Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

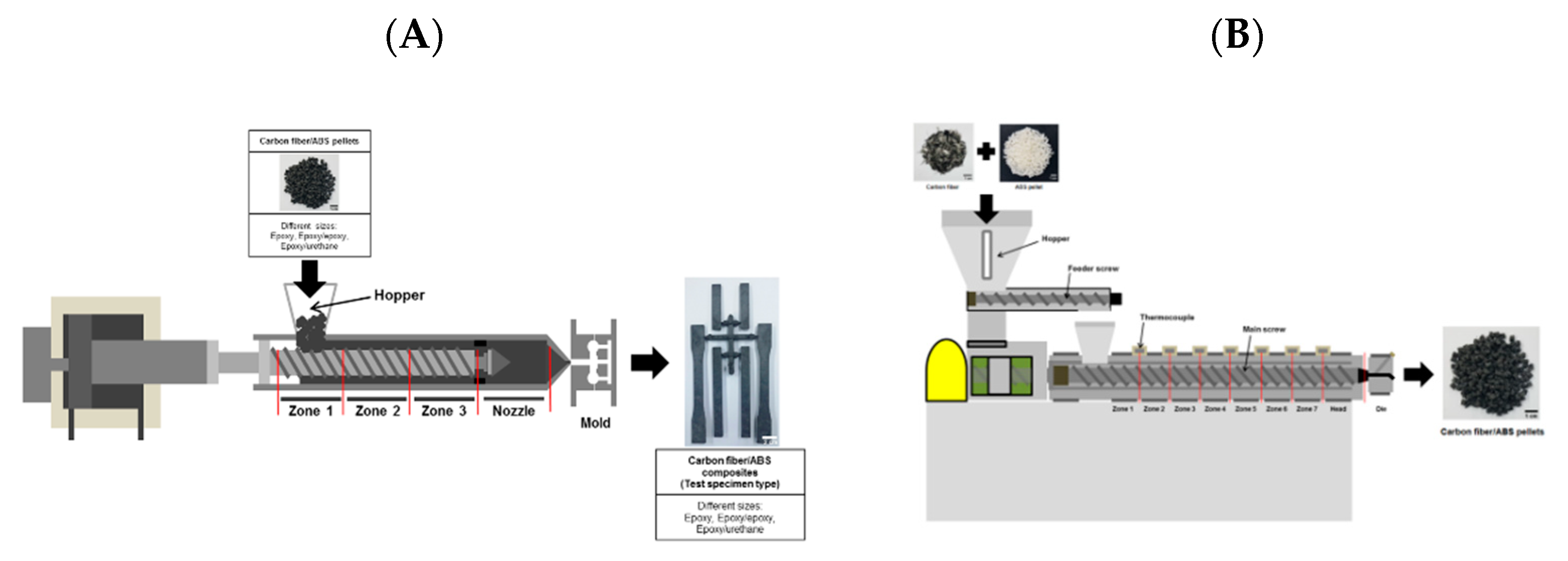

2.2. Preparation of Carbon Fiber/ABS Pellets and the Composites

2.3. Characterization

2.3.1. Scanning Electron Microscopic Analysis

2.3.2. X-ray Photoelectron Spectroscopy

2.3.3. Thermogravimetric Analysis

2.3.4. Fiber Length Distribution Analysis

2.3.5. Heat Deflection Temperature Measurement

2.3.6. Dynamic Mechanical Analysis

2.3.7. Tensile Test

2.3.8. Flexural Test

2.3.9. Impact Test

3. Results and Discussion

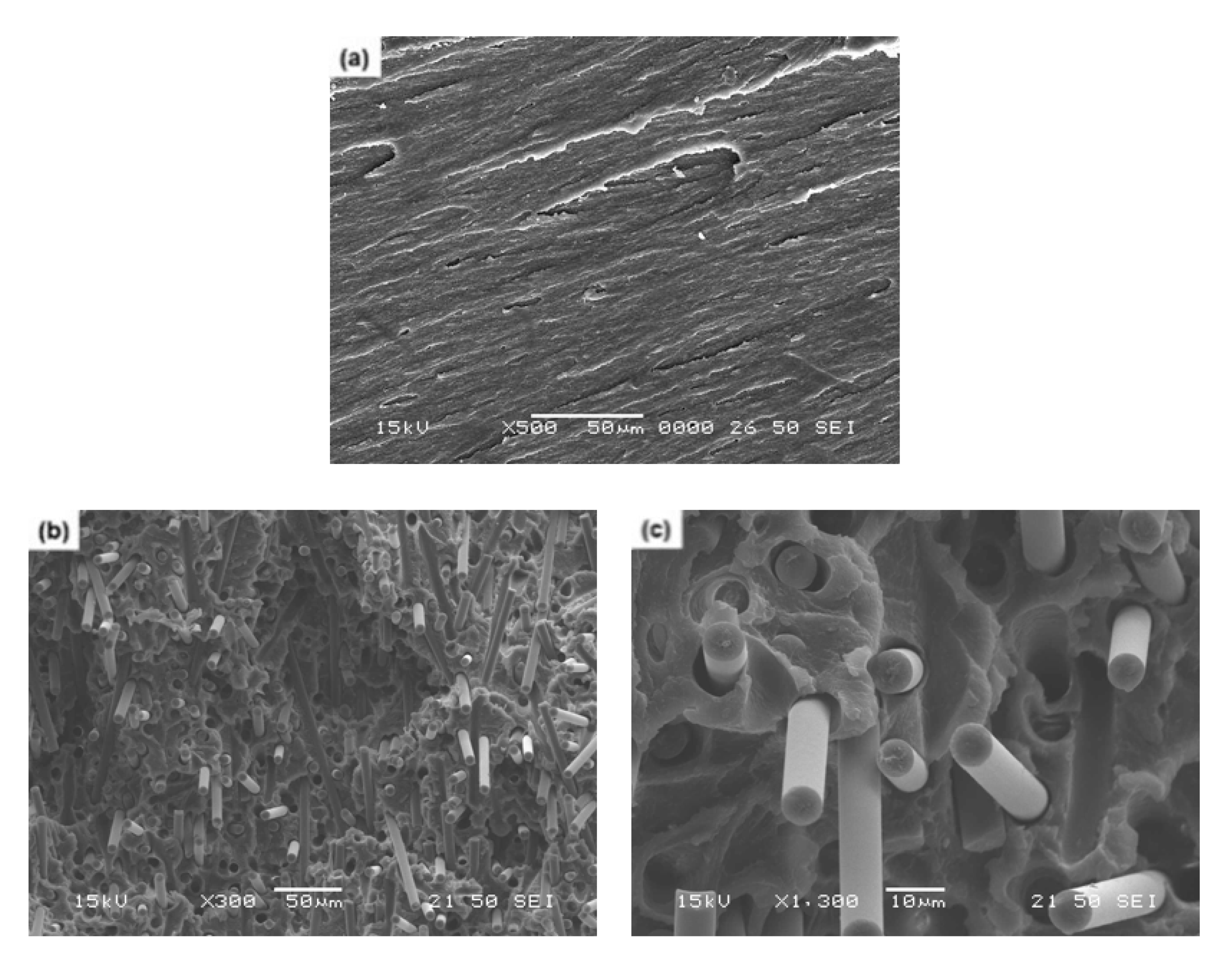

3.1. Surface Topography Analysis of Carbon Fiber

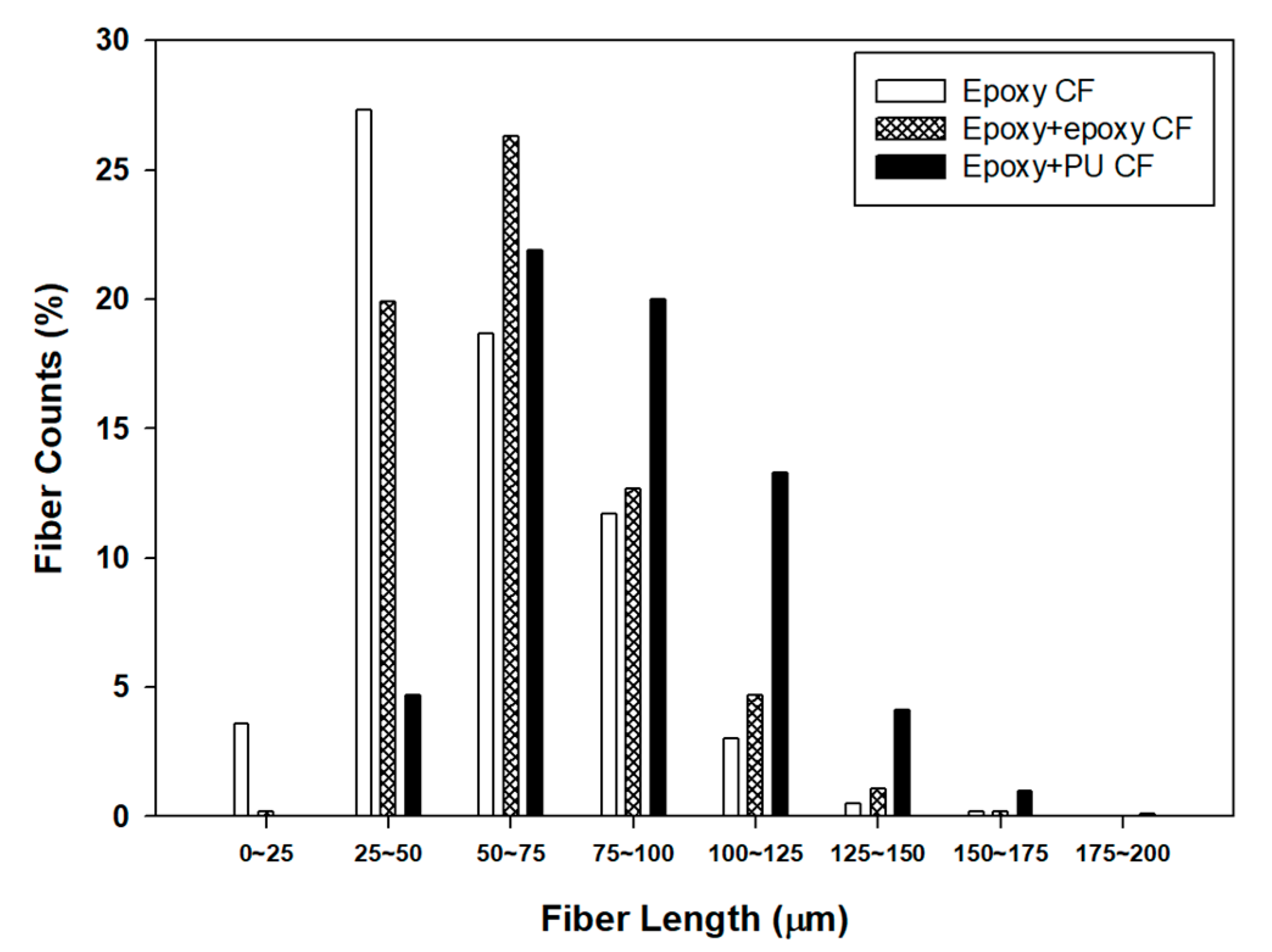

3.2. Fiber Length Distribution in Carbon Fiber/ABS Composites

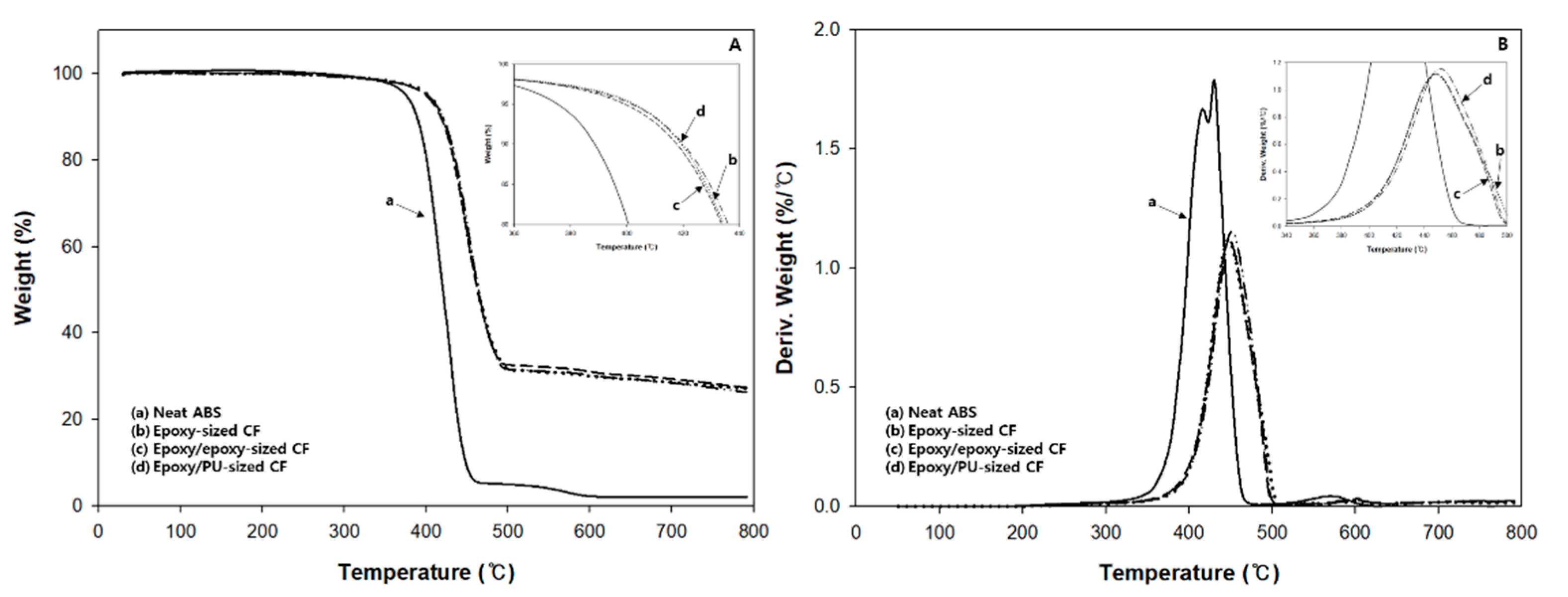

3.3. Thermal Stability of Composites

3.4. Heat Deflection Temperature of Composites

