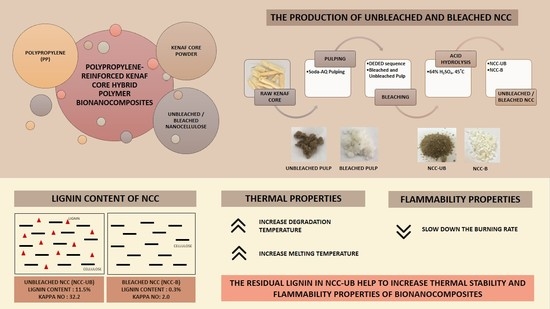

The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

2.2. Pulping of Kenaf

2.3. Bleaching

2.4. Isolation of Unbleached and Bleached Nanocellulose

2.5. Fabrication of Kenaf Core Nanocellulose Hybrid Composites

2.6. Characterization of Kenaf Core Nanocellulose

2.6.1. Lignin Composition of Bleached and Unbleached Kenaf Core

2.6.2. Morphological Analysis

2.7. Characterization of Kenaf Core Nanocellulose Hybrid Composites

2.7.1. Thermogravimetric Analysis (TGA)

2.7.2. Differential Scanning Calorimetry (DSC)

2.7.3. Dynamic Mechanical Analysis (DMA)

2.7.4. Flammability Testing

3. Results and Discussion

3.1. Chemical and Morphological Properties of Unbleached and Bleached Kenaf Core NCC

3.2. Thermal Properties of Kenaf Core Hybrid Nanocomposites

3.2.1. Thermogravimetric Analysis (TGA)

3.2.2. Differential Scanning Calorimetry (DSC)

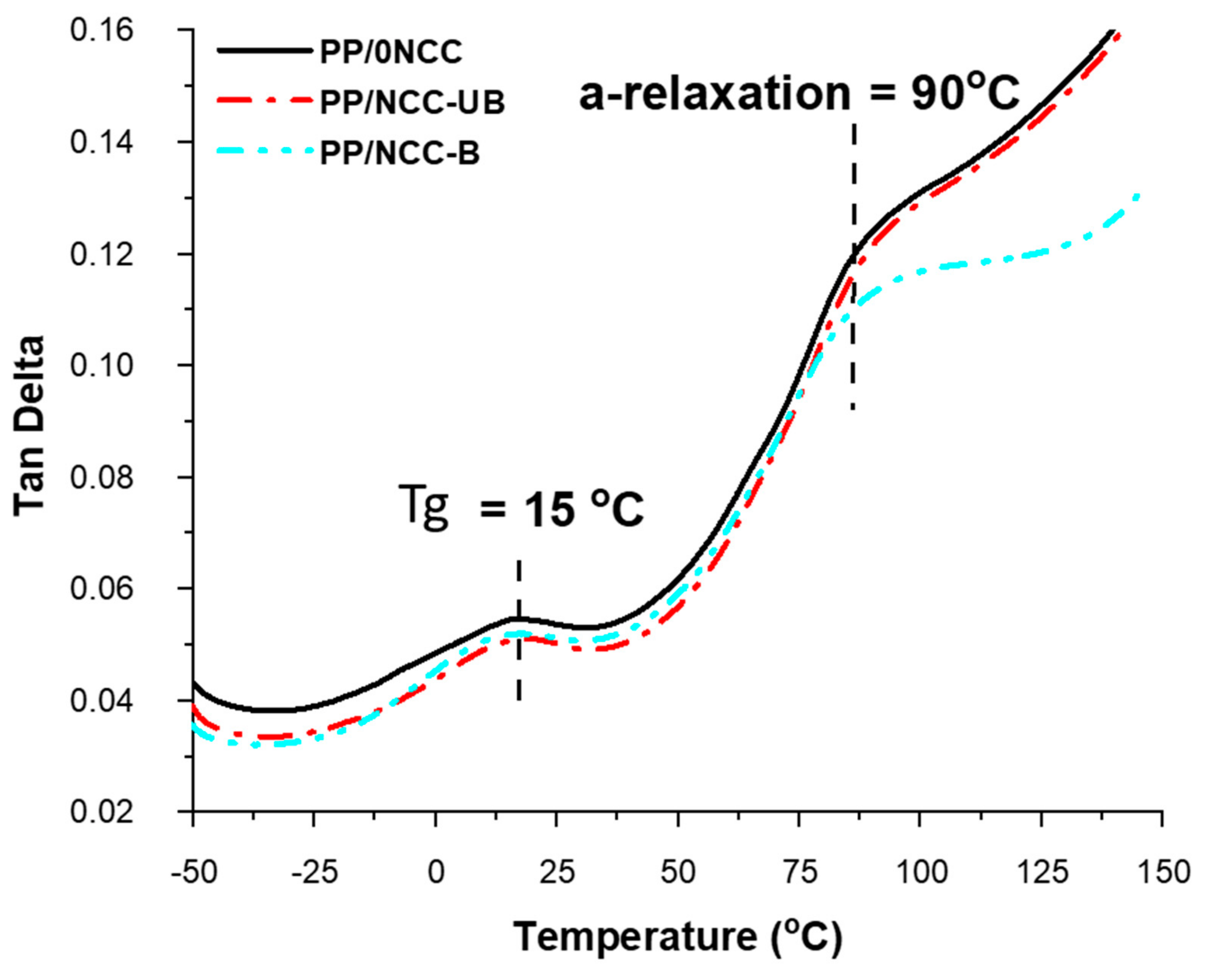

3.2.3. Dynamic Mechanical Analysis (DMA)

3.3. Flammability Properties of Kenaf Core Hybrid Nanocomposites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and Biocomposites: Chemistry and Technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef] [PubMed]

- Mazani, N.; Sapuan, S.M.; Sanyang, M.L.; Atiqah, A.; Ilyas, R.A. Design and Fabrication of a Shoe Shelf From Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. ISBN 9780128163542. [Google Scholar]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 5258621. [Google Scholar] [CrossRef] [Green Version]

- Abral, H.; Atmajaya, A.; Mahardika, M.; Hafizulhaq, F.; Kadriadi; Handayani, D.; Sapuan, S.M.; Ilyas, R.A. Effect of ultrasonication duration of polyvinyl alcohol (PVA) gel on characterizations of PVA film. J. Mater. Res. Technol. 2020, 9, 2477–2486. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose nanocrystals/graphene hybrids—a promising new class of materials for advanced applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial activities of starch-based biopolymers and biocomposites incorporated with plant essential oils: A review. Polymers (Basel) 2020, 12, 2403. [Google Scholar] [CrossRef]

