Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Method

2.1.1. FDM Technology

2.1.2. CFF Technology

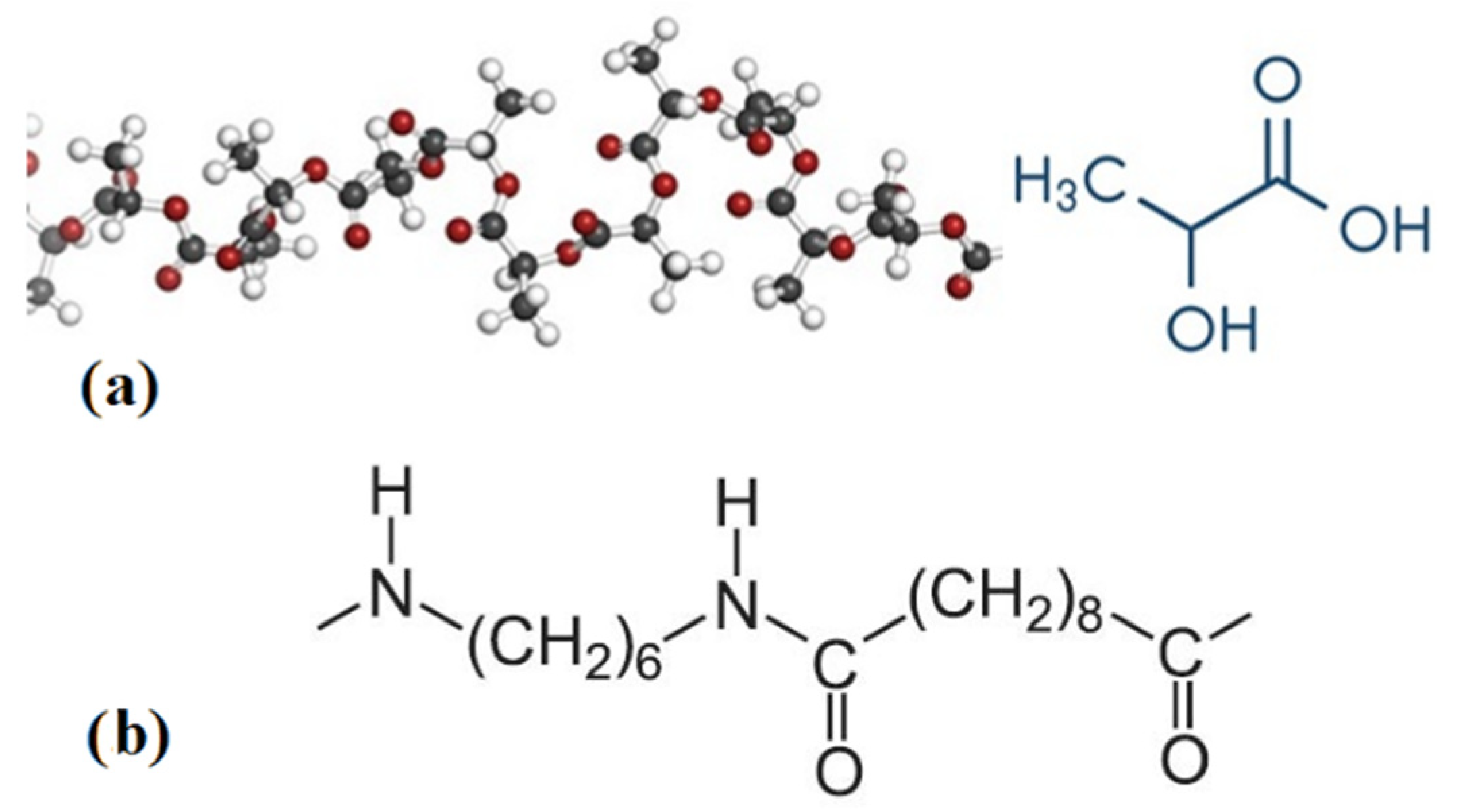

2.2. Materials

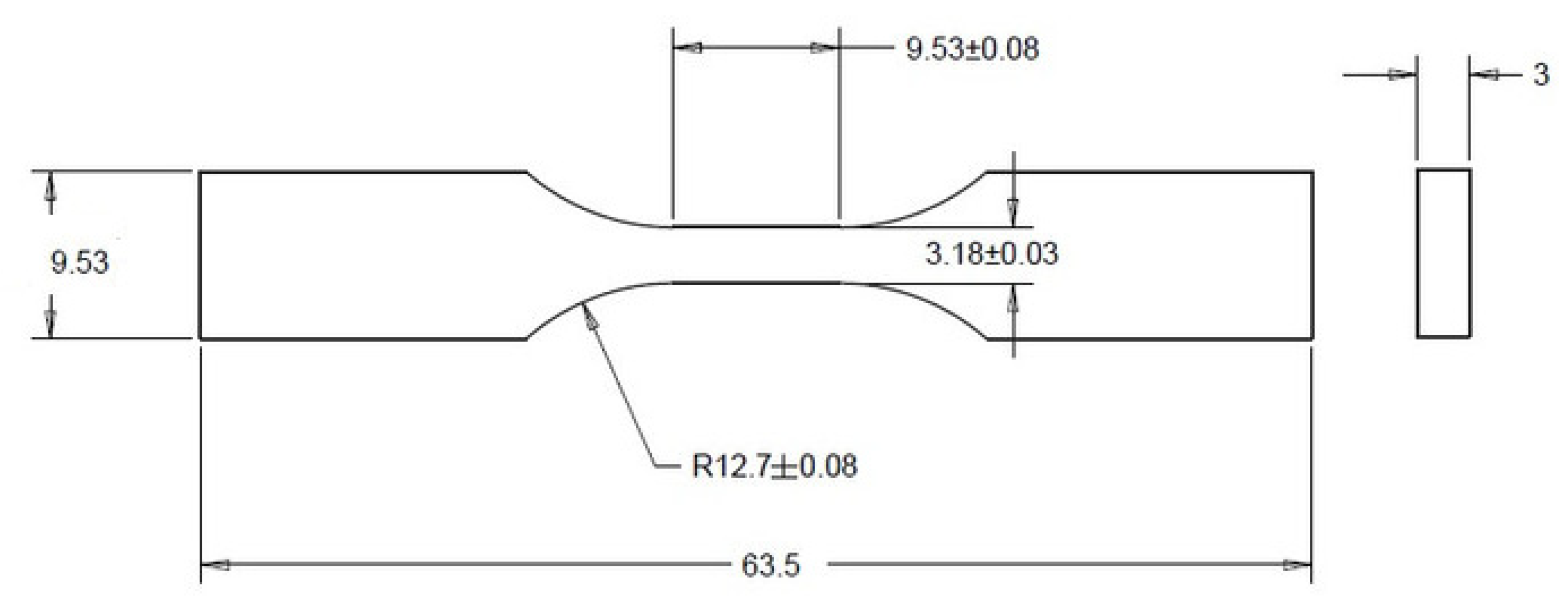

