The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device

Abstract

:1. Introduction

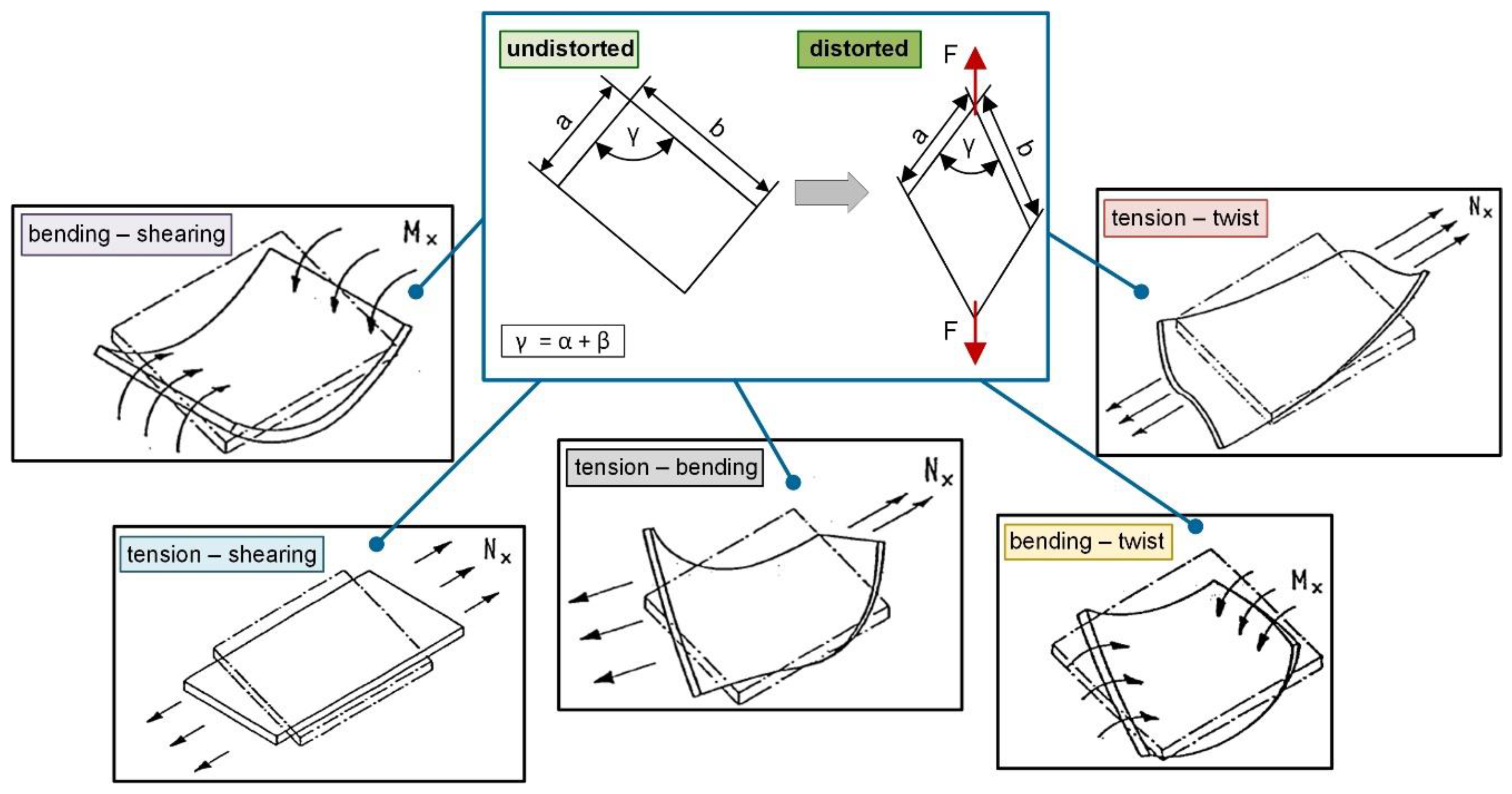

Theoretical Background for Load Coupled Structures and Design Principles

