An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Polyimide Films for Surface Modification

2.3. Surface Treatments of Polyimide Films

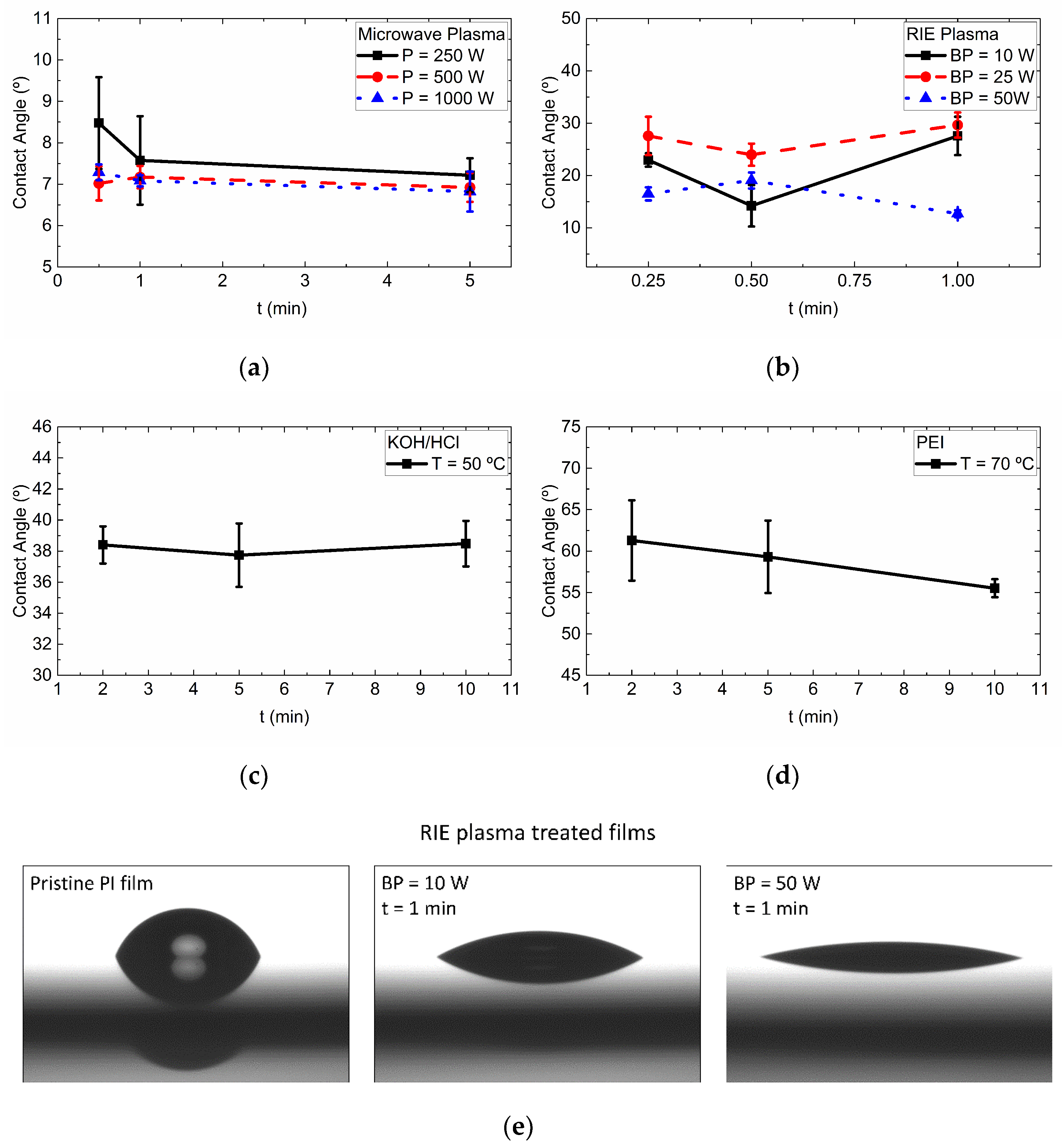

2.4. Contact Angle Measurements

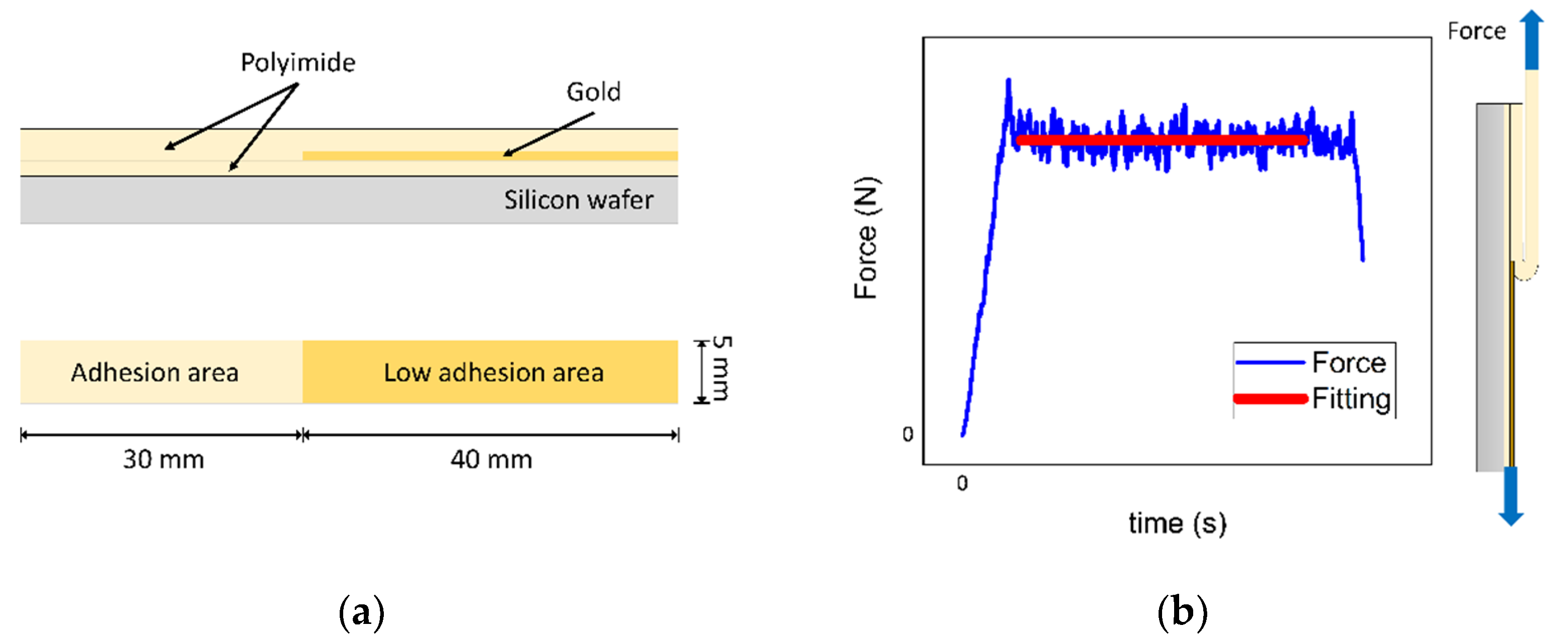

2.5. Fabrication of Scratch Test Samples

