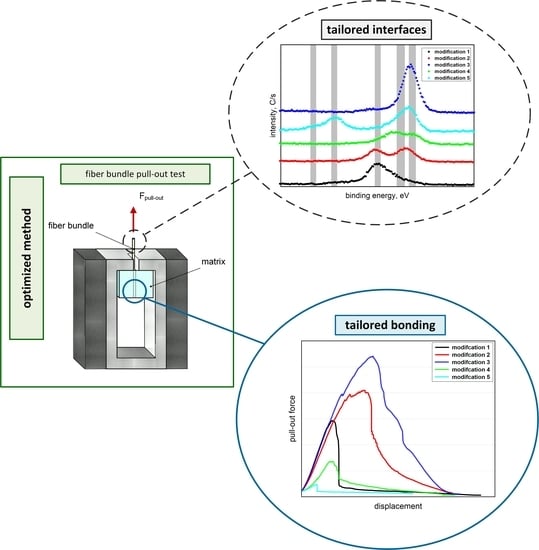

Tailored Interfaces in Fiber-Reinforced Elastomers: A Surface Treatment Study on Optimized Load Coupling via the Modified Fiber Bundle Debond Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Desizing Procedure of the Glass Fibers

2.3. Fiber Surface Modification

2.4. Sample Preparation

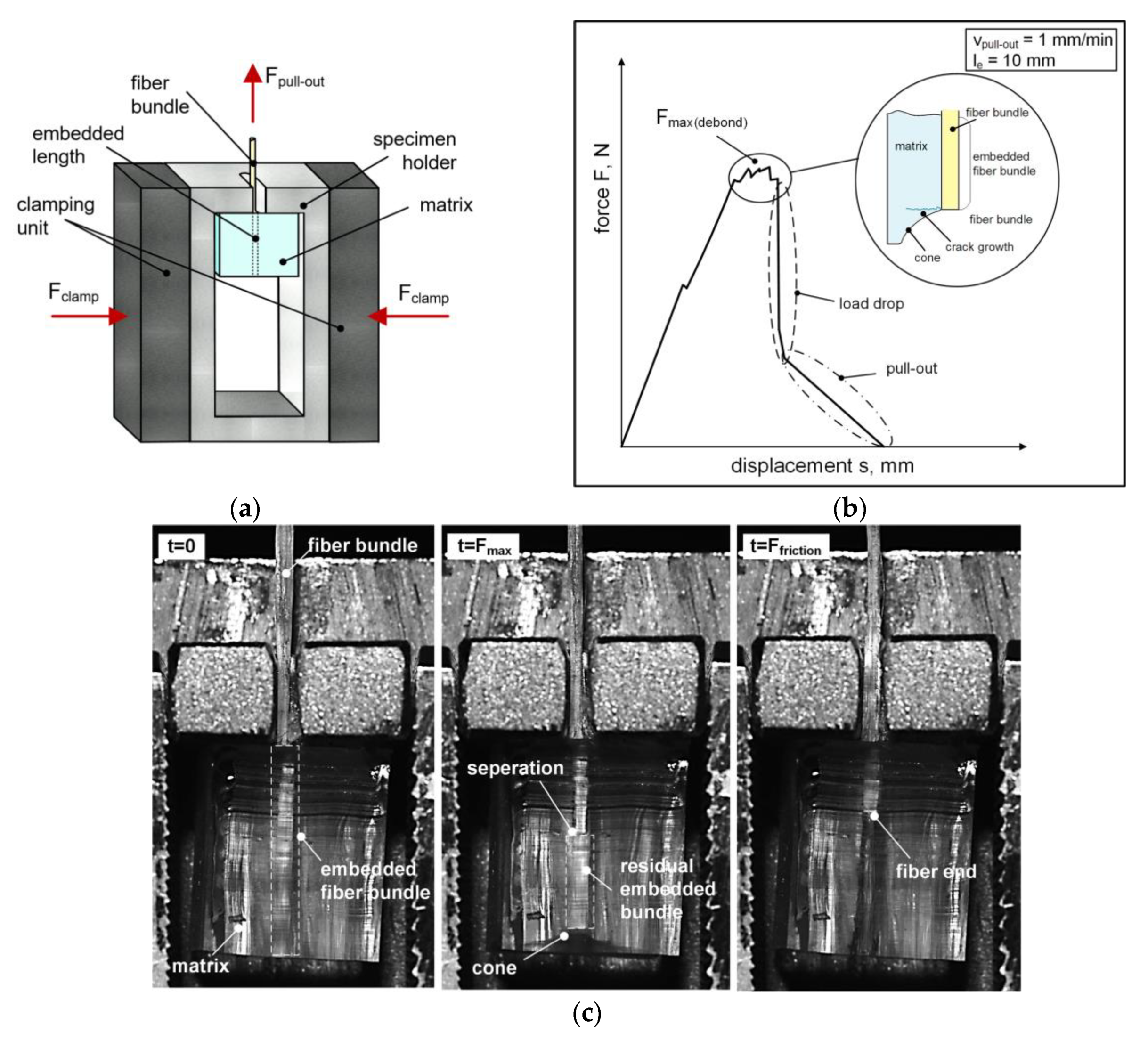

2.5. Test Setup and Measurement Procedure

2.6. Surface Characterization

2.7. Optical Damage Analysis

3. Results and Discussion

3.1. Surface Characterization

3.2. Characterization of Fiber–Matrix Interaction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, T.; Shi, Z.; Shi, Q.; Wang, T.J. Bioinspired bicipital muscle with fiber-constrained dielectric elastomer actuator. Extrem. Mech. Lett. 2016, 6, 75–81. [Google Scholar] [CrossRef]

- Peel, L.D.; Mejia, J.; Narvaez, B.; Thompson, K.; Lingala, M. Development of a Simple Morphing Wing Using Elastomeric Composites as Skins and Actuators. J. Mech. Des. 2009, 131, 91003. [Google Scholar] [CrossRef]

- Debiasi, M.T.; Chan, W.L.; Jadhav, S. Measurements of a Symmetric Wing Morphed by Macro Fiber Composite Actuators. In Proceedings of the 54th Aerospace Science Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef] [PubMed]

- Gohs, U.; Mueller, M.T.; Zschech, C.; Zhandarov, S. Enhanced Interfacial Shear Strength and Critical Energy Release Rate in Single Glass Fiber-Crosslinked Polypropylene Model Microcomposites. Materials 2018, 11, 2552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koschmieder, M. Verarbeitung und Eigenschaften von Faserverbundkunststoffen mit Elastomermatrix. Ph.D. Thesis, Rheinisch-Westfälischen Technischen Hochschule Aachen, Aachen, Germany, 2000. [Google Scholar]