2. Materials and Methods

2.1. Reinforcement

2.2. Matrix Material

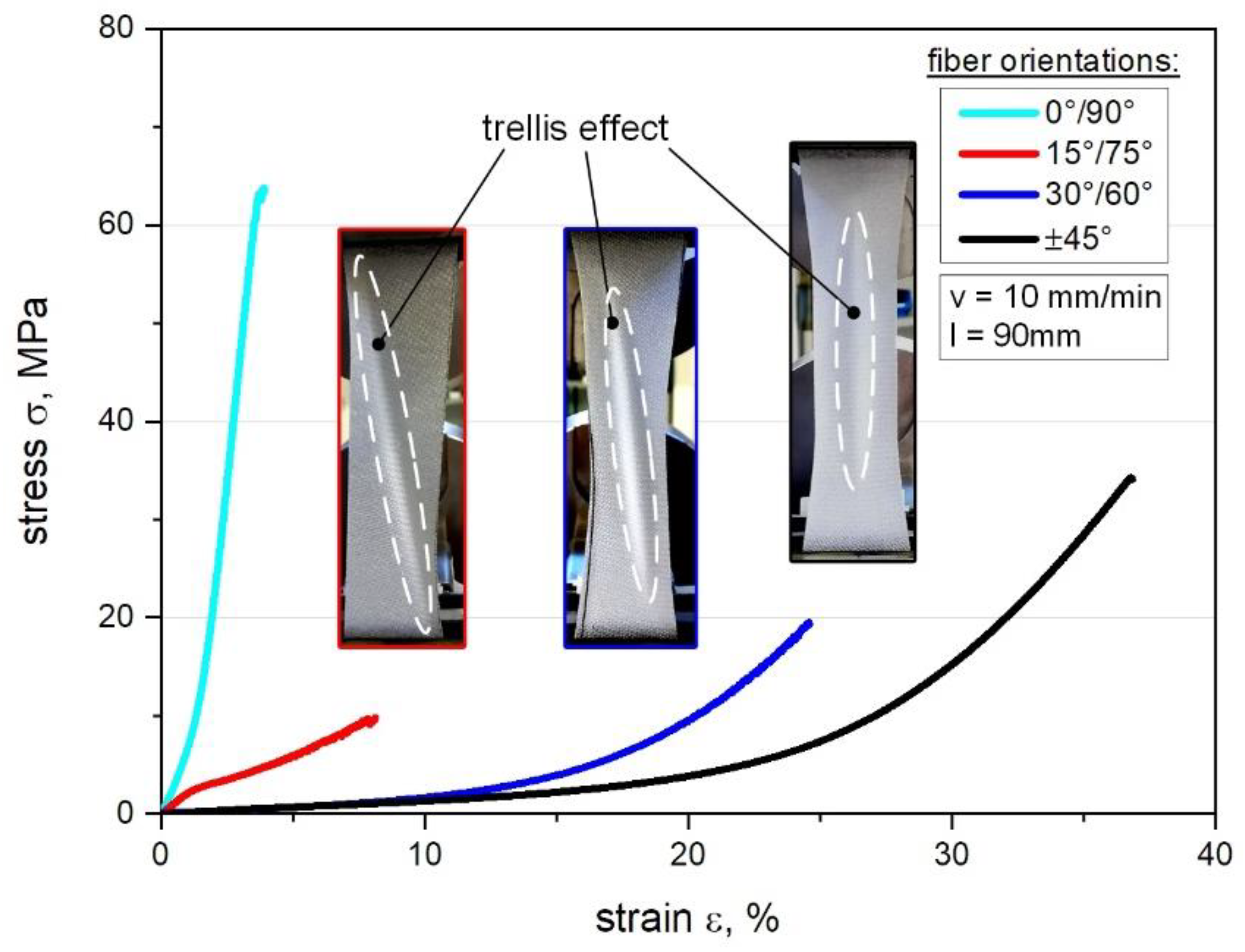

2.3. Shear Stresses Coupled by Fiber Orientation

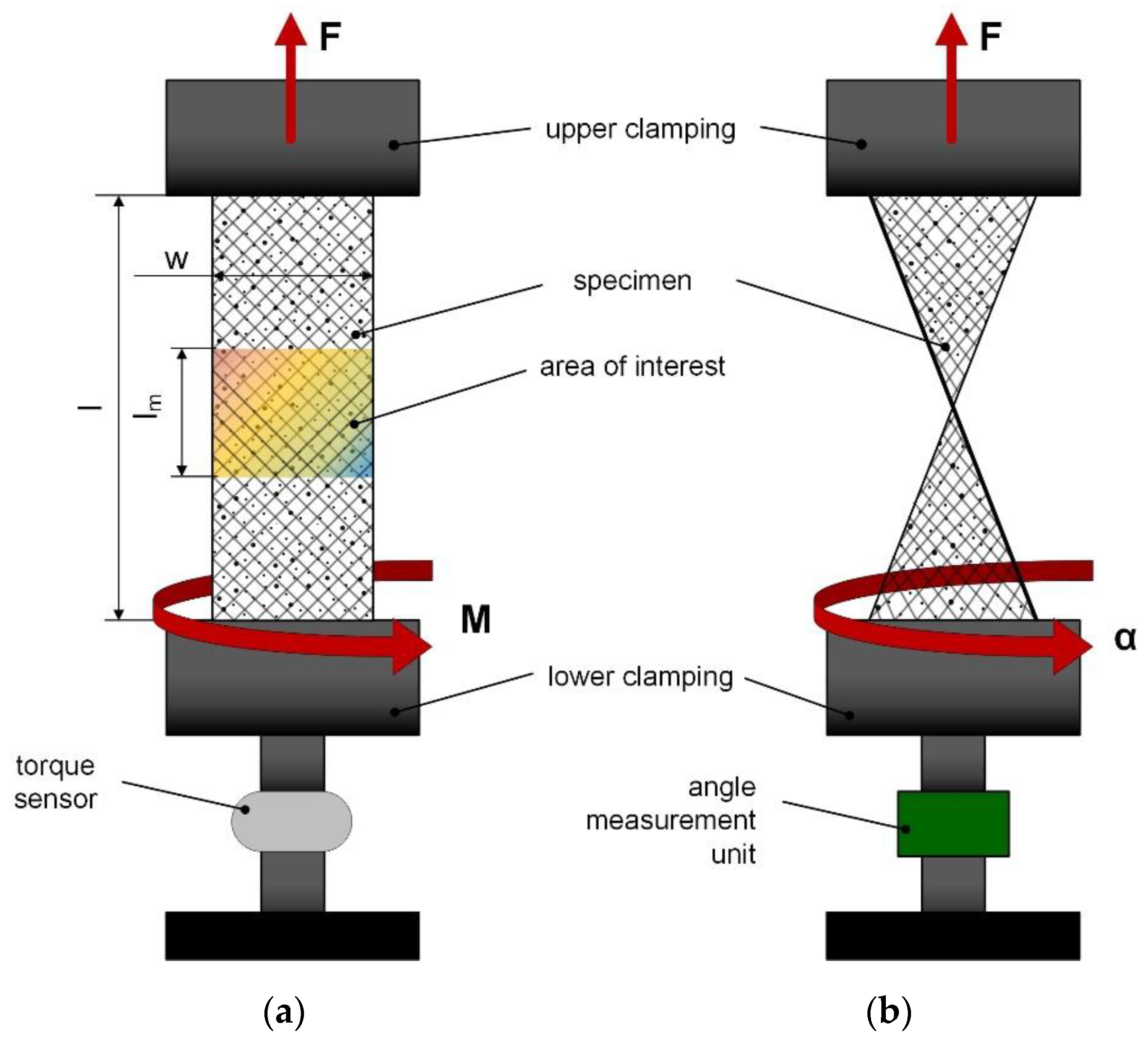

