3.2.1. Model Effluents

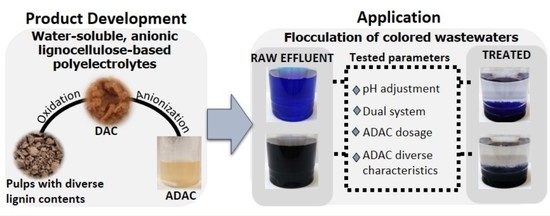

The results of the decolouration tests using the developed anionic PELs, obtained after 24 h and 72 h of sulfonation reaction, will be presented here for the two tested model effluents and discussed individually for each dye system.

The large availability of different types of dyes and shades leads to large amounts of wastewaters which are extremely challenging to treat, due to the unique chemical structures of the dyes, with positively or negatively charged organic chromophores and relatively small molecular weight. In addition, it is important to bear in mind that changes in pH can lead to ionization of certain groups and therefore to a variation of the charge of the dye, depending on the pH range. The zeta potential of the tested dyes as a function of pH was determined experimentally and is shown in

Figure 6, where the initial value for each dye is specifically highlighted. Both the zeta potential of Methylene Blue as well as that of Crystal Violet showed to be pH dependent. Different performances for the tested flocculants are then expected to be observed with the change of pH, when treating the model wastewaters containing these dyes.

The results of the Methylene Blue model effluent treatment, based on the turbidity reduction, obtained while using the anionic flocculation agents developed from

Eucalyptus raw materials of different cellulose, lignin, and hemicellulose contents, are summarized in

Figure 7,

Figure 8 and

Figure 9. The initial colour removal trials were carried out using single systems, with only ADAC

pD (anionic cellulose-based PEL obtained from bleached pulp after 24 h of sulfonation reaction) or aPAM (synthetic anionic PEL of similar charge) (

Figure 7). In addition, a range of different pHs was used to evaluate the influence of pH on the colour removal. In these preliminary tests, acidic pHs were considered (pH 1.0 and 2.5), due to poor results (no colour removal) when working at neutral or alkaline pH levels, because of the higher stability of the tested model dye-water system for those pHs. The decolouration results at pH 1.0 or at pH 2.5 were good overall and no difference could be noted between the cellulose-based and synthetic flocculation agents. Moreover, either aPAM or ADAC

pD were able to remove above 60% of the dye at pH 1.0 and above 55% of the dye at pH 2.5 after 24 h of treatment. Nevertheless, to try to increase colour removal, dual systems with bentonite were tested.

Figure 8 and

Figure 9 show the results obtained at pH 1.6 and 2.5, while using two different concentrations of flocculation agent: 1.33 mg/L (procedures A and C) or 2.67 mg/L (procedures B and D), and two different amounts of bentonite: 0.07 wt% (procedures A and B) or 0.14 wt% (procedures C and D). Additionally, procedures A–D were compared with the treatment performed only with bentonite in the absence of flocculation agent (see

Figure 10). Comparison with the reference synthetic flocculant, aPAM, in dual system with bentonite, is also included in all the

Figure 8 and

Figure 9.

In all the presented tests, colour removal increased with time, thus largest colour removal was obtained at the end of the 24 h test. Although Methylene Blue is typically positively charged, for lower pH values (pH < 3) the dye is more unstable possessing a lower zeta potential (see

Figure 6) and this was the reason for the selection of such low pH levels to perform this study. It was observed that at pH 2.5, while applying a dual system with bentonite followed by the anionic cellulose-based flocculants, almost full colour removal (≥99%) was obtained in most of the experiments, for the longest settling time (24 h).

At the tested pHs (1.0 to 2.5) bentonite alone allowed good colour removal (see

Figure 10), after 24 h, even if for pH 2.5 (the most interesting one) removal could be slightly lower when using bentonite alone rather than the dual system. Moreover, for this pH, and under the best conditions (0.07 wt% of bentonite), settling was slower when using bentonite alone rather than the dual system (compare

Figure 9 A,B with

Figure 10). Additionally, increasing the amount of bentonite, when used alone, was detrimental to colour removal kinetics (

Figure 10).

