Properties of Stone Matrix Asphalt Modified with Polyvinyl Chloride and Nano Silica

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

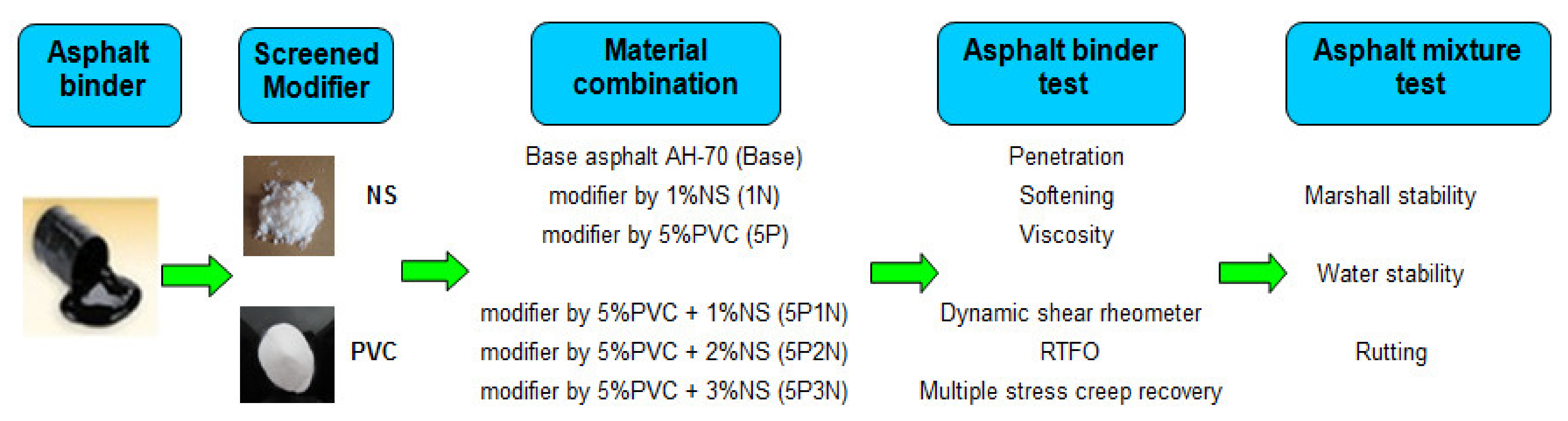

2.2. Experimental Design

2.3. Asphalt Modification

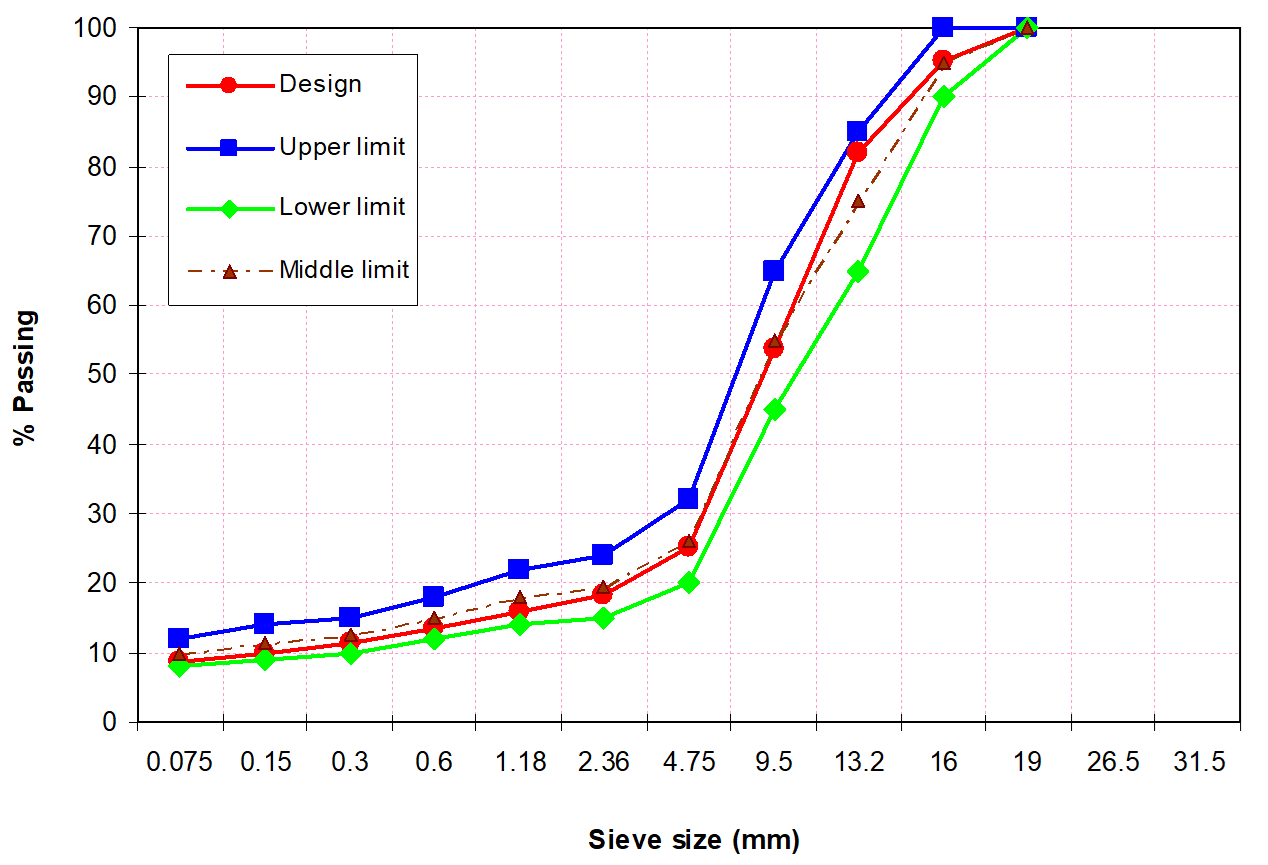

2.4. SMA Formulation

