Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement

Abstract

:1. Introduction

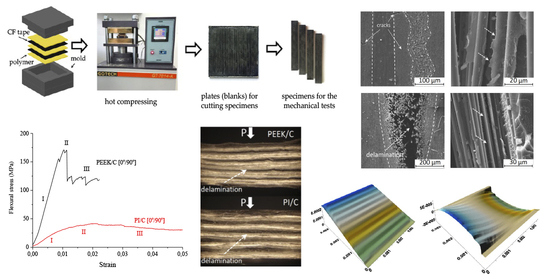

2. Materials and Methods

3. Results and Discussion

3.1. Experimental Part

3.1.1. Comparison between Powder and Film PEEK-Based Composites

3.1.2. Three-Point Bending Flexural Test

3.1.3. Structural Studies

3.2. Computational Part

3.2.1. Problem Statement

- Option 1 (Figure 10a): polymer layers alternate with CF layers directed along the x-axis;

- Option 2 (Figure 10b): along the z-axis;

- Option 3 (Figure 10c): a layer of polymer, a layer with CF directed along the x-axis, a layer of polymer, then a layer of fibers along the z-axis, then the sequence was repeated;

- Option 4 (Figure 10d): the polymer layers alternate with the layers of CF directed along the x and z axes, which imitated fabric, then the sequence was repeated.

3.2.2. Calculation of the Mechanical Properties of one Impregnated CF Layer (Monolayer)

3.2.3. Composite Characteristics in the Flexural Tests

4. Conclusions

- The laminated composites reinforced with continuous unidirectional CF oriented at (0°/0°) showed the maximum mechanical properties (both flexural modulus and strength) in the three-point flexural tests. The PEEK-based ones had twice the flexural strength compared to the PI-based samples (0.4 and 0.2 GPa, respectively), and the flexural modulus was four times higher (61 and 15 GPa, correspondingly). The difference in their flexural strength was not proportional to the variations of the respective characteristics of the used polymer binders.

- It was shown that the interlayer boundary between the PEEK film and CF was straight and did not contain any discontinuities. In addition, the molten polymer had effectively impregnated the CF layer to form a wavy interface. However, this transition layer contained defects, primarily microcracks. At the same time, satisfactory interfacial adhesion between the binder and individual CF was ensured.

- In the laminated PI-based composite, the straight interface without any discontinuities was observed between the polymer and CF tape layers. However, this polymer did not infiltrate the near-boundary zone of the CF tape to the required extent due to its lower MFI. As a result, pronounced delamination up to several tens of micrometers width was found inside the CF layer (tape) of the PI-based composite. There were no visible microcracks in this transition layer, and interfacial adhesion between the binder and the individual CF was satisfactory as well.

- It was found that the use of the PI powder for manufacturing the laminated CF reinforced composites was not very promising due to their low mechanical properties (in comparison with the PEEK-based ones). The reason was that the lower MFI of the PI powder resulted in the presence of interlayer discontinuities.

- A model of the CF reinforced composites was developed, taking into account discontinuities in the material, delamination between the polymer and CF, as well as the composite failure processes. On its basis, the effect of delamination and fracture on the strength properties was shown for both PEEK- and PI-based composites at various stress–strain states.

- It was reported that increasing CF/polymer adhesion enhanced the tensile strength of longitudinally reinforced composites but did not change their elasticity modulus (corresponding quantitative estimates were obtained).

- It was observed that the matrix type played a decisive influence on the properties of the composites reinforced in the transverse direction under tension. Increasing both adhesion and contact areas (number of contacting nodes) between CF and the polymers improved the strength characteristics of the composites. Similar results were obtained for the ones reinforced in the longitudinal direction under shear loads. The decrease in the number of contact points (simulating an increase in the number of defects) significantly reduced both shear modulus and strength.