- Kalinka, G.; Neumann, B. Bestimmung von Interface-Festigkeit oder Trennarbeit mit dem Pull-out-Versuch: Kassel, Germany. 2005. Available online: https://opus4.kobv.de/opus4-bam/frontdoor/index/index/docId/6085 (accessed on 2 December 2020).

- Kim, J.-K.; Mai, Y.-W. Engineered Interfaces in Fiber Reinforced Composites, 1st ed.; Elesvier Science Ltd.: Oxford, UK, 1998; ISBN 0-08-042695-6. [Google Scholar]

- Piggott, M.R. Why interface testing by single-fibre methods can be misleading. Compos. Sci. Technol. 1997, 57, 965–974. [Google Scholar] [CrossRef]

- Zhandarov, S. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 2005, 65, 149–160. [Google Scholar] [CrossRef]

- Shakun, A.; Sarlin, E.; Vuorinen, J. Material-related losses of natural rubber composites with surface-modified nanodiamonds. J. Appl. Polym. Sci. 2019, 137, 48629. [Google Scholar] [CrossRef]

- Hoffmann, J. Characterization of Fibre Reinforced Elastomers for Shape Morphing Structural Surfaces. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2012. [Google Scholar]

- Zhou, J.; Li, Y.; Li, N.; Hao, X.; Liu, C. Interfacial shear strength of microwave processed carbon fiber/epoxy composites characterized by an improved fiber-bundle pull-out test. Compos. Sci. Technol. 2016, 133, 173–183. [Google Scholar] [CrossRef]

- Kim, B.W.; Nairn, J.A. Observations of Fiber Fracture and Interfacial Debonding Phenomena Using the Fragmentation Test in Single Fiber Composites. J. Compos. Mater. 2016, 36, 1825–1858. [Google Scholar] [CrossRef]

- Cordin, M.; Bechtold, T.; Pham, T. Effect of fibre orientation on the mechanical properties of polypropylene–lyocell composites. Cellulose 2018, 25, 7197–7210. [Google Scholar] [CrossRef] [Green Version]

