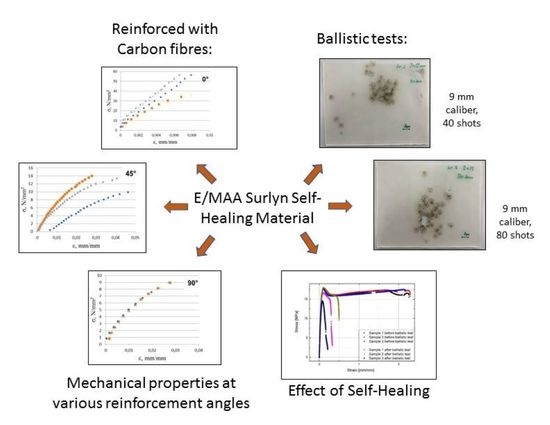

Mechanical Properties of Poly(ethylene-co-methacrylic acid) Reinforced with Carbon Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Matrix Material

2.2. Fibers

2.3. Processing Parameters

2.4. Preparation of Composites

2.5. Dynamic Mechanical Analysis (DMA)

2.6. Flexural Properties and Apparent Interlaminar Shear Strength

2.7. Tensile Properties

2.8. Ballistic Tests

3. Results

3.1. Dynamic Mechanical Analysis

3.2. Flexural and Tensile Properties

3.3. Ballistic Tests

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coughlin, C.S.; Martinelli, A.A.; Boswell, R.F. Mechanism of Ballistic Self-Healing in EMAA Ionomers. Abstr. Pap. Am. Chem. Soc. 2004, 228, 261. [Google Scholar]

- Kalista, S.J.; Pflug, J.R.; Varley, R.J. Effect of Ionic Content on Ballistic Self-Healing in EMAA Copolymers and Ionomers. Polym. Chem. 2013, 4, 4910–4926. [Google Scholar] [CrossRef]

- Sundaresan, V.B.; Morgan, A.; Castellucci, M. Self-Healing of Ionomeric Polymers with Carbon Fibers from Medium-Velocity Impact and Resistive Heating. Smart Mater. Res. 2013, 8, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Pingkarawat, K.; Wang, C.H.; Varley, R.J.; Mouritz, A.P. Mechanical Properties of Mendable Composites Containing Self-Healing Thermoplastic Agents. Compos. Part A Appl. Sci. Manuf. 2014, 65, 10–18. [Google Scholar] [CrossRef]

- Pingkarawat, K.; Mouritz, A.P. Stitched Mendable Composites: Balancing Healing Performance against Mechanical Performance. Compos. Struct. 2015, 123, 54–64. [Google Scholar] [CrossRef]

- Azevedo do Nascimento, A.; Fernandez, F.; da Silva, F.S.; Ferreira, E.P.; Melo, J.D.; Cysne Barbosa, A.P. Addition of Poly (Ethylene-Co-Methacrylic Acid) (EMAA) as Self-Healing Agent to Carbon-Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106016. [Google Scholar] [CrossRef]

- Calderón-Villajos, R.; López, A.J.; Peponi, L.; Manzano-Santamaría, J.; Ureña, A. 3D-Printed Self-Healing Composite Polymer Reinforced with Carbon Nanotubes. Mater. Lett. 2019, 249, 91–94. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Witten, E.; Mathes, V.; Sauer, M.; Kühnel, M. Composites Market Report 2018: Market Developments, Trends, Outlooks and Challenges; Industrievereinigung Verstärkte Kunststoffe: Frankfurt, Germany, 2018; pp. 1–59. [Google Scholar]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-Dimensional Printing of Continuous-Fiber Composites by in-Nozzle Impregnation. Sci. Rep. 2016, 6, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An Investigation into 3D Printing of Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D Printing for Continuous Fiber Reinforced Thermoplastic Composites: Mechanism and Performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic Implications of 3D Printing: Market Structure Models in Light of Additive Manufacturing Revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, L.; Li, L.; Wei, J. Effects of Strain Rate and High Temperature Environment on the Mechanical Performance of Carbon Fiber Reinforced Thermoplastic Composites Fabricated by Hot Press Molding. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105905. [Google Scholar] [CrossRef]

- Hia, I.L.; Vahedi, V.; Pasbakhsh, P. Self-Healing Polymer Composites: Prospects, Challenges, and Applications. Polym. Rev. 2016, 56, 225–261. [Google Scholar] [CrossRef]

- Kim, J.W.; Lee, J.S. The Effect of the Melt Viscosity and Impregnation of a Film on the Mechanical Properties of Thermoplastic Composites. Materials 2016, 9, 448. [Google Scholar] [CrossRef] [Green Version]

- Varley, R.J.; van der Zwaag, S. Towards an Understanding of Thermally Activated Self-Healing of an Ionomer System during Ballistic Penetration. Acta Mater. 2008, 56, 5737–5750. [Google Scholar] [CrossRef]

- Feih, S.; Mouritz, A.P. Tensile Properties of Carbon Fibres and Carbon Fibre-Polymer Composites in Fire. Compos. Part A Appl. Sci. Manuf. 2012, 43, 765–772. [Google Scholar] [CrossRef] [Green Version]