- Atikah, M.S.N.; Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Ibrahim, R.; Atiqah, A.; Ansari, M.N.M.; Jumaidin, R. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery 2019, 64, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Atikah, M.S.N.; Asrofi, M.; Atiqah, A. Characterization studies of biopolymeric matrix and cellulose fibres based composites related to functionalized fibre-matrix interface. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier: London, UK, 2020; pp. 29–93. ISBN 9780081026656. [Google Scholar]

- Lakshumu Naidu, A.; Jagadesh, V.; Raju Bahubalendruni, M.V. A review on chemical and physical properties of natural fiber reinforced composites. Int. J. Adv. Res. Eng. Technol. 2017, 8, 56–68. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part. A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Nguong, C.W.; Lee, S.N.B.; Sujan, D. A Review on Natural Fibre Reinforced Polymer Composites. Int. J. Mater. Metall. Eng. 2013, 7, 33–40. [Google Scholar]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers (Basel) 2020, 12, 1571. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Ilyas, R.A.; Saiful, M.; Hussin, F.; Mastura, M.T. Water Transport and Physical Properties of Sugarcane Bagasse Fibre Reinforced Thermoplastic Potato Starch Biocomposite. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 273–281. [Google Scholar]

- Jumaidin, R.; Saidi, Z.A.S.; Ilyas, R.A.; Ahmad, M.N.; Wahid, M.K.; Yaakob, M.Y.; Maidin, N.A.; Rahman, M.H.A.; Osman, M.H. Characteristics of Cogon Grass Fibre Reinforced Thermoplastic Cassava Starch Biocomposite: Water Absorption and Physical Properties. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 62, 43–52. [Google Scholar]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A.; Biofibers, S.P. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 34–43. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A. Mechanical properties of sugar palm yarn/woven glass fiber reinforced unsaturated polyester composites: Effect of fiber loadings and alkaline treatment. Polimery 2019, 64, 12–22. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 1–6. [Google Scholar] [CrossRef]

