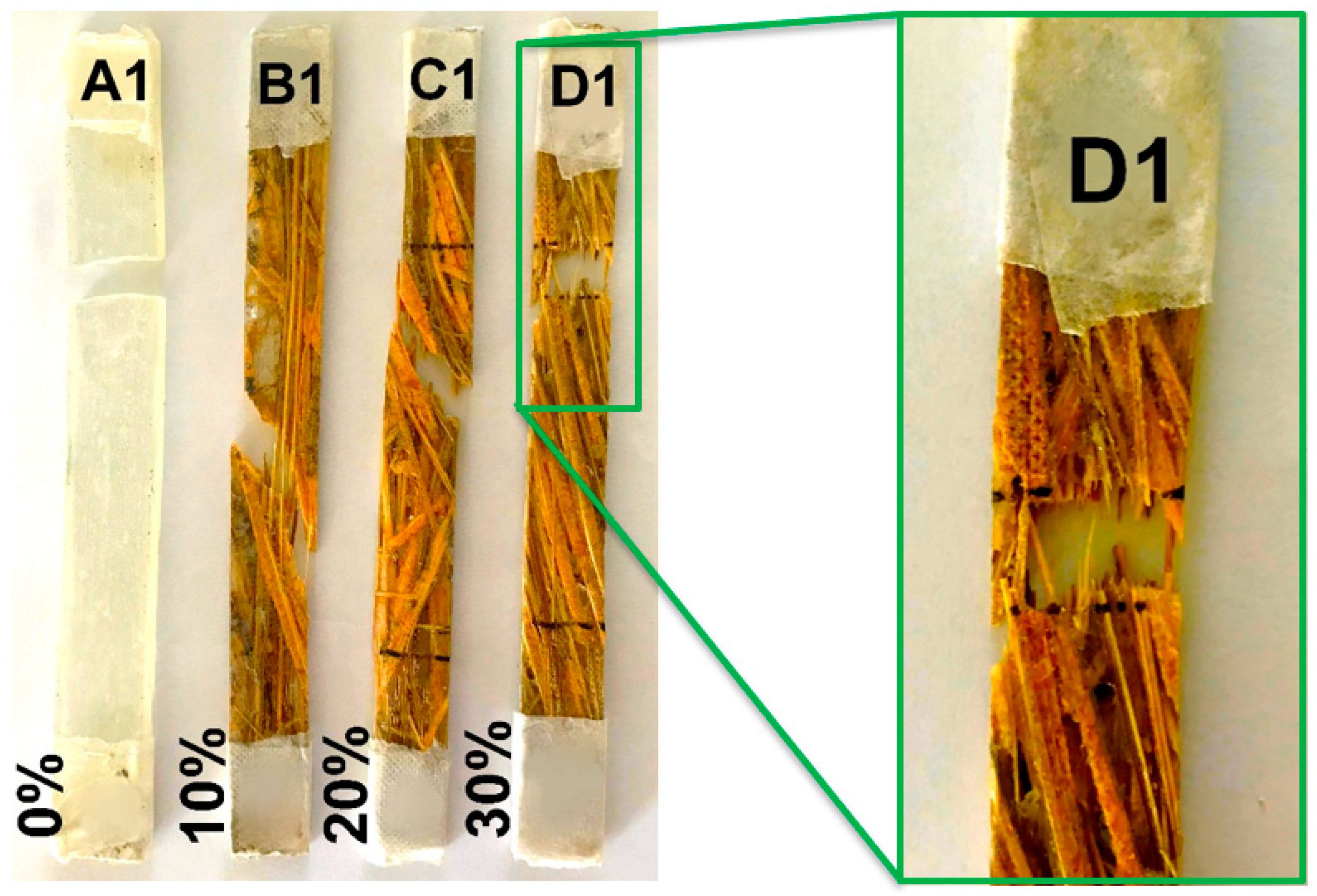

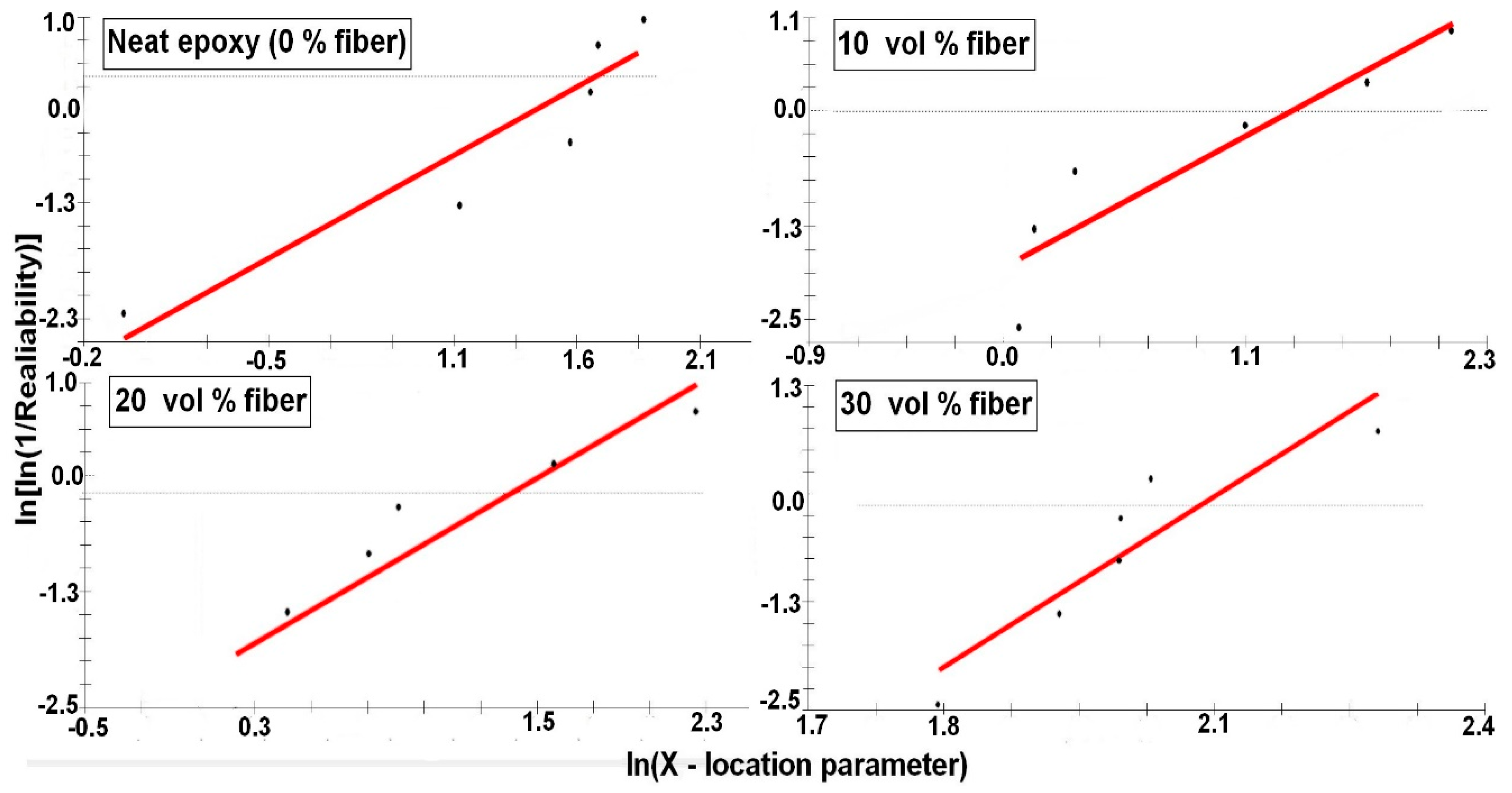

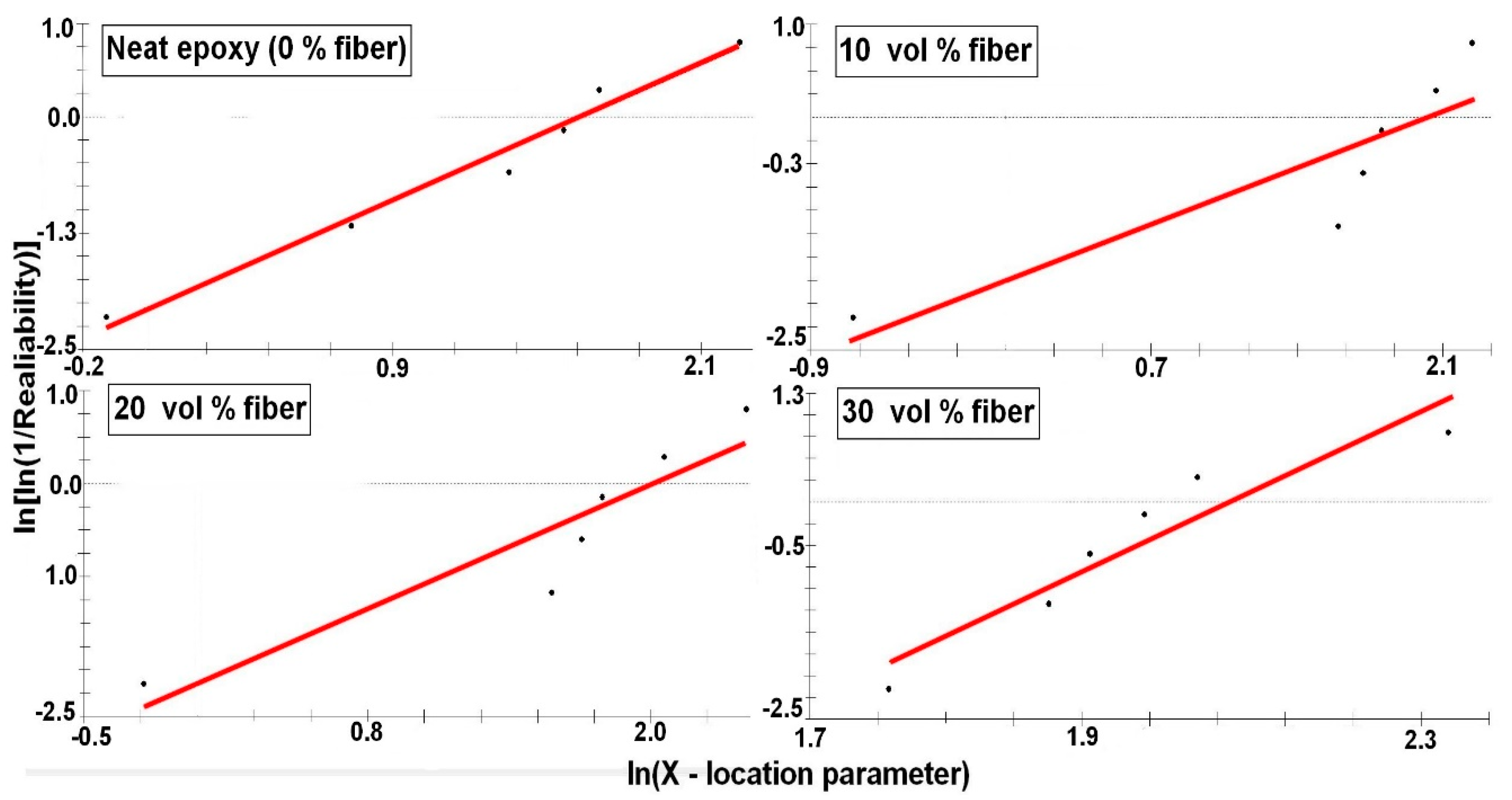

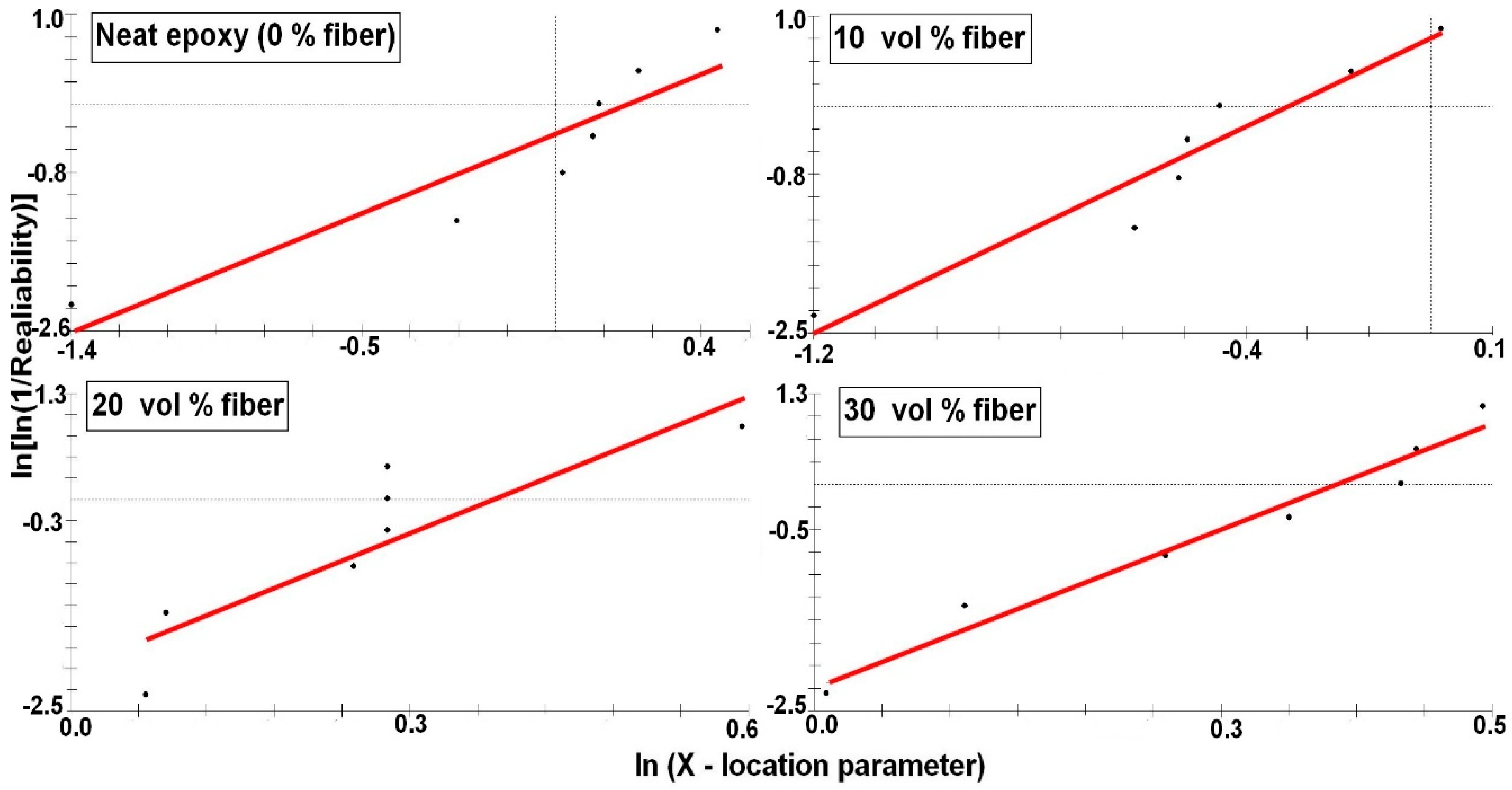

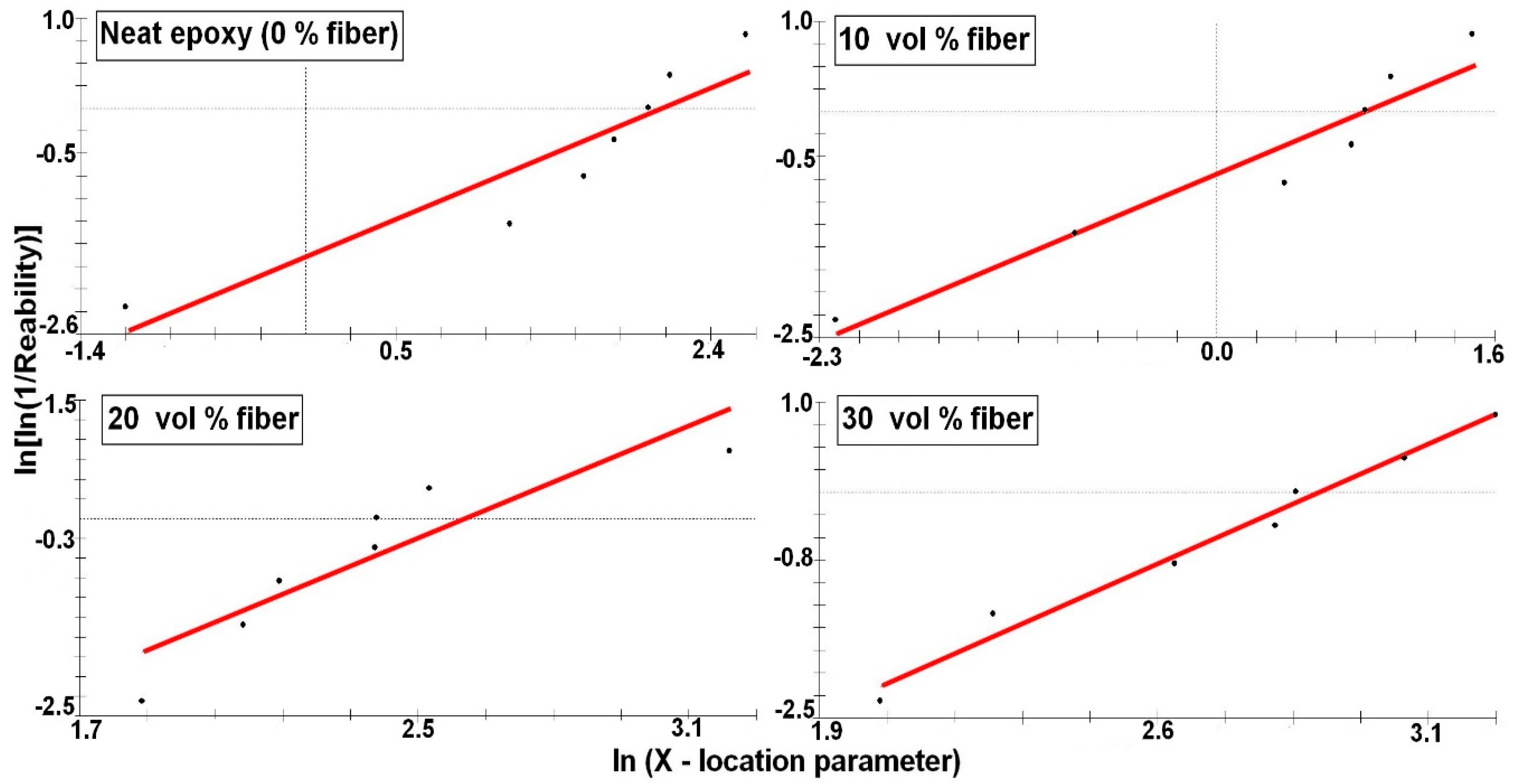

3.2. Tensile Test

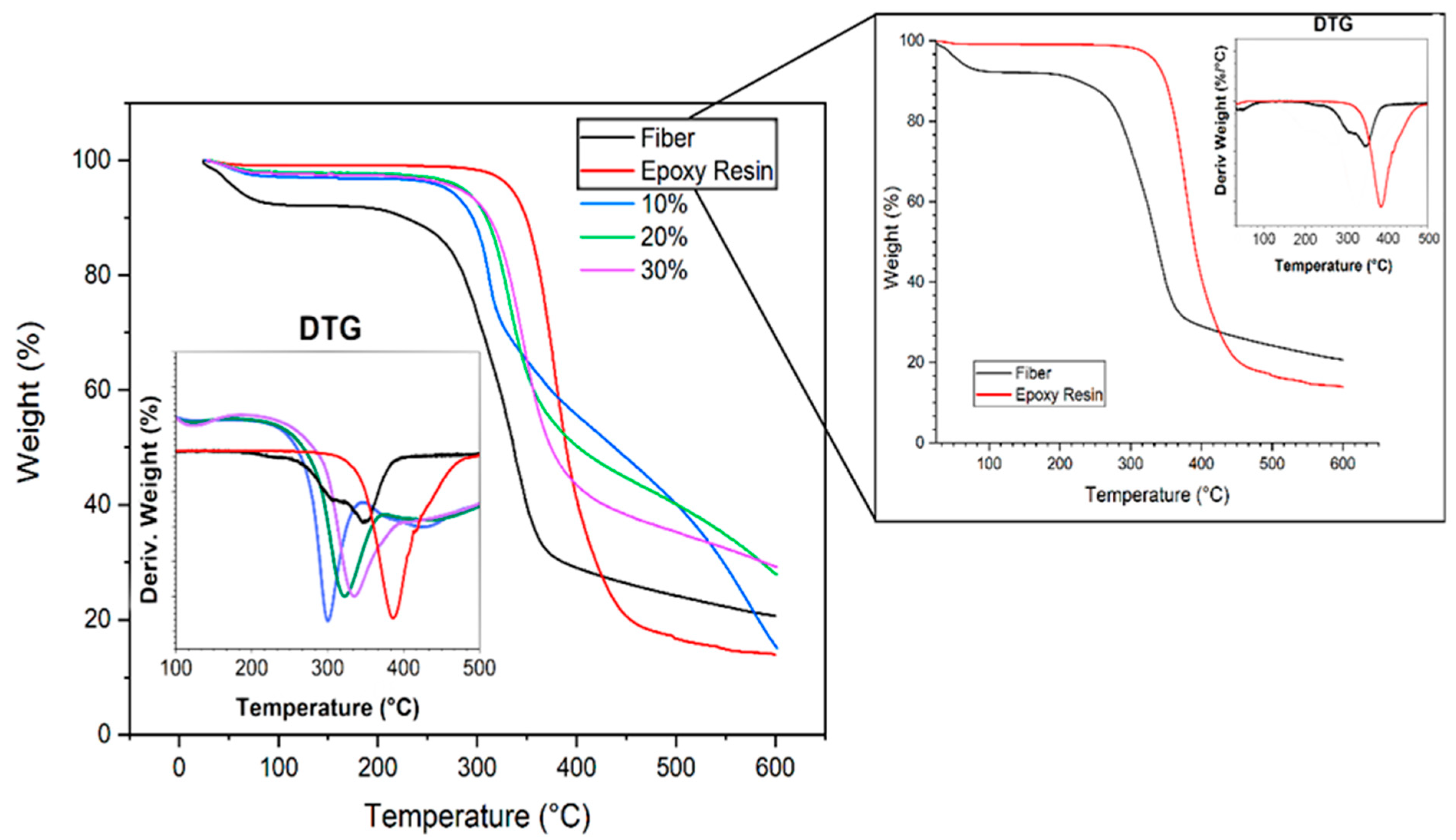

3.3. Thermogravimetric Analysis

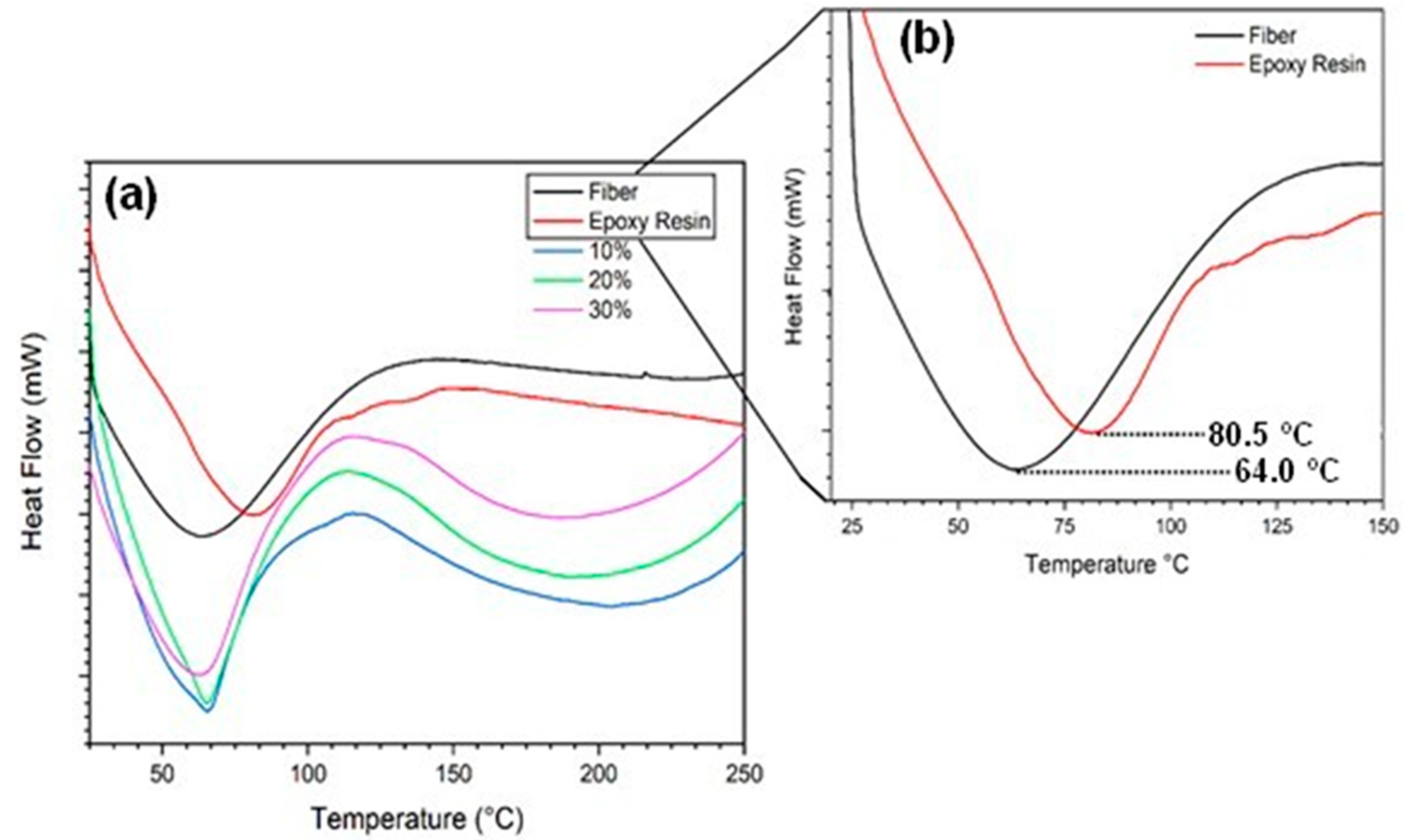

3.4. Differential Scanning Calorimetry Analysis

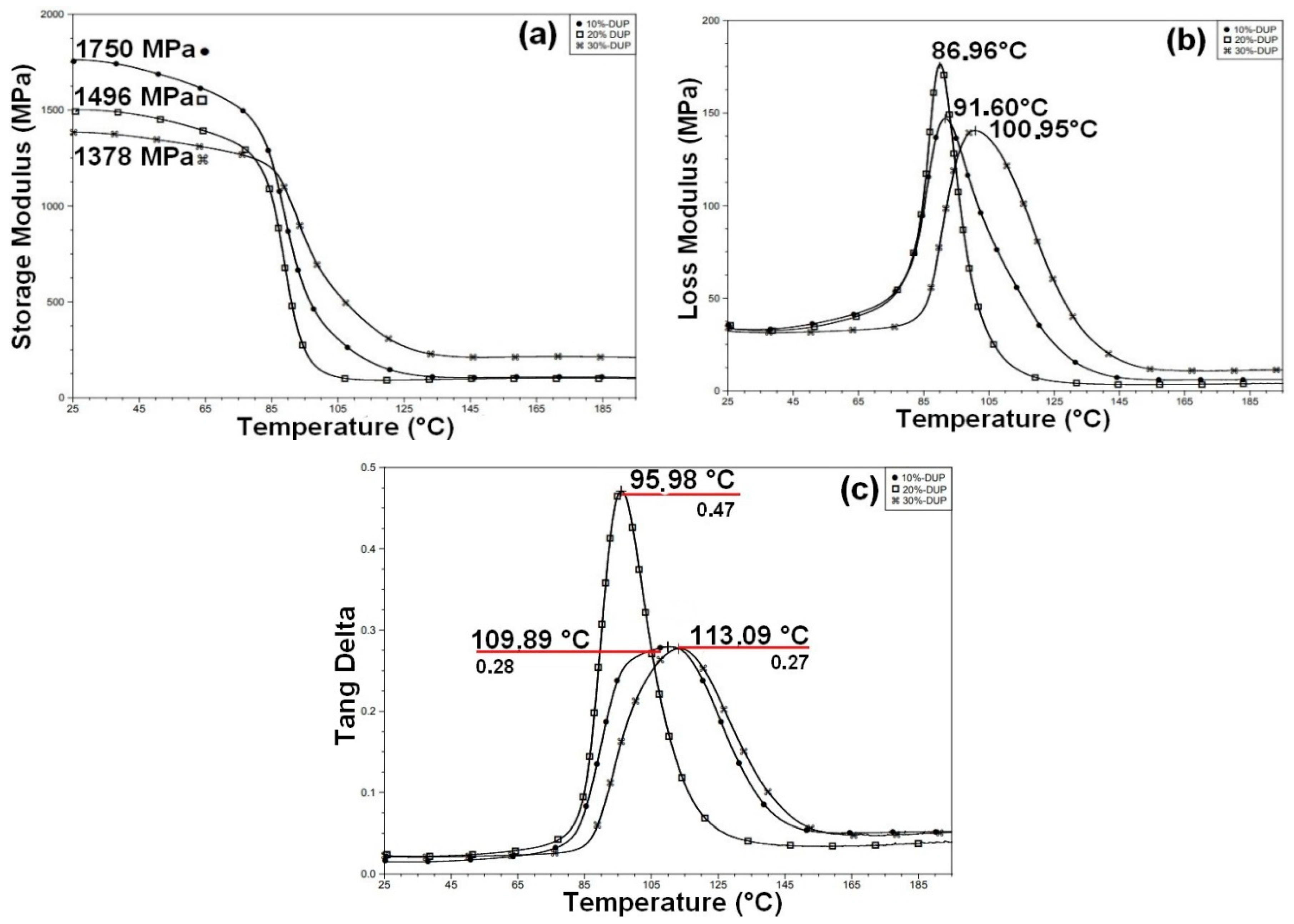

3.5. Dynamic Mechanical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hassan, K.M.; Horvath, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced Composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 108151. