Evaluation and Comparison of Mechanical Properties of Polymer-Modified Asphalt Mixtures

Abstract

:1. Introduction

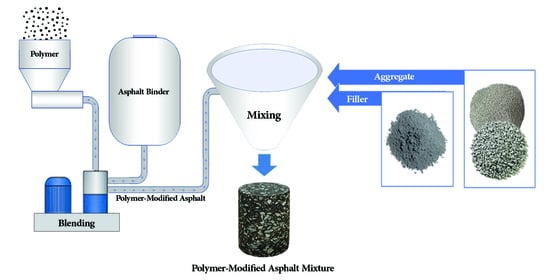

2. Materials

2.1. Asphalt Binder

2.2. Aggregate

2.3. Polymer-Modified Asphalt

3. Mix Design and Experimental Program

4. Mechanical Properties Tests

4.1. Dynamic Modulus (|E*|) Test

4.2. Flow Number (Fn)

4.3. Hamburg Wheel Tracking (HWT) Test

4.4. Indirect Tensile Strength (ITS)

4.5. Comparison and Overall Ranking of PMA Mixture Performance

4.5.1. Pair Comparison

4.5.2. Overall Ranking

5. Results and Discussions

5.1. Dynamic Modulus Result

5.2. Flow Number (Fn) Result

5.3. Hamburg Wheel Tracking Result

5.4. Indirect Tensile Strength Result

5.5. Overall Ranking of PMA Mixture Performance

6. Conclusions

- The dynamic moduli values of all modified asphalt mixtures increased by decreasing the temperature and increased by increasing the frequency. Polymer-modified asphalt mixtures showed higher dynamic modulus values than neat asphalt mixture values for different frequencies and temperatures.

- Modified mixtures showed significant improvement in flow number compared with neat asphalt mixture. Asphalt modified with Anglomak2144, Pavflex140, and Lucolast polymers ranked as the best mixtures to rut resistance.

- Hamburg wheel tracking test results showed that asphalt mixture modified with polymers has better adhesion between the binder and aggregates compared with the neat asphalt mixture. The asphalt mixture modified with EE-2 ranked as the best, followed by Anglomak2144, Paveflax140, Lucolast7010, and SBS KTR401.

- The mixture modified by SBS KTR401 showed the highest indirect tensile strength, while the mixture modified by polymer EE-2 showed the lowest strength compared with other PMA mixtures for dry conditions. For wet conditions, the highest wsa SBS KTR401 and the lowest was Lucolast7010. Moreover, there was an improvement in water susceptibility of PMA mixtures over that of neat asphalt mixture. The tensile strength ratios (TSRs) of neat and PMA mixtures were all higher than the recommended minimum value (80%).

- Based on the overall ranking of mechanical properties, the asphalt mixture with polymer Anglomk2144 was ranked as the best performing mixture, followed by the asphalt mixtures with Paveflex140 and EE-2 polymers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Costa, L.M.; Silva, H.M.R.D.; Oliveira, J.R.; Fernandes, S.R. Incorporation of waste plastic in asphalt binders to improve their performance in the pavement. Int. J. Pavement Res. Technol. 2013, 6, 457–464. [Google Scholar]

- Gama, D.A.; Júnior, J.M.R.; Melo, T.; Rodrigues, J.K.G. Rheological studies of asphalt modified with elastomeric polymer. Constr. Build. Mater. 2016, 106, 290–295. [Google Scholar] [CrossRef]

- Mansourian, A.; Goahri, A.R.; Khosrowshahi, F.K. Performance evaluation of asphalt binder modified with EVA/HDPE/nanoclay based on linear and non-linear viscoelastic behaviors. Constr. Build. Mater. 2019, 208, 554–563. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Rajabi, M.; Sahaf, A. The fatigue behavior of SBS/nanosilica composite modified asphalt binder and mixture. Constr. Build. Mater. 2019, 229, 116796. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Koting, S.; Sulong, N.H.R.; Karim, M.R. Optimization of mixing time for polymer modified asphalt. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 10th Malaysian Road Conference & Exhibition, Selangor, Malaysia, 29–31 October 2018; IOP Publishing: Bristol, UK, 2019; Volume 512, p. 012030. [Google Scholar]

