Characterization of Experimental Short-Fiber-Reinforced Dual-Cure Core Build-Up Resin Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Flexural Strength and Modulus of Elasticity

2.2. Fracture Toughness

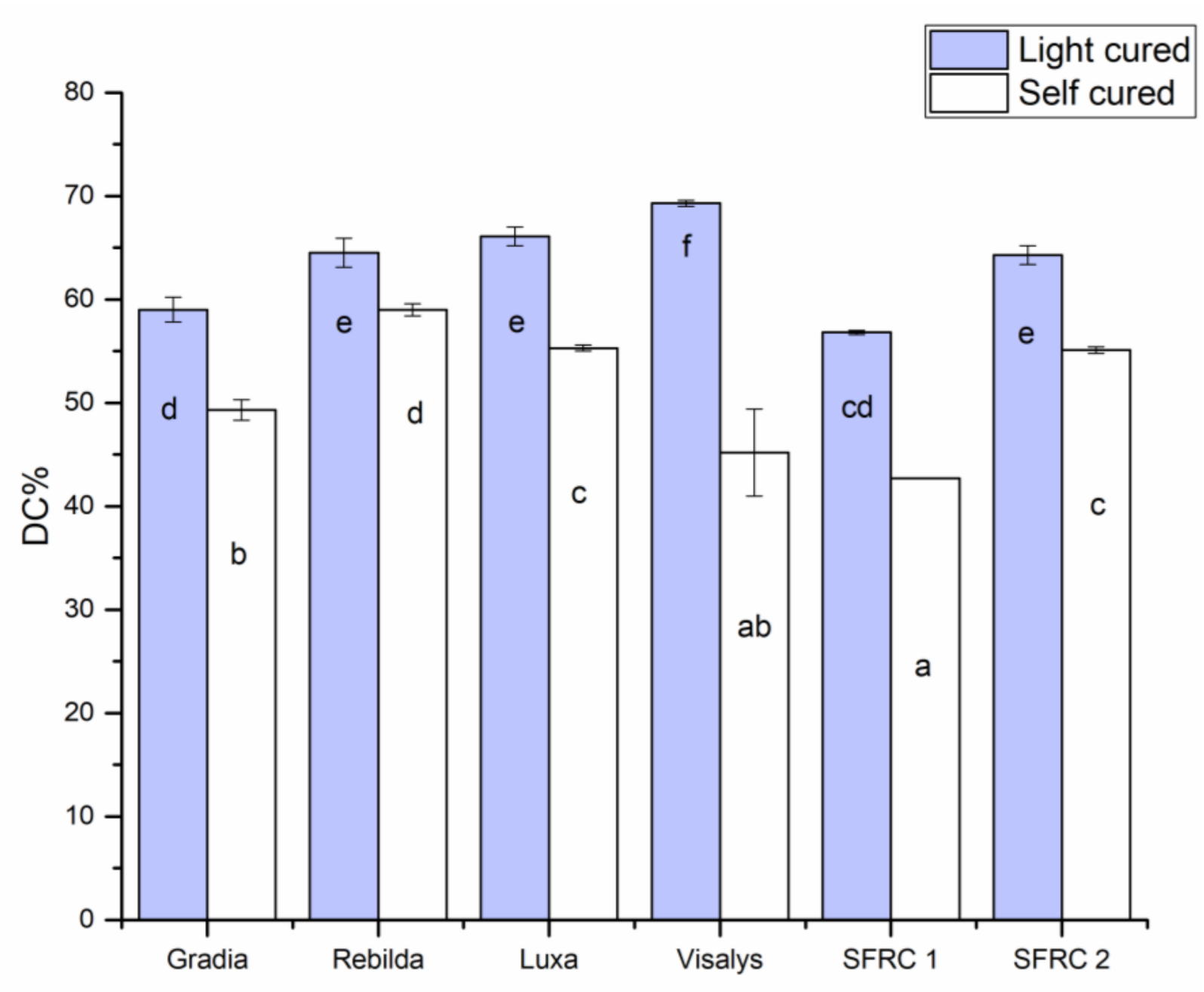

2.3. Degree of Conversion

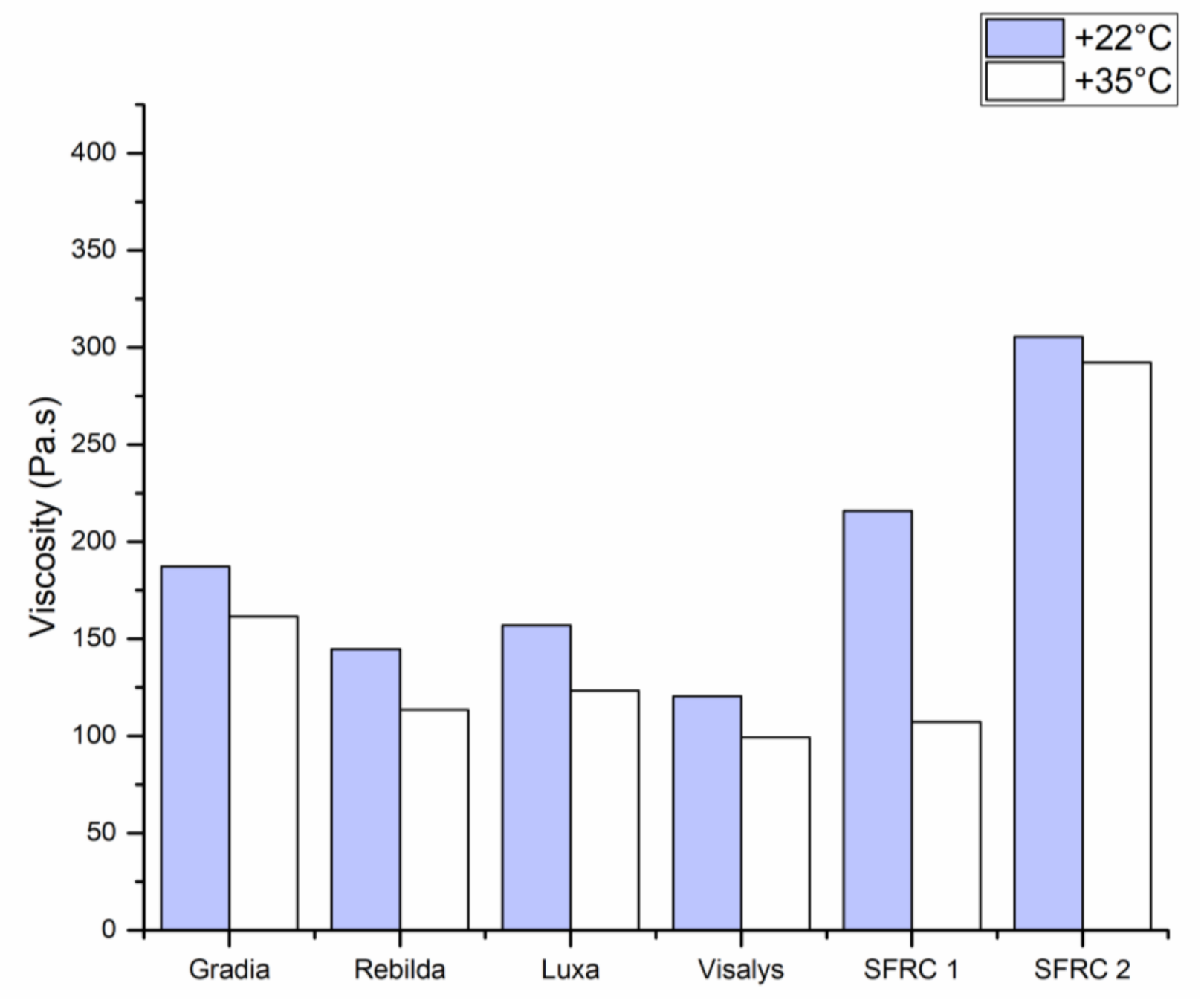

2.4. Viscosity

2.5. Microstructure Analysis

2.6. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zarow, M.; Ramírez-Sebastià, A.; Paolone, G.; Porta, J.D.R.; Mora, J.; Espona, J.; Durán-Sindreu, F.; Roig, M. A new classification system for the restoration of root filled teeth. Int. Endod. J. 2017, 51, 318–334. [Google Scholar] [CrossRef] [Green Version]