- Wakabayashi, K.; Register, R.A. Morphological Origin of the Multistep Relaxation Behavior in Semicrystalline Ethylene/methacrylic Acid Ionomers. Macromolecules 2006, 39, 1079–1086. [Google Scholar] [CrossRef]

- Gómez, G.H.; Gasparini, T.M.; Canevarolo, S.V. Solid-State Morphology Evolution of Sodium Neutralized Poly(ethylene-Ran-Methacrylic Acid) Ionomer under Dry and Wet Thermal Annealing. Mater. Res. 2019, 22, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Taltavull, C.; Lopez, A.J.; Teno, J.; Rams, J. Effect of Damage Type on Self-Healing Ability of Ionomeric Polymer. In Proceedings of the 13th European Conference on Spacecraft Structures, Materials & Environmental Testing, Braunschweig, Germany, 1–4 April 2014; Ouwehand, L., Ed.; European Space Agency Publications ESA SP: Hannover, Germany, 2014; p. 79. [Google Scholar]

| Parameter | Case1 | Case2 | Case3 | Case4 |

|---|---|---|---|---|

| Annealing temperature [°C] | 130 | 160 | 160 | 160 |

| Annealing time [min] | 15 | 15 | 20 | 15 |

| Pressure [bar] | 40 | 40 | 10 | Manual pressing |

| Compression time [min] | 15 | 15 | 2 | - |

| Modulus | E’ (25 °C) | E’ (40 °C) | E’ (55 °C) | E’ (75 °C) | E’ (80 °C) | E’ (89 °C) |

|---|---|---|---|---|---|---|

| Sample 1 1st run to 89 °C | 275.2 | 162.5 | 25.4 | 9.2 | 6.9 | 3.0 |

| Sample 1 2nd run | 241.8 | 94.7 | 24.0 | 6.4 | 5.5 | 2.9 |

| Sample 2 1st run to 98 °C | 250.3 | 142.9 | 24.2 | 8.1 | 6.7 | 2.8 |

| Sample 2 2nd run | 370.2 | 182.0 | 43.6 | 8.8 | 6.3 | 2.5 |

| 2L—90° | 2L—45° | 2L—0° | 1L—0° | Neat Polymer | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ef | Rmf | Ef | Rmf | Ef | Rmf | Ef | Rmf | Ef | Rmf | |

| 1 | 407.6 | 17.5 | 751.3 | 34.2 | 2375.8 | 38.1 | 236.9 | - | 206.9 | - |

| 2 | 479.6 | 13.5 | 382.6 | 28.5 | 2274.5 | 40.2 | 232.2 | - | 119.2 | - |

| 3 | 459.5 | 13.1 | 1046 | 39.4 | 2031.8 | 33.5 | 250.3 | - | 264.5 | - |

| 4 | 362.4 | 15.5 | 871.0 | 33.0 | 2560.8 | 47.7 | - | 196.8 | - | |

| M | 427.3 | 14.9 | 762.7 | 33.8 | 2310.7 | 39.9 | 239.8 | - | 196.9 | - |

| SD | 52.9 | 2.0 | 280.8 | 4.48 | 220.5 | 5.92 | 9.4 | - | 73.2 | - |

| 2L—90° | 2L—45° | 2L—0° | Neat Polymer | |||||

|---|---|---|---|---|---|---|---|---|

| Et | Rmt | Et | Rmt | Et | Rmt | Et | Rmt | |

| 1 | 463.0 | 9.5 | 767.1 | 22.6 | 4835.9 | 34.7 | 515.4 | 14.9 |

| 2 | 445.6 | 10.8 | 604.1 | 21 | 7047.7 | 78.6 | 495.5 | 15.3 |

| 3 | 486.9 | 9.6 | 413.3 | 15.1 | 7241.7 | 68.7 | 467.5 | 15.3 |

| 4 | 468.9 | 8.3 | 6363.8 | 72.2 | 487.6 | 15.2 | ||

| M | 466.1 | 9.6 | 594.8 | 19.6 | 6372.3 | 63.6 | 491.5 | 15.2 |

| SD | 17.0 | 1.0 | 177.1 | 4.0 | 1091.3 | 19.7 | 19.8 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haramina, T.; Pugar, D.; Ivančević, D.; Smojver, I. Mechanical Properties of Poly(ethylene-co-methacrylic acid) Reinforced with Carbon Fibers. Polymers 2021, 13, 165. https://doi.org/10.3390/polym13010165

Haramina T, Pugar D, Ivančević D, Smojver I. Mechanical Properties of Poly(ethylene-co-methacrylic acid) Reinforced with Carbon Fibers. Polymers. 2021; 13(1):165. https://doi.org/10.3390/polym13010165

Chicago/Turabian StyleHaramina, Tatjana, Daniel Pugar, Darko Ivančević, and Ivica Smojver. 2021. "Mechanical Properties of Poly(ethylene-co-methacrylic acid) Reinforced with Carbon Fibers" Polymers 13, no. 1: 165. https://doi.org/10.3390/polym13010165

APA StyleHaramina, T., Pugar, D., Ivančević, D., & Smojver, I. (2021). Mechanical Properties of Poly(ethylene-co-methacrylic acid) Reinforced with Carbon Fibers. Polymers, 13(1), 165. https://doi.org/10.3390/polym13010165