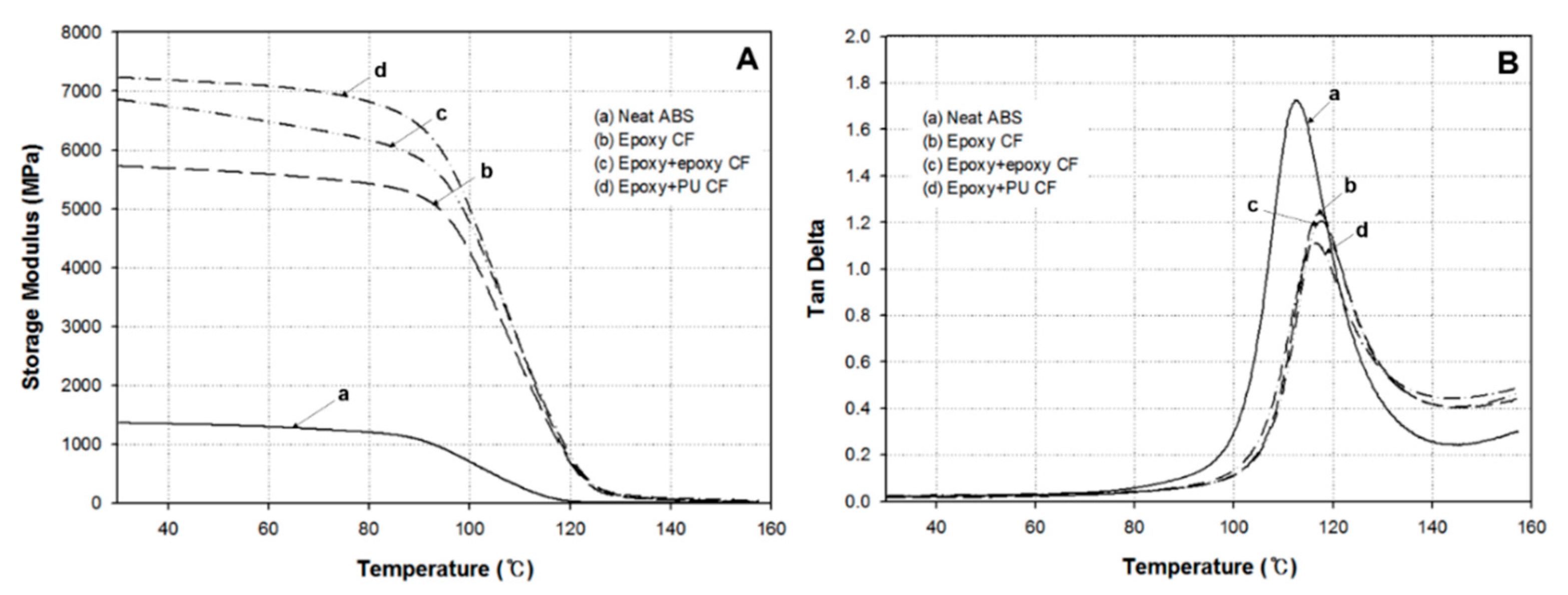

3.5. Dynamic Mechanical Properties of Composites

3.6. Tensile Properties of Composites

3.7. Flexural Properties of Composites

3.8. Izod Impact Strength of Composites

3.9. Fracture Surfaces of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khalil, Y.F. Eco-Efficient Lightweight Carbon-Fiber Reinforced Polymer for Environmentally Greener Commercial Aviation Industry. Sustain. Product. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Stewart, R. Rebounding Automotive Industry Welcome News for FRP. Reinf. Plast. 2011, 55, 38–44. [Google Scholar] [CrossRef]

- Zushi, H.; Takahashi, J.; Kageyama, K.; Murayama, H.; Nagai, H.; Matsui, J.I. Life Cycle Assessment and Long-Term CO2 Reduction Estimation of Ultra-Lightweight Vehicles Using CFRP. Key Eng. Mater. 2003, 243, 45–50. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Tension-Tension Fatigue Performance of a Large-Diameter Pultruded Carbon/Glass Hybrid Rod. Int. J. Fatigue 2019, 120, 141–149. [Google Scholar] [CrossRef]

- Kupski, J.; de Freitas, S.T. Design of Adhesively Bonded Lap Joints with Laminated CFRP Adherends: Review, Challenges and New Opportunities for Aerospace Structures. Compos. Struct. 2021, 268, 113923. [Google Scholar] [CrossRef]

- Li, C.; Yin, X.; Liu, Y.; Guo, R.; Xian, G. Long-Term Service Evaluation of a Pultruded Carbon/Glass Hybrid Rod Exposed to Elevated Temperature, Hydraulic Pressure and Fatigue Load Coupling. Int. J. Fatigue 2020, 134, 105480. [Google Scholar] [CrossRef]

- Li, C.; Guo, R.; Xian, G.; Li, H. Innovative Compound-Type Anchorage System for a Large-Diameter Pultruded Carbon/Glass Hybrid Rod for Bridge Cable. Mater. Struct. 2020, 53, 73. [Google Scholar] [CrossRef]

- Borrego, L.P.; Costa, J.D.M.; Ferreira, J.A.M.; Silva, H. Fatigue Behaviour of Glass Fibre Reinforced Epoxy Composites Enhanced with Nanoparticles. Compos. Part B 2014, 62, 65–72. [Google Scholar] [CrossRef]

- Cuenot, F. CO2 Emissions from New Cars and Vehicle Weight in Europe; How the EU Regulation Could Have Been Avoided and How to Reach It? Energy Policy 2009, 37, 3832–3842. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Effects of Maleated Polypropylene on the Morphology, Thermal and Mechanical Properties of Short Carbon Fiber Reinforced Polypropylene Composites. Mater. Des. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Wan, Y.; Takahashi, J. Tensile Properties and Aspect Ratio Simulation of Transversely Isotropic Discontinuous Carbon Fiber Reinforced Thermoplastics. Compos. Sci. Technol. 2016, 137, 167–176. [Google Scholar] [CrossRef]

- Liu, X.; Yang, B.; Lu, L.; Wan, Z.; Tang, Y. A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by A Two-Step Hot-Press Technique. Polymers 2018, 10, 720. [Google Scholar] [CrossRef] [Green Version]

- Chukov, D.I.; Nematulloev, S.G.; Tcherdyntsev, V.V.; Torokhov, V.G.; Stepashkin, A.A.; Zadorozhnyy, M.Y.; Zherebtsov, D.D.; Sherif, G. Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics. Polymers 2020, 12, 50. [Google Scholar] [CrossRef] [Green Version]

- Bae, J.S.; Bae, J.; Woo, H.; Lee, B.; Jeong, E. Novel Thermoplastic Toughening Agents in Epoxy Matrix for Vacuum Infusion Process Manufactured Composites. Carbon Lett. 2018, 25, 43–49. [Google Scholar]

- Huang, Y.; Young, R.J. Interfacial Micromechanics in Thermoplastic and Thermosetting Matrix Carbon Fibre Composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 973–980. [Google Scholar] [CrossRef]