- The simulation results showed that the achieved adhesion level in the studied composites was about 20%, and their flexural strength can be improved by several times through enhancing adhesion. In theory, PEEK- and PI-based composites can have comparable properties at the same adhesion level assessed relative to the polymer matrix yield point.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Prospects

Nomenclature

| PEEK | Polyetheretherketone |

| PI | Polyimide |

| CF | Carbon fiber |

| MFI | Melt flow index |

| FEM | Finite element method |

| Flexural modulus | |

| Bending strength | |

| Flextural stain | |

| σF | Flexural stress |

| εF | Flexural strain |

| τ | Tangential stress |

| Normal stress | |

| Yield point | |

| Maximum adhesion level | |

| Longitudinal composite tensile strength (along x-axis) | |

| Transverse composite tensile strength (along y-axis) | |

| Fiber elastic modulus | |

| Matrix elastic modulus | |

| Fiber shear modulus | |

| Matrix shear modulus | |

| Composite shear modulus along the x-axis | |

| Composite elastic modulus along the x and y axis | |

| ϕ | CF volumetric content |

| v, u | Total displacement along the y and x axis |

| vi, ui | Displacement along the y and x axis for one step |

| k, m, l | Node numbers |

| F | Load on sample |

| b | Sample width |

| yna | Deflection of the neutral axis |

| H | Sample height |

| L | Support span |

References

- Beaumont, P.W.R.; Soutis, C.; Hodzic, A. The Structural Integrity of Carbon Fiber Composites, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Pantelakis, S.; Tserpes, K. Revolutionizing Aircraft Materials and Processes, 1st ed.; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.-M. The Effect of Thermally Desized Carbon Fibre Reinforcement on the Flexural and Impact Properties of PA6, PPS and PEEK Composite Laminates: A Comparative Study. Comp. Part B Eng. 2021, 215, 108844. [Google Scholar] [CrossRef]

- Miao, Q.; Dai, Z.; Ma, G.; Niu, F.; Wu, D. Effect of Consolidation Force on Interlaminar Shear Strength of CF/PEEK Laminates Manufactured by Laser-Assisted Forming. Comp. Struct. 2021, 266, 113779. [Google Scholar] [CrossRef]

- Mallick, P.K. Thermoplastics and Thermoplastic–Matrix Composites for Lightweight Automotive Structures. In Materials, Design and Manufacturing for Lightweight Vehicles, 2nd ed.; Mallick, P.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 187–228. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Comp. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Morioka, K.; Tomita, Y. Effect of Lay-up Sequences on Mechanical Properties and Fracture Behavior of CFRP Laminate Composites. Mater. Charact. 2000, 45, 125–136. [Google Scholar] [CrossRef]

- Zhao, W.-S.; Ling, L. Influence of different laying-up direction of GF on properties of GF/EVE resin composite. Plast. Addit. 2010, 79, 45–48. [Google Scholar]

- Hassan, E.A.M.; Yang, L.; Elagib, T.H.H.; Ge, D.; Lv, X.; Zhou, J.; Yu, M.; Zhu, S. Synergistic Effect of Hydrogen Bonding and π-π Stacking in Interface of CF/PEEK Composites. Comp. Part B Eng. 2019, 171, 70–77. [Google Scholar] [CrossRef]

- Zhang, S.; Awaja, F.; James, N.; McKenzie, D.R.; Ruys, A.J. A Comparison of the Strength of Autohesion of Plasma Treated Amorphous and Semi-Crystalline PEEK Films. Polym. Adv. Technol. 2010, 22, 2496–2502. [Google Scholar] [CrossRef]

- Dcc Sun, C.; Min, J.; Lin, J.; Wan, H. Effect of Atmospheric Pressure Plasma Treatment on Adhesive Bonding of Carbon Fiber Reinforced Polymer. Polymers 2019, 11, 139. [Google Scholar]

- Jha, S.; Bhowmik, S.; Bhatnagar, N.; Bhattacharya, N.K.; Deka, U.; Iqbal, H.M.S.; Benedictus, R. Experimental Investigation into the Effect of Adhesion Properties of PEEK Modified by Atmospheric Pressure Plasma and Low Pressure Plasma. J. App. Polym. Sc. 2010, 118, 173–179. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Gorshenkov, M.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D. Surface Modification of Carbon Fibers and Its Effect on the Fiber–Matrix Interaction of UHMWPE Based Composites. J. All. Comp. 2014, 586, S459–S463. [Google Scholar] [CrossRef]