2.5. Asphalt Test

2.6. SMA Test

2.6.1. Marshall Test

2.6.2. Moisture Susceptibility Test

2.6.3. Rutting Test

3. Results and Discussion

3.1. Penetration

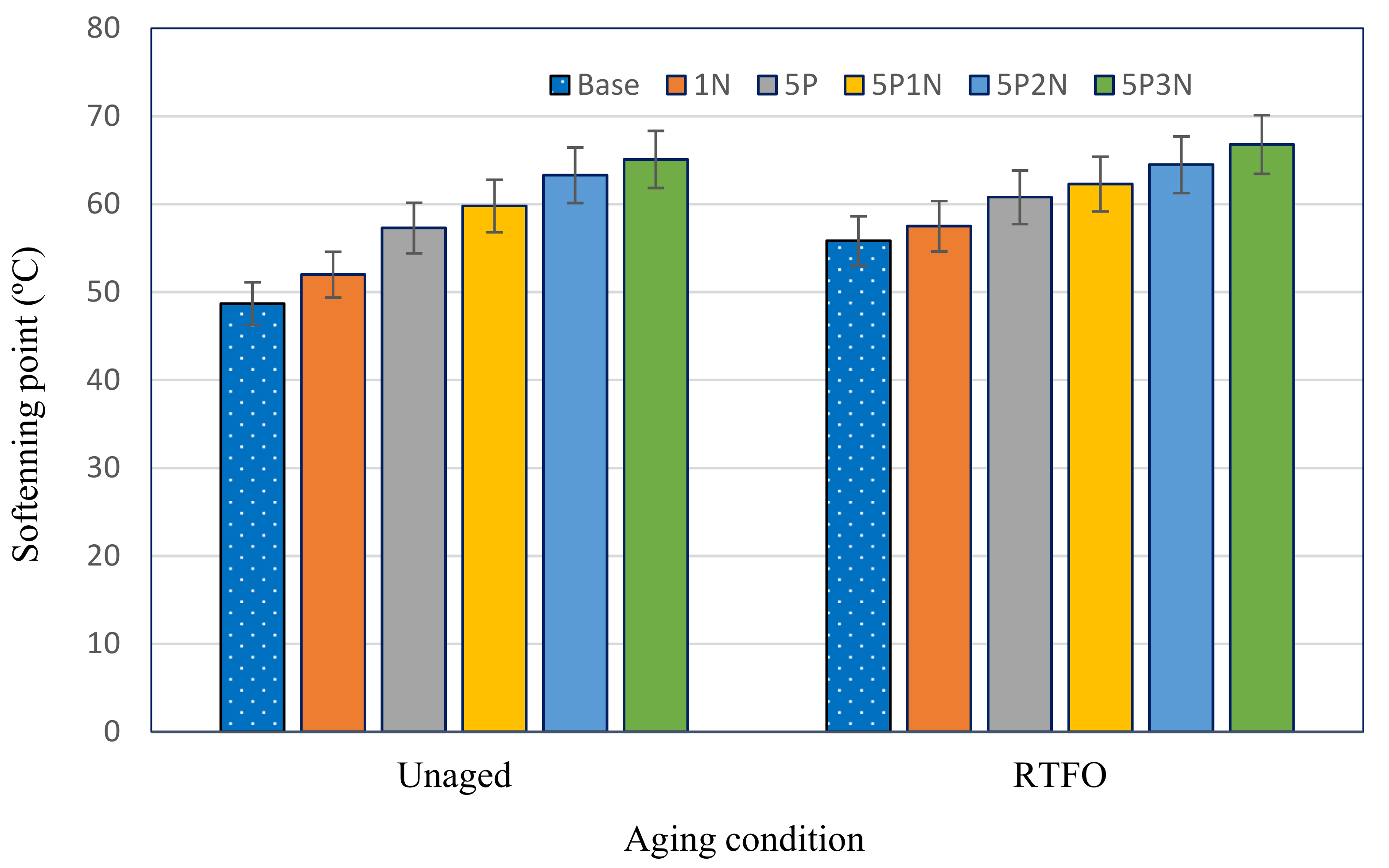

3.2. Softening Point

3.3. Rotational Viscosity

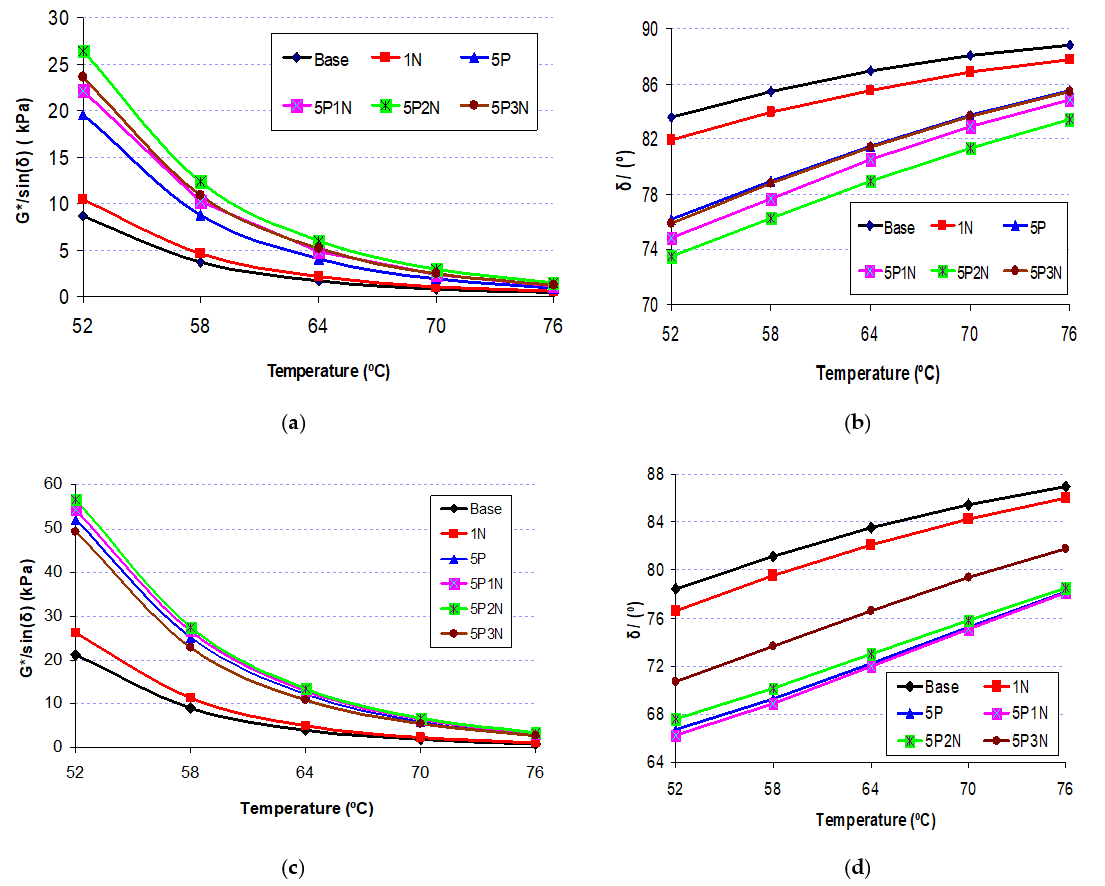