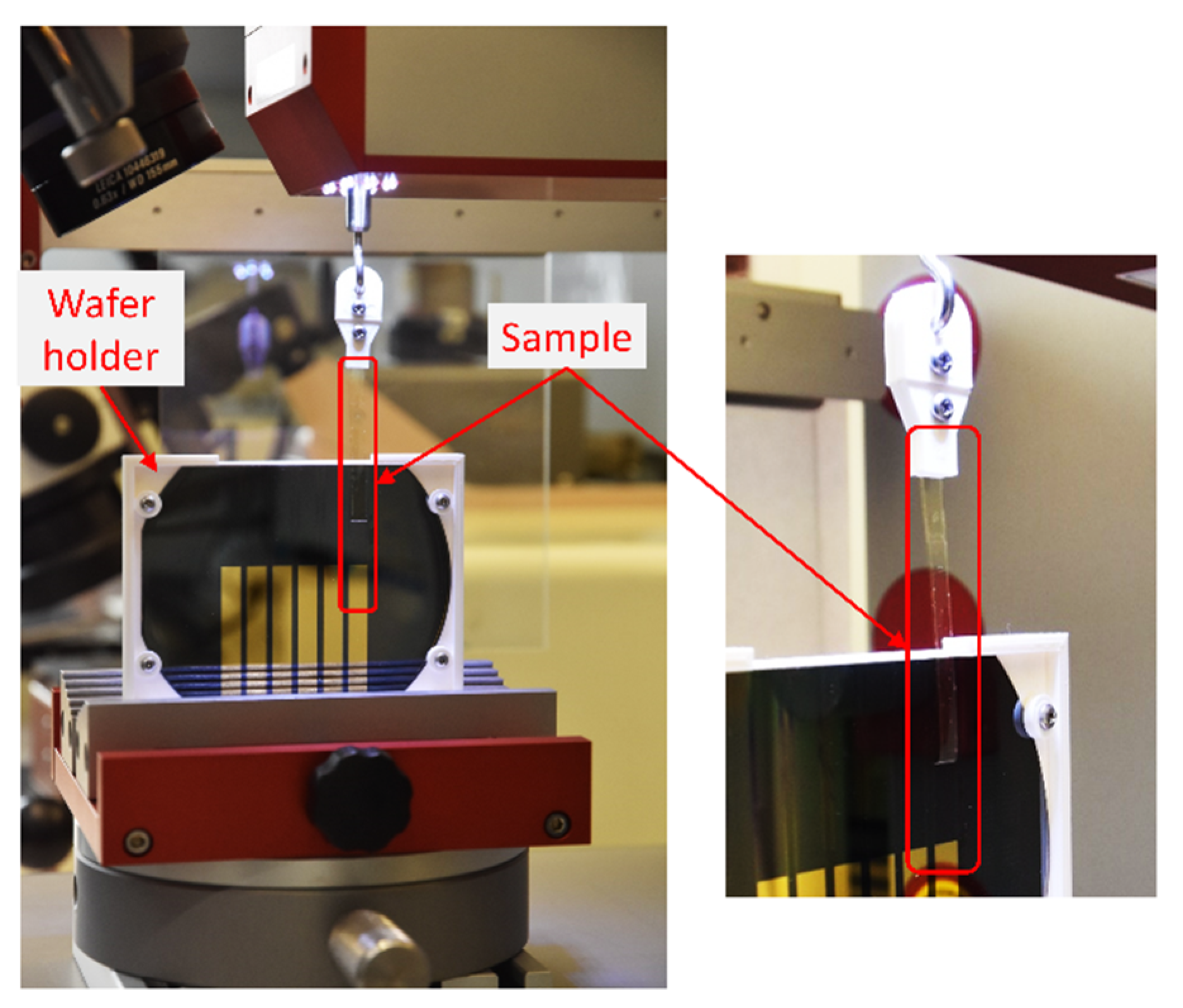

2.6. Fabrication of Peel Test Samples and Characterization

3. Results

3.1. Wettability and Surface Energy of PI Films

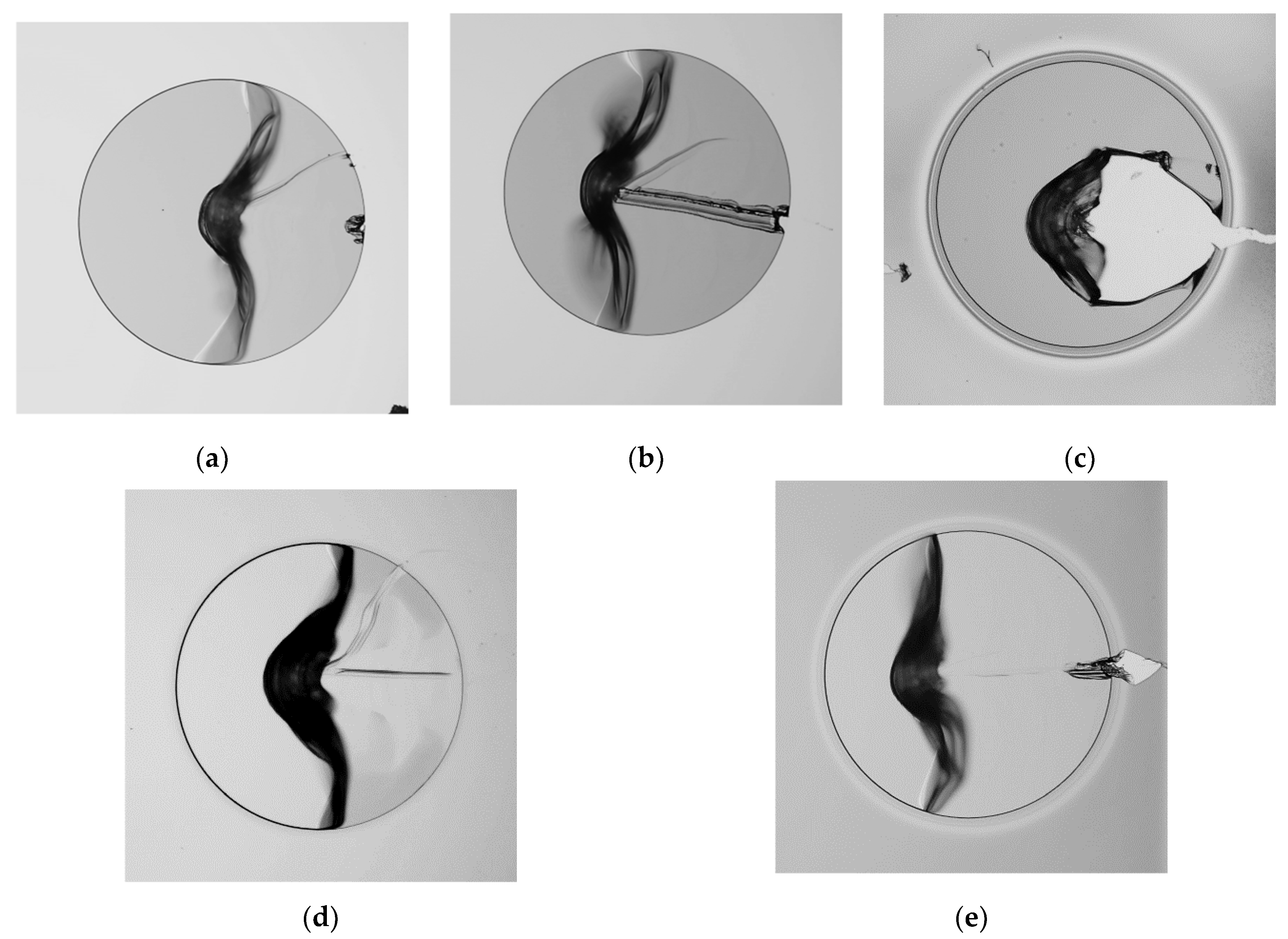

3.2. Scratch Test of Polyimide Films

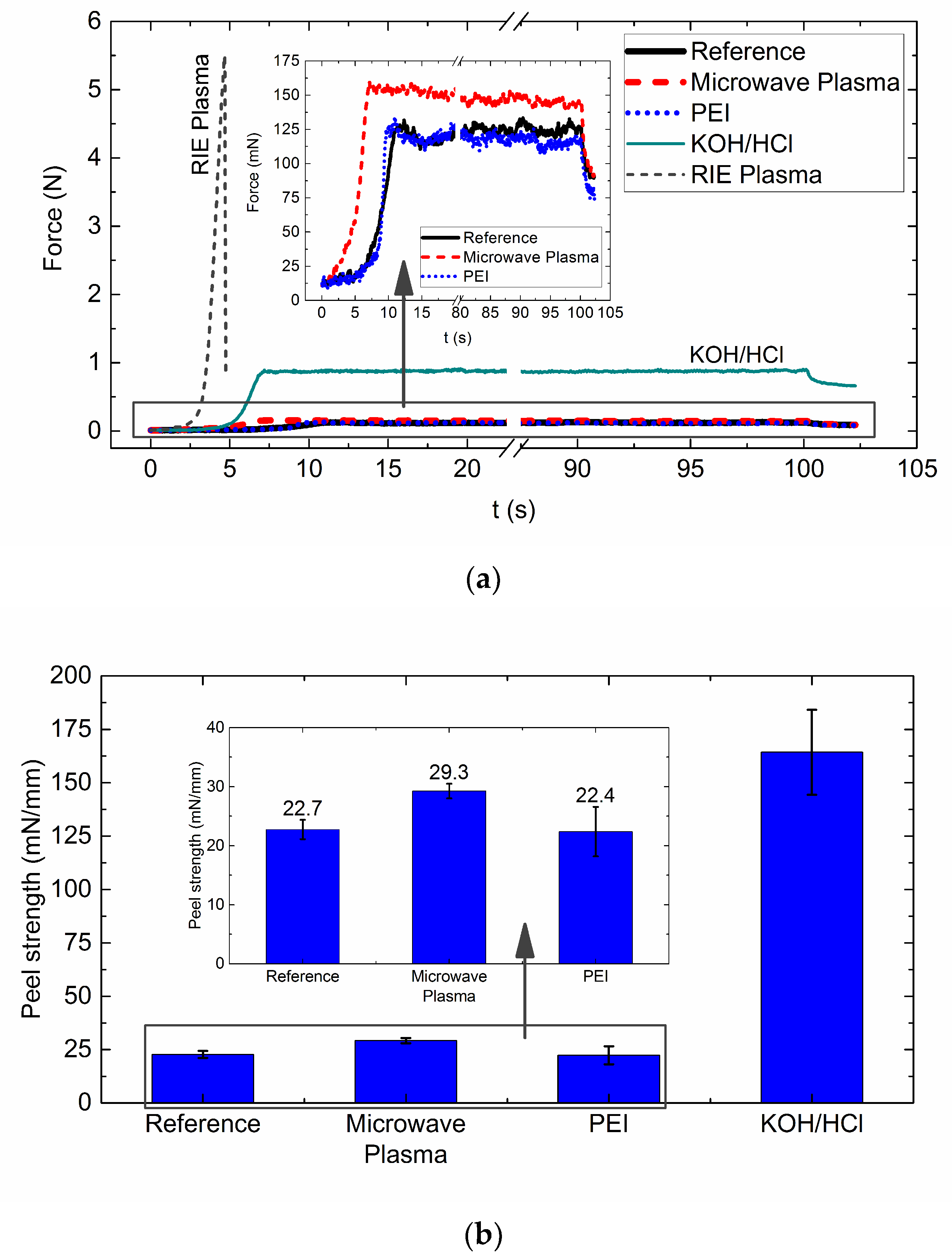

3.3. Peel Strength between PI Films

4. Discussion of the Adhesion Mechanisms between PI Films

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A. Calculation of Surface Free Energy of PI Films

| Liquid | σL (mN/m) | σLP (mN/m) | σLD (mN/m) |

|---|---|---|---|

| Water | 72.8 | 51.0 | 21.8 |

| DMSO | 44.0 | 8.0 | 36.0 |

| Isopropanol | 23.0 | 3.5 | 19.5 |

References

- Boll, D.; Schubert, K.; Brauner, C.; Lang, W. Miniaturized Flexible Interdigital Sensor for In Situ Dielectric Cure Monitoring of Composite Materials. IEEE Sens. J. 2014, 14, 2193–2197. [Google Scholar] [CrossRef]

- Gosh, M.K.; Mittal, K.L. Polyimides: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Chou, C.-Y.; Liu, H.-S.; Liou, G.-S. Highly transparent silver nanowire–polyimide electrode as a snow-cleaning device. RSC Adv. 2016, 6, 61386–61392. [Google Scholar] [CrossRef]