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Güven, O.; Monteiro, S.N.; Moura, E.A.; Drelich, J.W. Re-emerging field of lignocellulosic fiber–polymer composites and ionizing radiation technology in their formulation. Polym. Rev. 2016, 56, 702–736. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 243947. [Google Scholar] [CrossRef] [Green Version]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Raw natural fiber–based polymer composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites—An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Potluri, R.; Krishna, N.C. Potential and Applications of Green Composites in Industrial Space. Mater. Today Proc. 2020, 22, 2041–2048. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites materials for food packaging applications: Concepts and future outlook. Carbohyd. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Di Bella, G.; Fiore, V.; Galtieri, G.; Borsellino, C.; Valenza, A. Effects of natural fibres reinforcement in lime plasters (kenaf and sisal vs. Polypropylene). Constr. Build. Mater. 2014, 58, 159–165. [Google Scholar] [CrossRef]

- Majeed, K.; Jawaid, M.; Hassan, A.; Abu Bakar, A.; Abdul Khalil, H.P.S.; Salema, A.A.; Inuwa, I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Thomas, N.; Paul, S.A.; Pothan, L.A.; Deepa, B. Natural fibers: Structure, properties and applications. In Cellulose Fibers: Bio-and Nano-Polymer Composites; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: Berlin, Germany, 2011; pp. 3–42. [Google Scholar]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM-US 2016, 58, 80–86. [Google Scholar] [CrossRef]

- Maciel, N.D.O.R.; Ferreira, J.B.; da Vieira, J.S.; Ribeiro, C.G.D.; Lopes, F.P.D.; Margem, F.M.; Silva, L.C.d. Comparative tensile strength analysis between epoxy composites reinforced with curaua fiber and glass fiber. J. Mater. Res. Technol. 2018, 7, 561–565. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Joshi, S.; Drzal, L.; Mohanty, A.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Tarrés, Q.; Oliver-Orteza, H.; Alcala, M.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M. Research on the strengthening advantages on using cellulose nanofibers as polyvinyl alcohol reinforcement. Polymers 2020, 12, 974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Silva, I.L.A.D.; Costa, L.L.D. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef] [Green Version]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Da Costa Garcia Filho, F.; da Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- De Mendonça Neuba, L.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; de Sousa Lima, E.; Garcia Filho, F.D.C.; Monteiro, S.N.; da Silva Figueiredo, A.B.-H.; de Oliveira Braga, F.; de Azevedo, A.R.G. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; de Veiga, V.F.; Garcia Filho, F.D.C.; Pinheiro, M.A.; Monteiro, S.N. Guaruman fiber: Another possible reinforcement in composites. J. Mater. Res. Technol. 2020, 9, 622–628. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; da Luz, F.S.; Costa, U.O.; Braga, F.O.; Lima Júnior, É.P.; Monteiro, S.N. Curing Kinetic Parameters of Epoxy Composite Reinforced with Mallow Fibers. Materials 2019, 12, 3939. [Google Scholar] [CrossRef] [Green Version]