- Yan, K.; You, L.; Wang, D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers 2019, 11, 1404. [Google Scholar] [CrossRef] [Green Version]

- Bansal, S.; Misra, A.K.; Bajpai, P. Evaluation of modified bituminous concrete mix developed using rubber and plastic waste materials. Int. J. Sustain. Built Environ. 2017, 6, 442–448. [Google Scholar] [CrossRef]

- Kebria, D.Y.; Moafimadani, S.; Goli, Y. Laboratory investigation of the effect of crumb rubber on the characteristics and rheological behaviour of asphalt binder. Road Mater. Pavement Des. 2015, 16, 946–956. [Google Scholar] [CrossRef]

- Milad, A.; Ahmeda, A.G.F.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 1–14. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Koting, S.; Katman, H.Y.B.; Ibrahim, M.R.; Babalghaith, A.M.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Gawdzik, B.; Matynia, T.; Błażejowski, K. The Use of De-Vulcanized Recycled Rubber in the Modification of Road Bitumen. Materials 2020, 13, 4864. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourian, A.; Sheikhmotevali, A.H. Laboratory evaluation of ethylene vinyl acetate modified bitumens and mixtures based upon performance related parameters. Constr. Build. Mater. 2013, 40, 438–447. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Ameri, M.; Yeganeh, S.; Valipour, P.E. Experimental evaluation of fatigue resistance of asphalt mixtures containing waste elastomeric polymers. Constr. Build. Mater. 2019, 198, 638–649. [Google Scholar] [CrossRef]

- Peng, C.; Guo, C.; You, Z.; Xu, F.; Ma, W.; You, L.; Li, T.; Zhou, L.; Huang, S.; Ma, H.; et al. The Effect of Waste Engine Oil and Waste Polyethylene on UV Aging Resistance of Asphalt. Polymers 2020, 12, 602. [Google Scholar] [CrossRef] [Green Version]

- Anwar, M.; Shah, S.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S. Utilisation of Waste-Based Geopolymer in Asphalt Pavement Modification and Construction; A Review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Jeffry, S.N.A.; Jaya, R.P.; Hassan, N.A.; Yaacob, H.; Mirza, J.; Drahman, S.H. Effects of nanocharcoal coconut-shell ash on the physical and rheological properties of bitumen. Constr. Build. Mater. 2018, 158, 1–10. [Google Scholar] [CrossRef]

- Ramadhansyah, P.; Irwan, R.N.; Idris, A.M.; Ezree, A.M.; Khatijah, A.S.; Norhidayah, A.; Haryati, Y. Stability and voids properties of hot mix asphalt containing black rice husk ash. In Proceedings of the IOP Conference Series: Earth and Environmental Science, National Colloquium on Wind and Earthquake Engineering, Kuantan, Malaysia, 17–18 August 2018; IOP Publishing: Bristol, UK, 2019; Volume 244, p. 012044. [Google Scholar]

- Rusbintardjo, G.; Hainin, M.R.; Yusoff, N.I.M. Fundamental and rheological properties of oil palm fruit ash modified bitumen. Constr. Build. Mater. 2013, 49, 702–711. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Examination of hot mix asphalt and binder performance modified with nano silica. Constr. Build. Mater. 2017, 156, 976–984. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Rheological characterization of styrene-butadiene-styrene copolymer modified bitumens. Constr. Build. Mater. 1997, 11, 23–32. [Google Scholar] [CrossRef]

- Perezlepe, A. Influence of the processing conditions on the rheological behaviour of polymer-modified bitumen ☆. Fuel 2003, 82, 1339–1348. [Google Scholar] [CrossRef]

- Topal, A. Evaluation of the properties and microstructure of plastomeric polymer modified bitumens. Fuel Process. Technol. 2010, 91, 45–51. [Google Scholar] [CrossRef]

- Bernier, A.; Zofka, A.; Yut, I. Laboratory evaluation of rutting susceptibility of polymer-modified asphalt mixtures containing recycled pavements. Constr. Build. Mater. 2012, 31, 58–66. [Google Scholar] [CrossRef]