- Zafar, M.S.; Amin, F.; Fareed, M.A.; Ghabbani, H.; Riaz, S.; Khurshid, Z.; Kumar, N. Biomimetic Aspects of Re-storative Dentistry Biomaterials. Biomim 2020, 5, 34. [Google Scholar] [CrossRef]

- Keulemans, F.; Garoushi, S.; Lassila, L. Fillings and core-built ups. In A Clinical Guide to Principles of Fibre Reinforced Composites in Dentistry; Vallittu, P., Özcan, M., Eds.; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Skupien, J.A.; Cenci, M.S.; Opdam, N.J.; Kreulen, C.; Huysmans, M.-C.; Pereira-Cenci, T. Crown vs. composite for post-retained restorations: A randomized clinical trial. J. Dent. 2016, 48, 34–39. [Google Scholar] [CrossRef]

- Scotti, N.; Coero Borga, F.A.; Alovisi, M.; Rota, R.; Pasqualini, D.; Berutti, E. Is fracture resistance of endodonti-cally treated mandibular molars restored with indirect onlay composite restorations influenced by fibre post insertion? J. Dent. 2012, 40, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Uctasli, S.; Boz, Y.; Sungur, S.; Vallittu, P.; Garoushi, S.; Lassila, L. Influence of Post-Core and Crown Type on the Fracture Resistance of Incisors Submitted to Quasistatic Loading. Polymers 2021, 13, 1130. [Google Scholar] [CrossRef]

- Spinhayer, L.; Bui, A.; Leprince, J.; Hardy, C. Core build-up resin composites: An in-vitro comparative study. Biomater. Investig. Dent. 2020, 7, 159–166. [Google Scholar] [CrossRef]

- Koytchev, E.; Yamaguchi, S.; Shin-No, Y.; Suzaki, N.; Okamoto, M.; Imazato, S.; Datcheva, M.; Hayashi, M. Comprehensive micro-mechanical characterization of experimental direct core build-up resin composites with different amounts of filler contents. Dent. Mater. J. 2019, 38, 743–749. [Google Scholar] [CrossRef] [PubMed]

- Walcher, J.G.; Leitune, V.C.B.; Collares, F.M.; Balbinot, G.D.S.; Samuel, S.M.W. Physical and mechanical properties of dual functional cements—an in vitro study. Clin. Oral Investig. 2019, 23, 1715–1721. [Google Scholar] [CrossRef] [PubMed]

- Aksornmuang, J.; Nakajima, M.; Tagami, J. Effect of viscosity of dual-cure luting resin composite core materials on bond strength to fiber posts with various surface treatments. J. Dent. Sci. 2014, 9, 320–327. [Google Scholar] [CrossRef]

- Garoushi, S.; Säilynoja, E.; Vallittu, P.K.; Lassila, L. Physical properties and depth of cure of a new short fiber reinforced composite. Dent. Mater. 2013, 29, 835–841. [Google Scholar] [CrossRef]

- Vallittu, P.K. High-aspect ratio fillers: Fiber-reinforced composites and their anisotropic properties. Dent. Mater. 2015, 31, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Lassila, L.; Keulemans, F.; Säilynoja, E.; Vallittu, P.K.; Garoushi, S. Mechanical properties and fracture behavior of flowable fiber reinforced composite restorations. Dent. Mater. 2018, 34, 598–606. [Google Scholar] [CrossRef]

- ISO 4049. Dentistry—Polymer-Based Filling and Restorative Materials; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- ASTM E1820-20b. Standard Test Method for Measurement of Fracture Toughness; ASTM International: West Conshohocken, PA, USA, 2005; Available online: www.astm.org (accessed on 27 April 2021).

