Multi-Functional Luminescent Coating for Wood Fabric Based on Silica Sol-Gel Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

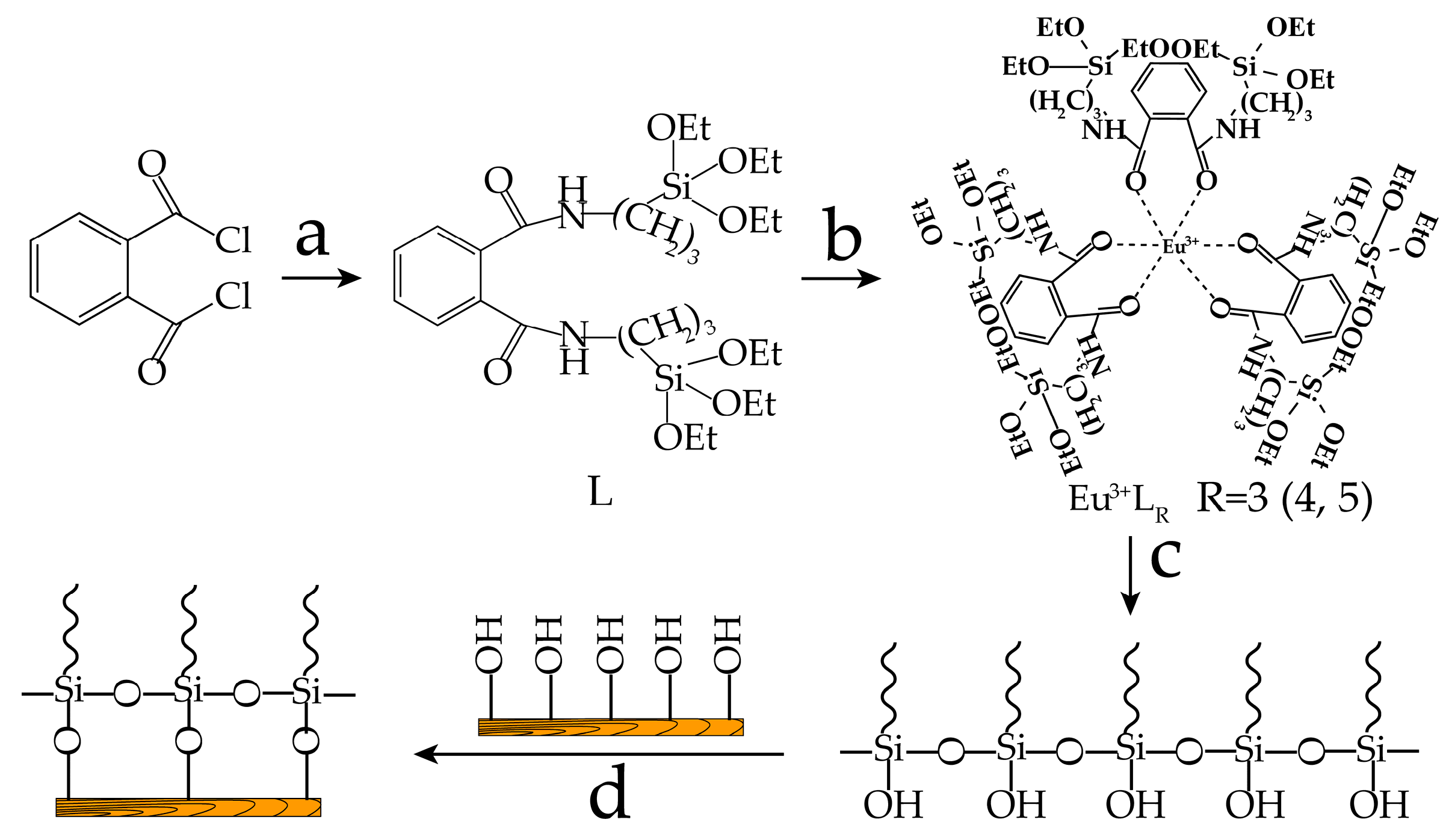

2.2. Synthesis of Modified Silane Monomer