- Da Demosthenes, L.C.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; da Garcia Filho, F.C.; da Luz, F.S.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and structural characterization of buriti fibers and their relevance in fabric reinforced composites. J. Mater. Res. Technol. 2019, 9, 115–123. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Elagib, T.H.H.; Hassan, F.E.A.A.; Yu, M. Rheological and dynamic mechanical properties of abutilon natural staw and polyactic acid biocomposites. Int. J. Polym. Sci. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Funk, V.; Hollowell, T.; Berry, P.; Kelloff, C.; Alexander, S.N.; Hollowell, T.H.; Kellof, C.L. Checklist of the plants of the Guayana Shield (Venezuela: Amazonas, Bolivar, Delta Amacuro; Guyana, Surinam, French Guiana); Contributions from the United States National Herbarium; Smithsonian Institution Press: Washington, DC, USA, 2007; Volume 55, pp. 1–584. [Google Scholar]

- Henderson, H. Araliaceae in: Steyermark JA. In Glora of the Venezuelan Guayana: Araliaceae—Cactaceae; Berry, P.E., Holst, B.K., Eds.; Missouri Botanical Garden Press: St Luis, MI, USA, 1997; Volume 3, pp. 32–112. [Google Scholar]

- Smith, N. Mauritiella Armata. Palms and People in the Amazon; Springer International Publishing: Cham, Switzerland, 2015; pp. 383–389. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2019, 9, 1296–1304. [Google Scholar] [CrossRef]

- Nayar, S.Y.; Sultan, M.T.B.H.; Shenuy, S.T.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amunthakkaannan, P. Potential of natural fibers in composites for ballistic applications—A review. J. Nat. Fibers 2020, 1–11. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in in polymer-matrix composites for body armor application. J. Comp. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Nascimento, L.F.C.; Louro, L.H.L.; Monteiro, S.N.; Lima, E.P., Jr.; Luz, F.S. Mallow fiber-reinforced epoxy composites in multilayered armor for personal ballistic protection. JOM-US 2017, 69, 2052–2056. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17. Standard (Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E1131-20. Standard Test Method for Compositional Analysis by Thermogravimetry; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4065. Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures; ASTM International: West Conshohocken, PA, USA, 2012.

- Hamad, S.F.; Stehling, N.; Holland, C.; Foreman, J.P.; Rodenburg, C. Low-Voltage SEM of Natural Plant Fibers: Microstructure Properties (Surface and Cross-Section) and their Link to the Tensile Properties. Procedia Eng. 2017, 200, 295–302. [Google Scholar] [CrossRef]

- Da Luz, F.S.; Ramos, F.J.H.T.V.; Nascimento, L.F.C.; da Silva Figueiredo, A.B.H.; Monteiro, S.N. Critical length and interfacial strength of PALF and coir fiber incorporated in epoxy resin matrix. J. Mater. Res. Technol. 2018, 7, 528–534. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Margem, F.M.; Margem, J.I.; de Souza Martins, L.B.; Oliveira, C.G.; Oliveira, M.P. Infra-Red Spectroscopy Analysis of Malva Fibers. Mater. Sci. Forum 2014, 775, 255–260. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Satyanarayana, K.G.; Ferreira, A.S.; Nascimento, D.C.O.; Lopes, F.P.D.; Silva, I.L.A.; Portela, T.G. Selection of high strength natural fibers. Matéria 2010, 15, 488–505. [Google Scholar] [CrossRef]

- Glória, G.O.; Teles, M.C.A.; Lopes, F.P.D.; Vieira, C.M.F.; Margem, F.M.; de Almeida Gomes, M.; Monteiro, S.N. Tensile strength of polyester composites reinforced with PALF. J. Mater. Res. Technol. 2017, 6, 401–405. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J. Modified Weibull Distribution for Analyzing the Tensile Strength of Bamboo Fibers. Polymers 2014, 6, 3005–3018. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric behavior of natural fibers reinforced polymer composites—An overview. Mater. Sci. Eng. 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.; Margem, F.M. Thermogravimetric Stability of Polymer Composites Reinforced with Less Common Lignocellulosic Fibers—An Overview. J. Mater. Res. Technol. 2012, 1, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Mézáros, E.; Jakob, E.; Várhegyl, G. Pyrolysis-GC/MS and TG/MS study of mediated laccase biodelinification of Eucalyptus globulus kraft pulp. J. Anal. Appl. Pyrol. 2007, 79, 61–70. [Google Scholar]

- Oliveira, M.S.; Pereira, A.C.; Monteiro, S.N.; da Costa Garcia Filho, F.; da Cruz Demosthenes, L.C. Thermal Behavior of Epoxy Composites Reinforced with Fique Fabric by DSC. In Green Materials Engineering; The Minerals, Metals & Materials Series; Ikhmayies, S., Li, J., Vieira, C., Margem, J., de Oliveira Braga, F., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 101–106. [Google Scholar] [CrossRef]