- Modarres, A. Investigating the toughness and fatigue behavior of conventional and SBS modified asphalt mixes. Constr. Build. Mater. 2013, 47, 218–222. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U.; Ekblad, J. Low-temperature properties of styrene–butadiene–styrene polymer modified bitumens. Constr. Build. Mater. 1998, 12, 405–414. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polyme. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Vargas, C.; El Hanandeh, A. Systematic literature review, meta-analysis and artificial neural network modelling of plastic waste addition to bitumen. J. Clean. Prod. 2021, 280, 124369. [Google Scholar] [CrossRef]

- Özdemir, D.K.; Topal, A.; Sengoz, B. The influences of altering the mixing conditions on the properties of polymer modified bitumen: An overview. Uludağ Univ. J. Fac. Eng. 2020, 25, 1105–1116. [Google Scholar]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens⋆. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Giuliani, F.; Merusi, F.; Filippi, S.; Biondi, D.; Finocchiaro, M.L.; Polacco, G. Effects of polymer modification on the fuel resistance of asphalt binders. Fuel 2009, 88, 1539–1546. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Sengoz, B.; Topal, A.; Isikyakar, G. Morphology and image analysis of polymer modified bitumens. Constr. Build. Mater. 2009, 23, 1986–1992. [Google Scholar] [CrossRef]

- Bulatović, V.O.; Rek, V.; Marković, K.J. Rheological properties and stability of ethylene vinyl acetate polymer-modified bitumen. Polym. Eng. Sci. 2013, 53, 2276–2283. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Alsoliman, H.A.; Al-Suhaibani, A.S. Comparison of rheological properties for polymer modified asphalt produced in riyadh. Int. J. Civil Environ. Eng. 2016, 10, 197–201. [Google Scholar]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A Review of the Utilisation of Recycled Waste Material as an Alternative Modifier in Asphalt Mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Wei, J.; Liu, Z.; Zhang, Y. Rheological properties of amorphous poly alpha olefin (APAO) modified asphalt binders. Constr. Build. Mater. 2013, 48, 533–539. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Fernandes, M.R.S.; Forte, M.M.C.; Leite, L.F.M. Rheological evaluation of polymer-modified asphalt binders. Mater. Res. 2008, 11, 381–386. [Google Scholar] [CrossRef] [Green Version]

- Robbins, M.M. An Investigation Into Dynamic Modulus of Hot-Mix Asphalt and its Contributing Factors, in Civil Engineering; Auburn University: Araba, AL, USA, 2009. [Google Scholar]

- Pareek, A.; Gupta, T.; Sharma, R.K. Performance of Polymer Modified Bitumen for Flexible Pavements. Int. J. Struct. Civil Eng. Res. 2012, 1, 77–86. [Google Scholar]

- Li, Q.; Ni, F.; Li, G.; Wang, H. Evaluation of the dynamic modulus for asphalt mixtures with varying volumetric properties. Int. J. Pavement Res. Technol. 2013, 6, 197–204. [Google Scholar]

- Zhu, H.; Sun, L.; Yang, J.; Chen, Z.; Gu, W. Developing Master Curves and Predicting Dynamic Modulus of Polymer-Modified Asphalt Mixtures. J. Mater. Civ. Eng. 2011, 23, 131–137. [Google Scholar] [CrossRef]

- Ping, W.; Xiao, Y. Evaluation of SBS Polymer Binder Effect on Resilient Modulus Properties of Florida HMA Mixtures. In Proceedings of the 24th OCTPA Annual Conference and NACGEAI International Symposium on Geo-Trans, Los Angeles, CA, USA, 27–29 May 2001. [Google Scholar]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Fakhri, M.; Hassani, K.; Ghanizadeh, A.R. Impact of Loading Frequency on the Fatigue behavior of SBS Modified Asphalt Mixtures. Procedia Soc. Behav. Sci. 2013, 104, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Al-Abdul-Wahhab, H.I. Effect of Modifiers and Additives on Fatigue Behavior of Asphalt Concrete Mixes in the Gulf. J. Pavement Res. Technol. 2012, 5, 326. [Google Scholar]

- Xu, Q.; Chen, H.; Prozzi, J.A. Performance of fiber reinforced asphalt concrete under environmental temperature and water effects. Constr. Build. Mater. 2010, 24, 2003–2010. [Google Scholar] [CrossRef]

- Arabani, M.; Mirabdolazimi, S.; Sasani, A. The effect of waste tire thread mesh on the dynamic behaviour of asphalt mixtures. Constr. Build. Mater. 2010, 24, 1060–1068. [Google Scholar] [CrossRef]