- Gupta, H.; Kanaujia, K.K.; Abbas, R.S.M.; Shukla, R. A review on the mechanical properties of Natural fibre reinforced Polypropylene Composites. Int. Res. J. Eng. Technol. 2019, 6, 337–342. [Google Scholar]

- Ramesh, M.; Nijanthan, S. Mechanical property analysis of kenaf-glass fibre reinforced polymer composites using finite element analysis. Bull. Mater. Sci. 2016, 39, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Paridah, M.T.; Juliana, A.H.; Zaidon, A.; Abdul Khalil, H.P.S. Nonwood-based composites. Curr. For. Rep. 2015, 1, 221–238. [Google Scholar] [CrossRef] [Green Version]

- Julkapli, N.M.; Bagheri, S.; Sapuan, S.M. Manufacturing of Natural Fibre Reinforced Polymer Composites. In Manufacturing of Natural Fibre Reinforced Polymer Composites; Salit, M.S., Ed.; Springer International Publishing Switzerland: Cham, Switzerland, 2015; pp. 233–265. ISBN 978-3-319-07944-8. [Google Scholar]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Khiruddin, M.A.A.; Asyul Sutan Saidi, Z.; Salit, M.S.; Ilyas, R.A. Effect of cogon grass fibre on the thermal, mechanical and biodegradation properties of thermoplastic cassava starch biocomposite. Int. J. Biol. Macromol. 2020, 146, 746–755. [Google Scholar] [CrossRef]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- McDonagh, B.H.; Chinga-Carrasco, G. Characterization of Porous Structures of Cellulose Nanofibrils Loaded with Salicylic Acid. Polymers (Basel) 2020, 12, 2538. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Thakur, M.; Bhattacharya, M.; Mandal, T.; Goswami, S. Commercial application of cellulose nano-composites—A review. Biotechnol. Rep. 2019, 21, e00316. [Google Scholar] [CrossRef] [PubMed]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.M.; Ilyas, R.A.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Sapuan, S.M.; Ilyas, R.A. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym. Test. 2019, 106186. [Google Scholar] [CrossRef]

- Ditzel, F.I.; Prestes, E.; Carvalho, B.M.; Demiate, I.M.; Pinheiro, L.A. Nanocrystalline cellulose extracted from pine wood and corncob. Carbohydr. Polym. 2017, 157, 1577–1585. [Google Scholar] [CrossRef] [PubMed]

- Rosa, M.F.M.; Medeiros, E.S.; Malmonge, J.A.J.; Gregorski, K.S.; Wood, D.F.; Mattoso, L.H.C.; Glenn, G.; Orts, W.J.; Imam, S.H. Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydr. Polym. 2010, 81, 83–92. [Google Scholar] [CrossRef]

- Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Rafiqah, S.A.; Aisyah, H.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2020. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int. J. Biol. Macromol. 2019, 123, 379–388. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Ajao, O.; Jeaidi, J.; Benali, M.; Restrepo, A.M.; El Mehdi, N.; Boumghar, Y. Quantification and Variability Analysis of Lignin Optical Properties for Colour-Dependent Industrial Applications. Molecules 2018, 23, 1–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thielemans, W.; Can, E.; Morye, S.S.; Wool, R.P. Novel applications of lignin in composite materials. J. Appl. Polym. Sci. 2002, 83, 323–331. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Vahabi, H.; Rastin, H.; Movahedifar, E.; Antoun, K.; Brosse, N.; Saeb, M.R. Flame Retardancy of Bio-Based Polyurethanes: Opportunities and Challenges. Polymers (Basel) 2020, 12, 1234. [Google Scholar] [CrossRef]

- Rad, E.R.; Vahabi, H.; de Anda, A.R.; Saeb, M.R.; Thomas, S. Bio-epoxy resins with inherent flame retardancy. Prog. Org. Coat. 2019, 135, 608–612. [Google Scholar] [CrossRef]

- Zheng, C.; Li, D.; Ek, M. Improving fire retardancy of cellulosic thermal insulating materials by coating with bio-based fire retardants. Nord. Pulp Pap. Res. J. 2019, 34, 96–106. [Google Scholar] [CrossRef] [Green Version]

- Sabaruddin, F.A.; Paridah, M.T. Effect of lignin on the thermal properties of nanocrystalline prepared from kenaf core. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012039. [Google Scholar] [CrossRef]