2.4. Specimen Preparation and Test Method

2.5. Optical Analysis

3. Results and Discussion

3.1. Reinforcement, Matrix and Composite

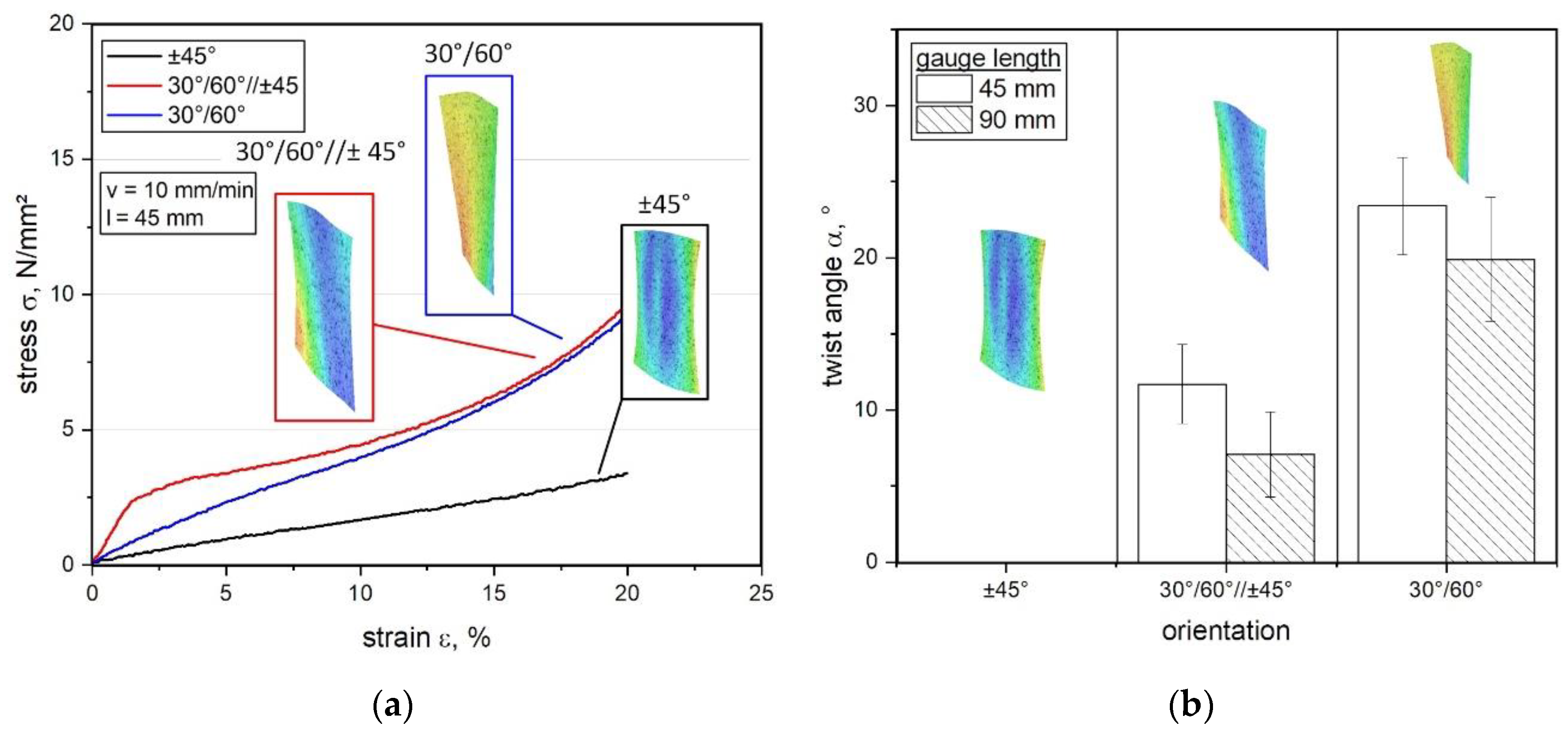

3.2. Tension-Twist Coupled Effect

3.3. Optical Damage Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peel, L. Fabrication and Mechanics of Fiber-Reinforced Elastomers. Ph.D. Thesis, Brigham Young University, Brigham, UT, USA, 1998. [Google Scholar]