3.4. Dynamic Shear Rheological Properties

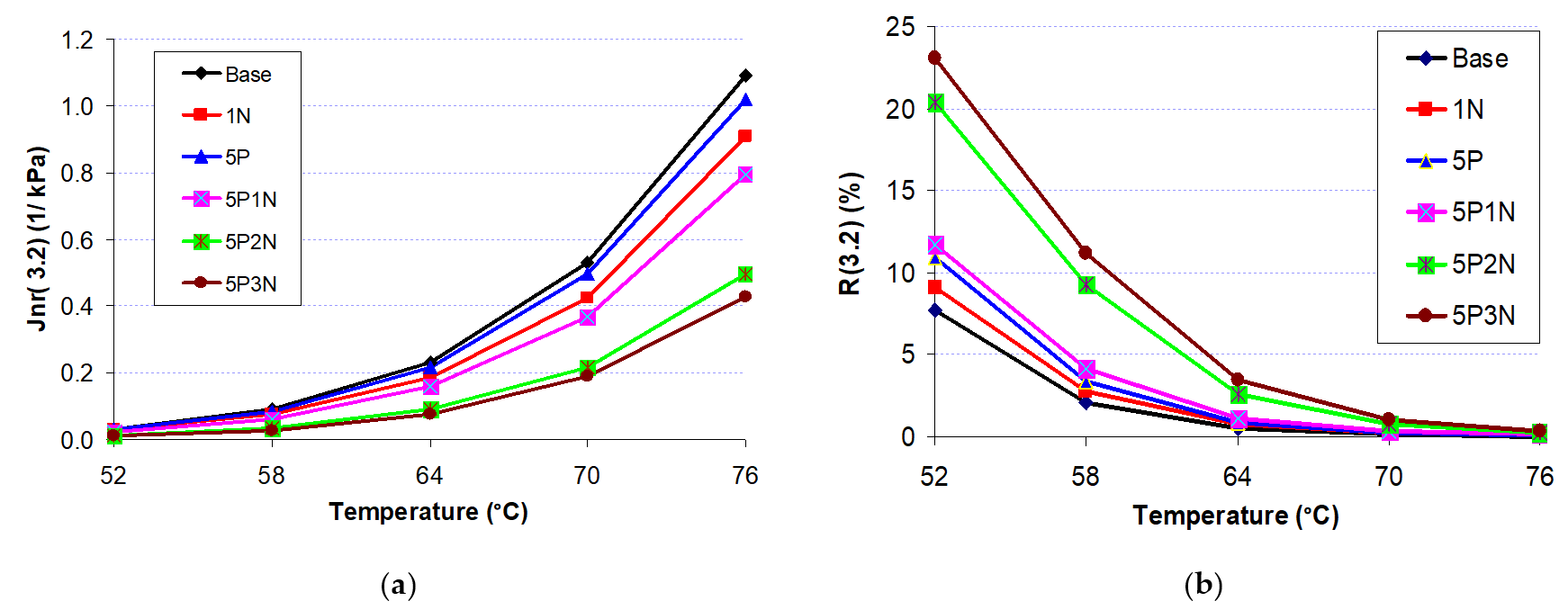

3.5. Multiple Stress Creep Recovery (MSCR)

3.6. Short-Term Aging Effect

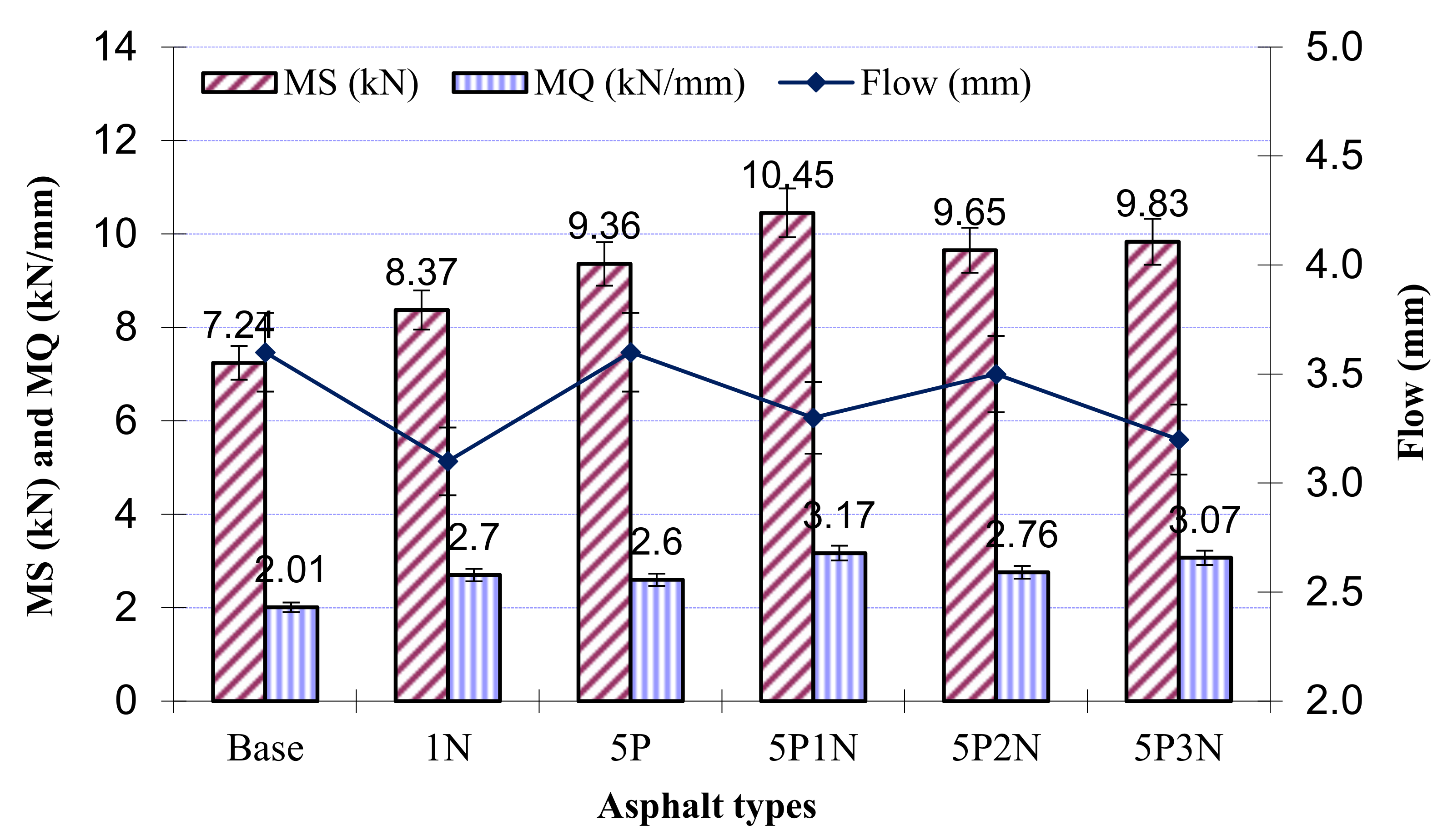

3.7. Marshall Experiment

3.8. Moisture Susceptibility Test

3.9. Rutting Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- França, B.R.; Azevedo, A.R.G.; Monteiro, S.N.; Garcia Filho, F.D.C.; Marvila, M.T.; Alexandre, J.; Zanelato, E.B. Durability of soil-cement blocks with the incorporation of limestone residues from the processing of marble. Mater. Res. 2018, 21. [Google Scholar] [CrossRef] [Green Version]

- Mharsi, K.; Chapeleau, X.; Fajoui, J.; Sellami, A.; Casari, P.; Kchaou, M. Characterization Shear Properties of PVC Foams Instrumented by Optical Fiber under Flexural Loading. J. Test. Eval. 2020, 50. [Google Scholar] [CrossRef]