- Berthold, U. Beitrag zur Thermoformung Gewebeverstärkter Thermoplaste Mittels Elastischer Stempel. Ph.D. Thesis, Technische Universität Chemnitz, Chemnitz, Germany, 2001. [Google Scholar]

- Cherif, C. Textile Werkstoffe für den Leichtbau. Techniken-Verfahren-Materialien-Eigenschaften; Springer: Berlin, Germany, 2011; ISBN 978-3-642-17992-1. [Google Scholar]

- Mansouri, M.R.; Fuchs, P.F.; Criscione, J.C.; Schrittesser, B.; Beter, J. The contribution of mechanical interactions to the constitutive modeling of fiber-reinforced elastomers. Eur. J. Mech. A Solid 2020, 104081. [Google Scholar] [CrossRef]

- Domnanovich, A.; Peterlik, H.; Kromp, K. Determination of interface parameters for carbon/carbon composites by the fibre-bundle pull-out test. Compos. Sci. Technol. 1996, 56, 1017–1029. [Google Scholar] [CrossRef]

- Schulz, E.; Kalinka, G.; Auersch, W. Effect of transcrystallization in carbon fiber reinforced poly(p-phenylene sulfide) composites on the interfacial shear strength investigated with the single fiber pull-out test. J. Macromol. Sci. Part B 2006, 35, 527–546. [Google Scholar] [CrossRef]

- Kerans, R.J.; Parthasarathy, T.A. Theoretical Analysis of the Fiber Pullout and Pushout Tests. J. Am. Ceram. Soc. 1991, 74, 1585–1596. [Google Scholar] [CrossRef]

- Kalinka, G.; Leistner, A.; Hampe, A. Characterisation of the fibre/matrix interface in reinforced polymers by the push-in technique. Compos. Sci. Technol. 1997, 57, 845–851. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Lilholt, H. Fiber pull-out test and single fiber fragmentation test—Analysis and modelling. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139, 012009. [Google Scholar] [CrossRef] [Green Version]

- DiFrancia, C.; Ward, T.C.; Claus, R.O. The single-fibre pull-out test: Review and Interpretation. Compos. Part A 1996, 27, 597–612. [Google Scholar] [CrossRef]

- Brandstetter, J.; Peterlik, H.; Kromp, K.; Weiss, R. A new fibre-bundle pull-out test to determine interface properties of a 2D-woven carbon/carbon composite. Compos. Sci. Technol. 2003, 63, 653–660. [Google Scholar] [CrossRef]

- von Essen, M.; Sarlin, E.; Tanhuanpää, O.; Kakkonen, M.; Laurikainen, P.; Hoikkanen, M.; Haakana, R.; Vuorinen, J.; Kallio, P. Automated high-throughput microbond tester for interfacial shear strength studies. In Proceedings of the SAMPE Europe Conference, Stuttgart, Germany, 13–16 November 2017; ISBN 978-90-821727-7-5. [Google Scholar]

- Hampe, A.; Kalinka, G.; Meretz, S.; Schulz, E. An advanced equipment for single-fibre pull-out test designed to monitor the fracture process. Composites 1995, 26, 40–46. [Google Scholar] [CrossRef]

- Desarmot, G.; Favre, J. Advances in pull-out testing and data analysis. Compos. Sci. Technol. 1991, 42, 151–187. [Google Scholar] [CrossRef]

- Palola, S.; Sarlin, E.; Kolahgar Azari, S.; Koutsos, V.; Vuorinen, J. Microwave induced hierarchical nanostructures on aramid fibers and their influence on adhesion properties in a rubber matrix. Appl. Surf. Sci. 2017, 410, 145–153. [Google Scholar] [CrossRef] [Green Version]

- Viel, Q.; Esposito, A.; Saiter, J.-M.; Santulli, C.; Turner, J. Interfacial Characterization by Pull-Out Test of Bamboo Fibers Embedded in Poly(Lactic Acid). Fibers 2018, 6, 7. [Google Scholar] [CrossRef] [Green Version]