- Hamdou, H.M.; Ismael, M.Q.; Abed, M.A. Effect of Polymers on Permanent Deformation of Flexible Pavement. J. Eng. 2014, 20, 150–166. [Google Scholar]

- Özen, H. Rutting evaluation of hydrated lime and SBS modified asphalt mixtures for laboratory and field compacted samples. Constr. Build. Mater. 2011, 25, 756–765. [Google Scholar] [CrossRef]

- Fontes, L.P.; Trichês, G.; Pais, J.C.; Pereira, P.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010, 24, 1193–1200. [Google Scholar] [CrossRef]

- Abed, A.H.; Bahia, H.U. Enhancement of permanent deformation resistance of modified asphalt concrete mixtures with nano-high density polyethylene. Constr. Build. Mater. 2020, 236, 117604. [Google Scholar] [CrossRef]

- Ameli, A.; Babagoli, R.; Khabooshani, M.; AliAsgari, R.; Jalali, F. Permanent deformation performance of binders and stone mastic asphalt mixtures modified by SBS/montmorillonite nanocomposite. Constr. Build. Mater. 2020, 239, 117700. [Google Scholar] [CrossRef]

- Al-Dubabe, I.A. Polymer Modification of Arab Asphalt to Suit Gulf Countries Performance Requirments in Civil Engineering; King Fahd University of Petroleum and Minerals: Dhahran, Saudi Arabia, 1996. [Google Scholar]

- Wahhab, H.I.A.; Balghunaim, F.A. Asphalt Pavement Temperature Related to Arid Saudi Environment. J. Mater. Civ. Eng. 1994, 6, 1–14. [Google Scholar] [CrossRef]

- Wahhab, H.I.A.-A.; Asi, I.M.; Al-Dubabe, I.A.; Ali, M.F. Development of performance-based bitumen specifications for the Gulf countries. Constr. Build. Mater. 1997, 11, 15–22. [Google Scholar] [CrossRef]

- General Directorate for Material and Research. Hot Asphalt Mix Design System; Ministry of Transportation (MOT): Riyadh, Saudi Arabia, 2006. [Google Scholar]

- Al-Dubabe, I.A.; Wahhab, H.I.A.-A.; Asi, I.M.; Ali, M.F. Polymer Modification of Arab Asphalt. J. Mater. Civ. Eng. 1998, 10, 161–167. [Google Scholar] [CrossRef]

- National Asphalt Pavement Association. Designing and Constructing SMA Mixtures: State of the Practice; National Asphalt Pavement Association (NAPA): Lanham, MD, USA, 2002. [Google Scholar]

- Dongré, R.; D’Angelo, J.; Copeland, A. Refinement of Flow Number as Determined by Asphalt Mixture Performance Tester: Use in Routine Quality Control—Quality Assurance Practice. Transp. Res. Rec. J. Transp. Res. Board 2009, 2127, 127–136. [Google Scholar] [CrossRef]

- Bonaquist, R.F.; Christensen, D.W.; Stump, W. Simple Performance Tester for Superpave Mix Design: First-Article Development and Evaluation; NCHRP Report 513; Transportation Research Board: Washington, DC, USA, 2003. [Google Scholar]

- Bower, N.; Wen, H.; Wu, S.; Willoughby, K.; Weston, J.; Devol, J. Evaluation of the performance of warm mix asphalt in Washington state. Int. J. Pavement Eng. 2015, 17, 423–434. [Google Scholar] [CrossRef]

- Tan, G.; Wang, W.; Cheng, Y.; Wang, Y.; Zhu, Z. Master Curve Establishment and Complex Modulus Evaluation of SBS-Modified Asphalt Mixture Reinforced with Basalt Fiber Based on Generalized Sigmoidal Model. Polymers 2020, 12, 1586. [Google Scholar] [CrossRef]

- Khattak, M.J. Engineering Characteristics of Polymer Modified Asphalt Mixtures, in Department of Civil and Environmental Engineering; Michigan State University: East Lansing, MI, USA, 1999. [Google Scholar]

- Alsoliman, H.A. Engineering Characteristics of Local Polymer Modified Asphalt Mixtures. Ph.D. Thesis, King Saud University, Riyadh, Saudi Arabia, 2010. [Google Scholar]