Analysing in more detail the results obtained for the dual systems (

Figure 8 and

Figure 9), similar good decolouration results could be obtained for pH 1.6 and 2.5, not only for the longest settling time (at 24 h of treatment), but also for intermediate settling times (compare

Figure 8A,B and

Figure 9A,B). However, flocculation was faster (higher removal after 30 min of treatment) when working at pH 2.5, using procedures A or B (0.07 wt% of bentonite followed by 1.33 mg/l of flocculant or 0.07 wt% of bentonite followed by 2.67 mg/l of flocculant, respectively), in particular in the case of procedure A. The influence of pH was more noticeable when a higher amount of bentonite was used, for which slightly lower removals were obtained at higher pH (compare

Figure 8C,D and

Figure 9C,D for pH 1.6 and 2.5, respectively). Additionally, increasing the amount of bentonite from 0.07 wt% to 0.14 wt%, did not improve decolouration. The procedure with 0.07 wt% of bentonite followed by 1.33 mg/L of ADAC provided good decolouration results, with no significant benefit appearing also from increasing the polymers concentration from 1.33 to 2.67 mg/l (compare A and B in

Figure 8 or in

Figure 9). When working at higher bentonite dosages, 0.14 wt% (see

Figure 8C,D and

Figure 9C,D) in dual system, for shorter contact times (up to 1 h) synthetic aPAM appeared to be more effective. However, after 24 h of settling both the synthetic and the cellulose-based flocculation agents showed very similar flocculation efficiency.

When applying the dual system, primarily, bentonite adsorbs the dye, and the turbidity of the system can even increase at the very beginning of the process, due to the presence of non-settled bentonite, leading to negative values of colour/turbidity removal, whereas later addition of the polymer triggers flocculation, based on the bridging mechanism, and leads to rapid settling. In all the tested procedures, for different pH levels, the underlying mechanism appeared to be the same.

Typically, in this coloured effluent, decolouration efficiency obtained with anionic cellulose-based flocculation agents showed to be as good as for the synthetic aPAM reference. When comparing the performance of the different ADACs tested, there is no clear pattern relating their characteristics, especially the purity of the initial fibres used for the modification, to flocculation performance. Indeed, the ADACs obtained from the pulp with the highest kappa number (lignin content) such as ADACD4A or ADACD4C were as effective in the decolouration of Methylene Blue, as the other evaluated cellulose-based flocculation agents obtained from higher purity cellulosic pulps. One can thus conclude that anionic lignocellulose-based flocculants work well for this purpose, independently of the raw material used in the modification procedure.

The results obtained for the Crystal Violet model effluent using anionic cellulose-based flocculation agents produced from

Eucalyptus raw materials of different cellulose and lignin contents, are summarized in

Figure 11 and

Figure 12,

Figure A2 and

Figure A3. Results of preliminary tests of Crystal Violet decolouration, using the polymer alone (anionic cellulose-based PEL obtained from bleached pulp after 24 h of sulfonation reaction (ADAC

pD) or aPAM (synthetic PEL of similar charge)) are presented in

Figure 11. Different pH values were used to perform trials using this model effluent so as to evaluate the influence of pH on the flocculation ability and efficiency of the tested polymers. Crystal Violet is positively charged (see

Figure 6) but varying pH can promote a charge variation of the dye. It was then important to evaluate the performance of the produced polyelectrolytes at an acidic pH (2.0) and at alkaline pH (10.6), considering the different stability of the system in these conditions.