- Fujita, R.; Nagano, H. Novel Fiber Orientation Evaluation Method for CFRP/CFRTP Based on Measurement of Anisotropic In-Plane Thermal Diffusivity Distribution. Compos. Sci. Technol. 2017, 140, 116–122. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mader, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon Fiber Surfaces and Composite Interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A.; Deniz, V. Effects of Initial Fiber Length and Fiber Length Distribution on the Properties of Carbon-Fiber-Reinforced-Polypropylene Composites. J. Reinf. Plast. Compos. 2012, 31, 1053–1060. [Google Scholar] [CrossRef]

- Yin, X.; Yin, Y.; Cheng, D.; Feng, Y.; Zhang, G.; Wen, J. In-Situ Bubble Stretching Assisted Melt Extrusion for the Preparation of HDPE/UHMWPE/CF Composites. Polymers 2019, 11, 2054. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strong, A.B. Fundamentals of Composites Manufacturing: Materials, Methods, and Applications, 2nd ed.; Society of Manufacturing Engineers: Dearborn, MN, USA, 1989; pp. 207–216. [Google Scholar]

- Cho, D.; Lee, J.; Park, J.K. Effects of Quasi-Carbonization Process on the Mechanical Properties of Spun Yarn Type Quasi-Carbon Fabrics. Macromol. Res. 2002, 10, 318–324. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, S.; Yang, J.; Ji, M.; Yu, J.; Wang, M.; Chai, X.; Yang, B.; Zhu, C.; Xu, J. Preparation, Stabilization and Carbonization of a Novel Polyacrylonitrile-Based Carbon Fiber Precursor. Polymers 2019, 11, 1150. [Google Scholar] [CrossRef] [Green Version]

- Unterweger, C.; Bruggemann, O.; Furst, C. Synthetic Fibers and Thermoplastic Short-Fiber-Reinforced Polymers: Properties and Characterization. Polym. Compos. 2014, 35, 227–236. [Google Scholar] [CrossRef]

- Duchoslav, J.; Unterweger, C.; Steinberger, R.; Furst, C. Investigation on the Thermo-Oxidative Stability of Carbon Fiber Sizings for Application in Thermoplastic Composites. Polym. Degrad. Stab. 2016, 125, 33–42. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A Study on the Failure Behavior and Mechanical Properties of Unidirectional Fiber Reinforced Thermosetting and Thermoplastic Composites. Compos. Part B 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Lee, J.S.; Kang, T.J. Changes in Physico-Chemical and Morphological Properties of Carbon Fiber by Surface Treatment. Carbon 1997, 35, 209–216. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Song, C.; Zhang, Y.; Fang, Y.; Yang, B.; Wang, X. An Effective Surface Modification of Carbon Fiber for Improving the Interfacial Adhesion of Polypropylene Composites. Mater. Des. 2015, 88, 810–819. [Google Scholar] [CrossRef]

- Cho, D.; Yun, S.H.; Kim, J.; Lim, S.; Park, M.; Lee, G.W.; Lee, S.S. Effects of Fiber Surface-Treatment and Sizing on the Dynamic Mechanical and Interfacial Properties of Carbon/Nylon 6 Composites. Carbon Sci. 2004, 5, 1–5. [Google Scholar]

- Downey, M.A.; Drzal, L.T. Toughening of Carbon Fiber-Reinforced Epoxy Polymer Composites Utilizing Fiber Surface Treatment and Sizing. Compos. Part A 2016, 90, 687–698. [Google Scholar] [CrossRef]

- Kobayashi, S.; Tsukada, T.; Morimoto, T. Resin Impregnation Behavior in Carbon Fiber Reinforced Polyamide 6 Composite: Effects of Yarn Thickness, Fabric Lamination and Sizing Agent. Compos. Part A 2017, 101, 283–289. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Kim, S.S. Evaluation of Fiber Surface Treatment on the Interfacial Behavior of Carbon Fiber-reinforced Polypropylene Composites. Compos. Part B 2014, 60, 98–105. [Google Scholar] [CrossRef]

- Ozkan, C.; Karsli, N.G.; Aytac, A.; Deniz, V. Short Carbon Fiber Reinforced Polycarbonate Composites: Effects of Different Sizing Materials. Compos. Part B 2014, 62, 230–235. [Google Scholar] [CrossRef]