- Kumar, P.; Chandra, S.; Bose, S. Strength characteristics of polymer modified mixes. Int. J. Pavement Eng. 2006, 7, 63–71. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Alsolieman, H.A.; Al-Suhaibani, A.S.; Koting, S. Master curve of dynamic modulus for modified asphalt mixtures. In AIP Conference Proceedings; AIP Publishing LLC: New York, NY, USA, 2020. [Google Scholar]

| Properties | Unit | References | Values |

|---|---|---|---|

| High-temperature grade | °C | ASTM-D7175 | 64 |

| Low-temperature grade | °C | ASTM-D6648 | −22 |

| G*/sinδ @ 64 °C | - | - | 1.62 |

| Penetration @ 25 °C | 0.1 mm | ASTM-D0005 | 68 |

| Softening Point | °C | ASTM-D0036 | 48 |

| Flash Point | °C | ASTM-D1310 | 300 |

| Penetration index | - | - | −0.99 |

| Ductility | cm | ASTM-D0113 | +100 |

| Rotational viscosity @ 135 °C, cps | cp | ASTM-D4402 | 487 |

| Rotational viscosity @ 165 °C, cps | cp | ASTM-D4402 | 150 |

| Specific gravity | - | ASTM-D0070 | 1.025 |

| Loss after RTFO | % | ASTM-D2872 | 0.07 |

| Sieve Opening (mm) | % Passing | Specification | |

|---|---|---|---|

| 19.00 | 100.0 | 100 | |

| 12.50 | 94.5 | 90 | 100 |

| 9.50 | 89.5 | 90 | |

| 4.75 | 71.3 | ||

| 2.36 | 49.1 | 28 | 58 |

| 1.18 | 30.3 | ||

| 0.60 | 18.0 | ||

| 0.30 | 9.0 | ||

| 0.15 | 5.2 | ||

| 0.075 | 3.2 | 2 | 10 |

| Property | Test Method | Value |

|---|---|---|

| Percentage loss by Los Angeles Abrasion Test, % | ASTM-C0131 | 21 |

| Flat and Elongated Particles, % | ASTM-D4791 | 7 |

| The Specific gravity of coarse aggregate | ASTM-C0127 | 2.585 |

| Water absorption of coarse aggregate, % | ASTM-C0127 | 2.7 |

| The Specific gravity of fine aggregate | ASTM-C0128 | 2.567 |

| Water absorption of fine aggregate, % | ASTM0C0128 | 2.2 |

| Modifiers | Physical Form | Density (g/cm3) | Melting Point (°C) | Melt Flow Index (g/10 min) | Components |

|---|---|---|---|---|---|

| Lucolast7010 | Pellet | 0.924 | 95 | 3.9 | Ethylene and Butyl Acrylate (EBA) with low crystallinity. |

| Anglomak2144 | Pellet | 0.930 | 96 | 3.5 | Oxidized Polyethylene Homopolymer. |

| Paveflex140 | Powder | - | 212 | - | Ethylene Vinyl Acetate Resins. |

| SBS KTR 401 | Pellet | 0.94 | 270 | <1 | Styrene Butadiene Styrene. |

| EE-2 | Pellet | 0.96 | - | - | Medium-Density Oxidized Polyethylene. |

| Modifiers | Code | % | Penetration | Softening Point | G*/sinδ | m-Value | PG | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 64 °C | 70 °C | 76 °C | −10 °C | −16 °C | −22 °C | ||||||

| Lucolast7010 | LU | 3.6 | 36 | 59 | 5.69 | 2.68 | 1.37 | 0.366 | 0.315 | 0.285 | 76-16 |

| Anglomak 2144 | AM | 3.2 | 34 | 60.8 | 7.51 | 3.39 | 1.68 | 0.312 | 0.279 | - | 76-10 |

| Pavflex140 | PF | 5.0 | 34 | 59.2 | 6.25 | 2.99 | 1.49 | 0.320 | 0.290 | - | 76-10 |