- Zhang, C.; Nair, S.S.; Chen, H.; Yan, N.; Farnood, R.; Li, F. Thermally stable, enhanced water barrier, high strength starch bio-composite reinforced with lignin containing cellulose nanofibrils. Carbohydr. Polym. 2020, 230, 115626. [Google Scholar] [CrossRef]

- Yetiş, F.; Liu, X.; Sampson, W.W.; Gong, R.H. Acetylation of lignin containing microfibrillated cellulose and its reinforcing effect for polylactic acid. Eur. Polym. J. 2020, 134, 109803. [Google Scholar] [CrossRef]

- Ballner, D.; Herzele, S.; Keckes, J.; Edler, M.; Griesser, T.; Saake, B.; Liebner, F.; Potthast, A.; Paulik, C.; Gindl-Altmutter, W. Lignocellulose Nanofiber-Reinforced Polystyrene Produced from Composite Microspheres Obtained in Suspension Polymerization Shows Superior Mechanical Performance. ACS Appl. Mater. Interfaces 2016, 8, 13520–13525. [Google Scholar] [CrossRef]

- Nair, S.S.; Kuo, P.-Y.; Chen, H.; Yan, N. Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Ind. Crops Prod. 2017, 100, 208–217. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Shakeri, A.; Misra, M.; Oksmand, K. Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 2009, 4, 626–639. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Lignin Structure, Properties and Application. Adv. Polym. Sci. 2010, 232, 1–63. [Google Scholar] [CrossRef]

- Zainuddin, N.; Ahmad, I.; Kargarzadeh, H.; Ramli, S. Hydrophobic kenaf nanocrystalline cellulose for the binding of curcumin. Carbohydr. Polym. 2017, 163, 261–269. [Google Scholar] [CrossRef]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J.M. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Han, G.; Zhou, C.; Gao, S.; Zhang, Y.; Li, M.; Gong, Y.; Via, B. The Degradation of Lignin, Cellulose, and Hemicellulose in Kenaf Bast Under Different Pressures Using Steam Explosion Treatment. J. Wood Chem. Technol. 2017, 37, 359–368. [Google Scholar] [CrossRef]

- Gan, P.G.; Sam, S.T.; Faiq, M.; Omar, M.F. Thermal properties of nanocellulose-reinforced composites: A review. J. Appl. Polym. Sci. 2019, 137, 48544. [Google Scholar] [CrossRef] [Green Version]

- Rahman, R.; Hamdan, S.; Lai, J.; Hui, C. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) of Wood polymer nanocomposites. In MATEC Web of Conference, Proceedings of the 9th International Unimas Stem Engineering Conference (ENCON 2016) “Innovative Solutions for Engineering and Technology Challenges”, Kuching, Sarawak, 26–28 October 2016; EDP Sciences: Les Ulis, France, 2017; Volume 87, p. 03013. [Google Scholar]

- Chan, C.H.; Chia, C.H.; Zakaria, S.; Ahmad, I.; Dufresne, A. Production and Characterisation of Cellulose and Nanocrystalline Cellulose from Kenaf Core Wood. BioResources 2013, 8, 785–794. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Zhou, L.; Li, M.C.; Wu, Q.; Zhou, D. Cellulose nanocrystals (CNCs) from corn stalk: Activation energy analysis. Materials (Basel) 2017, 10, 80. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Phiri, G.; Khoathane, M.C.; Sadiku, E.R. Effect of fibre loading on mechanical and thermal properties of sisal and kenaf fibre-reinforced injection moulded composites. J. Reinf. Plast. Compos. 2014, 33, 283–293. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Thermal Properties of Wood-Plastic Composites with Different Compositions. Materials (Basel) 2019, 12, 881. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tan, K.W.; Kumar, R.N.; Abubakar, A.; Ishak, Z.A.M.; Ismail, H. The effect of lignin as a compatibilizer on the physical properties of coconut fiber–polypropylene composites. Eur. Polym. J. 2000, 36, 1483–1494. [Google Scholar] [CrossRef]

- Mirjalili, F.; Chuah, L.; Salahi, E. Mechanical and Morphological Properties of Polypropylene/Nano α-Al2O3 Composites. Sci. World J. 2014. [Google Scholar] [CrossRef] [Green Version]

- Guo, C.; Song, Y.; Wang, Q.; Shen, C.-S. Dynamic-mechanical analysis and SEM morphology of wood flour/polypropylene composites. J. For. Res. 2006, 17, 315–318. [Google Scholar] [CrossRef]