- Zarges, J.-C.; Kaufhold, C.; Feldmann, M.; Heim, H.-P. Single fiber pull-out test of regenerated cellulose fibers in polypropylene: An energetic evaluation. Compos. Part A 2018, 105, 19–27. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Meier, G.; Fuchs, P.F.; Pinter, G. Influence of Fiber Orientation and Adhesion Properties on Tailored Fiber-reinforced Elastomers. Appl. Compos. Mater. 2020, 149–164. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Maroh, B.; Sarlin, E.; Fuchs, P.F.; Pinter, G. Comparison and Impact of Different Fiber Debond Techniques on Fiber Reinforced Flexible Composites. Polymers 2020, 12, 472. [Google Scholar] [CrossRef] [Green Version]

- Neitzel, M.; Mitschang, P.; Breuer, U. Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-3-446-43696-1. [Google Scholar]

- Sahin, M.; Schlögl, S.; Kalinka, G.; Wang, J.; Kaynak, B.; Mühlbacher, I.; Ziegler, W.; Kern, W.; Grützmacher, H. Tailoring the interfaces in glass fiber-reinforced photopolymer composites. Polymer 2018, 141, 221–231. [Google Scholar] [CrossRef]

- Kanerva, M.; Korkiakoski, S.; Lahtonen, K.; Jokinen, J.; Sarlin, E.; Palola, S.; Iyer, A.; Laurikainen, P.; Liu, X.W.; Raappana, M.; et al. DLC-treated aramid-fibre composites: Tailoring nanoscale-coating for macroscale performance. Compos. Sci. Technol. 2019, 171, 62–69. [Google Scholar] [CrossRef]

- Zhang, D.; He, M.; Qin, S.; Yu, J. Effect of fiber length and dispersion on properties of long glass fiber reinforced thermoplastic composites based on poly(butylene terephthalate). RSC Adv. 2017, 7, 15439–15454. [Google Scholar] [CrossRef] [Green Version]

- Zhamu, A.; Zhong, W.H.; Stone, J.J. Experimental study on adhesion property of UHMWPE fiber/nano-epoxy by fiber bundle pull-out tests. Compos. Sci. Technol. 2006, 66, 2736–2742. [Google Scholar] [CrossRef]

- Liu, M.H.; Li, R.; Wang, G.; Hou, Z.Y.; Huang, B. Morphology and dynamic mechanical properties of long glass fiber-reinforced polyamide 6 composites. J. Therm. Anal. Calorim. 2016, 126, 1281–1288. [Google Scholar] [CrossRef]

- Vleugels, N. Short Fibre-Reinforced Elastomeric Composites: Fundamental Routes towards Improvement of the Interfacial Interaction of Short-Cut Aramid Fibres in a SBR Compound, to Improve Friction and Wear Properties. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2017. [Google Scholar]

- Peel, L. Fabrication and Mechanics of Fiber-Reinforced Elastomers. Doctoral Thesis, Brigham Young University, Brigham, UT, USA, 1998. [Google Scholar]

- Sideridou, I.D.; Karabela, M.M. Effect of the structure of silane-coupling agent on dynamic mechanical properties of dental resin-nanocomposites. J. Appl. Polym. Sci. 2008, 110, 507–516. [Google Scholar] [CrossRef]

- Wilson, K.S.; Allen, A.J.; Washburn, N.R.; Antonucci, J.M. Interphase effects in dental nanocomposites investigated by small-angle neutron scattering. J. Biomed. Mater. Res. A 2007, 81, 113–123. [Google Scholar] [CrossRef] [PubMed]

- Wilson, K.S.; Antonucci, J.M. Interphase structure-property relationships in thermoset dimethacrylate nanocomposites. Dent. Mater. 2006, 22, 995–1001. [Google Scholar] [CrossRef] [PubMed]

- Lung, C.Y.K.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Liao, M.; Yang, Y.; Hamada, H. Mechanical performance of glass woven fabric composite: Effect of different surface treatment agents. Compos. Part B 2016, 86, 17–26. [Google Scholar] [CrossRef]

- Calabrò, R. Mechanical characterization of elastomers under quasi-static and dynamic biaxial loading conditions. Ph.D. Thesis, Politecnico di Milano, Milan, Italy, 2013. [Google Scholar]

- Lim, K.-B.; Lee, D.-C. Surface modification of glass and glass fibres by plasma surface treatment. Surf. Interface Anal. 2004, 36, 254–258. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Yu, E.; Ying, Z.; Zhang, Y.; Liu, X.; Eli, W. Modification of Glass Fiber Surface and Glass Fiber Reinforced Polymer Composites Challenges and Opportunities: From Organic Chemistry Perspective. Curr. Org. Chem. 2015, 19, 991–1010. [Google Scholar] [CrossRef]