- Zhang, R.L.; Huang, Y.D.; Su, D.; Liu, L.; Tang, Y.R. Influence of Sizing Molecular Weight on the Properties of Carbon Fibers and Its Composites. Mater. Des. 2012, 34, 649–654. [Google Scholar] [CrossRef]

- Cho, D.; Choi, Y.; Drzal, L.T. Characterization, Properties, and Processing of LaRC PETI-5 as A High-Temperature Sizing Material. III. Adhesion Enhancement of Carbon/BMI Composites. J. Adhes. 2003, 79, 1–23. [Google Scholar] [CrossRef]

- Karsli, N.G.; Ozkan, C.; Aytac, A.; Deniz, V. Effects of Sizing Materials on the Properties of Carbon Fiber-Reinforced Polyamide 6,6 Composites. Polym. Compos. 2013, 34, 1583–1590. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, Y.; Duan, Y.; Du, S. Surface and Wettability Property Analysis of CCF300 Carbon Fibers with Different Sizing or without Sizing. Mater. Des. 2011, 32, 941–946. [Google Scholar] [CrossRef]

- Zenkiewicz, M.; Rytlewski, P.; Moraczewski, K.; Stepczynska, M.; Karasiewicz, T.; Malinowski, R.; Ostrowicki, W. Some Effects of Multiple Injection Moulding on Selected Properties of ABS. J. Achieve. Mater. Manuf. Eng. 2009, 37, 361–368. [Google Scholar]

- Seo, J.S.; Jeon, H.T.; Han, T.H. Rheological Investigation of Relaxation Behavior of Polycarbonate/Acrylonitrile-Butadiene-Styrene Blends. Polymers 2020, 12, 1916. [Google Scholar] [CrossRef]

- Li, J.; Cai, C.L. The Carbon Fiber Surface Treatment and Addition of PA6 on Tensile Properties of ABS Composites. Cur. Appl. Phys. 2011, 11, 50–54. [Google Scholar] [CrossRef]

- Hwang, D.; Cho, D. Fiber Aspect Ratio Effect on Mechanical and Thermal Properties of Carbon Fiber/ABS Composites via Extrusion and Long Fiber Thermoplastic Processes. J. Indus. Eng. Chem. 2019, 80, 335–344. [Google Scholar] [CrossRef]

- Bismarck, A.; Kumru, M.E.; Song, B.; Springer, J.; Moos, E.; Kocsis, J.K. Study on Surface and Mechanical Fiber Characteristics and Their Effect on the Adhesion Properties to A Polycarbonate Matrix Tuned by Anodic Carbon Fiber Oxidation. Compos. Part A 1999, 30, 1351–1366. [Google Scholar] [CrossRef]

- Jia, Q.M.; Zheng, M.; Zhu, Y.C.; Li, J.B.; Xu, C.Z. Effect of Organophilic Montmorillonite on Hydrogen Bonding, Free Volume and Glass Transition Temperature of Epoxy Resin/Polyurethane Interpenetrating Polymer Networks. Macromol. Nanotechnol. 2007, 43, 35–42. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Cai, X.; Liu, J.; Qiao, K.; Yu, J. Optimization of Interfacial Properties of Carbon Fiber/Epoxy Composites via A Modified Polyacrylate Emulsion Sizing. Appl. Surf. Sci. 2017, 401, 414–423. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Experimental and Modeling Study of the Evolution of Mechanical Properties of PAN-Based Carbon Fibers at Elevated Temperatures. Polymers 2019, 12, 724. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Huang, X.; Xian, G.; Li, H. Effects of Surface Treatment of Carbon Fiber: Tensile Property, Surface Characteristics, and Bonding to Epoxy. Polym. Compos. 2016, 37, 2921–2932. [Google Scholar] [CrossRef]

- Bondy, M.; Pinter, P.; Altenhof, W. Experimental Characterization and Modelling of the Elastic Properties of Direct Compounded Compression Molded Carbon Fibre/Polyamide 6 Long Fibre Thermoplastic. Mater. Des. 2017, 122, 184–196. [Google Scholar] [CrossRef]

- Kim, Y.H.; Yoon, S.H.; Jang, S.H.; Lee, Y.K.; Sung, Y.T.; Lee, H.S.; Kim, W.N. Effects of Fiber Characteristics on the Rheological and Mechanical Properties of Polycarbonate/Carbon Fiber Composites. Compos. Interf. 2009, 16, 477–491. [Google Scholar] [CrossRef]