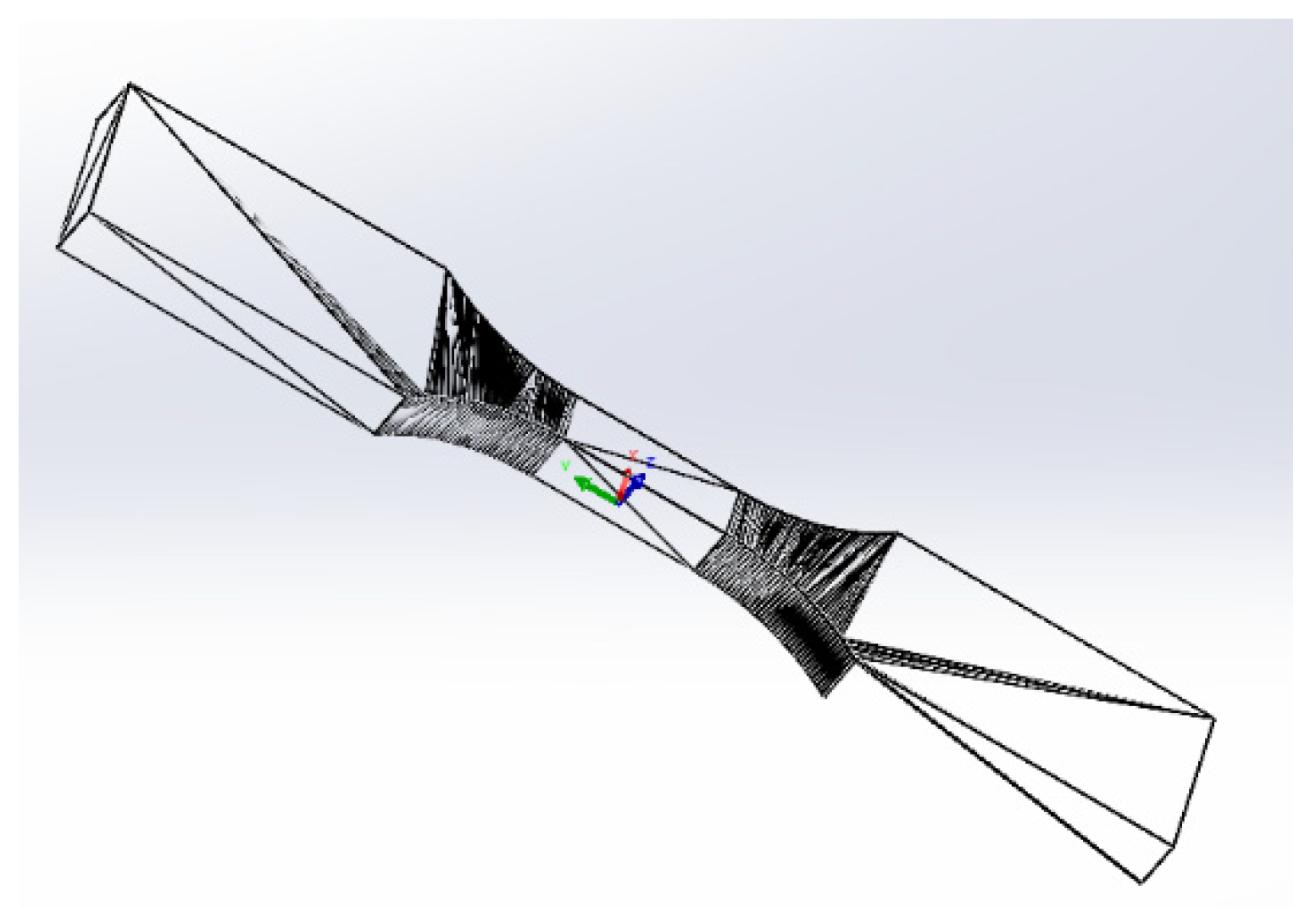

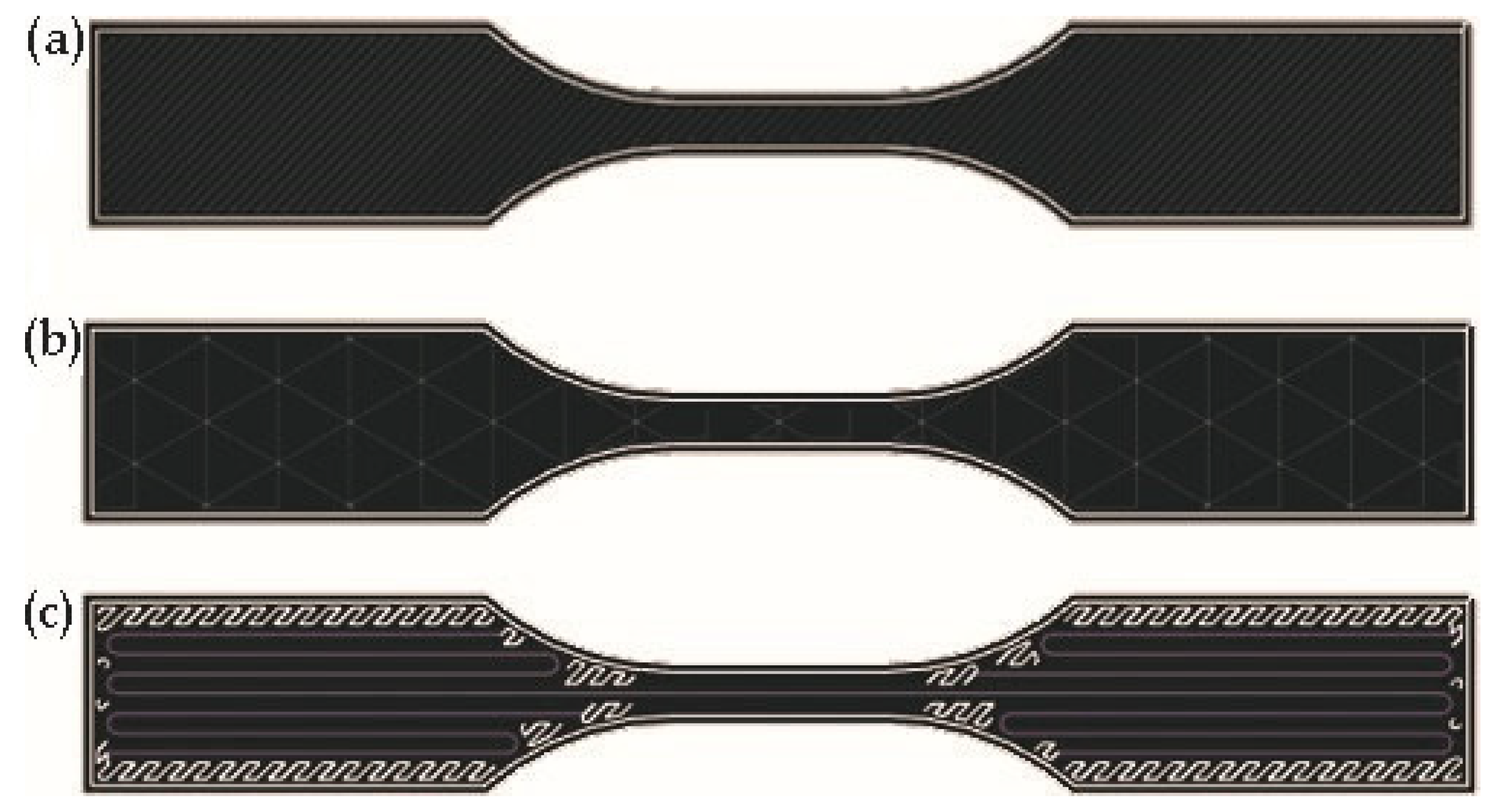

2.3. Preparation of Samples

2.4. Measurement Methods

3. Results