2.3. Synthesis of Europium Coordination Complex

2.4. Synthesis of Organosilicon Sol Coordinated by Europium (III)

2.5. Synthesis of Coating Composites

2.6. Artificial Ultraviolet Aging Test

3. Results

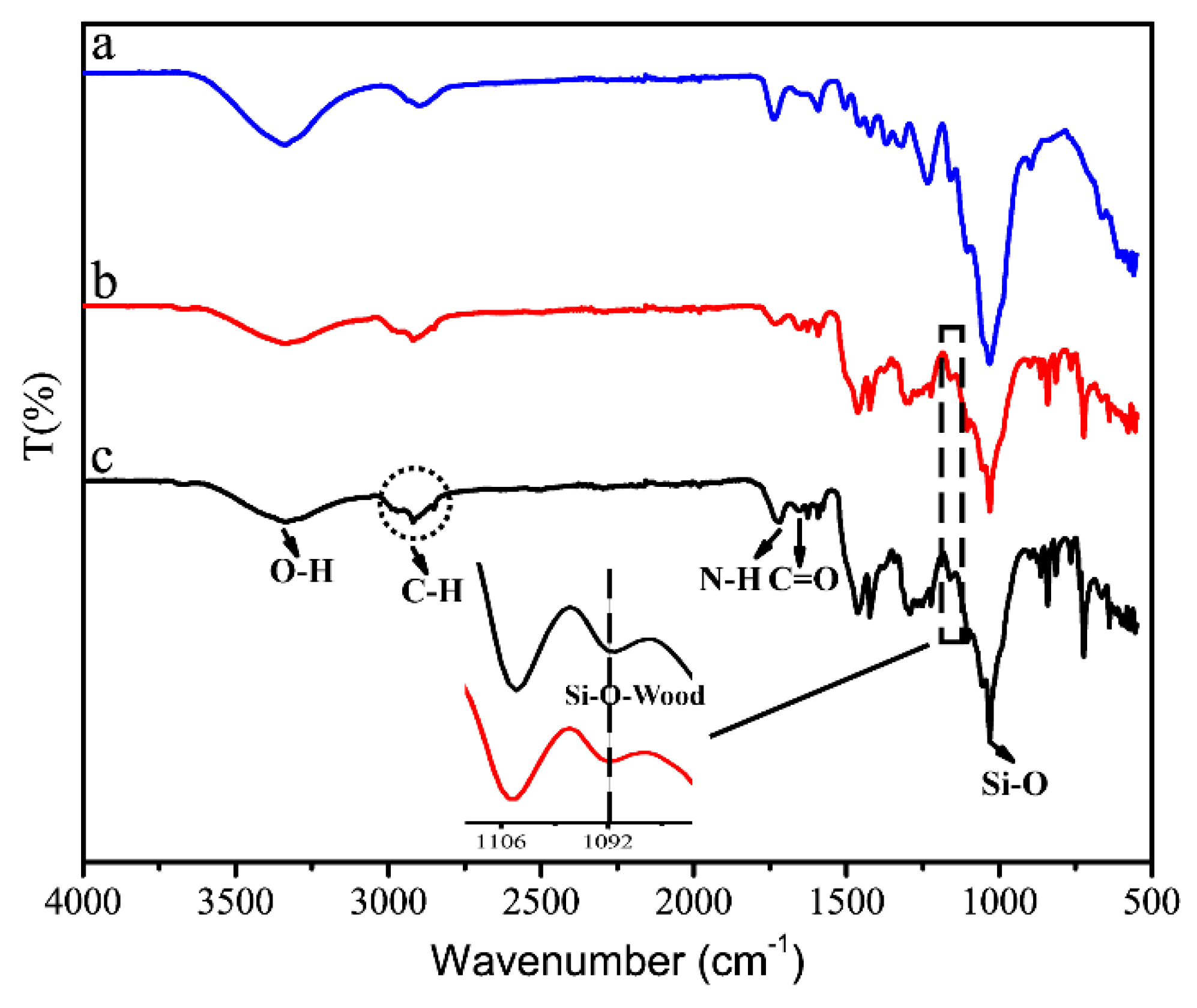

3.1. Structural Characteristics

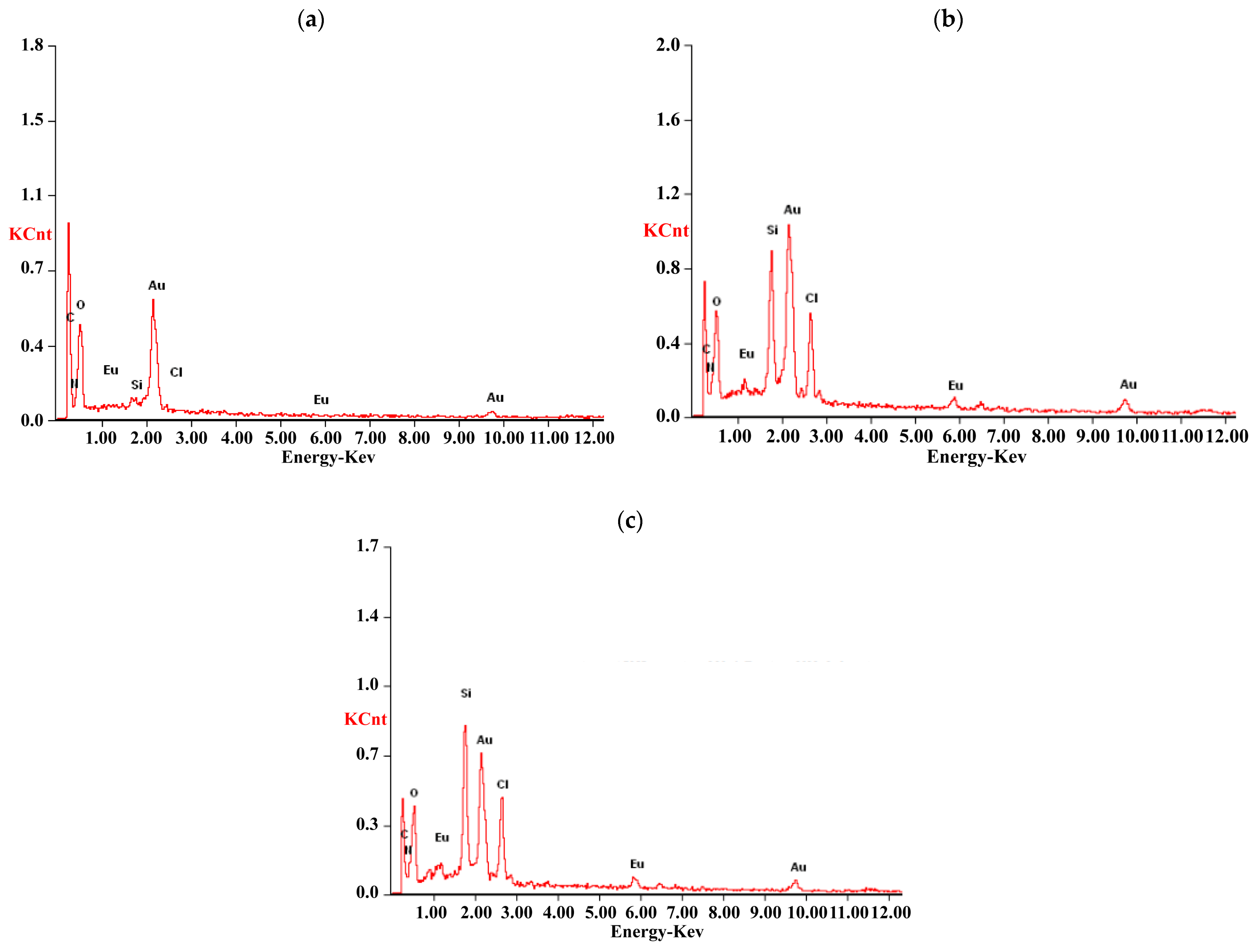

3.2. SEM-EDX Analysis

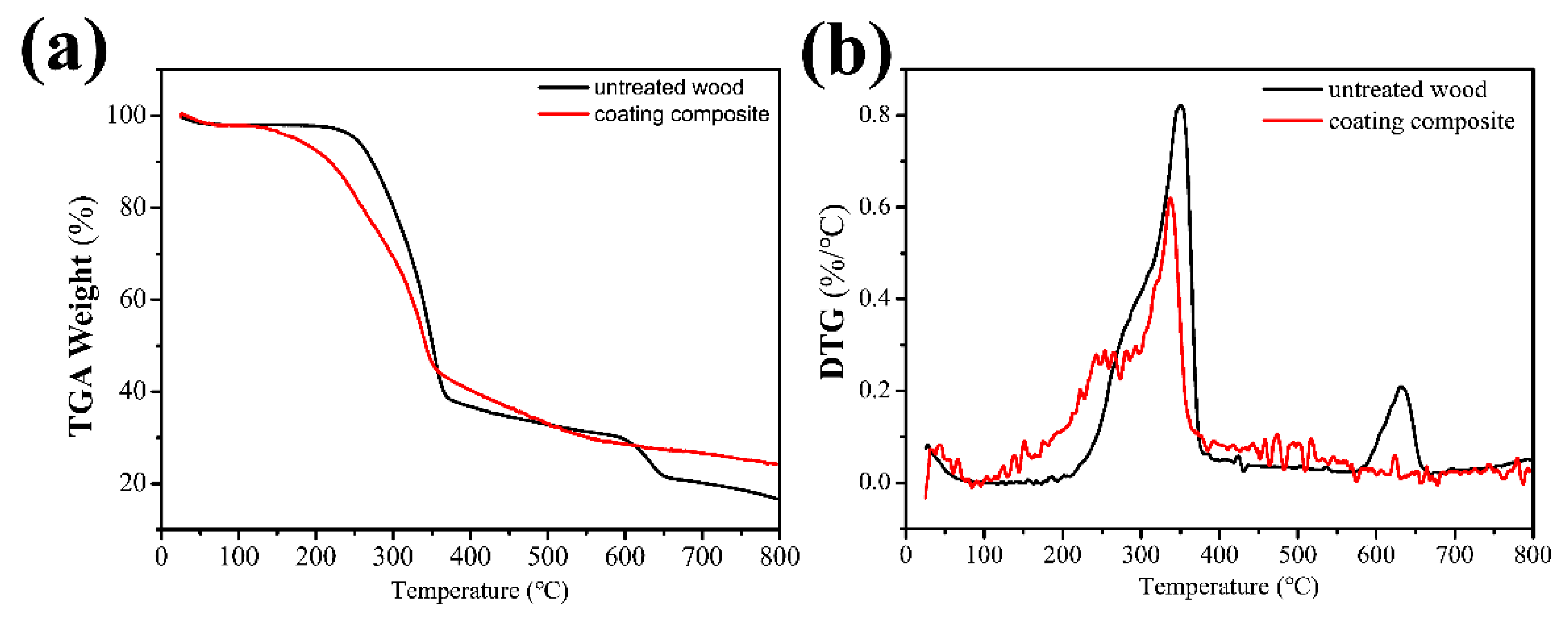