- Neitzel, M.; Mitschang, P.; Breuer, U. Handbuch Verbundwerkstoffe. Werkstoffe, Verarbeitung, Anwendung, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-3-446-43696-1. [Google Scholar]

- Chillara, V.S.C.; Dapino, M.J. Review of Morphing Laminated Composites. Appl. Mech. Rev. 2020, 72, 10801. [Google Scholar] [CrossRef]

- Chou, T.-W. Flexible composites. J. Mater. Sci. 1989, 24, 761–783. [Google Scholar] [CrossRef]

- Drenkelford, S. Energy-Saving Potential of Aramid-Based Conveyor Belts. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Toopchi-Nezhad, H.; Tait, M.J.; Drysdale, R.G. Bonded versus unbonded strip fiber reinforced elastomeric isolators: Finite element analysis. Compos. Struct. 2011, 93, 850–859. [Google Scholar] [CrossRef]

- Kang, G.J.; Kang, B.S. Dynamic analysis of fiber-reinforced elastomeric isolation structures. J. Mech. Sci. Technol. 2009, 23, 1132–1141. [Google Scholar] [CrossRef]

- Katti, K.S.; Katti, D.R.; Mohanty, B. Biomimetic Lessons Learnt from Nacre. In Biomimetics Learning from Nature; Mukherjee, A., Raichur, A.M., Mathew, L., Chandrasekaran, N., Eds.; INTECH Open Access Publisher: London, UK, 2010; ISBN 978-953-307-025-4. [Google Scholar]

- Gupta, H.S.; Seto, J.; Wagermaier, W.; Zaslansky, P.; Boesecke, P.; Fratzl, P. Cooperative deformation of mineral and collagen in bone at the nanoscale. Proc. Natl. Acad. Sci. USA 2006, 103, 17741–17746. [Google Scholar] [CrossRef] [Green Version]

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- Vocke, R.D.; Kothera, C.S.; Woods, B.K.S.; Wereley, N.M. Development and Testing of a Span-Extending Morphing Wing. J. Intell. Mater. Syst. Struct. 2011, 22, 879–890. [Google Scholar] [CrossRef]

- Peel, L.D.; Baur, J.; Phillips, D.; McClung, A. The effect of scaling on the performance of elastomer composite actuators. Proc. SPIE- Int. Soc. Opt. Eng. 2010. [Google Scholar] [CrossRef]

- Chen, Y.; Tan, X.; Yan, D.; Zhang, Z.; Gong, Y. A Composite Fabric-Based Soft Rehabilitation Glove with Soft Joint for Dementia in Parkinson’s Disease. IEEE J. Transl. Eng. Health Med. 2020, 8, 1400110. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Shan, S.; Kang, S.H.; Raney, J.R.; Wang, P.; Fang, L.; Candido, F.; Lewis, J.A.; Bertoldi, K. Multistable Architected Materials for Trapping Elastic Strain Energy. Adv. Mater. 2015, 27, 4296–4301. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Dong, E.; Xu, M.; Liu, C.; Alici, G.; Jie, Y. Soft and smart modular structures actuated by shape memory alloy (SMA) wires as tentacles of soft robots. Smart Mater. Struct. 2016, 25, 85026. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Bishop-Moser, J.; Krishnan, G.; Kim, C.; Kota, S. Design of soft robotic actuators using fluid-filled fiber-reinforced elastomeric enclosures in parallel combinations. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura, Portugal, 7–12 October 2012; pp. 4264–4269. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.L. Air/Liquid-Pressure and Heartbeat-Driven Flexible Fiber Nanogenerators as a Micro/Nano-Power Source or Diagnostic Sensor. Adv. Mater. 2011, 23, 84–89. [Google Scholar] [CrossRef]