- Yang, S.; Castilleja, J.R.; Barrera, E.V.; Lozano, K. Thermal Analysis of An Acrylonitrile-Butadiene-Styrene/SWNT Composite. Polym. Degrad. Stab. 2004, 83, 383–388. [Google Scholar] [CrossRef]

- Suzuki, M.; Wilkie, C.A. The Thermal Degradation of Acrylonitrile-Butadiene-Styrene Terpolymer as Studied by TGA/FTIR. Polym. Degrad. Stab. 1995, 47, 217–221. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on Mechanical Performance of Biofibre/Glass Reinforced Polyester Hybrid Composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic Mechanical and Thermal Properties of MAPE Treated Jute/HDPE Composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, Y.; Qian, J.; Liu, Z.; Yang, B.; Wang, X. Bio-Inspired Polydopamine Functionalization of Carbon Fiber for Improving the Interfacial Adhesion of Polypropylene Composites. RSC Adv. 2015, 5, 107652–107661. [Google Scholar] [CrossRef]

- Li, S.; Li, D. Carbon Fiber Reinforced Highly Filled Charcoal Powder/Ultra-high Molecular Weight Polyethylene Composites. Mater. Lett. 2014, 134, 99–102. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N.A. Effect of Fiber Length on Thermomechanical Properties of Short Carbon Fiber Reinforced Polypropylene Composites. Mater. Des. 2009, 30, 260–263. [Google Scholar] [CrossRef]

- Harris, B.; Braddel, O.; Almond, D.; Lefebure, C.; Verbic, J. Study of Carbon Fibre Surface Treatments by Dynamic Mechanical Analysis. J. Mater. Sci. 1993, 28, 3353–3366. [Google Scholar] [CrossRef]

- Jacob, M.; Francis, B.; Thomas, B.; Varughese, K.T. Dynamical Mechanical Analysis of Sisal/Oil Palm Hybrid Fiber-Reinforced Natural Rubber Composites. Polym. Compos. 2006, 27, 671–680. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Kaerkitcha, N.; Athipongarporn, N. Effect of Surface Treatment on Performance of Pineapple Leaf Fiber-Polycarbonate Composites. Compos. Part B 2009, 40, 628–632. [Google Scholar] [CrossRef]

- Sanchez, M.; Campo, M.; Suarez, A.J.; Urena, A. Effect of the Carbon Nanotube Functionalization on Flexural Properties of Multiscale Carbon Fiber/Epoxy Composites Manufactured by VARIM. Compos. Part B 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V.; Jappes, J.T.W.; Uthayakumar, M. Effect of Fibre Length and Fibre Content on Mechanical Properties of Short Basalt Fibre Reinforced Polymer Matrix Composites. Mater. Phys. Mech. 2013, 16, 107–117. [Google Scholar]

- Tekinalp, H.L.; Kunc, V.; Garcia, G.M.V.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Oxcan, S. Highly Oriented Carbon Fiber–Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Hassan, A.; Rahman, N.A.; Yahya, R. Extrusion and Injection-molding of Glass Fiber/MAPP/Polypropylene: Effect of Coupling Agent on DSC, DMA, and Mechanical Properties. J. Reinf. Plast. Compos. 2011, 30, 1223–1232. [Google Scholar] [CrossRef]

| Carbon Fiber Sizing Type | Carbon Atomic C1s (%) | Oxygen Atomic O1s (%) | Nitrogen Atomic N1s (%) |

|---|---|---|---|

| Epoxy | 77.7 | 20.9 | 1.4 |

| Epoxy + epoxy | 77.1 | 22.5 | 0.4 |

| Epoxy + PU | 74.0 | 25.0 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, D.; Lee, S.G.; Cho, D. Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites. Polymers 2021, 13, 2298. https://doi.org/10.3390/polym13142298

Hwang D, Lee SG, Cho D. Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites. Polymers. 2021; 13(14):2298. https://doi.org/10.3390/polym13142298

Chicago/Turabian StyleHwang, Daekyun, Seung Goo Lee, and Donghwan Cho. 2021. "Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites" Polymers 13, no. 14: 2298. https://doi.org/10.3390/polym13142298

APA StyleHwang, D., Lee, S. G., & Cho, D. (2021). Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites. Polymers, 13(14), 2298. https://doi.org/10.3390/polym13142298