- Marvila, M.; Azevedo, A.; Alexandre, J.; Zanelato, E.; Azeredo, N.; Simonassi, N.; Monteiro, S. Correlation between the properties of structural clay blocks obtained by destructive tests and Ultrasonic Pulse Tests. J. Build. Eng. 2019, 26, 100869. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2020, 280, 124355. [Google Scholar] [CrossRef]

- Soares, M.P.S.P.; Cerqueira, N.A.; de Almeida, F.F.; Azevedo, A.R.G.; Marvila, M.T. Technical, Environmental, and Economic Advantages in the Use of Asphalt Rubber. In Characterization of Minerals, Metals, and Materials 2021; Springer International Publishing: Cham, Switzerland, 2021; pp. 577–586. [Google Scholar]

- Padhan, R.K.; Sreeram, A.; Mohanta, C.S. Chemically recycled polyvinyl chloride as a bitumen modifier: Synthesis, characterisation and performance evaluation. Road Mater. Pavement Des. 2021, 22, 639–652. [Google Scholar] [CrossRef]

- Pérez, N.A.; Nava, A.; Rincón, G.; Meza, A.; Velásquez, J. Effect of resin and asphaltene content present on the vacuum residue on the yield of delayed coking products (Efecto del contenido de resinas y asfaltenos presente en el residuo de vacio sobre el rendimiento de los productos de la coquización retardada). Rev. Latinoam. Metal. Mater. 2019, 39, 49–58. [Google Scholar]

- Rodríguez, B.C.B.; Del Carpio, E.; de Navarro, C.U.; Ortega, N. Morphological and spectroscopic characterization of asphaltenes from different heavy oils. Rev. Latinoam. Metal. Mater. 2013, 34, 218–229. [Google Scholar]

- Asi, I.M. Laboratory comparison study for the use of stone matrix asphalt in hot weather climates. Constr. Build. Mater. 2006, 20, 982–989. [Google Scholar] [CrossRef]

- Gibreil, H.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Baghini, M.S.; Ismail, A.; Karim, M.R.; Shokri, F.; Firoozi, A.A. Effect of styrene–butadiene copolymer latex on properties and durability of road base stabilized with Portland cement additive. Constr. Build. Mater. 2014, 68, 740–749. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, T.; Zhang, D.; Shi, Z.; Zhang, X.; Li, C.; Wang, L.; Song, J.; Lin, Q. Enhanced photodegradability of PVC plastics film by codoping nano-graphite and TiO2. Polym. Degrad. Stab. 2020, 181, 109332. [Google Scholar] [CrossRef]

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117. [Google Scholar] [CrossRef]

- Ziari, H.; Nasiri, E.; Amini, A.; Ferdosian, O. The effect of EAF dust and waste PVC on moisture sensitivity, rutting resistance, and fatigue performance of asphalt binders and mixtures. Constr. Build. Mater. 2019, 203, 188–200. [Google Scholar] [CrossRef]

- Köfteci, S.; Gunay, T.; Ahmedzade, P. Rheological Analysis of Modified Bitumen by PVC Based Various Recycled Plastics. J. Transp. Eng. Part B Pavements 2020, 146, 04020063. [Google Scholar] [CrossRef]

- Abdel-Goad, M.A.H. Waste polyvinyl chloride-modified bitumen. J. Appl. Polym. Sci. 2006, 101, 1501–1505. [Google Scholar] [CrossRef]

- Al-Harahsheh, M.; Al-Nu’airat, J.; Al-Otoom, A.; Al-jabali, H.; Al-zoubi, M. Treatments of electric arc furnace dust and halogenated plastic wastes: A review. J. Environ. Chem. Eng. 2019, 7, 102856. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Li, R.; Pei, J.; Sun, C. Effect of nano-ZnO with modified surface on properties of bitumen. Constr. Build. Mater. 2015, 98, 656–661. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Performance analysis of nano modified bitumen and hot mix asphalt. Constr. Build. Mater. 2018, 173, 228–237. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wistuba, M.P. Effect of Fumed Silica Nanoparticles on Ultraviolet Aging Resistance of Bitumen. Nanomaterials 2021, 11, 454. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Dai, W.; Qian, G.; Gong, X.; Zhou, D.; Li, X.; Zhou, X. The NOx degradation performance of nano-TiO2 coating for asphalt pavement. Nanomaterials 2020, 10, 897. [Google Scholar] [CrossRef] [PubMed]