| SBS KTR 401 | SBS | 3.0 | 47 | 55 | 3.47 | 1.77 | 1.01 | 0.367 | 0.311 | 0.287 | 76-16 |

| EE-2 | EE | 4.0 | 35 | 67 | 4.38 | 2.27 | 1.35 | 0.309 | 0.288 | - | 76-10 |

| Property | Values | MOT Specification | |||

|---|---|---|---|---|---|

| Binder Content, % | 4.5 | 5.0 | 5.5 | 6.0 | - |

| %Gmm @ Nini, % | 83.1 | 85.5 | 87.4 | 88.4 | ≤89 |

| %Gmm @ Ndes, % | 92.2 | 95.2 | 97.3 | 98.0 | 96 |

| Air Voids, % | 7.8 | 4.8 | 2.7 | 2.0 | 4 |

| VMA, % | 14.9 | 14.1 | 13.3 | 13.3 | ≥14 |

| VFA, % | 47.6 | 65.6 | 79.4 | 85.0 | 65–75 |

| Effective Binder Content (Pbe) | 3.1 | 4.0 | 4.6 | 4.9 | - |

| Dust Proportion (DP ratio) | 0.99 | 0.77 | 0.68 | 0.64 | 0.6–1.2 |

| Property | Control | Anglomak | SBS | Lucolast | Pavflex | EE-2 | Criteria |

|---|---|---|---|---|---|---|---|

| Gmm @ Nini, % | 85.7 | 86.9 | 86.6 | 86.5 | 85.5 | 85.9 | ≤89 |

| Gmm @ Ndes, % | 95.8 | 96.6 | 96.1 | 96.2 | 95.4 | 96 | 96.0 |

| Air Voids, % | 4.2 | 3.4 | 3.9 | 3.8 | 4.6 | 4.0 | 3.0–5.0 |

| VMA, % | 13.7 | 13.0 | 13.2 | 13.1 | 13.8 | 13.9 | 14 |

| VFA, % | 68 | 73.3 | 70.4 | 70.8 | 66.7 | 71 | 65–75 |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 4.96 | 6.04 | 9.01 | 9.52 | 2.66 |

| LU | 4.96 | - | 2.81 | 8.15 | 9.48 | 0.26 |

| AM | 6.04 | 2.81 | - | 2.66 | 3.15 | 1.62 |

| PF | 9.01 | 8.15 | 2.66 | - | 0.57 | 3.21 |

| SBS | 9.52 | 9.48 | 3.15 | 0.57 | - | 3.47 |

| EE | 2.66 | 0.26 | 1.62 | 3.21 | 3.47 | - |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 1.11 | 7.09 | 3.59 | 99.74 | 2.16 |

| LU | 1.11 | - | 7.21 | 3.74 | 63.32 | 1.93 |

| AM | 7.09 | 7.21 | - | 1.75 | 6.47 | 6.30 |

| PF | 3.59 | 3.74 | 1.75 | - | 7.61 | 4.10 |

| SBS | 99.74 | 63.32 | 6.47 | 7.61 | - | 13.95 |

| EE | 2.16 | 1.93 | 6.30 | 4.10 | 13.95 | - |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 5.00 | 7.64 | 10.38 | 5.75 | 0.83 |

| LU | 5.00 | - | 5.17 | 11.48 | 1.01 | 3.92 |

| AM | 7.64 | 5.17 | - | 1.62 | 4.95 | 6.92 |

| PF | 10.38 | 11.48 | 1.62 | - | 16.62 | 9.20 |

| SBS | 5.75 | 1.01 | 4.95 | 16.62 | - | 4.62 |

| EE | 0.83 | 3.92 | 6.92 | 9.20 | 4.62 | - |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 6.58 | 11.80 | 8.83 | 2.76 | 4.09 |

| LU | 6.58 | - | 3.03 | 0.42 | 5.45 | 2.84 |

| AM | 11.80 | 3.03 | - | 2.96 | 10.43 | 6.55 |

| PF | 8.83 | 0.42 | 2.96 | - | 7.35 | 3.75 |

| SBS | 2.76 | 5.45 | 10.43 | 7.35 | - | 2.65 |

| EE | 4.09 | 2.84 | 6.55 | 3.75 | 2.65 | - |

| Asphalt Mixture | Fn | Failure | ||

|---|---|---|---|---|

| Cycles | Strain | Cycles | Strain | |

| Control | 25 | 19,683 | 66 | 52,377 |

| Lucolast7010 | 182 | 23,652 | 432 | 50,184 |

| Anglomk2144 | 120 | 18,982 | 336 | 50,292 |

| Paveflex140 | 93 | 20,209 | 244 | 50,058 |

| SBS KTR401 | 33 | 16,811 | 93 | 52,246 |

| EE-2 | 46 | 21,338 | 114 | 51,111 |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 7.54 | 8.29 | 17.86 | 2.22 | 5.09 |