- Yang, T.; Yu, Y.Z.; Zhu, L.S.; Wu, X.; Wang, X.H.; Zhang, J. Fabrication of silver interdigitated electrodes on polyimide films via surface modification and ion-exchange technique and its flexible humidity sensor application. Sens. Actuators B Chem. 2015, 208, 327–333. [Google Scholar] [CrossRef]

- Hubner, M.; Lepke, D.; Hardi, E.; Koerdt, M.; Herrmann, A.S.; Lang, W. Online Monitoring of Moisture Diffusion in Carbon Fiber Composites Using Miniaturized Flexible Material Integrated Sensors. Sensors 2019, 19, 1748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Engel, J.; Chen, J.; Liu, C. Development of polyimide flexible tactile sensor skin. J. Micromech. Microeng. 2003, 13, 359–366. [Google Scholar] [CrossRef] [Green Version]

- Schander, A.; Stemmann, H.; Kreiter, A.K.; Lang, W. Silicon-Based Microfabrication of Free-Floating Neural Probes and Insertion Tool for Chronic Applications. Micromachines 2018, 9, 131. [Google Scholar] [CrossRef] [Green Version]

- Schander, A.; Strokov, S.; Stemmann, H.; Tebmann, T.; Kreiter, A.K.; Lang, W. A Flexible 202-Channel Epidural ECoG Array With PEDOT: PSS Coated Electrodes for Chronic Recording of the Visual Cortex. IEEE Sens. J. 2019, 19, 820–825. [Google Scholar] [CrossRef]

- Lin, F.; Li, W.; Tang, Y.; Shao, H.; Su, C.; Jiang, J.; Chen, N. High-Performance Polyimide Filaments and Composites Improved by O2 Plasma Treatment. Polymers 2018, 10, 695. [Google Scholar] [CrossRef] [Green Version]

- Qu, H.; Wang, Z.; Cang, D. Flexible Bandpass Filter Fabricated on Polyimide Substrate by Surface Modification and In Situ Self-Metallization Technique. Polymers 2019, 11, 2068. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.J.; Yu, D.M.; Ahn, J.H.; Choi, J.-H.; Hong, Y.T. Surface modification of polyimide films by an ethylenediamine treatment for a flexible copper clad laminate. Macromol. Res. 2012, 20, 168–173. [Google Scholar] [CrossRef]

- Bouhamed, A.; Kia, A.M.; Naifar, S.; Dzhagan, V.; Müller, C.; Zahn, D.R.T.; Choura, S.; Kanoun, O. Tuning the adhesion between polyimide substrate and MWCNTs/epoxy nanocomposite by surface treatment. Appl. Surf. Sci. 2017, 422, 420–429. [Google Scholar] [CrossRef]

- Miyauchi, K.; Yuasa, M. A study of adhesive improvement of a Cr–Ni alloy layer on a polyimide surface by low pressure gas plasma modification. Prog. Org. Coat. 2013, 76, 1536–1542. [Google Scholar] [CrossRef]

- Usami, K.; Ishijima, T.; Toyoda, H. Rapid plasma treatment of polyimide for improved adhesive and durable copper film deposition. Thin Solid Films 2012, 521, 22–26. [Google Scholar] [CrossRef]

- Lin, Y.S.; Liu, H.M. Enhanced adhesion of plasma-sputtered copper films on polyimide substrates by oxygen glow discharge for microelectronics. Thin Solid Films 2008, 516, 1773–1780. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, H.Y. Effect of atmospheric-pressure plasma on adhesion characteristics of polyimide film. J. Colloid Interface Sci. 2005, 285, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Inagaki, N.; Tasaka, S.; Hibi, K. Improved adhesion between plasma-treated polyimide film and evaporated copper. J. Adhes. Sci. Technol. 1994, 8, 395–410. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Chandra Sil, M.; Chen, C.-M. Surface composite engineering of polyimide to create amine functionalities for autocatalytic metallization. Appl. Surf. Sci. 2021, 541, 148500. [Google Scholar] [CrossRef]