- Patrick, L.; Gabor, K.; Silvain, M. Characterization of dielectric elastomer actuators based on a hyperelastic film model. Sens. Actuat. A-Phys. 2007, 135, 748–757. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, X.; Huang, L.; Li, D.; Malakhov, A.V.; Polilov, A.N. Programmable morphing composites with embedded continuous fibers by 4D printing. Mater. Des. 2018, 155, 404–413. [Google Scholar] [CrossRef]

- Tasdemir, B.; Coker, D. Comparison of damage mechanisms in curved composite laminates under static and fatigue loading. Compos. Struct. 2019, 213, 190–203. [Google Scholar] [CrossRef]

- Haynes, R.; Armanios, E. Overview of hygrothermally stable laminates with improved extension-twist coupling. In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Yamashita, T.; Takamatsu, S.; Miyake, K.; Itoh, T. Fabrication and evaluation of a conductive polymer coated elastomer contact structure for woven electronic textile. Sens. Actuat. A Phys. 2013, 195, 213–218. [Google Scholar] [CrossRef]

- Tawfik, S.A.; Stefan Dancila, D.; Armanios, E. Unsymmetric composite laminates morphing via piezoelectric actuators. Compos. Part A 2011, 42, 748–756. [Google Scholar] [CrossRef]

- Bowen, C.R.; Butler, R.; Jervis, R.; Kim, H.A.; Salo, A.I.T. Morphing and Shape Control using Unsymmetrical Composites. J. Intell. Mater. Syst. Struct. 2006, 18, 89–98. [Google Scholar] [CrossRef]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric Elastomer Based “Grippers” for Soft Robotics. Adv. Mater. Weinh. 2015, 27, 6814–6819. [Google Scholar] [CrossRef]

- Subramani, K.B.; Cakmak, E.; Spontak, R.J.; Ghosh, T.K. Enhanced electroactive response of unidirectional elastomeric composites with high-dielectric-constant fibers. Adv. Mater. Weinh. 2014, 26, 2949–2953. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, J.-Y.; Chu, W.-S.; Ahn, S.-H. Design and Fabrication of Soft Morphing Ray Propulsor: Undulator and Oscillator. Soft Robot. 2017, 4, 49–60. [Google Scholar] [CrossRef]

- Capuzzi, M.; Pirrera, A.; Weaver, P.M. Structural design of a novel aeroelastically tailored wind turbine blade. Thin-Walled Struct. 2015, 95, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Cui, D.; Li, D. Bending-twisting coupled structures based on composite laminates with extension-shear coupling effect. Compos. Struct. 2019, 209, 434–442. [Google Scholar] [CrossRef]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Basic Experimental Characterization of Polymer Matrix Composite Materials. Polym. Rev. 2013, 53, 277–302. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Lechner, B.; Mansouri, M.R.; Marano, C.; Fuchs, P.F.; Pinter, G. Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers 2020, 12, 1862. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Lee, K.-T.; Kim, H.-J.; Wu, R.; Kim, J.-S.; Song, S.H. Smart soft composite: An integrated 3D soft morphing structure using bend-twist coupling of anisotropic materials. Int. J. Precis. Eng. Manuf. 2012, 13, 631–634. [Google Scholar] [CrossRef]

- Vannucci, P. Anisotropic Elasticity; Springer: Singapore, 2018; ISBN 978-981-10-5438-9. [Google Scholar]

- Brunetti, M.; Vincenti, A.; Vidoli, S. A class of morphing shell structures satisfying clamped boundary conditions. Int. J. Sol. Struct. 2016, 82, 47–55. [Google Scholar] [CrossRef]

- Chillara, V.S.C.; Headings, L.M.; Dapino, M.J. Multifunctional composites with intrinsic pressure actuation and prestress for morphing structures. Compos. Struct. 2016, 157, 265–274. [Google Scholar] [CrossRef] [Green Version]

- Selden, P.H. Glasfaserverstärkte Kunststoffe; Springer: Berlin/Heidelberg, Germany, 1967; ISBN 978-3-642-48456-8. [Google Scholar]

- Koschmieder, M. Verarbeitung und Eigenschaften von Faserverbundkunststoffen mit Elastomermatrix. Ph.D. Thesis, Rheinisch-Westfälischen Technischen Hochschule Aachen, Aachen, Germany, 2000. [Google Scholar]