Figure 11 shows Crystal Violet decolouration results at two different pHs (2.0 and 10.6) using 2.67 mg/L of ADAC

pD or synthetic aPAM, without addition of any complexing agent. Decolouration was better at pH 2.0 for both cellulose-based and synthetic flocculation agents. Moreover, aPAM was marginally more effective in the treatment of this dye for acidic conditions, removing 42% of colour, while ADAC

pD removed only 39%, after 24 h of treatment. However, for the alkaline conditions, better colour removal was observed with ADAC

pD (26% after 24 h) comparing to aPAM (20% after 24 h). Nevertheless, the polymer alone was not enough to achieve an adequate colour removal. Thus, once again, dual systems with bentonite were studied in order to intensify the decolouration ability of the tested flocculants.

Figure 12,

Figure A2 and

Figure A3 show the results obtained at pH 2.0, 6.0 and 10.6, while using two different amounts of bentonite: 0.07 wt% (procedure A) or 0.14 wt% (procedure B), followed by the addition of 1.33 mg/L of the flocculation agent. Additionally, procedures A and B were compared with the treatment performed only with bentonite for the same amounts of this component (see

Figure 13). In all the tests, colour removal increased with time, with the best results obtained at the end of the 24 h tests. Crystal Violet is positively charged for all pHs examined herein, however, at pH 6.0 (near the initial pH of the model system) the system showed to be the most stable (see

Figure 6). At this particular pH, the tests showed the worst decolouration results (

Figure A2), with null or very low colour removal (maximum 20%) being achieved. At the lowest pH, while applying dual systems, colour removal reached the highest values (removals between 91 and 100% after 24 h). Typically, as referred to previously, the addition of bentonite destabilises the dye-water system and addition of an anionic polymer allows bridging between bentonite-dye complexes, therefore flocs become larger, and faster settling over time occurs. Additionally, in the dual system flocculation with the ADACs at pH 2.0 (

Figure 12), colour removal was already high (from 80 to 90%) after 30 min of treatment (procedures A, B), characteristic of an efficient flocculation. Furthermore, at this pH, increasing the amount of bentonite (compare A and B in

Figure 12) did not lead to a significant increase in colour removal, except in the first minute of treatment. Performance of the ADACs was similar to that of the reference synthetic aPAM.

At pH 10.6, bentonite presents a negative surface charge [

23], which was not completely neutralized by the positively charged dye molecules in this tested system. This resulted in less effective decolouration while using ADACs (anionic PEL) combined with bentonite, when compared with colour removals at pH 2.0, in particular at lower settling times. The reference aPAM presented worse decolouration results for higher pH values when compared to the tested anionic natural-based flocculants.

For all the situations tested (pH and amount of bentonite used), the dual system always performed better than when bentonite alone was used (compare

Figure 12,

Figure A2 and

Figure A3 with

Figure 13).

In summary, after the bentonite complexation with the dye, turbidity of the system usually increases, but, as some sites on the bentonite surface remain without being complexed with the dye, they are available for further polymer adsorption, followed by bridging, and effective flocculation occurs thereafter. The most effective Crystal Violet removal was obtained while working at pH 2.0 with a lower amount of bentonite (0.07 wt%), followed by 1.33 mg/L of polymer (ADACD1A, ADACD1C or aPAM), which allows for a colour removal near 100% after 24 h of treatment and faster flocculation kinetics (higher removal for 30 min of treatment). Generally, by increasing the effluent acidity, the system tends to be more unstable and flocculation treatment with the ADACs in these conditions leads to higher decolouration levels. In addition, as in the case of the Methylene Blue removal tests, a clear trend relating the characteristics of the initial raw material (pulp) used to produce the ADACs and their performance in flocculation was not observed. It is worth stressing that the lignocellulose-based PELs obtained from the pulp with the highest kappa number (ADACD4A and ADACD4C) were as effective as the synthetic reference or other ADACs obtained from pulps with lower chemical complexity, when working at pH 2.0. It is also worth noting that, at pH 10.6, the ADACs proved to be more effective than the synthetic reference. Moreover, the success of colour removal showed to be highly pH dependent, due to ionization of functional groups in the chemical structure of the dye, as well as due to the influence the pH can have on the inorganic additive, bentonite, used in the process.