3.3. Thermal Stability

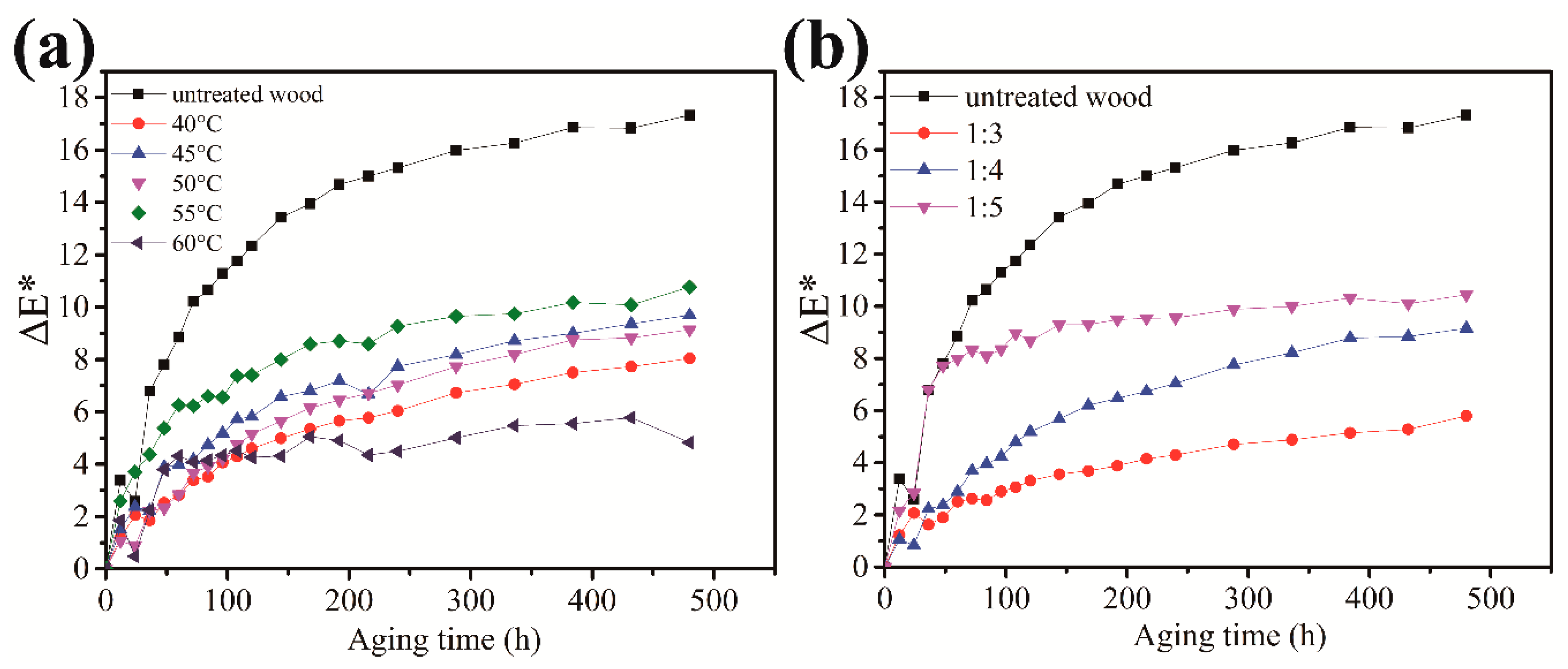

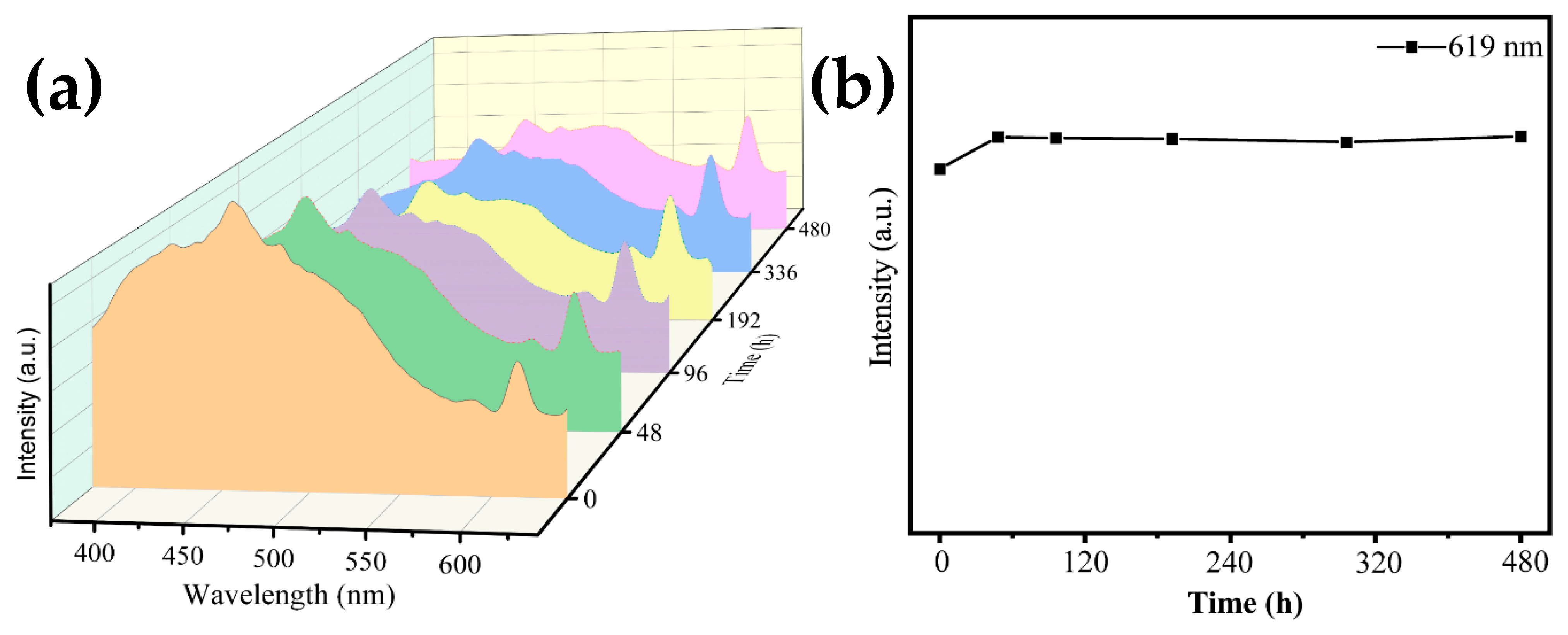

3.4. Aging Property and Optical Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Goodell, B.; Winandy, J.E.; Morrell, J.J. Fungal Degradation of Wood: Emerging Data, New Insights and Charging Perceptions. Coatings 2020, 10, 1210. [Google Scholar] [CrossRef]