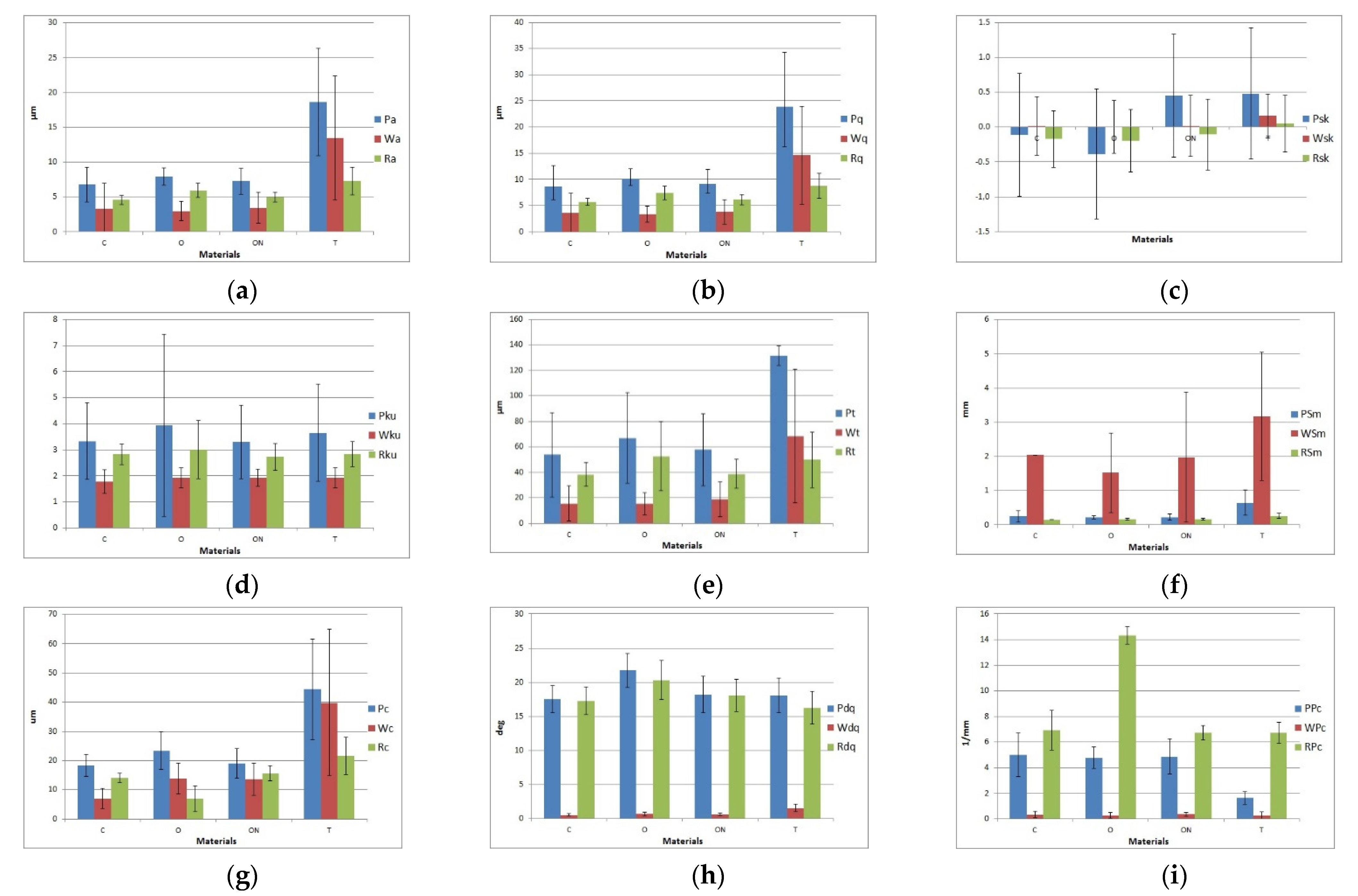

3.1. Surface Texture

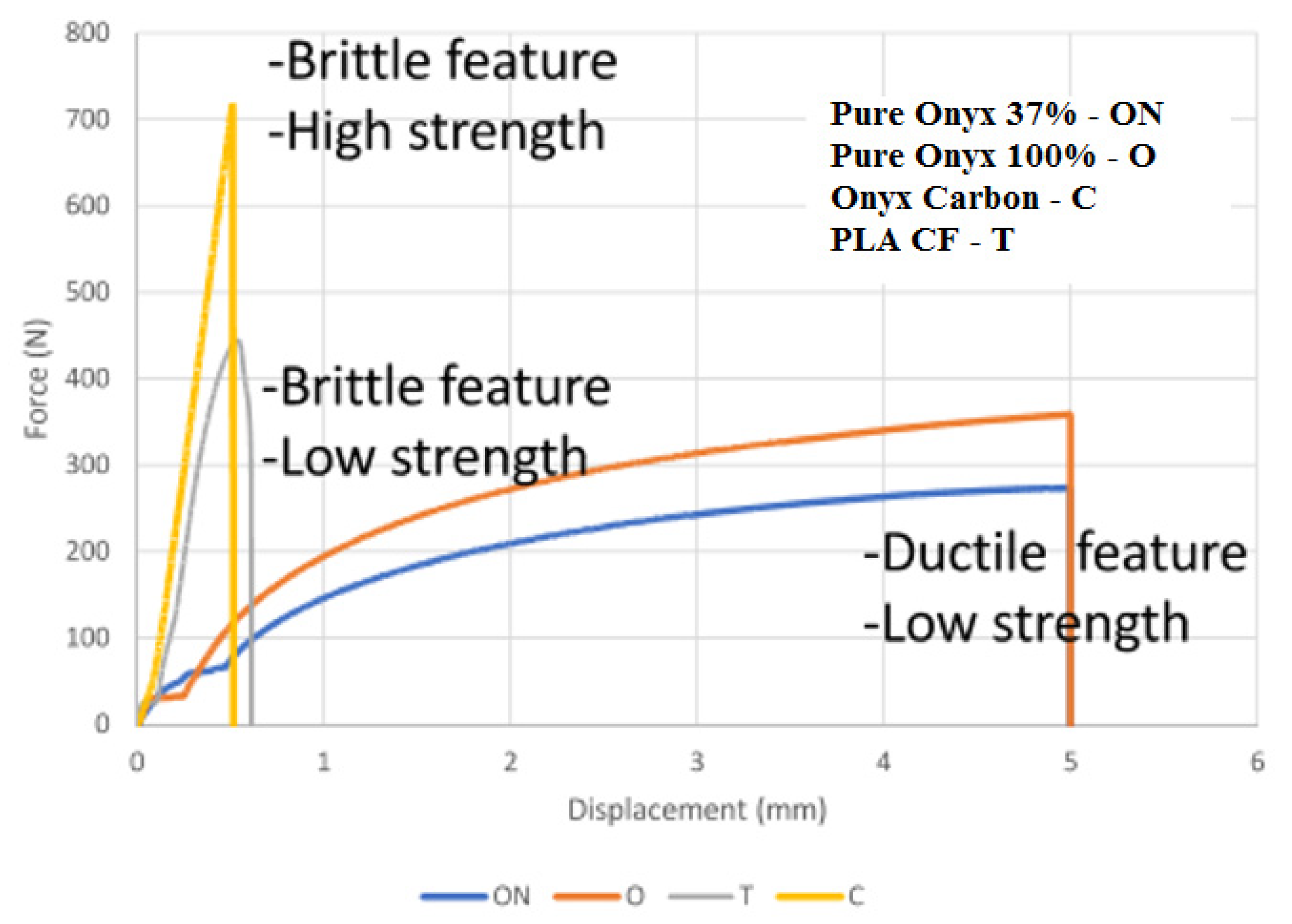

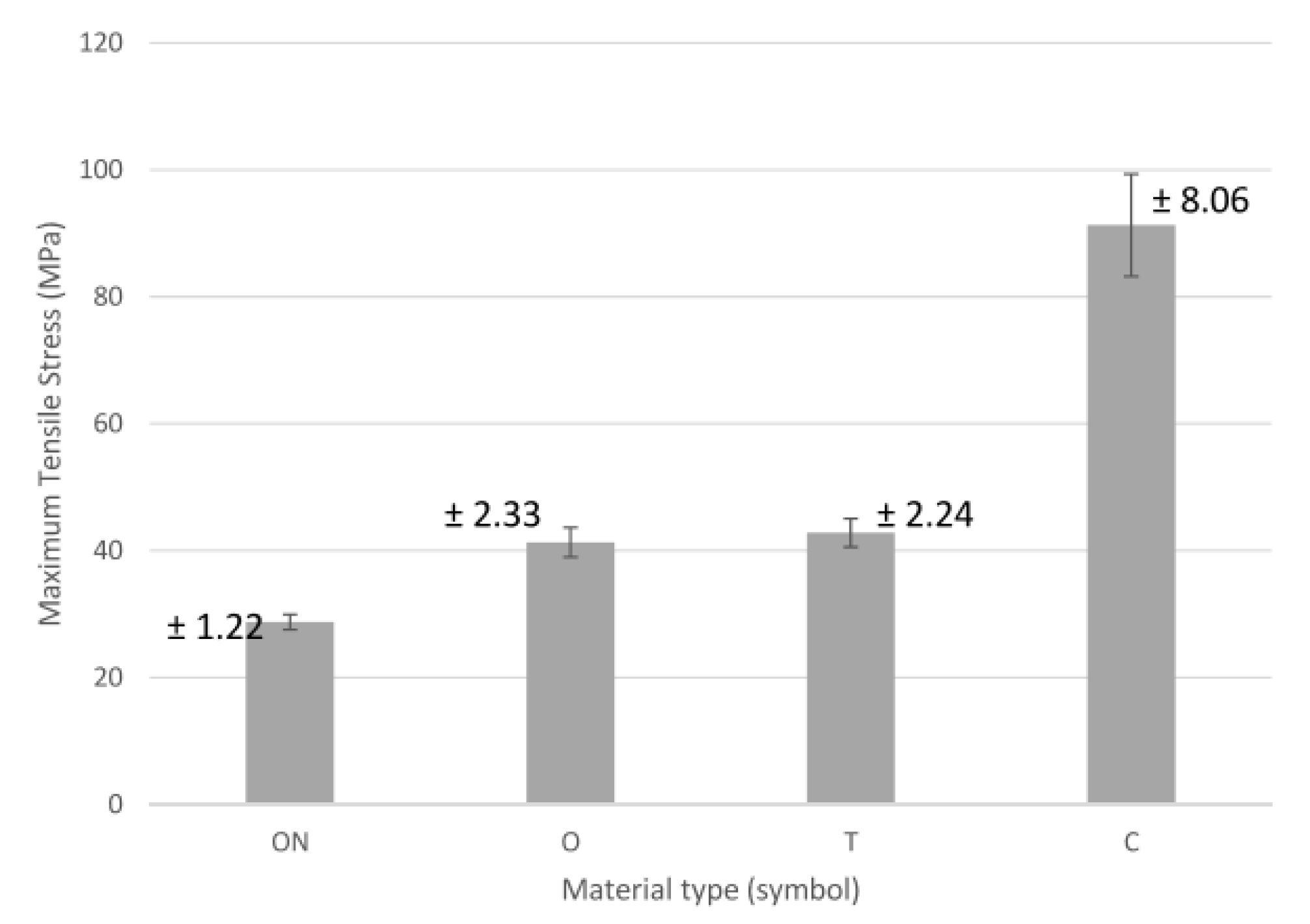

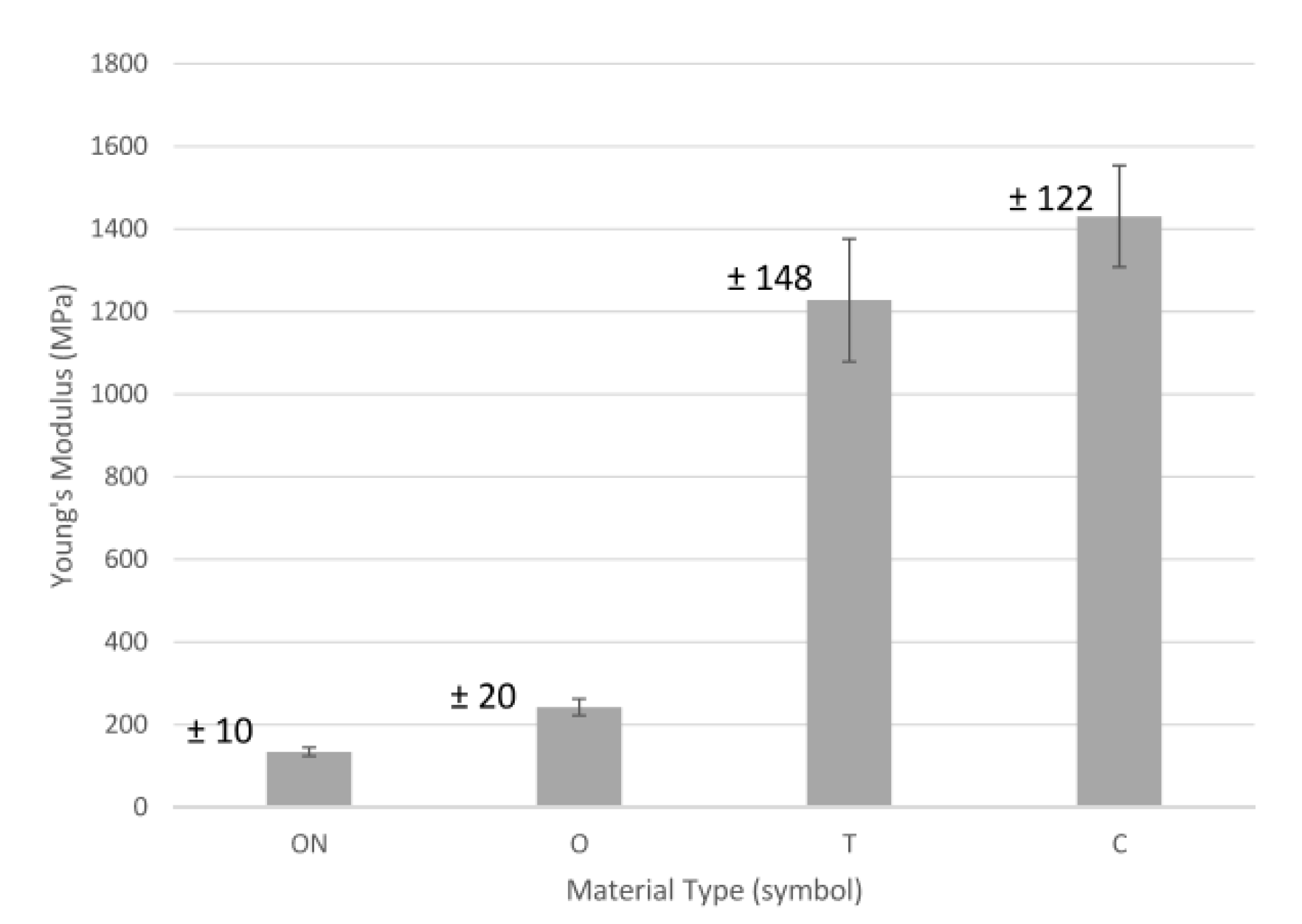