- Modi, V.; Singh, K.K.; Shrivastava, R. Effect of Stacking Sequence on Interlaminar Shear Strength of Multidirectional GFRP Laminates. Mater. Today-Proc. 2020, 22, 2207–2214. [Google Scholar] [CrossRef]

- Rohde, S.E.; Ifju, P.G.; Sankar, B.V.; Jenkins, D.A. Experimental Testing of Bend-Twist Coupled Composite Shafts. Exp. Mech. 2015, 55, 1613–1625. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Grassegger, F. Klemmvorrichtung und Verfahren zur Prüfung Einer Zugfestigkeit Eines Objektes. Austrian Patent A50009/2020, 20 January 2020. [Google Scholar]

- Gude, M.; Hufenbach, W.; Andrich, M.; Mertel, A.; Schirner, R. Modified V-notched rail shear test fixture for shear characterisation of textile-reinforced composite materials. Polym. Test. 2015, 43, 147–153. [Google Scholar] [CrossRef]

- Cherif, C. Textile Werkstoffe für den Leichtbau. Techniken—Verfahren—Materialien—Eigenschaften; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-17992-1. [Google Scholar]

- Selezneva, M.; Naouar, N.; Denis, Y.; Gorbatikh, L.; Hine, P.; Lomov, S.V.; Swolfs, Y.; Verpoest, I.; Boisse, P. Identification and validation of a hyperelastic model for self-reinforced polypropylene draping. Int. J. Mater. Form. 2020, 39, 1455. [Google Scholar] [CrossRef]

- Palola, S.; Sarlin, E.; Kolahgar Azari, S.; Koutsos, V.; Vuorinen, J. Microwave induced hierarchical nanostructures on aramid fibers and their influence on adhesion properties in a rubber matrix. Appl. Surf. Sci. 2017, 410, 145–153. [Google Scholar] [CrossRef] [Green Version]

- Beter, J.; Schrittesser, B.; Meier, G.; Fuchs, P.F.; Pinter, G. Influence of Fiber Orientation and Adhesion Properties On Tailored Fiber-reinforced Elastomers. Appl. Compos. Mater. 2020, 149–164. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Maroh, B.; Sarlin, E.; Fuchs, P.F.; Pinter, G. Comparison and Impact of Different Fiber Debond Techniques on Fiber Reinforced Flexible Composites. Polymers 2020, 12, 472. [Google Scholar] [CrossRef] [Green Version]

- Sedlan, K. Viskoelastisches Materialverhalten von Elastomerwerkstoffen: Experimentelle Untersuchung und Modellbildung. Ph.D. Thesis, Universität Gesamthochschule Kassel, Kassel, Germany, 2000. [Google Scholar]

- Gereke, T.; Döbrich, O.; Hübner, M.; Cherif, C. Experimental and computational composite textile reinforcement forming: A review. Compos. Part A 2013, 46, 1–10. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D2256-02: 2015: Test Method for Tensile Properties of Yarns by the Single-Strand Method; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- International Organization for Standardization. ISO 37: 2011-12: Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Nosrat-Nezami, F.; Gereke, T.; Eberdt, C.; Cherif, C. Characterisation of the shear–tension coupling of carbon-fibre fabric under controlled membrane tensions for precise simulative predictions of industrial preforming processes. Compos. Part A 2014, 67, 131–139. [Google Scholar] [CrossRef]

- Potter, K. Bias extension measurements on cross-plied unidirectional prepreg. Compos. Part A 2002, 33, 63–73. [Google Scholar] [CrossRef]

- Hoffmann, J. Characterization of Fibre Reinforced Elastomers for Shape Morphing Structural Surfaces. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2012. [Google Scholar]

- International Organization for Standardization. ISO 291:2008-08: Plastics—Standard Atmospheres for Conditioning and Testing; International Organization for Standardization: Berlin, Germany, 2008. [Google Scholar]