- Yu, Z.J.; Kang, E.T.; Neoh, K.G. Electroless plating of copper on polyimide films modified by surface grafting of tertiary and quaternary amines polymers. Polymer 2002, 43, 4137–4146. [Google Scholar] [CrossRef]

- Inagaki, N.; Tasaka, S.; Masumoto, M. Improved Adhesion between Kapton Film and Copper Metal by Plasma Graft Polymerization of Vinylimidazole. Macromolecules 1996, 29, 1642–1648. [Google Scholar] [CrossRef]

- Yu, W.X.; Hong, L.; Chen, B.H.; Ko, T.M. A study on the interfacial composition of the electroless-copper-plated BPDA-PDA polyimide sheet. J. Mater. Chem. 2003, 13, 818–824. [Google Scholar] [CrossRef]

- Wang, Z.; Furuya, A.; Yasuda, K.; Ikeda, H.; Baba, T.; Hagiwara, M.; Toki, S.; Shingubara, S.; Kubota, H.; Ohmi, T. Adhesion improvement of electroless copper to a polyimide film substrate by combining surface microroughening and imide ring cleavage. J. Adhes. Sci. Technol. 2002, 16, 1027–1040. [Google Scholar] [CrossRef]

- Wu, P.-Y.; Lin, C.-H.; Chen, C.-M. Study of Surface Metallization of Polyimide Film and Interfacial Characterization. Metals 2017, 7, 189. [Google Scholar] [CrossRef] [Green Version]

- Brown, H.; Yang, A.; Russell, T.; Volksen, W.; Kramer, E. Diffusion and self-adhesion of the polyimide PMDA-ODA. Polymer 1988, 29, 1807–1811. [Google Scholar] [CrossRef]

- Sun, X.; Bu, J.; Liu, W.; Niu, H.; Qi, S.; Tian, G.; Wu, D. Surface modification of polyimide fibers by oxygen plasma treatment and interfacial adhesion behavior of a polyimide fiber/epoxy composite. Sci. Eng. Compos. Mater. 2017, 24, 477–484. [Google Scholar] [CrossRef]

- Wen, Y.; Meng, X.; Liu, J.; Yan, J.; Wang, Z. Surface modification of high-performance polyimide fibers by oxygen plasma treatment. High Perform. Polym. 2016, 29, 1083–1089. [Google Scholar] [CrossRef]

- Lee, K.W.; Kowalczyk, S.P.; Shaw, J.M. Surface modification of BPDA-PDA polyimide. Langmuir 1991, 7, 2450–2453. [Google Scholar] [CrossRef]

- Tian, G.; Chen, B.; Qi, S.; Niu, H.; Han, E.; Wu, D. Enhanced surface free energy of polyimide fibers by alkali treatment and its interfacial adhesion behavior to epoxy resins. Compos. Interfaces 2015, 23, 145–155. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, N.; Lu, Z.; Zhuo, L.; Yang, B.; Song, S.; Qin, P.; Wei, N. Highly improved mechanical and dielectric properties of paper-based composites with polyimide chopped fiber functionalized by ethylenediamine. High Perform. Polym. 2018, 31, 852–860. [Google Scholar] [CrossRef]

- Yun, H.K.; Cho, K.; Kim, J.K.; Park, C.E.; Sim, S.M.; Oh, S.Y.; Park, J.M. Adhesion improvement of epoxy resin/polyimide joints by amine treatment of polyimide surface. Polymer 1997, 38, 827–834. [Google Scholar] [CrossRef]

- Egitto, F.D.; Matienzo, L.J.; Blackwell, K.J.; Knoll, A.R. Oxygen plasma modification of polyimide webs: Effect of ion bombardment on metal adhesion. J. Adhes. Sci. Technol. 1994, 8, 411–433. [Google Scholar] [CrossRef]

- Albrecht, W.; Seifert, B.; Weigel, T.; Schossig, M.; Holländer, A.; Groth, T.; Hilke, R. Amination of Poly(ether imide) Membranes Using Di- and Multivalent Amines. Macromol. Chem. Phys. 2003, 204, 510–521. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, Y.J.; Choi, J.-H.; Han, H.S.; Hong, Y.T. Surface modification of polyimide film by coupling reaction for copper metallization. J. Ind. Eng. Chem. 2009, 15, 23–30. [Google Scholar] [CrossRef]