- Revanth, J.S.; Madhav, V.S.; Sai, Y.K.; Krishna, D.V.; Srividya, K.; Sumanth, C.H.M. TGA and DSC analysis of vinyl ester reinforced by Vetiveria zizanioides, jute and glass fiber. Mater. Today Proc. 2020, 26, 460–465. [Google Scholar] [CrossRef]

- Silva, I.L.A.; Bevitare, A.B.; Oliveira, C.G.; Margem, F.M.; Monteiro, S.N. Dynamical-Mechanical Behavior of Epoxy Composites Reinforced with Jutefiber. Characterization of Minerals, Metals and Materials; The Minerals, Metals and Materials Society, TMS-Willey: Hoboken, NJ, USA, 2014. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofiber, biodegradable polymers and Biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

| Fiber Volume (%) | Density (g/cm3) | Porosity (%) |

|---|---|---|

| 0 | 1.110 | 9.01 |

| 10 | 1.065 | 9.32 |

| 20 | 1.020 | 9.74 |

| 30 | 0.975 | 11.90 |

| Fiber Volume (%) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Total Elongation (%) | Tensile Toughness (J/mm3) |

|---|---|---|---|---|

| 0 | 50.0 ± 6.4 | 4.9 ± 1.7 | 1.0 ± 1.0 | 6.6 ± 4.0 |

| 10 | 38.3 ± 3.6 | 5.7 ± 1.5 | 0.7 ± 0.6 | 1.7 ± 1.35 |

| 20 | 91.7 ± 5.9 | 6.9 ± 0.2 | 1.3 ± 1.3 | 11.3 ± 5.14 |

| 30 | 105.2 ± 6.0 | 7.4 ± 0.3 | 1.4 ± 1.4 | 15.4 ± 5.54 |

| Fiber Volume (%) | Tensile Strength | Modulus of Elasticity | Total Strain | Tensile Toughness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | β | ϴ | R2 | β | θ | R2 | β | θ | R2 | β | θ | |

| 0 | 0.88 | 1.66 | 56.67 | 0.86 | 1.69 | 1.22 | 0.94 | 0.97 | 8.51 | 0.86 | 0.82 | 8.38 |

| 10 | 0.85 | 3.28 | 42.95 | 0.92 | 2.76 | 0.76 | 0.92 | 3.72 | 7.02 | 0.94 | 0.81 | 2.32 |

| 20 | 0.87 | 5.02 | 99.28 | 0.79 | 5.29 | 1.46 | 0.90 | 3.22 | 8.06 | 0.82 | 2.35 | 12.86 |

| 30 | 0.84 | 5.59 | 113.5 | 0.97 | 5.27 | 1.53 | 0.89 | 5.23 | 8.43 | 0.98 | 2.54 | 17.53 |

| Condition | Tonset (°C) | Weight Loss (%) | Maximum Degradation Temperature (°C) |

|---|---|---|---|

| Caranan Fiber | 257.5 | 69.7 | 339.0 |

| Epoxy Resin | 286.5 | 77.6 | 386.3 |

| 10% | 210.5 | 49.6 | 309.4 |

| 20% | 272.6 | 42.6 | 323.5 |

| 30% | 298.1 | 36.5 | 334.2 |

| Condition | Tg (°C) |

|---|---|

| Caranan Fiber | 64 |

| Epoxy Resin | 81 |

| 10% | 65 |

| 20% | 65 |

| 30% | 63 |

| Material | G’ (35 °C) | G’’ Tg(°C) | Tan δ Tg (°C) | Reference |

|---|---|---|---|---|

| 0% (epoxy) | 1352 | 64 | 72 | [53] |

| 10% | 1750 | 92 | 110 | PW |

| 20% | 1496 | 87 | 96 | PW |

| 30% | 1378 | 101 | 113 | PW |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza, A.T.; Pereira Junio, R.F.; Neuba, L.d.M.; Candido, V.S.; da Silva, A.C.R.; de Azevedo, A.R.G.; Monteiro, S.N.; Nascimento, L.F.C. Caranan Fiber from Mauritiella armata Palm Tree as Novel Reinforcement for Epoxy Composites. Polymers 2020, 12, 2037. https://doi.org/10.3390/polym12092037

Souza AT, Pereira Junio RF, Neuba LdM, Candido VS, da Silva ACR, de Azevedo ARG, Monteiro SN, Nascimento LFC. Caranan Fiber from Mauritiella armata Palm Tree as Novel Reinforcement for Epoxy Composites. Polymers. 2020; 12(9):2037. https://doi.org/10.3390/polym12092037

Chicago/Turabian StyleSouza, Andressa Teixeira, Raí Felipe Pereira Junio, Lucas de Mendonça Neuba, Verônica Scarpini Candido, Alisson Clay Rios da Silva, Afonso Rangel Garcez de Azevedo, Sergio Neves Monteiro, and Lucio Fabio Cassiano Nascimento. 2020. "Caranan Fiber from Mauritiella armata Palm Tree as Novel Reinforcement for Epoxy Composites" Polymers 12, no. 9: 2037. https://doi.org/10.3390/polym12092037

APA StyleSouza, A. T., Pereira Junio, R. F., Neuba, L. d. M., Candido, V. S., da Silva, A. C. R., de Azevedo, A. R. G., Monteiro, S. N., & Nascimento, L. F. C. (2020). Caranan Fiber from Mauritiella armata Palm Tree as Novel Reinforcement for Epoxy Composites. Polymers, 12(9), 2037. https://doi.org/10.3390/polym12092037