In general, colour removal for the two model effluents tested was very high and similar in acidic conditions, using the polymer (ADACs) with a concentration of 1.33 mg/l and a dosage of bentonite of 0.07 wt%, even if flocculation was slightly faster (after 1 min of treatment) in the case of methylene blue, which agrees with the higher instability of this dye at acidic pH (see

Figure 6).

3.2.2. Industrial Effluent

The flocculation performance of the developed anionic polyelectrolytes in multi-coloured industrial effluent treatment was evaluated using PELs obtained after 24 and 72 h of sulfonation reaction. This industrial effluent (COD 0.687 gO2/L, pH 4.5 and turbidity 57 NTU) was collected from several dyeing/washing sessions, at the end of the dyeing process, thus containing a mixture of different shades and dyes, being representative of a real wastewater from the textile industry.

The stability of dye-containing effluents is determined mainly by particle charge, which is affected by the pH of the medium as was seen in the model systems described previously. The zeta potential of the multi-colour effluent after pH adjustments (initial value is highlighted) was measured, and the obtained values with accompanying standard deviations are presented in

Figure 14. In this industrial effluent, the particles are mainly negatively charged. With the increase of pH, a significant increase in negative charge of the particles was observed. The highly negatively charged dye molecules and other suspended solids of this system promote stabilization of the effluent, making it more difficult to destabilize and treat at alkaline pH levels. At neutral pH and at the initial pH 4.5, the zeta potentials were sufficiently high (−48 mV and −45 mV, respectively) to likely provide strong repulsive interactions between the particles. It is then expected that better colour removals can be obtained for acidic conditions where the effluent possesses a lower charge, thus being more unstable.

The results of the industrial effluent treatment, based on the turbidity reduction, obtained while using the developed anionic flocculation agents from

Eucalyptus raw materials of different cellulose and lignin contents, and aPAM (synthetic anionic PEL of similar charge), are summarized in

Figure 15,

Figure 16,

Figure 17 and

Figure 18. In this case the supernatant water turbidity over time for 30 min, 1 h and 24 h, was used to evaluate the PELs performance in the treatment of this industrial effluent. Due to the negative charge of the particles of the effluent at different pHs, poor flocculation was expected while using only the negatively charged PELs. This was confirmed while performing tests, using single systems only. Indeed, using the anionic natural-based (ADAC

pD) or synthetic (aPAM) polyelectrolytes on their own at a concentration of 5.34 mg/L and at two different pHs, namely pH 1.5 and pH 4.5 (initial effluent pH) led to poor colour removal (see

Figure 15). In this case, the highest colour removal was obtained with ADAC

pD at pH 1.5 (17% turbidity reduction after 24 h). At pH 1.5, the effluent tends to be less stable (zeta potential of −19 mV), as compared to the initial pH 4.5 (zeta potential of −45 mV), which minimizes the repulsion effect between particles. Although, some turbidity reduction was obtained while using these single systems, the clarification results were poor and the removals were never higher than 20% after 24 h of treatment. Thus, dual systems combining the anionic PELs with the previously used inorganic complexation agent (bentonite) were also tested.

In general, applying the dual system (bentonite-flocculant) (

Figure 17 and

Figure 18) increased flocculation efficiency, when compared to results obtained using a single system, either bentonite alone (

Figure 16) or the flocculant alone (

Figure 15), for the same pH and dosages. For all tested pH levels (initial 4.5, 1.5 and 7.0) bentonite alone was not effective enough to clarify the effluent (see

Figure 16). Moreover, when using bentonite on its own, at the initial pH of the effluent (pH 4.5), a higher turbidity reduction was achieved with 0.3 wt% of bentonite (close to 70%) and thus this dosage was also selected when performing the tests with the dual systems. In addition, since the initial pH (4.5) and neutral pH led to comparable results when using bentonite alone, it was decided to use these two pHs in the tests with the dual systems. In these tests (