- Teo, K.T.; Hassan, A.; Gan, S.N. UV-Curable Urethane Acrylate Resin from Palm Fatty Acid Distillate. Polymers 2018, 10, 1374. [Google Scholar] [CrossRef]

- Pánek, M.; Šimůnková, K.; Novák, D.; Dvořák, O.; Schönfelder, O.; Šedivka, P.; Kobetičová, K. Caffeine and TiO2 Nanoparticles Treatment of Spruce and Beech Wood for Increasing Transparent Coating Resistance against UV-Radiation and Mould Attacks. Coatings 2020, 10, 1141. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of natural and artificial weathering on the colour change of different wood and wood-based materials. Forests 2018, 9, 488. [Google Scholar]

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of wood Degradation Protected by Clear Coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Frommen, C.; Sørby, M.H.; Heere, M.; Humphries, T.D.; Olsen, J.E.; Hauback, B.C. Rare Earth Borohydrides—Crystal Structures and Thermal Properties. Energies 2017, 10, 2115. [Google Scholar] [CrossRef]

- Massi, M.; Ogden, M.I. Luminescent Lanthanoid Calixarene Complexes and Materials. Materials 2017, 10, 1369. [Google Scholar] [CrossRef]

- Guo, G.; Wu, X.L.; Yan, X.Q.; Yan, L.; Li, X.F.; Zhang, S.W.; Qiu, N.N. Unprecedentedly High Activity and/or High Regio-/Stereoselectivity of Fluorenyl-Based CGC Allyl-Type η3: η1-tert-Butyl (dimethylfluorenylsilyl) amido Ligated Rare Earth Metal Monoalkyl Complexes in Olefin Polymerization. Polymers 2019, 11, 19. [Google Scholar]

- Gan, W.; Gao, L.; Sun, Q.; Jin, C.; Lu, Y.; Li, J. Multifunctional wood materials with magnetic, superhydrophobic and anti-ultraviolet properties. Appl. Surf. Sci. 2015, 332, 565–572. [Google Scholar] [CrossRef]

- Hayoz, P.; Peter, W.; Rogez, D. A new innovative stabilization method for the protection of natural wood. Prog. Org. Coat. 2003, 48, 297–309. [Google Scholar] [CrossRef]

- Patachia, S.; Croitoru, C.; Friedrich, C. Effect of UV exposure on the surface chemistry of wood veneers treated with ionic liquids. Appl. Surf. Sci. 2012, 258, 6723–6729. [Google Scholar] [CrossRef]

- Liu, C.Z.; Mei, C.T.; Xu, B.; Chen, W.M.; Yong, C.; Wang, K.; Wu, Q.L. Light stabilizers added to the shell of co-extruded wood/high-density polyethylene composites to improve mechanical and anti-UV ageing properties. R. Soc. Open Sci. 2018, 5, 180074. [Google Scholar] [CrossRef] [PubMed]

- Salla, J.; Pandey, K.K.; Srinivas, K. Improvement of UV resistance of wood surfaces by using ZnO nanoparticles. Polym. Degrad. Stab. 2012, 97, 592–596. [Google Scholar] [CrossRef]

- Han, W.-L.; Xu, Z.-P.; Wang, X.-Y.; Li, A. Mechanism of organic coating damage induced by ultraviolet radiation and its prevention measures. Pet. Eng. Constr. 2007, 4, 18–20. [Google Scholar]

- Ma, M.; Chen, Q.; Wang, C.; Fu, H.; Li, T. High-performance organosilicon–refractory bauxite: Coating and fundamental properties. Constr. Build. Mater. 2019, 207, 563–571. [Google Scholar] [CrossRef]

- Zhang, X.; Long, Z. Preparation and properties of tungsten-doped VO2 microcapsule intelligent temperature-control packaging paper. Prog. Org. Coat. 2019, 131, 219–226. [Google Scholar] [CrossRef]

- Li, H.; Bao, H.; Bok, K.X.; Lee, C.; Li, B.; Zin, M.T.; Kang, L. High durability and low toxicity antimicrobial coatings fabricated by quaternary ammonium silane copolymers. Biomater. Sci. 2016, 4, 299–309. [Google Scholar] [CrossRef]