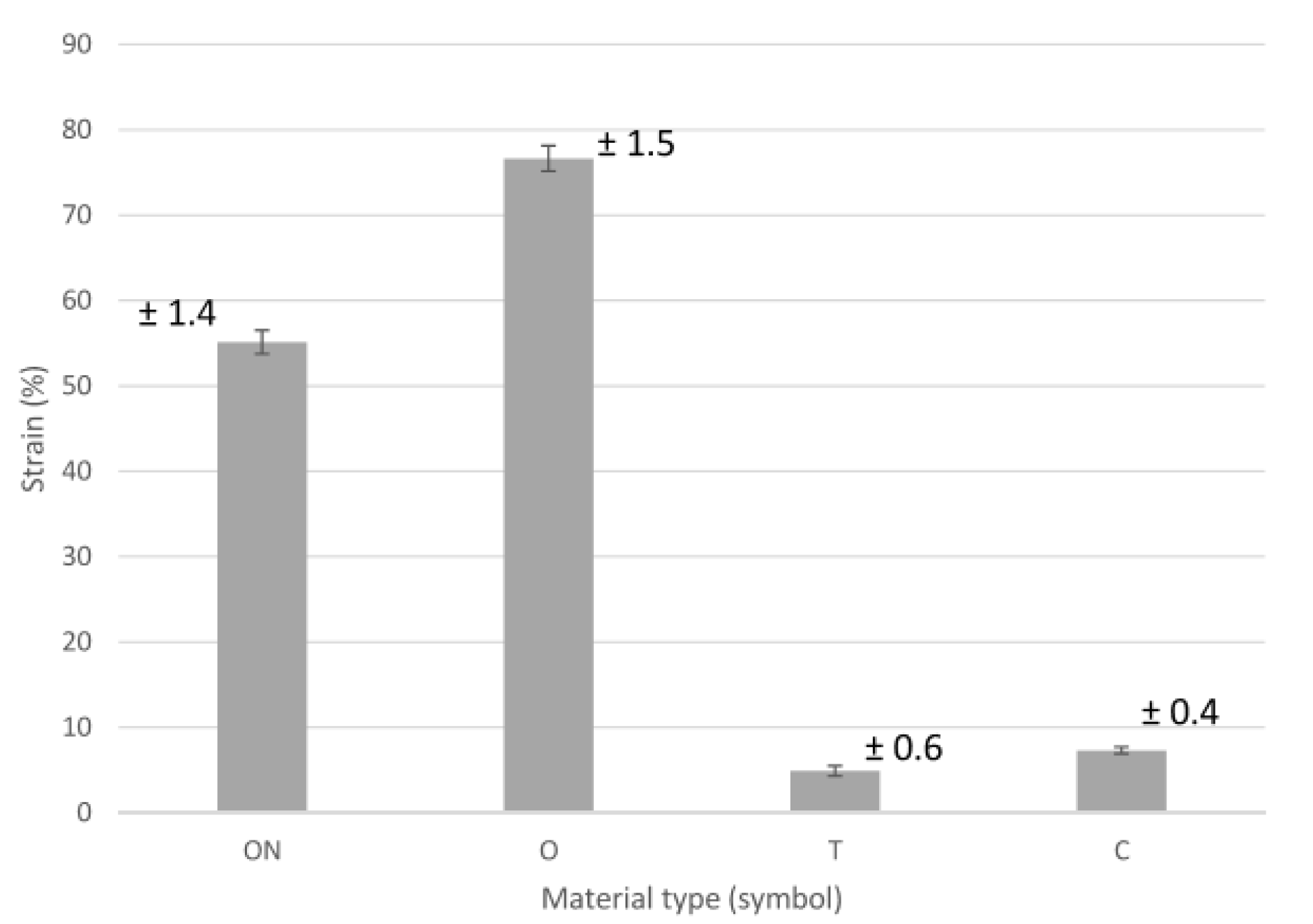

3.2. Tensile Test

4. Discussion

5. Conclusions

- The addition of carbon fibers greatly affected the strength of the manufactured models—increasing both the tensile strength and the modulus of elasticity. It seems that models manufactured in CFF technology, where only selected layers consist of carbon material, show the greatest strength.