- Mahani, A.G.; Bazoobandi, P.; Hosseinian, S.M.; Ziari, H. Experimental investigation and multi-objective optimization of fracture properties of asphalt mixtures containing nano-calcium carbonate. Constr. Build. Mater. 2021, 285, 122876. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. A study investigating the influence of nano Al2O3 on the performance of SBS modified asphalt binder. Constr. Build. Mater. 2021, 271, 121499. [Google Scholar] [CrossRef]

- Arshad, A.; Shaffie, E.; Hashim, W.; Ismail, F.; Masri, K. Evaluation of nanosilica modified stone mastic asphalt. Int. J. Civ. Eng. Technol. 2019, 10, 1508–1516. [Google Scholar]

- Singh, L.; Karade, S.; Bhattacharyya, S.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A. Characteristics of asphalt binder and mixture containing nanosilica. Int. J. Pavement Res. Technol. 2017, 10, 148–157. [Google Scholar] [CrossRef]

- Karnati, S.R.; Oldham, D.; Fini, E.H.; Zhang, L. Surface functionalization of silica nanoparticles to enhance aging resistance of asphalt binder. Constr. Build. Mater. 2019, 211, 1065–1072. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Alhamali, D.I.; Ibrahim, A.N.H.; Rosyidi, S.A.P.; Hassan, N.A. Engineering characteristics of nanosilica/polymer-modified bitumen and predicting their rheological properties using multilayer perceptron neural network model. Constr. Build. Mater. 2019, 204, 781–799. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Chang, M.; Dai, W. Evaluating the effect of hydrophobic nanosilica on the viscoelasticity property of asphalt and asphalt mixture. Materials 2018, 11, 2328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, X.; Cai, L.; Xu, W.; Fan, J.; Wang, X. Effects of nano-silica and rock asphalt on rheological properties of modified bitumen. Constr. Build. Mater. 2018, 161, 705–714. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Motamedi, M.; Firouznia, M.; Isazadeh, M. Experimental investigation of the effect of asphalt binder modified with nanosilica on the rutting, fatigue and performance grade. Pet. Sci. Technol. 2019, 37, 1495–1500. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Breem, A.A.S.; Alattug, H.N.; Hamim, A.; Ahmad, J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- Van Thanh, D.; Feng, C.P. Study on Marshall and Rutting test of SMA at abnormally high temperature. Constr. Build. Mater. 2013, 47, 1337–1341. [Google Scholar] [CrossRef]

- López-Montero, T.; Crucho, J.; Picado-Santos, L.; Miró, R. Effect of nanomaterials on ageing and moisture damage using the indirect tensile strength test. Constr. Build. Mater. 2018, 168, 31–40. [Google Scholar] [CrossRef]

- Jie, J.; Zhe, W.; Ran, Z.; Jianming, W.; Zhi, S.; Zhanping, Y.; Junpeng, H. Rutting resistance of direct coal liquefaction residue (DCLR) modified asphalt mixture under variable loads over a wide temperature range. Constr. Build. Mater. 2020, 257, 119489. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, Y.; Sun, Y.; Xu, W.; Yu, D.; Xie, H.; Cheng, R. Performance of hot mix epoxy asphalt binder and its concrete. Mater. Struct. 2015, 48, 3825–3835. [Google Scholar] [CrossRef]

- Wang, H.; You, Z.; Mills-Beale, J.; Hao, P. Laboratory evaluation on high temperature viscosity and low temperature stiffness of asphalt binder with high percent scrap tire rubber. Constr. Build. Mater. 2012, 26, 583–590. [Google Scholar] [CrossRef]

- Anurag, K.; Xiao, F.; Amirkhanian, S.N. Laboratory investigation of indirect tensile strength using roofing polyester waste fibers in hot mix asphalt. Constr. Build. Mater. 2009, 23, 2035–2040. [Google Scholar] [CrossRef]

- Shunyashree, T.; Archana, M.; Amarnath, M. Effect of use of recycled materials on indirect tensile strength of asphalt concrete mixes. In Proceedings of the IC-RICE Conference Issue, Gulbarga, India, 25–27 October 2013; pp. 226–232. [Google Scholar]