- Gulyás, J.; Földes, E.; Lázár, A.; Pukánszky, B. Electrochemical Oxidation of Carbon Fibres: Surface Chemistry and Adhesion. Comp. Part A Appl. Sc. Manuf. 2001, 32, 353–360. [Google Scholar] [CrossRef]

- Liu, F.; Deng, S.; Zhang, J. Mechanical Properties of Epoxy and Its Carbon Fiber Composites Modified by Nanoparticles. J. Nanomat. 2017, 8146248. [Google Scholar] [CrossRef] [Green Version]

- Díez-Pascual, A.M.; Naffakh, M. Tuning the Properties of Carbon Fiber-Reinforced Poly(Phenylene Sulphide) Laminates via Incorporation of Inorganic Nanoparticles. Polymers 2012, 53, 2369–2378. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.K.; Gupta, V.; Yerramalli, C.S.; Singh, A. Flexural Strength Enhancement in Carbon-Fiber Epoxy Composites through Graphene Nano-Platelets Coating on Fibers. Comp. Part B Eng. 2019, 179, 107539. [Google Scholar] [CrossRef]

- Zhu, S.; Qian, Y.; Hassan, E.A.M.; Shi, R.; Yang, L.; Cao, H.; Zhou, J.; Ge, D.; Yu, M. Enhanced Interfacial Interactions by PEEK-Grafting and Coupling of Acylated CNT for GF/PEEK Composites. Comp. Commun. 2020, 18, 43–48. [Google Scholar] [CrossRef]

- Yan, T.; Yan, F.; Li, S.; Li, M.; Liu, Y.; Zhang, M.; Jin, L.; Shang, L.; Liu, L.; Ao, Y. Interfacial Enhancement of CF/PEEK Composites by Modifying Water-Based PEEK-NH2 Sizing Agent. Comp. Part B Eng. 2020, 199, 108258. [Google Scholar] [CrossRef]

- Khan, M.A.; Mitschang, P.; Schledjewski, R. Identification of Some Optimal Parameters to Achieve Higher Laminate Quality through Tape Placement Process. Adv. Polym. Technol. 2010, 29, 98–111. [Google Scholar] [CrossRef]

- Lu, C.; Xu, N.; Zheng, T.; Zhang, X.; Lv, H.; Lu, X.; Xiao, L.; Zhang, D. The Optimization of Process Parameters and Characterization of High-Performance CF/PEEK Composites Prepared by Flexible CF/PEEK Plain Weave Fabrics. Polymers 2018, 11, 53. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Zhang, M.; Wang, G.; Luan, J. Bending Property and Fracture Behavior of Continuous Glass Fiber-Reinforced PEEK Composites Fabricated by the Wrapped Yarn Method. High Perform. Polym. 2018, 31, 321–330. [Google Scholar] [CrossRef]

- Guo, Q.; Yao, W.; Li, W.; Gupta, N. Constitutive Models for the Structural Analysis of Composite Materials for the Finite Element Analysis: A Review of Recent Practices. Comp. Struct. 2021, 260, 113267. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, Z.; Li, D.; Guo, Z.; Dong, L. Constitutive Modeling for Linear Viscoelastic Fiber-Reinforced Composites. Comp. Struct. 2021, 263, 113679. [Google Scholar] [CrossRef]

- Andraju, L.B.; Raju, G. Continuum and Cohesive Zone Damage Models to Study Intra/Inter-Laminar Failure of Curved Composite Laminates under Four-Point Bending. Comp. Struct. 2020, 253, 112768. [Google Scholar] [CrossRef]

- Pérez, M.A.; Martínez, X.; Oller, S.; Gil, L.; Rastellini, F.; Flores, F. Impact Damage Prediction in Carbon Fiber-Reinforced Laminated Composite Using the Matrix-Reinforced Mixing Theory. Comp. Struct. 2013, 104, 239–248. [Google Scholar] [CrossRef] [Green Version]

- Luccioni, B.M. Constitutive Model For-Reinforced Composite Laminates. J. Appl. Mech. 2006, 73, 901–910. [Google Scholar] [CrossRef]