- Plueddemann, E.P. Silane Coupling Agents, 2nd ed.; Springer: Boston, MA, USA, 1991; ISBN 978-1-4899-2070-6. [Google Scholar]

- Mansouri, M.; Fuchs, P.F.; Schuecker, C. Hyperelastic modeling of woven structures undergoing large deformations. In Proceedings of the 18th European Conference on Composite Materials ECCM18, Athen, Greece, 24–28 June 2018. [Google Scholar]

- Muliana, A.; Rajagopal, K.R.; Tscharnuter, D.; Schrittesser, B.; Saccomandi, G. Determining material properties of natural rubber using fewer material moduli in virtue ofa novel constitutive approach for elastic bodies. Rubber Chem. Technol. 2018, 91, 375–389. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Meier, G.; Lechner, B.; Mansouri, M.; Fuchs, P.F.; Pinter, G. The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device. Polymers 2020, 12, 2780. [Google Scholar] [CrossRef] [PubMed]

- American Society for Testing and Materials. ASTM D2256-02: 2015: Test Method for Tensile Properties of Yarns by the Single-Strand Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Beter, J.; Schrittesser, B.; Fuchs, P.F. Investigation of adhesion properties in load coupling applications for flexible composites. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Roth, L.E.; Vallés, E.M.; Villar, M.A. Bulk hydrosilylation reaction of poly(dimethylsiloxane) chains catalyzed by a platinum salt: Effect of the initial concentration of reactive groups on the final extent of reaction. J. Polym. Sci. A Polym. Chem. 2003, 41, 1099–1106. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 37: 2011-12: Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- International Organization for Standardization. ISO 291:2008-08: Plastics—Standard Atmospheres for Conditioning and Testing; International Organization for Standardization: Berlin, Germany, 2008. [Google Scholar]

- Zhandarov, S.; Mäder, E. Analysis of a pull-out test with real specimen geometry. Part I: Matrix droplet in the shape of a spherical segment. J. Adhes. Sci. Technol. 2013, 27, 430–465. [Google Scholar] [CrossRef]

- Jacobasch, H.-J. Surface phenomena at polymers. Makromol. Chem. Macromol. Symp. 1993, 75, 99–113. [Google Scholar] [CrossRef]

- Cras, J.J.; Rowe-Taitt, C.A.; Nivens, D.A.; Ligler, F.S. Comparison of chemical cleaning methods of glass in preparation for silanization. Biosens. Bioelectron. 1999, 14, 683–688. [Google Scholar] [CrossRef]

- Bismarck, A.; Boccaccini, A.R.; Egia-Ajuriagojeaskoa, E.; Hülsenberg, D.; Leutbecher, T. Surface characterization of glass fibers made from silicate waste: Zeta-potential and contact angle measurements. J. Mater. Sci. 2004, 39, 401–412. [Google Scholar] [CrossRef]

- Mittal, K.L. Silanes and Other Coupling Agents, 4th ed.; CRC Press: Boca Raton, FL, USA, 2007; ISBN 978-9-04-742001-9. [Google Scholar]

- Wang, D.; Goel, V.; Oleschuk, R.D.; Horton, J.H. Surface modification of poly(dimethylsiloxane) with a perfluorinated alkoxysilane for selectivity toward fluorous tagged peptides. Langmuir 2008, 24, 1080–1086. [Google Scholar] [CrossRef] [Green Version]

- Sedai, B.R.; Khatiwada, B.K.; Mortazavian, H.; Blum, F.D. Development of superhydrophobicity in fluorosilane-treated diatomaceous earth polymer coatings. Appl. Surf. Sci. 2016, 386, 178–186. [Google Scholar] [CrossRef]

- Pazokifard, S.; Mirabedini, S.M.; Esfandeh, M.; Farrokhpay, S. Fluoroalkylsilane treatment of TiO2 nanoparticles in difference pH values: Characterization and mechanism. Adv. Powder Technol. 2012, 23, 428–436. [Google Scholar] [CrossRef]

- Liu, J.; Wu, S.; Zou, M.; Zheng, X.; Cai, Z. Surface modification of silica and its compounding with polydimethylsiloxane matrix: Interaction of modified silica filler with PDMS. Iran. Polym. J. 2012, 21, 583–589. [Google Scholar] [CrossRef]