- Iskender, E. Evaluation of mechanical properties of nano-clay modified asphalt mixtures. Measurement 2016, 93, 359–371. [Google Scholar] [CrossRef]

- Golestani, B.; Nam, B.H.; Nejad, F.M.; Fallah, S. Nanoclay application to asphalt concrete: Characterization of polymer and linear nanocomposite-modified asphalt binder and mixture. Constr. Build. Mater. 2015, 91, 32–38. [Google Scholar] [CrossRef]

| Basic Properties | Method | Value | Unit |

|---|---|---|---|

| Penetration (100 g, 5 s, 25 °C) | ASTM D5 | 75.5 | 0.1 mm |

| Ductility (25 °C cm/min, 5 cm/min) | ASTM D113 | >150 | cm |

| Softening point | ASTM D36 | 48.7 | °C |

| Rotation viscosity (135 °C) | ASTM D4402 | 0.581 | Pa. s |

| Specific gravity at 25 °C | ASTM D70 | 1.04 | g/cm3 |

| Flash point | ASTM D92 | 320 | °C |

| Appearance | Melting Point (°C) | Density (g/cm3) | Tensile Strength (MPa) |

|---|---|---|---|

| White | 170 | 1.42 | 60 |

| Type | Appearance | Silica Content (%) | Average Grain Size (nm) | Specific Surface Area (m2/g) | pH Value |

|---|---|---|---|---|---|

| SP15 | White | 99.8 | 15 ± 5 | 250 ± 30 | 5–7 |

| Appearance | Length (mm) | Diameter (μm) | Density (g/m3) | pH Value |

|---|---|---|---|---|

| Gray | <5 | 46 | 1.6 | 7.5 ± 1 |

| Aggregate Properties | Method | Value | Unit |

|---|---|---|---|

| Crushed stone value | ASTM D6928 | 13.1 | % |

| Los Angeles abrasion loss | ASTM C131 | 15.9 | % |

| Apparent specific gravity | ASTM C128 | 2.78 | g/cm3 |

| Water absorption | ASTM C70 | 0.41 | % |

| Fine aggregate specific gravity | ASTM C127 | 2.78 | g/cm3 |

| Sand equivalent | ASTM D2419 | 75.6 | % |

| Binder Type | Binder-Aggregate Ratio (%) | Fiber-Aggregate Ratio (%) |

|---|---|---|

| Control | 6.1 | 0.28 |

| 1% NS | 6.1 | 0.31 |

| 5% PVC | 6.1 | 0.32 |

| 5P1N | 6.2 | 0.33 |

| 5P2N | 6.2 | 0.33 |

| 5P3N | 6.2 | 0.33 |

| Asphalt Type | Aging Indices at Difference Temperatures | ||||

|---|---|---|---|---|---|

| 52 °C | 58 °C | 64 °C | 70 °C | 76 °C | |

| Base | 2.44 | 2.47 | 2.38 | 2.28 | 2.15 |

| 1N | 2.53 | 2.48 | 2.35 | 2.20 | 2.10 |

| 5P | 2.66 | 2.88 | 3.04 | 3.10 | 3.11 |

| 5P1N | 2.46 | 2.60 | 2.70 | 2.75 | 2.74 |

| 5P2N | 2.15 | 2.23 | 2.29 | 2.32 | 2.30 |

| 5P3N | 2.08 | 2.12 | 2.14 | 2.16 | 2.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, H.P.; Cheng, P.; Nguyen, T.T. Properties of Stone Matrix Asphalt Modified with Polyvinyl Chloride and Nano Silica. Polymers 2021, 13, 2358. https://doi.org/10.3390/polym13142358

Nguyen HP, Cheng P, Nguyen TT. Properties of Stone Matrix Asphalt Modified with Polyvinyl Chloride and Nano Silica. Polymers. 2021; 13(14):2358. https://doi.org/10.3390/polym13142358

Chicago/Turabian StyleNguyen, Hoang Phong, Peifeng Cheng, and Tat Thang Nguyen. 2021. "Properties of Stone Matrix Asphalt Modified with Polyvinyl Chloride and Nano Silica" Polymers 13, no. 14: 2358. https://doi.org/10.3390/polym13142358