Figure 17 and

Figure 18), bentonite starts by destabilizing the system interacting with the negatively charged particles/dyes suspended in the effluent, due to bentonite slightly positively charged surface, leading, thereafter, to higher turbidity in the effluent because of the presence of the unflocculated bentonite, which justifies the negative colour removal values during the first period of treatment (up to 30 min). Further addition of polymer allows for flocs formed of bentonite particles and adsorbed dyes to grow, increasing the settling rate, and thus colour removal rate also increases. Furthermore, using dual systems with natural-based anionic flocculants led to similar clarification results as compared to those with the synthetic anionic reference (aPAM), for the same conditions. Moreover, working at initial pH 4.5 allowed better clarification results (colour removal after 24 h reaching 85% when using procedure A), as compared to results obtained at pH 7.0 (colour removal reaching 75% after 24 h for the same conditions). Generally, procedure B did not appear to lead to higher colour removal levels than procedure A (higher polymer dosage in procedure B) for both pHs. This means that for this effluent and for the conditions tested, increasing the polymer dosage does not favour colour removal which may be due to the increase of the steric effect which hinders flocculation.

Additionally, pH influences the selection of the most effective anionic cellulose-based PEL, as it appears to be different according to the pH conditions (particularly with procedure A). However, the flocculants obtained from

Eucalyptus-pulp with the highest kappa numbers (higher lignin content) and the larger hydrodynamic diameters (ADACs D4, ADACs D1 and ADACs D3), typically showed the best performance among tested PELs for the different conditions tested. This was clearly noticeable for pH 7.0 in particular for ADACs D1 in conditions A. Since flocculation is more difficult for this pH, a higher hydrodynamic diameter associated with a higher molecular weight may favour flocculation, particularly when the bridging mechanism is relevant. Also, a higher hydrophobic/lignin fraction, still unmodified in the sample, can interact better with the negatively charged effluent impurities. It is also worth stressing that for the initial pH (4.5) the two ADACs D4 (higher lignin content in the raw fibres) led to much faster colour removal in conditions A (see

Figure 17).

Anionic natural-based PELs, produced from bleached pulp, ADAC

pD, obtained after 24 h of sulfonation, and ADAC

pB obtained after 72 h of reaction, as well as anionic cellulose-based PELs obtained from pulp with the highest lignin content, ADAC

D4A (24 h of modification reaction) and ADAC

D4C (72 h of modification reaction), and the reference polymer aPAM, were tested also for COD reduction after 24 h of treatment. The conditions used for the COD measurements refer to the initial pH of 4.5, 0.3 wt% bentonite and the lower concentration of flocculant, corresponding to procedure A (0.3 wt% bentonite followed by 2.67 mg/L of flocculation agent), since this was the procedure which led to better results (see

Figure 19). The COD reduction obtained with the tested new anionic bio-polyelectrolytes (ADACs) was poor, in the range of 34–39% (with turbidity reduction of 70–75% for these polymers and procedure), while with the synthetic reference performance in COD reduction was still lower, 32%. However, it is known that flocculation alone does not usually lead to high COD reductions when treating this type of industrial effluents [

24].

Considering the overall results, the negative charge of the tested industrial effluent, seems to have a crucial influence on the performance of the flocculation process using the developed anionic polyelectrolytes, as expected. However, previous studies by the authors [

25], showed that for this type of highly coloured effluents containing small dyes’ molecules, the addition of an inorganic complexation agent is always required, even if oppositely charged polymers are used. Thus, based on the results obtained it is possible to state that the anionic cellulosic PELs developed proved to be a good and promising solution for the treatment of this highly complex effluent, especially considering that they work better for lower concentrations and either for the initial effluent pH or even at neutral pH (pH 7.0), as long as they are combined with an intermediate inorganic component of opposite charge (e.g., bentonite).