- Zhang, C.; Huo, R.; Wang, X.; Zhang, J.; Cheng, J.; Shi, L. In-situ encapsulation of flaky aluminum pigment with poly (methylhydrosiloxane) anti-corrosion film for high-performance waterborne coatings. J. Ind. Eng. Chem. 2020, 86, 239–249. [Google Scholar] [CrossRef]

- Suleiman, R.K.; Kumar, A.M.; Adesina, A.Y.; Al-Badour, F.A.; Meliani, M.H.; Saleh, T.A. Hybrid Organosilicon-Metal oxide Composites and their Corrosion Protection Performance for Mild Steel in 3.5% NaCl Solution. Corros. Sci. 2020, 169, 108637. [Google Scholar] [CrossRef]

- Zhao, X.; Hou, Z.; Wang, B.; Shen, Q.; Jia, H.; Zhang, A.; Liu, X.; Xu, B. Synthesis, luminance and ultraviolet resistance of a copolymer phosphor of Eu-complex and siloxane in near UV-based LED. Res. Chem. Intermed. 2017, 43, 4129–4143. [Google Scholar] [CrossRef]

- Qiao, Q.; Shen, Z.Q.; Wu, X.S.; Wang, X.Z.; Pei, W.B.; Liu, S.X.; Ren, X.M. Glowing kaolinite intercalated with N-Methyl imidazole and Eu3+/Tb3+ salts and potential application in UV-to-red light conversion. Appl. Clay Sci. 2020, 186, 105473. [Google Scholar] [CrossRef]

- Zhou, Q.; Dong, X.L.; Xiong, Y.X.; Zhang, B.B.; Lu, S.; Wang, Q.; Liao, Y.G.; Yang, Y.J.; Wang, H. Multi-Responsive Lanthanide-Based Hydrogel with Encryption, Naked Eye Sensing, Shape Memory, Self-Healing, and Antibacterial Activity. ACS Appl. Mater. Interfaces 2020, 12, 28539–28549. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.X.; Yang, C.H.; Liu, Z.Q.; Zhou, J.; Xu, F.; Suo, Z.; Yang, J.H.; Chen, Y.M. Tough Photoluminescent Hydrogels Doped with Lanthanide. Macromol. Rapid Commun. 2015, 36, 465–471. [Google Scholar] [CrossRef] [PubMed]

- Sabarinathan, P.; Rajkumar, K.; Annamalai, V.E.; Vishal, K. Characterization on chemical and mechanical properties of silane treated fish tail palm fibres. Int. J. Biol. Macromol. 2020, 163, 2457–2464. [Google Scholar] [CrossRef] [PubMed]

- Célino, A.; Fréour, S.; Jacquemin, F.; Casari, P. Characterization and modeling of the moisture diffusion behavior of natural fibers. J. Appl. Polym. Sci. 2013, 130, 297–306. [Google Scholar] [CrossRef]

- Xuan, L.H.; Han, G.P.; Wang, D.; Cheng, W.L.; Gao, X.; Chen, F.; Li, Q.D. Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites. Materials 2017, 10, 456. [Google Scholar] [CrossRef]

- Jiang, T.; Kuila, T.; Kim, N.H.; Lee, J.H. Effects of surface-modified silica nanoparticles attached graphene oxide using isocyanate-terminated flexible polymer chains on the mechanical properties of epoxy composites. J. Mater. Chem. A 2014, 2, 10557–10567. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H. Preparation and luminescent properties of lanthanide (Eu3+ and Tb3+) complexes grafted to 3-aminopropyltriethoxysilane by covalent bonds. Opt. Mater. 2015, 50, 208–214. [Google Scholar] [CrossRef]