- Ree, M.; Park, Y.H.; Shin, T.J.; Nunes, T.L.; Volksen, W. Self-adhesion of poly(4,4′-oxydiphenylene biphenyltetracarboximide) and its adhesion to substrates. Polymer 2000, 41, 2105–2111. [Google Scholar] [CrossRef]

- Kim, S.H.; Na, S.W.; Lee, N.E.; Nam, Y.W.; Kim, Y.-H. Effect of surface roughness on the adhesion properties of Cu/Cr films on polyimide substrate treated by inductively coupled oxygen plasma. Surf. Coat. Technol. 2005, 200, 2072–2079. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Korpacz, A.N.; Dufour, C.R.; Weiland, Z.J.; Lambert, C.R.; Timko, M.T. Binary Liquid Mixture Contact-Angle Measurements for Precise Estimation of Surface Free Energy. Langmuir 2019, 35, 12317–12325. [Google Scholar] [CrossRef]

- Yarce, C.J.; Pineda, D.; Correa, C.E.; Salamanca, C.H. Relationship between Surface Properties and In Vitro Drug Release from a Compressed Matrix Containing an Amphiphilic Polymer Material. Pharmaceuticals 2016, 9, 34. [Google Scholar] [CrossRef] [Green Version]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

| Device | Time (Min) | Power (Watts) |

|---|---|---|

| Microwave Plasma | 0.5, 1.0, 5.0 | 250, 500, 1000 |

| ICP RIE | 0.25, 0.5, 1.0 | 10, 25, 50 |

| Solution | Time (Min) | Temperature (°C) |

|---|---|---|

| KOH | 2, 5, 10 | 50 |

| PEI | 2, 5, 10 | 70 |

| Treatment | Conditions |

|---|---|

| Microwave Oxygen Plasma | P = 1000 W, t = 5 min |

| RIE Oxygen Plasma | BP = 50 W, t = 1 min |

| KOH/HCl | KOH: T = 50 °C, t = 10 min |

| PEI | T = 70 °C, t = 10 min |

| Treatment | Conditions | Peel Strength (mN/mm) | Contact Angle (°) | Surface Energy (mN/m) | Etching (μm) |

|---|---|---|---|---|---|

| Pristine | - | 22.7 ± 1.65 | 67.6 ± 2.78 | 37.6 | - |

| PEI | T = 70 °C t = 10 min | 22.4 ± 4.19 | 55.5 ± 1.09 | 48.1 | Neglectable |

| Microwave plasma | P = 500 W t = 5 min | 29.3 ± 1.24 | 6.82 ± 0.48 | 87.3 | Neglectable |

| KOH/HCl | T = 50 °C t = 10 min | 164.3 ± 19.9 | 38.4 ± 2.04 | 65.4 | 0.40 ± 0.024 |

| RIE Plasma | BP = 50 W t = 1 min | Non-peelable | 12.7 ± 0.69 | 84.7 | 0.92 ± 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cen-Puc, M.; Schander, A.; Vargas Gleason, M.G.; Lang, W. An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films. Polymers 2021, 13, 1955. https://doi.org/10.3390/polym13121955

Cen-Puc M, Schander A, Vargas Gleason MG, Lang W. An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films. Polymers. 2021; 13(12):1955. https://doi.org/10.3390/polym13121955

Chicago/Turabian StyleCen-Puc, Marco, Andreas Schander, Minerva G. Vargas Gleason, and Walter Lang. 2021. "An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films" Polymers 13, no. 12: 1955. https://doi.org/10.3390/polym13121955

APA StyleCen-Puc, M., Schander, A., Vargas Gleason, M. G., & Lang, W. (2021). An Assessment of Surface Treatments for Adhesion of Polyimide Thin Films. Polymers, 13(12), 1955. https://doi.org/10.3390/polym13121955