Synergetic Effects during Co-Pyrolysis of Sheep Manure and Recycled Polyethylene Terephthalate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Thermogravimetric Analysis

2.3. Kinetic Analysis

2.3.1. The Flynn–Wall–Ozawa (FWO) Method

2.3.2. Thermodynamic Parameters

3. Results and Discussion

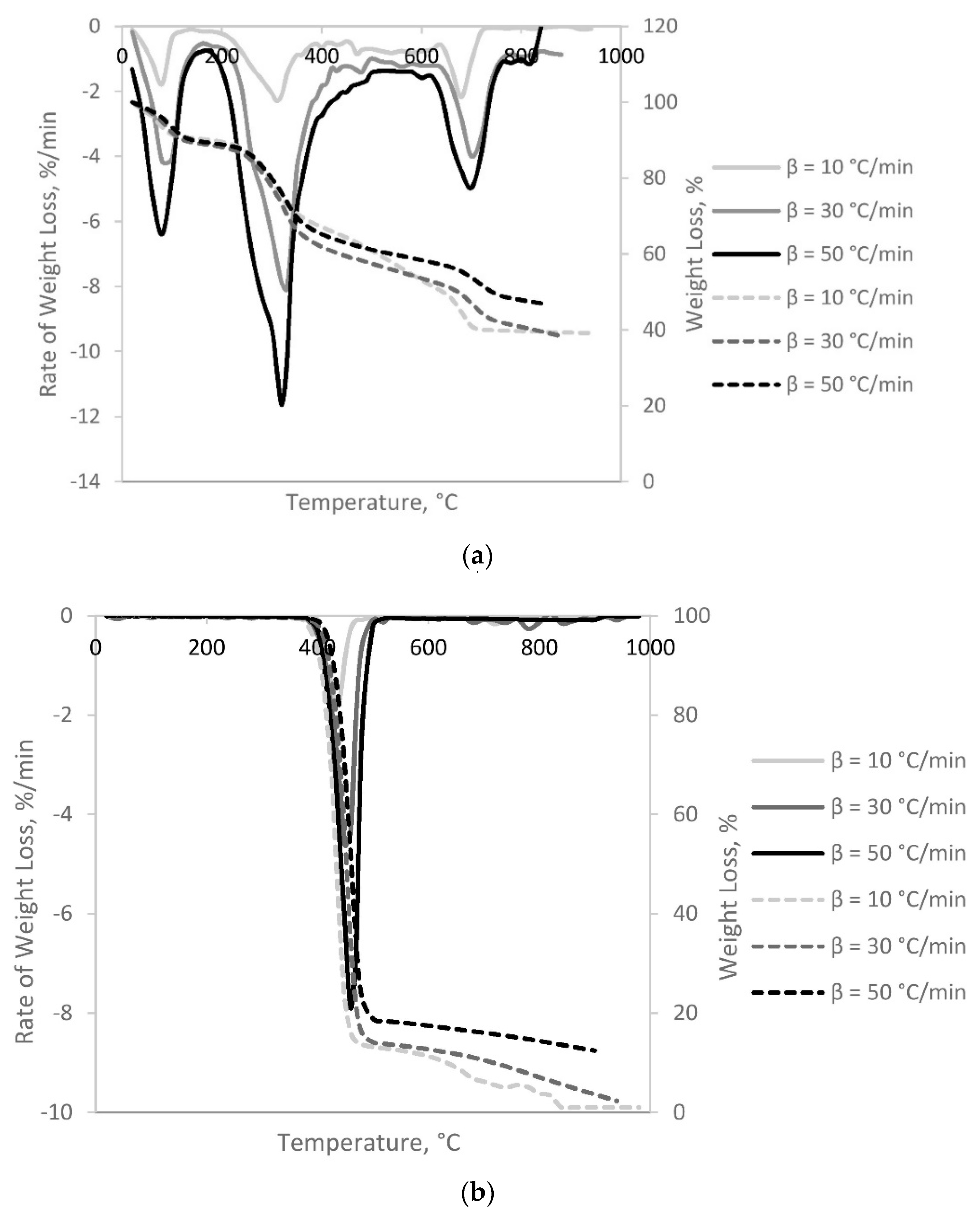

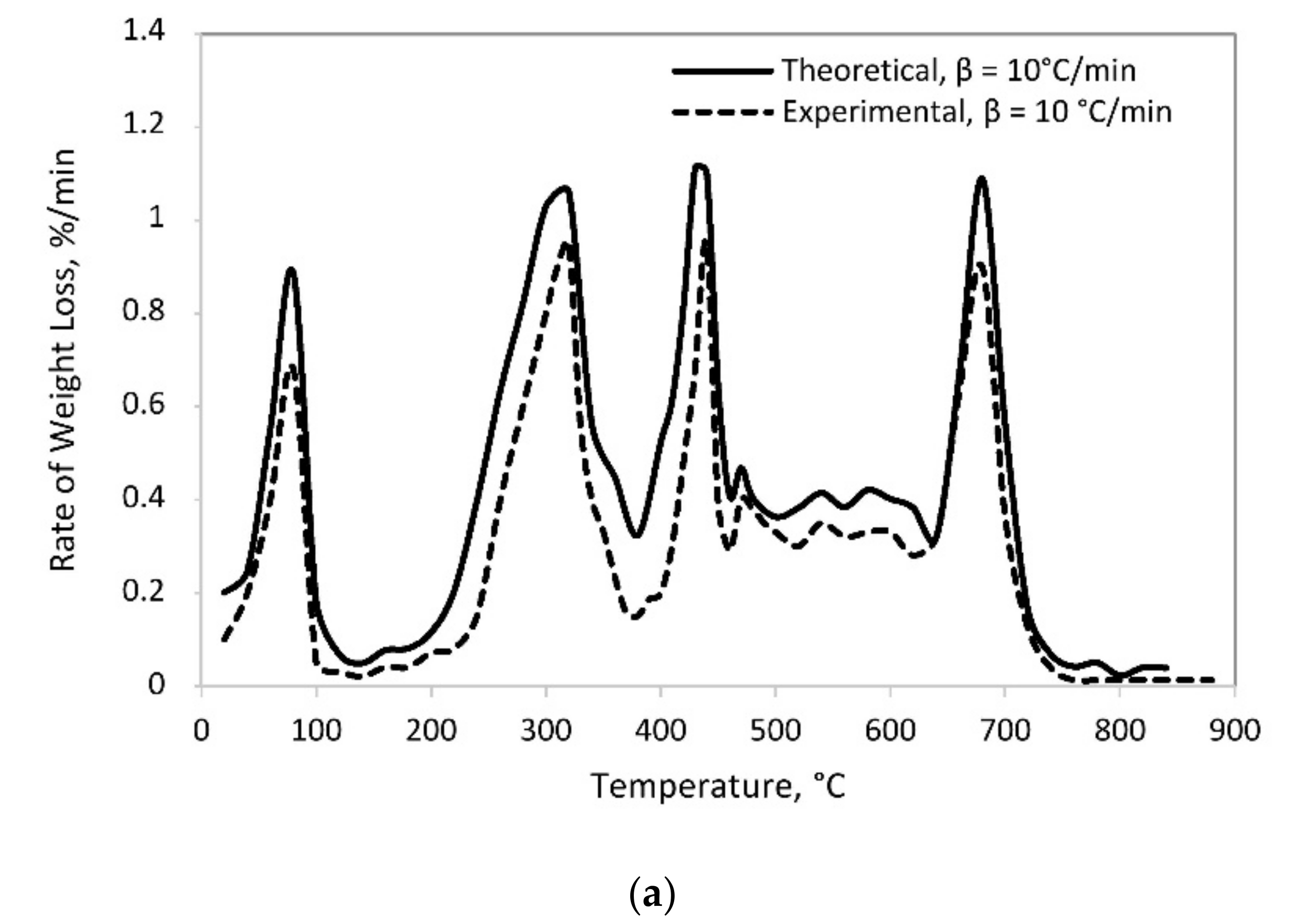