- Beter, J.; Schrittesser, B.; Fuchs, P.F. Investigation of adhesion properties in load coupling applications for flexible composites. Mater. Today-Proc. 2020. [Google Scholar] [CrossRef]

- Mansouri, M.; Fuchs, P.F.; Schuecker, C. Hyperelastic modeling of woven structures undergoing large deformations. In Proceedings of the 18th European Conference on Composite Materials ECCM18, Athen, Greece, 24–18 June 2018. [Google Scholar]

- Harrison, P.; Abdiwi, F.; Guo, Z.; Potluri, P.; Yu, W.R. Characterising the shear–tension coupling and wrinkling behaviour of woven engineering fabrics. Compos. Part A 2012, 43, 903–914. [Google Scholar] [CrossRef]

- Peng, X.; Guo, Z.; Du, T.; Yu, W.-R. A simple anisotropic hyperelastic constitutive model for textile fabrics with application to forming simulation. Compos. Part B 2013, 52, 275–281. [Google Scholar] [CrossRef]

- Berthold, U. Beitrag zur Thermoformung Gewebeverstärkter Thermoplaste Mittels Elastischer Stempel. Ph.D. Thesis, Technische Universität Chemnitz, Chemnitz, Germany, 2001. [Google Scholar]

- Röthemeyer, F.; Sommer, F. Kautschuk—Technologie. Werkstoffe—Verarbeitung—Produkte, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-3-446-43776-0. [Google Scholar]

- Ehrenstein, G. Polymer-Werkstoffe. Struktur; Eigenschaften; Anwendung, 3rd ed.; Carl Hanser Verlag: Munich, Germany, 2011; ISBN 978-3-446-42283-4. [Google Scholar]

- Bergmann, T.; Heimbs, S.; Maier, M. Mechanical properties and energy absorption capability of woven fabric composites under ±45° off-axis tension. Compos. Struct. 2015, 125, 362–373. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 527-4: 1997: Plastics. Determination of Tensile Properties; International Organization for Standardization: London, UK, 1997. [Google Scholar]

- Fu, C.; Wang, T.; Xu, F.; Huo, Y.; Potier-Ferry, M. A modeling and resolution framework for wrinkling in hyperelastic sheets at finite membrane strain. J. Mech. Phys. Solids 2019, 124, 446–470. [Google Scholar] [CrossRef]

| GF | PDMS | |

|---|---|---|

| max. force Fmax, N | 119.8 ± 2.3 | 36.1 ± 1.1 |

| max. strain εmax, % | 1.4 ± 0.1 | 108.6 ± 8.6 |

| Max. Twist Angle α, ° | Max. Torque T, Nmm | |

|---|---|---|

| ±45° | 0.0 | 0.0 |

| 30°/60°//±45° | 11.7 ± 2.6 | 56.3 ± 9.6 |

| 30°/60° | 24.4 ± 3.2 | 82.3 ± 11.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beter, J.; Schrittesser, B.; Meier, G.; Lechner, B.; Mansouri, M.; Fuchs, P.F.; Pinter, G. The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device. Polymers 2020, 12, 2780. https://doi.org/10.3390/polym12122780

Beter J, Schrittesser B, Meier G, Lechner B, Mansouri M, Fuchs PF, Pinter G. The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device. Polymers. 2020; 12(12):2780. https://doi.org/10.3390/polym12122780

Chicago/Turabian StyleBeter, Julia, Bernd Schrittesser, Gerald Meier, Bernhard Lechner, Mohammad Mansouri, Peter Filipp Fuchs, and Gerald Pinter. 2020. "The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device" Polymers 12, no. 12: 2780. https://doi.org/10.3390/polym12122780

APA StyleBeter, J., Schrittesser, B., Meier, G., Lechner, B., Mansouri, M., Fuchs, P. F., & Pinter, G. (2020). The Tension-Twist Coupling Mechanism in Flexible Composites: A Systematic Study Based on Tailored Laminate Structures Using a Novel Test Device. Polymers, 12(12), 2780. https://doi.org/10.3390/polym12122780