- Garoushi, S.; Lassila, L.V.J.; Vallittu, P.K. Influence of nanometer scale particulate fillers on some properties of microfilled composite resin. J. Mater. Sci. Mater. Electron. 2011, 22, 1645–1651. [Google Scholar] [CrossRef]

- Oja, J.; Lassila, L.; Vallittu, P.; Garoushi, S. Effect of Accelerated Aging on Some Mechanical Properties and Wear of Different Commercial Dental Resin Composites. Materials 2021, 14, 2769. [Google Scholar] [CrossRef] [PubMed]

- Karakis, D.; Yıldırım-Bicer, A.Z.; Dogan, A.; Koralay, H.; Cavdar, S. Effect of self and dual-curing on degree of conversion and crosslink density of dual-cure core build-up materials. J. Prosthodont. Res. 2017, 61, 210–216. [Google Scholar] [CrossRef]

- I Nokoshi, M.; Nozaki, K.; Takagaki, T.; Okazaki, Y.; Yoshihara, K.; Minakuchi, S.; Eerbeek, B.V.A.M. Initial curing characteristics of composite cements under ceramic restorations. J. Prosthodont. Res. 2021, 65, 39–45. [Google Scholar] [CrossRef]

- Sulaiman, T.A.; Abdulmajeed, A.A.; Donovan, T.E.; Ritter, A.V.; Lassila, L.V.; Vallittu, P.K.; Närhi, T.O. Degree of conversion of dual-polymerizing cements light polymerized through monolithic zirconia of different thickness-es and types. J. Prosthet. Dent. 2015, 114, 103–108. [Google Scholar] [CrossRef]

- Opdam, N.J.; Bronkhorst, E.M.; Roeters, J.M.; Loomans, B.A. A retrospective clinical study on longevity of poste-rior composite and amalgam restorations. Dent. Mater. 2007, 23, 2–8. [Google Scholar] [CrossRef]

- Lassila, L.; Säilynoja, E.; Prinssi, R.; Vallittu, P.K.; Garoushi, S. Fracture behavior of Bi-structure fiber-reinforced composite restorations. J. Mech. Behav. Biomed. Mater. 2020, 101, 103444. [Google Scholar] [CrossRef]

- Garoushi, S.; Tanner, J.; Keulemans, F.; Le Bell-Rönnlöf, A.-M.; Lassila, L.; Vallittu, P.K. Fiber Reinforcement of Endodontically Treated Teeth: What Options Do We Have? Literature Review. Eur. J. Prosthodont. Restorat. Dent 2020, 28, 54–63. [Google Scholar]

- Bijelic, J.; Garoushi, S.; Vallittu, P.K.; Lassila, L.V.J. Fracture load of tooth restored with fiber post and experi-mental short fiber composite. Open Dent J. 2011, 5, 58–65. [Google Scholar]

- Fráter, M.; Sáry, T.; Jókai, B.; Braunitzer, G.; Säilynoja, E.; Vallittu, P.K.; Lassila, L.; Garoushi, S. Fatigue behavior of endodontically treated premolars restored with different fiber-reinforced designs. Dent. Mater. 2021, 37, 391–402. [Google Scholar] [CrossRef]

- Tiu, J.; Belli, R.; Lohbauer, U. R-curve behavior of a short-fiber reinforced resin composite after water storage. J. Mech. Behav. Biomed. Mater. 2020, 104, 103674. [Google Scholar] [CrossRef]

- Tiu, J.; Belli, R.; Lohbauer, U. Rising R-curves in particulate/fiber-reinforced resin composite layered systems. J. Mech. Behav. Biomed. Mater. 2020, 103, 103537. [Google Scholar] [CrossRef] [PubMed]

- Vallittu, P.K. An overview of development and status of fiber-reinforced composites as dental and medical bi-omaterials. Acta Biomater. Odontol. Scandinavica. 2018, 4, 44–55. [Google Scholar] [CrossRef]