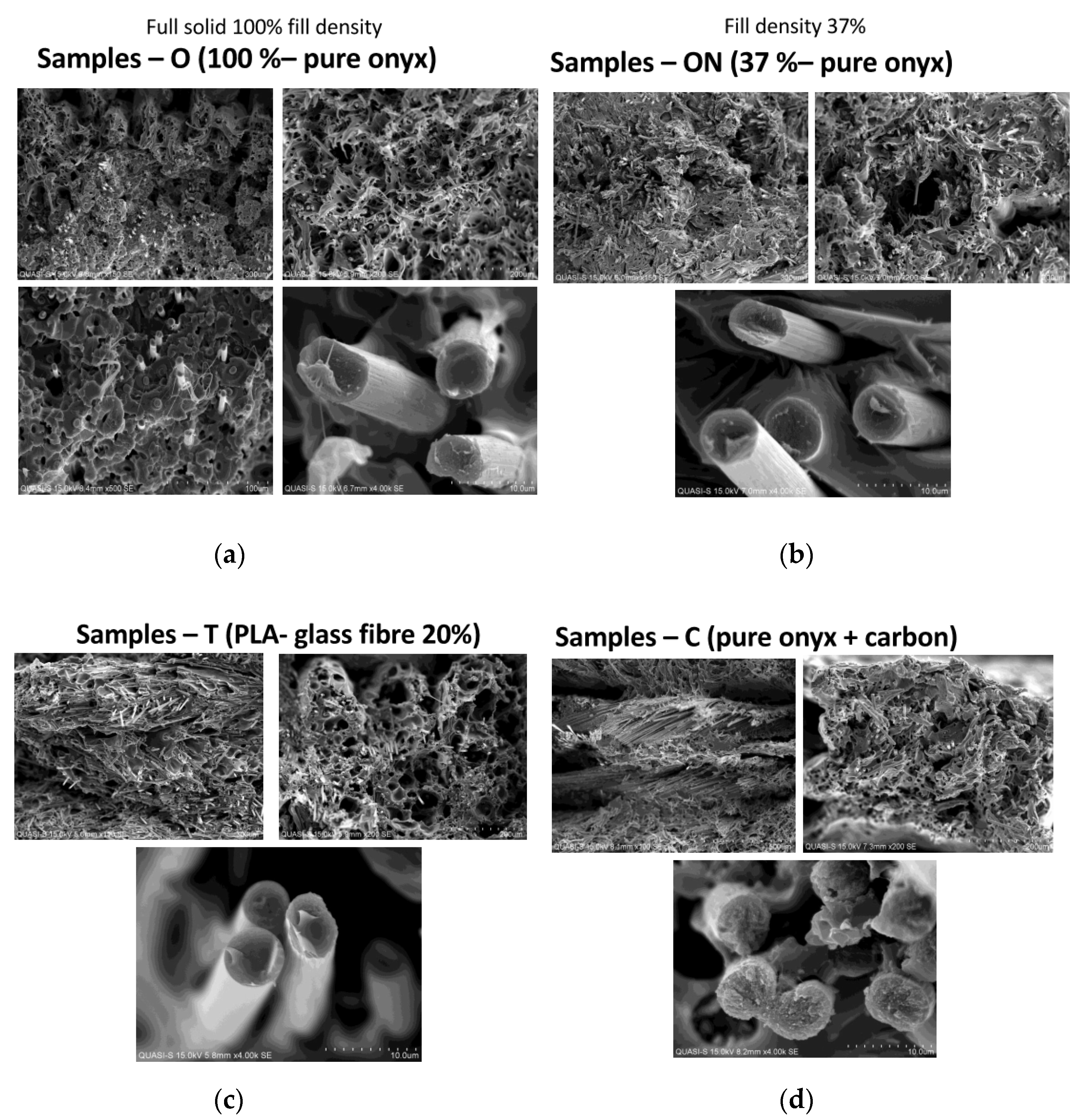

- The analysis of SEM microscopic photos shows that in the case of samples based on PA (O and ON samples), both types of infill material had high porosity, and there were voids in the variant of 37% filling, which negatively affected the strength of the models. Carbon fibers were uniformly visible in the case of samples manufactured with FDM technology and in a layered manner for CFF technology, which, as can be seen from the strength, shows the advantage of the second variant of placing additives in the form of carbon fibers.

- The presented studies of the surface texture have shown that there is a dependence between the obtained surface texture of the samples and the applied technology. Depending on the method used, a different distribution of surface irregularities was obtained, in which, depending on the technology, waviness or roughness was the dominant component.

- One-way ANOVA analysis showed only sporadically significant differences in the values of parameters between samples made by CFF technology. On the other hand, these differences were observed to a larger extent when comparing the values of parameters of waviness, roughness and primary profile for samples made with the use of the two analyzed technologies.

- Summarizing the results of the research in which both FDM and CFF 3D printing technologies were compared, many interesting conclusions showed that the addition of carbon fiber alone is not a factor determining high mechanical properties, the method of fiber supply depending on the 3D printing method is also important. It seems that the use of CFF technology and a material based on carbon fiber reinforced polyamide for the construction of thin-walled models is the right solution, which, as shown by measurements of the surface structure, ensures better roughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| Pa/Wa/Ra | Arithmetical mean height of primary/waviness/roughness profile |

| Pq/Wq/Rq | Root mean square deviation of primary/waviness/roughness profile |

| Psk/Wsk/Rsk | Skewness of primary/waviness/roughness profile |

| Pku/Wku/Rku | Kurtosis of primary/waviness/roughness profile |

| Pt/Wt/Rt | Total height of primary/waviness/roughness profile. |

| PSm/WSm/RSm | Mean width of primary/waviness/roughness profile elements |

| Pc/Wc/Rc | Mean height of primary/waviness/roughness profile elements |

| Pdq/Wdq/Rdq | Root mean square slope of primary/waviness/roughness profile |

| PPc/WPc/Rpc | the number of local peak of primary/waviness/roughness profile |

| FDM | Fused Deposition Modeling |

| CFF | Continuous Filament Fabrication |

| PA | Polyamide |

| PLA | Polylactic acid |

References

- Grimmelsmann, N.; Martens, Y.; Schäl, P.; Meissner, H.; Ehrmann, A. Mechanical and Electrical Contacting of Electronic Components on Textiles by 3D Printing. Procedia Technol. 2016, 26, 66–71. [Google Scholar] [CrossRef] [Green Version]