- Llorca, J.; González, C.; Molina-Aldareguía, J.M.; Lópes, C.S. Multiscale Modeling of Composites: Toward Virtual Testing and Beyond. JOM 2012, 65, 215–225. [Google Scholar] [CrossRef] [Green Version]

- Peng, X.Q.; Cao, J. A Continuum Mechanics-Based Non-Orthogonal Constitutive Model for Woven Composite Fabrics. Comp. Part. A Appl. Sc. Manuf. 2005, 36, 859–874. [Google Scholar] [CrossRef]

- Bochkareva, S.A.; Panin, S.V.; Lyukshin, B.A.; Lyukshin, P.A.; Grishaeva, N.Y.; Matolygina, N.Y.; Aleksenko, V.O. Simulation of Frictional Wear with Account of Temperature for Polymer. Phys. Mesomech. 2020, 23, 147–159. [Google Scholar] [CrossRef]

- Gibson, R.F. Principles of Composite Material Mechanics, 4th ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

| Sample Type | MFI, g/10 min | |

|---|---|---|

| 1 | PEEK powder | 7.92 ± 0.44 |

| 2 | PEEK film/CF | 8.25 ± 0.23 |

| 3 | PI powder | 4.56 ± 0.53 |

| Sample | ||||

|---|---|---|---|---|

| 1 | PEEK powder/CF (0°/0°) | 55.4 ± 2.1 | 443 ± 24 | 0.020 ± 0.005 |

| 2 | PEEK film/CF (0°/0°) | 59.5 ± 3.7 | 422.8 ± 12.5 | 0.034 ± 0.001 |

| Sample | Density, g/cm3 | ||||

|---|---|---|---|---|---|

| 1 | PEEK | 1.30 | 4.2 ± 0.6 | 166.2 ± 6.1 | 0.050 ± 0.005 |

| 2 | PEEK/CF (0°/0°) | 1.54 | 59.5 ± 3.7 | 422.8 ± 12.5 | 0.034 ± 0.001 |

| 3 | PEEK/CF (90°/90°) | 1.51 | 4.1 ± 0.3 | 42.3 ± 6.4 | 0.007 ± 0.004 |

| 4 | PEEK/CF (0°/90°) | 1.46 | 19.8 ± 7.2 | 173.8 ± 26.8 | 0.022 ± 0.001 |

| 5 | PEEK/CF (biaxial) | 1.33 | 27.4 ± 0.3 | 277.2 ± 34.9 | 0.014 ± 0.001 |

| 6 | PI | 1.37 | 2.4 ± 0.4 | 143.3 ± 6.2 | 0.050 ± 0.001 |

| 7 | PI/CF (0°/0°) | 1.40 | 15.0 ± 2.0 | 190.2 ± 18.7 | 0.035 ± 0.001 |

| 8 | PI/CF (90°/90°) | 1.43 | 4.1 ± 0.5 | 30.1 ± 4.1 | 0.010 ± 0.001 |

| 9 | PI/CF (0°/90°) | 1.33 | 3.8 ± 1.1 | 43.0 ± 5.2 | 0.050 ± 0.001 |

| 10 | PI/CF (biaxial) | 1.38 | 10.8 ± 1.1 | 158.4 ± 1.2 | 0.040 ± 0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosmachev, P.V.; Alexenko, V.O.; Bochkareva, S.A.; Panin, S.V. Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement. Polymers 2021, 13, 2268. https://doi.org/10.3390/polym13142268

Kosmachev PV, Alexenko VO, Bochkareva SA, Panin SV. Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement. Polymers. 2021; 13(14):2268. https://doi.org/10.3390/polym13142268

Chicago/Turabian StyleKosmachev, Pavel V, Vladislav O Alexenko, Svetlana A Bochkareva, and Sergey V Panin. 2021. "Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement" Polymers 13, no. 14: 2268. https://doi.org/10.3390/polym13142268

APA StyleKosmachev, P. V., Alexenko, V. O., Bochkareva, S. A., & Panin, S. V. (2021). Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement. Polymers, 13(14), 2268. https://doi.org/10.3390/polym13142268