| LU | 7.54 | - | 2.65 | 4.33 | 7.26 | 6.60 |

| AM | 8.29 | 2.65 | - | 2.49 | 7.97 | 6.67 |

| PF | 17.86 | 4.33 | 2.49 | - | 37.95 | 18.43 |

| SBS | 2.22 | 7.26 | 7.97 | 37.95 | - | 5.81 |

| EE | 5.09 | 6.60 | 6.67 | 18.43 | 5.81 | - |

| Asphalt Mixture | Tensile Strength, kPa | |

|---|---|---|

| Dry Condition | Wet Condition | |

| Control | 1027.5 | 843.6 |

| Lucolast7010 | 990.8 | 859.3 |

| Anglomk2144 | 1029.7 | 917.5 |

| Paveflex140 | 1086.9 | 940.20 |

| SBS KTR401 | 1139.6 | 1033.7 |

| EE-2 | 957.8 | 861.6 |

| NEAT | LU | AM | PF | SBS | EE | |

|---|---|---|---|---|---|---|

| NEAT | - | 1.09 | 3.28 | 1.97 | 2.95 | 3.42 |

| LU | 1.09 | - | 0.50 | 0.12 | 0.81 | 0.70 |

| AM | 3.28 | 0.50 | - | 1.83 | 0.71 | 0.60 |

| PF | 1.97 | 0.12 | 1.83 | - | 1.72 | 2.09 |

| SBS | 2.95 | 0.81 | 0.71 | 1.72 | - | 0.31 |

| EE | 3.42 | 0.70 | 0.60 | 2.09 | 0.31 | - |

| Property | Mix Design | |||||

|---|---|---|---|---|---|---|

| Control | Lucolast7010 | Anglomk2144 | Paveflex140 | SBS KTR401 | EE-2 | |

| ITS-Dry | 4 | 5 | 3 | 2 | 1 | 6 |

| ITS-Wet | 6 | 5 | 3 | 2 | 1 | 4 |

| TSR | 6 | 4 | 3 | 5 | 1 | 2 |

| Fn | 6 | 1 | 2 | 3 | 5 | 4 |

| E* at −10 | 1 | 3 | 4 | 6 | 5 | 2 |

| E* at 4.4 | 3 | 2 | 5 | 4 | 6 | 1 |

| E* at 21.1 | 6 | 4 | 1 | 2 | 3 | 5 |

| E* at 54.4 | 6 | 3 | 1 | 2 | 5 | 4 |

| HWT | 6 | 4 | 2 | 3 | 5 | 1 |

| Sum | 44 | 31 | 24 | 29 | 32 | 29 |

| Relative index | 0.352 | 0.593 | 0.722 | 0.630 | 0.574 | 0.630 |

| Overall Ranking | 6 | 4 | 1 | 2 | 5 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsolieman, H.A.; Babalghaith, A.M.; Memon, Z.A.; Al-Suhaibani, A.S.; Milad, A. Evaluation and Comparison of Mechanical Properties of Polymer-Modified Asphalt Mixtures. Polymers 2021, 13, 2282. https://doi.org/10.3390/polym13142282

Alsolieman HA, Babalghaith AM, Memon ZA, Al-Suhaibani AS, Milad A. Evaluation and Comparison of Mechanical Properties of Polymer-Modified Asphalt Mixtures. Polymers. 2021; 13(14):2282. https://doi.org/10.3390/polym13142282

Chicago/Turabian StyleAlsolieman, Hamad Abdullah, Ali Mohammed Babalghaith, Zubair Ahmed Memon, Abdulrahman Saleh Al-Suhaibani, and Abdalrhman Milad. 2021. "Evaluation and Comparison of Mechanical Properties of Polymer-Modified Asphalt Mixtures" Polymers 13, no. 14: 2282. https://doi.org/10.3390/polym13142282