- Richter, C.; Schmülling, S.; Ehrmann, A.; Finsterbusch, K. FDM Printing of 3D Forms with Embedded Fibrous Materials. In Design, Manufacturing and Mechatronics, Proceedings of the 2015 Annual International Conference on Design, Manufacturing and Mechatronics (ICDMM2015), Wuhan, China, 17–18 April 2015; World Scientific: Singapore, 2015; pp. 961–969. [Google Scholar]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef] [Green Version]

- Zmarzły, P.; Gogolewski, D.; Kozior, T. Design guidelines for plastic casting using 3D printing. J. Eng. Fibers Fabr. 2020, 15. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, A. 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines 2020, 11, 434. [Google Scholar] [CrossRef] [Green Version]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the surface texture and mechanical properties of FDM printed samples after thermal and chemical treatment. J. Mech. Eng. 2020, 66, 105–113. [Google Scholar]

- Dezaki, M.L.; Ariffin, M.K.A.M.; Ismail, M.I.S. Effects of CNC Machining on Surface Roughness in Fused Deposition Modelling (FDM) Products. Materials 2020, 13, 2608. [Google Scholar] [CrossRef] [PubMed]

- Nowakowski, L.; Miko, E.; Skrzyniarz, M. Designation of the Minimum Thickness of Machined Layer for the Milling Process of Duralumin PA6. In Proceedings of the 23rd International Conference of Engineering Mechanics, Svratka, Czech Republic, 15–18 May 2017. [Google Scholar]

- Kousiatza, C.; Tzetzis, D.; Karalekas, D. In-situ characterization of 3D printed continuous fiber reinforced composites: A methodological study using fiber Bragg grating sensors. Compos. Sci. Technol. 2019, 174, 134–141. [Google Scholar] [CrossRef]

- Bochnia, J.; Blasiak, M.; Kozior, T. Tensile Strength Analysis of Thin-Walled Polymer Glass Fiber Reinforced Samples Manufactured by 3D Printing Technology. Polymers 2020, 12, 2783. [Google Scholar] [CrossRef]

- Kozior, T. The Influence of Selected Selective Laser Sintering Technology Process Parameters on Stress Relaxation, Mass of Models, and Their Surface Texture Quality. 3D Print. Addit. Manuf. 2020, 7, 126–138. [Google Scholar] [CrossRef]

- Adamczak, S.; Zmarzly, P.; Kozior, T.; Gogolewski, D. Assessment of Roundness and Waviness Deviations of Elements Produced by Selective Laser Sintering Technology. In Proceedings of the 23rd International Conference of Engineering Mechanics, Svratka, Czech Republic, 15–18 May 2017. [Google Scholar]

- Kozior, T. Rheological Properties of Polyamide PA 2200 in SLS Technology. Tech. Gaz. 2020, 27, 1092–1100. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Kozior, T.; Kundera, C. Surface texture of models manufactured by FDM technology. AIP Conf. Proc. 2018, 2017, 020011. [Google Scholar] [CrossRef]

- Valvez, S.; Santos, P.; Parente, J.; Silva, M.; Reis, P. 3D printed continuous carbon fiber reinforced PLA composites: A short review. Procedia Struct. Integr. 2020, 25, 394–399. [Google Scholar] [CrossRef]

- Chaudhry, F.N.; Butt, S.I.; Mubashar, A.; Bin Naveed, A.; Imran, S.H.; Faping, Z. Effect of carbon fibre on reinforcement of thermoplastics using FDM and RSM. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic reinforcement of polyamide-based composites by combination of short and continuous carbon fibers via fused filament fabrication. Compos. Struct. 2019, 207, 232–239. [Google Scholar] [CrossRef]

- Liu, T.; Tian, X.; Zhang, M.; Abliz, D.; Li, D.; Ziegmann, G. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 368–376. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Ivey, M.; Melenka, G.W.; Carey, J.P.; Ayranci, C. Characterizing short-fiber-reinforced composites produced using additive manufacturing. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Calignano, F.; Lorusso, M.; Roppolo, I.; Minetola, P. Investigation of the Mechanical Properties of a Carbon Fibre-Reinforced Nylon Filament for 3D Printing. Machines 2020, 8, 52. [Google Scholar] [CrossRef]

- Beniak, J.; Križan, P.; Šooš, L.; Matus, M. Roughness and compressive strength of FDM 3D printed specimens affected by acetone vapour treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 297, 012018. [Google Scholar] [CrossRef]

- Zmarzły, P. Influence of bearing raceway surface topography on the level of generated vibration as an example of operational heredity. Indian J. Eng. Mater. Sci. 2020, 27, 356–364. [Google Scholar]

- Zmarzły, P. Multi-Dimensional Mathematical Wear Models of Vibration Generated by Rolling Ball Bearings Made of AISI 52100 Bearing Steel. Materials 2020, 13, 5440. [Google Scholar] [CrossRef]

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T.G. Waviness of Freeform Surface Characterizations from Austenitic Stainless Steel (316L) Manufactured by 3D Printing-Selective Laser Melting (SLM) Technology. Materials 2020, 13, 4372. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Bochnia, J. The Influence of Printing Orientation on Surface Texture Parameters in Powder Bed Fusion Technology with 316L Steel. Micromachines 2020, 11, 639. [Google Scholar] [CrossRef] [PubMed]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, Y.; Wang, Y.; Jiang, G.; Liang, M.; Chen, X.; Long, G. A fractal model for Kozeny–Carman constant and dimensionless permeability of fibrous porous media with roughened surfaces. Fractals 2019, 27, 1950116. [Google Scholar] [CrossRef]

- Gogolewski, D. Influence of the edge effect on the wavelet analysis process. Measurement 2020, 152, 107314. [Google Scholar] [CrossRef]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Gogolewski, D. Fractional spline wavelets within the surface texture analysis. Measurement 2021, 179, 109435. [Google Scholar] [CrossRef]

- Adamczak, S.; Zmarzły, P.; Stępień, K. Identification and analysis of optimal method parameters of the V-block waviness measurements. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 325–332. [Google Scholar] [CrossRef] [Green Version]

- Markforged. The Mark Two Desktop 3D Printer. 2019. Available online: https://3d.markforged.com/say-hello.html?mfa=ga-search& (accessed on 14 April 2021).