- Yousefian, H.; Rodrigue, D. Effect of nanocrystalline cellulose on morphological, thermal, and mechanical properties of Nylon 6 composites. Polym. Compos. 2016, 37, 1473–1479. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Kovacs, J.G. Comparison of injection moulded, natural fibre reinforced composites with Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2014, 25, 927–948. [Google Scholar] [CrossRef]

- Subasinghe, A.D.L.; Das, R.; Bhattacharyya, D. Fiber dispersion during compounding/injection molding of PP/kenaf composites: Flammability and mechanical properties. Mater. Des. 2015, 86, 500–507. [Google Scholar] [CrossRef]

- Chapple, S.; Anandjiwala, R. Flammability of natural fiber-reinforced composites and strategies for fire retardancy: A review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

| Bleaching Stage | Chemical Charge | Reaction Time (min) | Temperature (°C) | Consistency (%) |

|---|---|---|---|---|

| D1 | 2% Sodium Chlorite 3% Acetic Acid | 120 | 70 | 10 |

| EP | 1.5% NaOH 1% H2O2 | 90 | 70 | 10 |

| D2 | 1.5% Sodium Chlorite 3% Acetic Acid | 90 | 60 | 10 |

| Sample | Acid Concentration (%) | Reaction Time (min) | Temperature (°C) |

|---|---|---|---|

| NCC-UB | 64% H2SO4 | 60 | 45 |

| NCC-B | 64% H2SO4 | 60 | 45 |

| Sample | NCC | Matrix | Kenaf Core | MAPP |

|---|---|---|---|---|

| wt % | wt % | wt % | wt % | |

| PP/0NCC | 0 | 59 | 40 | 1 |

| PP/NCC-UB | 1 | 58 | 40 | 1 |

| PP/NCC-B | 1 | 58 | 40 | 1 |

| Sample | Lignin Content (%) | Kappa No |

|---|---|---|

| Raw KC | 33.7 | 36.7 |

| Unbleached KC (UB) | 11.5 | 32.2 |

| Bleached KC (B) | 0.3 | 2.0 |

| PP/0NCC | PP/NCC-UB | PP/NCC-B | |

|---|---|---|---|

| Onset 1st stage (°C) | 102.3 | 111.2 | 101.4 |

| Onset 2nd stage (°C) | 199.2 | 200.1 | 198.9 |

| 2nd stage main degradation temperature (°C) | 313.0 | 311.1 | 311.1 |

| Onset 3rd stage (°C) | 348.0 | 367.5 | 333.8 |

| 3rd stage main degradation temperature (°C) | 447.2 | 450.1 | 411.9 |

| Residue (%) | 9.04 | 10.23 | 3.49 |

| Sample | Enthalpy, ∆Hf (J/g) | Crystallinity, X (%) | 1st Endothermic Peak (°C) | 2nd Endothermic Peak (°C) |

|---|---|---|---|---|

| PP/0NCC | 87.14 | 71.35 | 165.05 | - |

| PP/NCC-UB | 71.07 | 59.19 | 165.62 | 219.13 |

| PP/NCC-B | 61.67 | 51.36 | 163.93 | 185.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2021, 13, 116. https://doi.org/10.3390/polym13010116

Sabaruddin FA, Paridah MT, Sapuan SM, Ilyas RA, Lee SH, Abdan K, Mazlan N, Roseley ASM, Abdul Khalil HPS. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers. 2021; 13(1):116. https://doi.org/10.3390/polym13010116

Chicago/Turabian StyleSabaruddin, Fatimah Athiyah, M.T. Paridah, S. M. Sapuan, R. A. Ilyas, Seng Hua Lee, Khalina Abdan, Norkhairunnisa Mazlan, Adlin Sabrina Muhammad Roseley, and H.P.S. Abdul Khalil. 2021. "The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites" Polymers 13, no. 1: 116. https://doi.org/10.3390/polym13010116

APA StyleSabaruddin, F. A., Paridah, M. T., Sapuan, S. M., Ilyas, R. A., Lee, S. H., Abdan, K., Mazlan, N., Roseley, A. S. M., & Abdul Khalil, H. P. S. (2021). The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers, 13(1), 116. https://doi.org/10.3390/polym13010116