- Oliveira, M.; Cesar, P.F.; Giannini, M.; Rueggeberg, F.A.; Rodrigues, J.; Arrais, C.A. Effect of temperature on the degree of conversion and working time of dual-cured resin cements exposed to different curing conditions. Oper. Dent. 2012, 37, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Guerra, R.M.; Duran, I.; Ortiz, P. FTIR monomer conversion analysis of UDMA-based dental resins. J. Oral Rehabil. 2008, 23, 632–637. [Google Scholar] [CrossRef] [PubMed]

- Zeller, D.K.; Fischer, J.; Rohr, N. Viscous behavior of resin composite cements. Dent. Mater. J. 2021, 40, 253–259. [Google Scholar] [CrossRef]

- Pegoraro, T.; Fulgêncio, R.; Butignon, L.; Manso, A.; Carvalho, R.; Pegoraro, T. Effects of Temperature and Aging on Working/Setting Time of Dual-cured Resin Cements. Oper. Dent. 2015, 40, E222–E229. [Google Scholar] [CrossRef] [PubMed]

| Material | Manufacturer (Lot. No.) | Matrix Composition a (wt%) | Inorganic Filler Content a (wt%) |

|---|---|---|---|

| Gradia Core | GC Corp, Tokyo, Japan (1809041) | UDMA and other dimethacrylate (20–30) | alumino-silicate glass and silicon dioxide (70–75) |

| Rebilda DC | VOCO, Guxhaven, Germany (2003648) | Bis-GMA, DDDMA, UDMA (30) | Silanized silica (70) |

| LuxaCore Z | DMG, Hamburg, Germany (217782) | Bis-GMA and other dimethacrylate (15–45) | Silanized silica (55–75) |

| Visalys® CemCore | Kettenbach GmbH & Co. KG, Eschenburg, Germany (20081) | UDMA and other dimethacrylate (20–50) | Ytterbium flourid and silica polymorph (50–70) |

| Short-fiber flowable composite (SFRC1) | GC Corp, Tokyo, Japan (Experimental) | UDMA and other dimethacrylate (30) | Short glass fiber (200–300 µm and Ø6 μm) + Barium glass (70) |

| Short-fiber flowable composite (SFRC2) | GC Corp, Tokyo, Japan (Experimental) | UDMA and other dimethacrylate (25) | Short glass fiber (200–300 µm and Ø6 μm) + Barium glass (75) |

| Materials | Weight % |

|---|---|

| Gradia Core | C 37%, O 28%, Sr 13%, F 7.1%, Si 7.5%, Al 7%, Ba 0.2%, P 0.4% |

| Rebilda DC | C 28.8%, O 33.6%, Al 3.5%, Si 21.9%, Ba 12.2% |

| LuxaCore Z | C 30.5%, O 32.9%, Al 3.2%, Si 21.5%, Ba 11.9% |

| Visalys® CemCore | C 20.7%, O 22.5%, F 9.2%, Si 17.3%, Ge 0.8%, Yb 29.5% |

| SFRC1 | C 27.9%, O 36%, F 1.7%, Al 4.4%, Si 19.5%, Ba 8.8%, Ca 1.4% |

| SFRC2 | C 17%, O 32,9%, F 1.4%, Al 4.4%, Si 24%, Ca 1.2%, Ba 19% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Säilynoja, E.; Garoushi, S.; Vallittu, P.K.; Lassila, L. Characterization of Experimental Short-Fiber-Reinforced Dual-Cure Core Build-Up Resin Composites. Polymers 2021, 13, 2281. https://doi.org/10.3390/polym13142281

Säilynoja E, Garoushi S, Vallittu PK, Lassila L. Characterization of Experimental Short-Fiber-Reinforced Dual-Cure Core Build-Up Resin Composites. Polymers. 2021; 13(14):2281. https://doi.org/10.3390/polym13142281

Chicago/Turabian StyleSäilynoja, Eija, Sufyan Garoushi, Pekka K. Vallittu, and Lippo Lassila. 2021. "Characterization of Experimental Short-Fiber-Reinforced Dual-Cure Core Build-Up Resin Composites" Polymers 13, no. 14: 2281. https://doi.org/10.3390/polym13142281