- Devi, R.R.; Maji, T.K. Interfacial effect of surface modified TiO2 and SiO2 nanoparticles reinforcement in the properties of wood polymer clay nanocomposites. J. Taiwan Inst. Chem. Eng. 2013, 44, 505–514. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, H.; Qiu, J. Fabrication of biomimetic robust self-cleaning superhydrophobic wood with canna-leaf-like micro/nanostructure through morph-genetic method improved water-, UV-, and corrosion resistance properties. J. Mol. Struct. 2020, 1219, 128616. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, C.; Wu, D.; Chen, Z.; Zhu, N.; Gui, C.; Zhang, M.; Umemura, K.; Yong, Q. Utilization of enzymatic hydrolysate from corn stover as a precursor to synthesize an eco-friendly plywood adhesive. Ind. Crop. Prod. 2020, 152, 112501. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, Z.; Hong, W.; Zhang, Y.; Guo, J.; Wang, Y.; Miao, Y.; Jia, H.; Wang, H. Synthesis, characterization and the fluorescent enhancement mechanism of bonded poly (Eu(TTA)2(phen) MAA-co-VA) nanofibers by electrospinning. Opt. Mater. 2020, 106, 110007. [Google Scholar] [CrossRef]

- Li, Y.; Xie, D.; Pang, X.; Yu, X.; Yu, T.; Ge, X. Highly selective fluorescent sensing for fluoride based on a covalently bonded europium mesoporous hybrid material. Sens. Actuators B Chem. 2016, 227, 660–667. [Google Scholar] [CrossRef]

- Singh, K.; Banerjee, S.; Patra, A.K. Photocytotoxic luminescent lanthanide complexes of DTPA–bisamide using quinoline as photosensitizer. RSC Adv. 2015, 5, 107503–107513. [Google Scholar] [CrossRef]

- Kumar, K.S.; Schäfer, B.; Lebedkin, S.; Karmazin, L.; Kappes, M.M.; Ruben, M. Highly luminescent charge-neutral europium (iii) and terbium (iii) complexes with tridentate nitrogen ligands. Dalton Trans. 2015, 44, 15611–15619. [Google Scholar] [CrossRef]

- Huang, L.B.; Cheng, L.H.; Yu, H.Q.; Zhang, J.S.; Zhou, L.; Sun, J.S.; Zhong, H.Y.; Li, X.P.; Tian, Y.; Zheng, Y.F.; et al. Electrospinning preparation and optical transition properties of Eu(DBM)3Phen/PS fluorescent composite fibers. Opt. Commun. 2012, 285, 1476–1480. [Google Scholar] [CrossRef]

- Kumar, B.; Kaur, G.; Rai, S.B. Sensitized green emission of terbium with dibenzoylmethane and 1, 10 phenanthroline in polyvinyl alcohol and polyvinyl pyrrolidone blends. Spectrochim. Acta. A 2017, 187, 75–81. [Google Scholar] [CrossRef]

| Sample | Tmax1 (°C) | Residue at 120 °C (%) | Tmax2 (°C) | Residue at 400 °C (%) | Tmax3 (°C) | Residue at 600 °C (%) | Tmax4 (°C) | Residue at 700 °C (%) | Tmax5 (°C) | Residue at 800 °C (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| Untreated wood | 69.2 | 98.0 | 370.7 | 36.8 | 596.8 | 29.6 | 651.4 | 20.2 | 800 | 16.7 |

| Coating composite | 72.2 | 97.7 | 354.3 | 40.3 | 573.1 | 28.6 | -- | 26.6 | 800 | 24.2 |

| Radiation Time (d) | 0 | 2 | 4 | 8 | 14 | 20 |

|---|---|---|---|---|---|---|

| 5D0→7F2/5D0→7F1 | 1.40 | 1.51 | 1.62 | 1.70 | 1.74 | 1.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Huang, R.; Fu, Z.; Wang, D.; Wang, C.; Li, J. Multi-Functional Luminescent Coating for Wood Fabric Based on Silica Sol-Gel Approach. Polymers 2021, 13, 127. https://doi.org/10.3390/polym13010127

Li M, Huang R, Fu Z, Wang D, Wang C, Li J. Multi-Functional Luminescent Coating for Wood Fabric Based on Silica Sol-Gel Approach. Polymers. 2021; 13(1):127. https://doi.org/10.3390/polym13010127

Chicago/Turabian StyleLi, Ming, Rui Huang, Zhengquan Fu, Di Wang, Chengyu Wang, and Jian Li. 2021. "Multi-Functional Luminescent Coating for Wood Fabric Based on Silica Sol-Gel Approach" Polymers 13, no. 1: 127. https://doi.org/10.3390/polym13010127

APA StyleLi, M., Huang, R., Fu, Z., Wang, D., Wang, C., & Li, J. (2021). Multi-Functional Luminescent Coating for Wood Fabric Based on Silica Sol-Gel Approach. Polymers, 13(1), 127. https://doi.org/10.3390/polym13010127