- Markforged. Available online: http://static.markforged.com/downloads/composites-data-sheet.pdf (accessed on 14 April 2021).

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- PLA Structural Formula. Available online: https://omnexus.specialchem.com/selection-guide/polylactide-pla-bioplastic (accessed on 14 April 2021).

- Polyamides. (n.d.). Available online: https://www.essentialchemicalindustry.org/polymers/polyamides.html (accessed on 14 April 2021).

- Chabaud, G.; Castro, M.; Denoual, C.; Le Duigou, A. Hygromechanical properties of 3D printed continuous carbon and glass fibre reinforced polyamide composite for outdoor structural applica-tions. Addit. Manuf. 2019, 26, 94–105. [Google Scholar]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

| Properties | Carbonfil | Onyx | Carbon Fibers (CFF) |

|---|---|---|---|

| Specific gravity | 1.19 g/cm3 | 1.2 g/cm3 | 1.4 g/cm3 |

| Impact strength | 7.9 KJ/m2 (ASTM D792) | 0.33 KJ/m (D256-10 A) | 0.96 KJ/m (D256-10 A) |

| Tensile modulus | 3800 MPa (ASTM D256) | 2400 MPa (D638) | 60,000 MPa (D638) |

| Elongation at break | 8% (ISO 527) | 25% (D638) | 1.5% (D3039) |

| Print temperature | ±230–265 °C | ±270 °C | ±250 °C |

| Sample | Layer Height (mm) | Infill (-) | Fill Density (%) | Reinforcement (-) | No. of Layers (-) | Filament Consumption (cm3) |

|---|---|---|---|---|---|---|

| O | 0.100 | Full solid | 100 | - | 32 | 1.56 |

| ON | 0.100 | Triangular | 37 | - | 32 | 1.09 |

| C | 0.125 | Triangular | 37 | Carbon Fibers | 26/8 | 1.56/0.26 |

| T | 0.200 | Full solid | 95 | Carbon Fibers | 16 | 1.93 |

| Pa | Pq | Psk | Pku | Pt | Wa | Wq | Wsk | Wku | Wt | Ra | Rq | Rsk | Rku | Rt | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C:O | 0.56052 | 0.629928 | 0.562303 | 0.64953 | 0.397417 | 0.989091 | 0.995307 | 0.99962 | 0.293084 | 0.999997 | 0.000142 | 8.88 × 10−5 | 0.987628 | 0.630119 | 0.009705 |

| C:ON | 0.952145 | 0.975447 | 0.917981 | 0.999837 | 0.96512 | 0.99952 | 0.998654 | 0.99986 | 0.935582 | 0.958012 | 0.554604 | 0.599038 | 0.887035 | 0.928208 | 0.999427 |

| C:T | 3.77 × 10−9 | 3.77 × 10−9 | 0.949736 | 0.999811 | 5.54 × 10−9 | 4.90 × 10−9 | 4.26 × 10−9 | 0.379502 | 0.93208 | 1.54 × 10−8 | 4.70 × 10−8 | 3.99 × 10−7 | 0.120838 | 0.474314 | 0.048985 |

| O:ON | 0.859765 | 0.860392 | 0.225224 | 0.602362 | 0.680432 | 0.974073 | 0.979474 | 0.999102 | 0.099345 | 0.95306 | 0.006442 | 0.003454 | 0.720634 | 0.284806 | 0.013146 |

| O:T | 3.77 × 10−9 | 3.78 × 10−9 | 0.268985 | 0.698237 | 1.92 × 10−7 | 4.24 × 10−9 | 4.02 × 10−9 | 0.326845 | 0.096993 | 1.48 × 10−8 | 0.052979 | 0.301727 | 0.060152 | 0.054372 | 0.913548 |

| ON:T | 3.77 × 10−9 | 3.78 × 10−9 | 0.999575 | 0.998603 | 1.06 × 10−8 | 5.31 × 10−9 | 4.52 × 10−9 | 0.397974 | 0.999999 | 5.51 × 10−8 | 2.36 × 10−6 | 1.80 × 10−5 | 0.413538 | 0.832496 | 0.063714 |

| PSm | Pc | Pdq | PPc | WSm | Wc | Wdq | WPc | RSm | Rc | Rdq | RPc | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C:O | 0.997059 | 0.393189 | 0.000227 | 0.927642 | 0.999805 | 0.716727 | 0.8039596 | 0.668703 | 0.779801 | 0.009563 | 0.000209 | 9.70 × 10−1 |

| C:ON | 0.999327 | 0.99661 | 0.817928 | 0.986484 | 0.970443 | 0.73294 | 0.932891 | 0.997436 | 0.85164 | 0.663348 | 0.731507 | 0.938505 |

| C:T | 8.43 × 10−6 | 1.77 × 10−6 | 0.889543 | 5.58 × 10−7 | 5.18 × 10−1 | 6.61 × 10−3 | 6.46 × 10−7 | 0.869892 | 6.48 × 10−9 | 2.48 × 10−4 | 5.59 × 10−1 | 3.76 × 10−7 |

| O:ON | 0.999822 | 0.508183 | 0.001267 | 0.992553 | 0.952718 | 0.999991 | 0.989322 | 0.555353 | 0.998882 | 0.091186 | 0.001614 | 0.7419495 |

| O:T | 6.03 × 10−6 | 2.68 × 10−5 | 0.000921 | 1.40 × 10−6 | 4.72 × 10−1 | 5.48 × 10−2 | 2.60 × 10−6 | 0.980451 | 1.14 × 10−8 | 2.98 × 10−1 | 1.83 × 10−5 | 2.01 × 10−7 |

| ON:T | 6.87 × 10−6 | 2.46 × 10−6 | 0.998507 | 9.21 × 10−7 | 7.74 × 10−1 | 5.19 × 10−2 | 1.59 × 10−6 | 0.776959 | 1.02 × 10−8 | 2.44 × 10−3 | 1.25 × 10−1 | 8.76 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saharudin, M.S.; Hajnys, J.; Kozior, T.; Gogolewski, D.; Zmarzły, P. Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies. Polymers 2021, 13, 1671. https://doi.org/10.3390/polym13111671

Saharudin MS, Hajnys J, Kozior T, Gogolewski D, Zmarzły P. Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies. Polymers. 2021; 13(11):1671. https://doi.org/10.3390/polym13111671

Chicago/Turabian StyleSaharudin, Mohd Shahneel, Jiri Hajnys, Tomasz Kozior, Damian Gogolewski, and Paweł Zmarzły. 2021. "Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies" Polymers 13, no. 11: 1671. https://doi.org/10.3390/polym13111671

APA StyleSaharudin, M. S., Hajnys, J., Kozior, T., Gogolewski, D., & Zmarzły, P. (2021). Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies. Polymers, 13(11), 1671. https://doi.org/10.3390/polym13111671