- Goscianska, J.; Olejnik, A.; Nowak, I. APTES-functionalized mesoporous silica as a vehicle for antipyrine—Adsorption and release studies. Colloids Surf. A Physicochem. Eng. Asp. 2017, 533, 187–196. [Google Scholar] [CrossRef]

- Stamm, M. Polymer Surfaces and Interfaces. In Characterization, Modification and Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-73864-0. [Google Scholar]

- Jakša, G.; Štefane, B.; Kovač, J. XPS and AFM characterization of aminosilanes with different numbers of bonding sites on a silicon wafer. Surf. Interface Anal. 2013, 45, 1709–1713. [Google Scholar] [CrossRef]

- Kaynak, B.; Alpan, C.; Kratzer, M.; Ganser, C.; Teichert, C.; Kern, W. Anti-adhesive layers on stainless steel using thermally stable dipodal perfluoroalkyl silanes. Appl. Surf. Sci. 2017, 416, 824–833. [Google Scholar] [CrossRef]

- Flink, S.; van Veggel, F.C.J.M.; Reinhoudt, D.N. Functionalization of self-assembled monolayers on glass and oxidized silicon wafers by surface reactions. J. Phys. Org. Chem. 2001, 14, 407–415. [Google Scholar] [CrossRef]

- Lipke, M.C.; Liberman-Martin, A.L.; Tilley, T.D. Elektrophile Aktivierung von Silicium-Wasserstoff—Bindungen in katalytischen Hydrosilierungen. Angew. Chem. 2017, 129, 2298–2335. [Google Scholar] [CrossRef]

| Surface Modification | Feature | Label |

|---|---|---|

| 1 | commercial sizing FK144 | sized |

| 2 | piranha treatment | desized |

| 3 | vinyltriethoxysilane | VTES |

| 4 | 3-aminopropyltriethoxysilane | APTES |

| 5 | 1H,1H,2H,2H-perfluoro-1-octyl)triethoxysilane | FOTES |

| Sized | Desized | VTES | APTES | FOTES | |

|---|---|---|---|---|---|

| Si | 9.4 | 20.3 | 11.9 | 21.4 | 14.2 |

| C | 58.0 | 33.2 | 61.8 | 40.2 | 25.4 |

| O | 32.6 | 46.5 | 26.3 | 35.2 | 32.3 |

| F | - | - | - | - | 28.1 |

| N | - | - | - | 3.2 | - |

| Surface Treatment | Sized (Supplier) | Desized (Piranha Solution) | VTES | APTES | FOTES |

|---|---|---|---|---|---|

| max. pull-out force Fmax,pull, N | 14.5 ± 1.8 | 20.5 ± 2.4 | 27.1 ± 2.9 | 6.7 ± 1.1 | 2.5 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beter, J.; Maroh, B.; Schrittesser, B.; Mühlbacher, I.; Griesser, T.; Schlögl, S.; Fuchs, P.F.; Pinter, G. Tailored Interfaces in Fiber-Reinforced Elastomers: A Surface Treatment Study on Optimized Load Coupling via the Modified Fiber Bundle Debond Technique. Polymers 2021, 13, 36. https://doi.org/10.3390/polym13010036

Beter J, Maroh B, Schrittesser B, Mühlbacher I, Griesser T, Schlögl S, Fuchs PF, Pinter G. Tailored Interfaces in Fiber-Reinforced Elastomers: A Surface Treatment Study on Optimized Load Coupling via the Modified Fiber Bundle Debond Technique. Polymers. 2021; 13(1):36. https://doi.org/10.3390/polym13010036

Chicago/Turabian StyleBeter, Julia, Boris Maroh, Bernd Schrittesser, Inge Mühlbacher, Thomas Griesser, Sandra Schlögl, Peter Filipp Fuchs, and Gerald Pinter. 2021. "Tailored Interfaces in Fiber-Reinforced Elastomers: A Surface Treatment Study on Optimized Load Coupling via the Modified Fiber Bundle Debond Technique" Polymers 13, no. 1: 36. https://doi.org/10.3390/polym13010036

APA StyleBeter, J., Maroh, B., Schrittesser, B., Mühlbacher, I., Griesser, T., Schlögl, S., Fuchs, P. F., & Pinter, G. (2021). Tailored Interfaces in Fiber-Reinforced Elastomers: A Surface Treatment Study on Optimized Load Coupling via the Modified Fiber Bundle Debond Technique. Polymers, 13(1), 36. https://doi.org/10.3390/polym13010036