3.1. Pyrolysis and Co-Pyrolysis of SM and PET

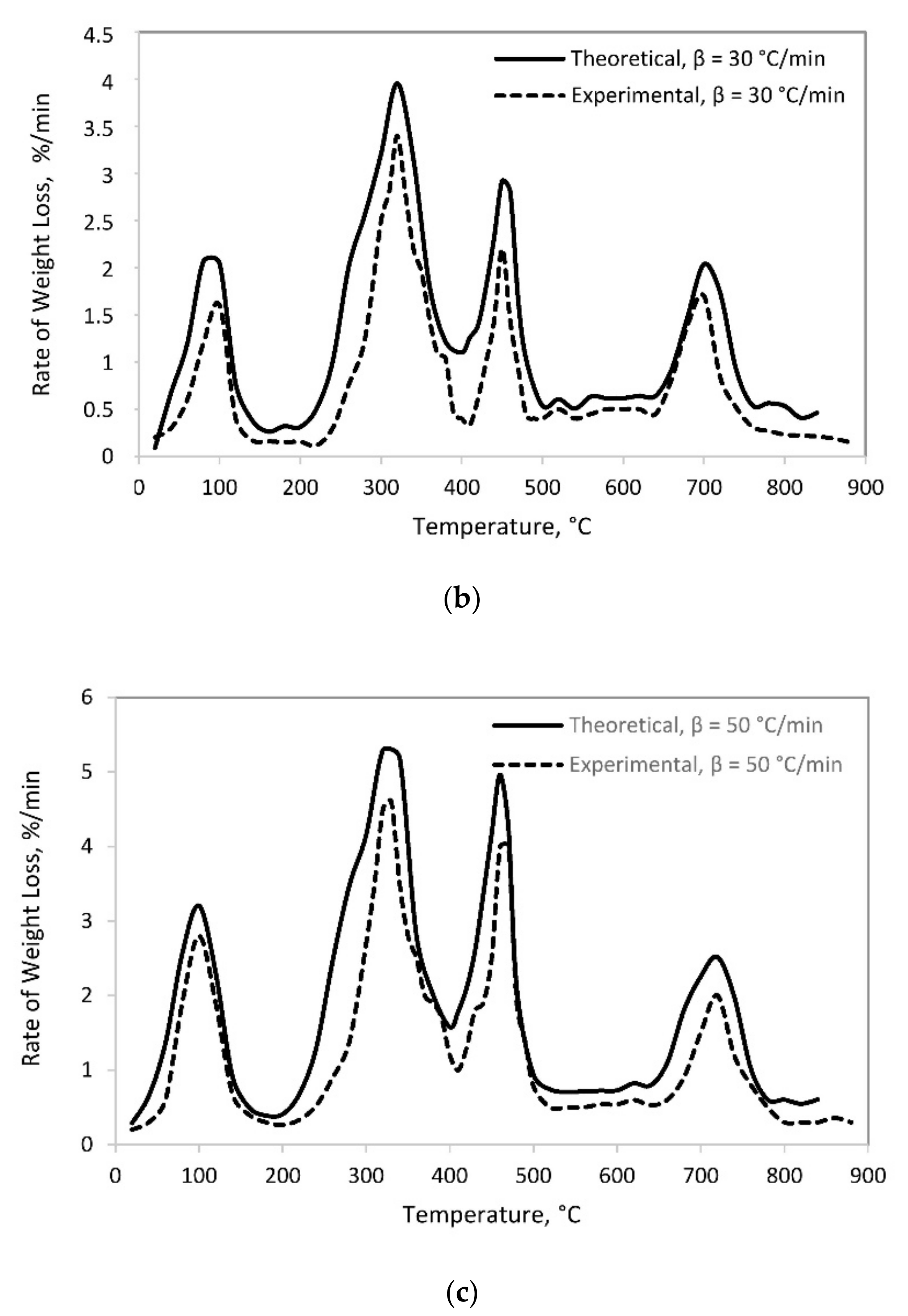

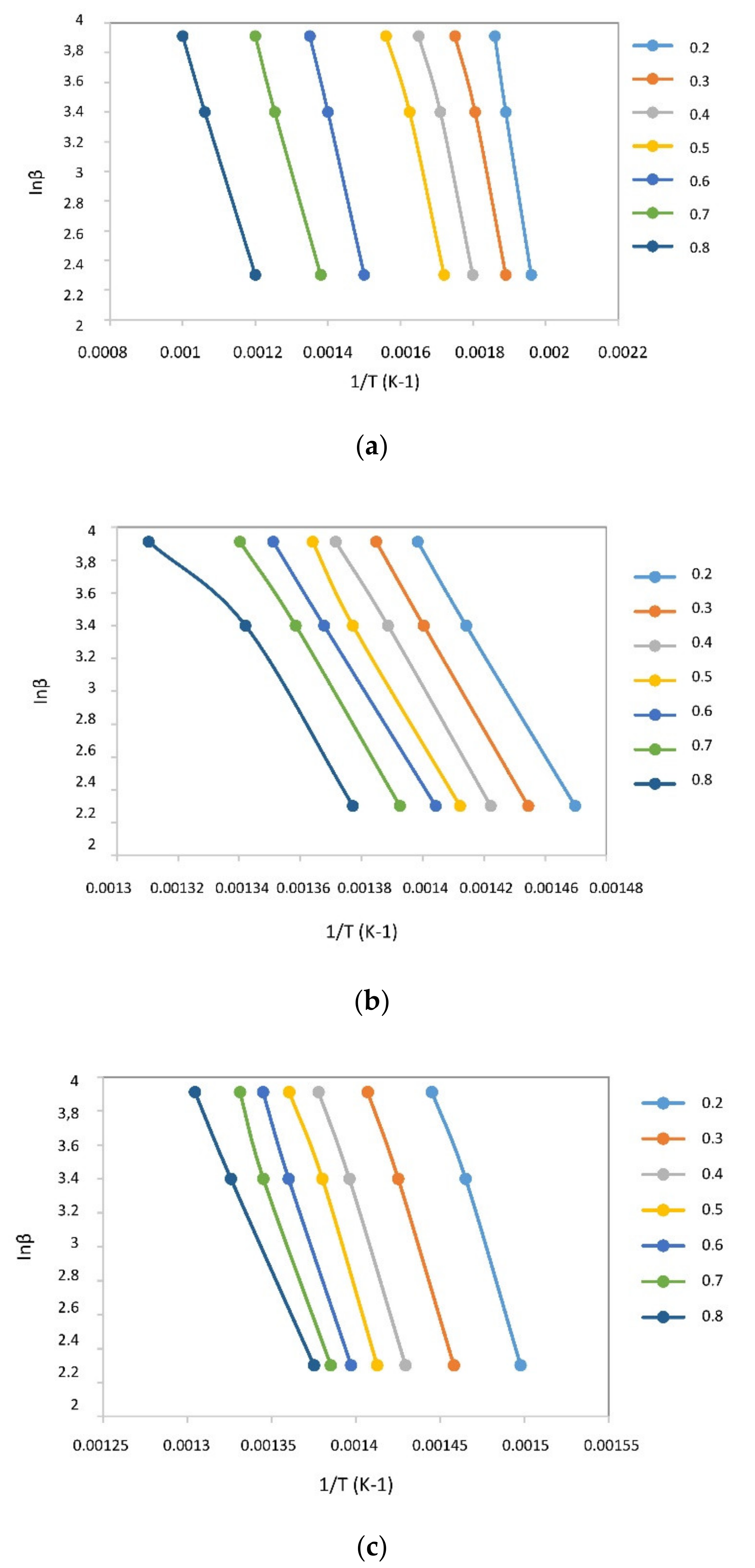

3.2. Kinetic Analysis

4. Conclusions

Funding

Conflicts of Interest

References

- CO2 Emissions from Fuel Combustion: Overview. Statistics Report. International Energy Agency. 2020. Available online: https://www.iea.org/reports/co2-emissions-from-fuel-combustion-overview (accessed on 29 April 2021).

- Bioenergy Annual Report. International Energy Agency. 2020. Available online: https://www.iea.org/reports/bioenergy-power-generation (accessed on 15 June 2021).

- World Energy Outlook, Sustainable Development Scenario. 2020. Available online: https://iea.blob.core.windows.net/assets/dd88335f-91ab-4dbd-8de7-d2dc4fee90e0/WEM_Documentation_WEO2020.pdf (accessed on 15 June 2021).

- Burra, K.G.; Gupta, A.K. Kinetics of synergistic effects in co-pyrolysis of biomass with plastic wastes. Appl. Energy 2018, 220, 408–418. [Google Scholar] [CrossRef]

- Graham, J.P.; Nachman, K.E. Managing Waste from confined animal feeding operations in the United States: The need for sanitary reform. J. Water Health 2010, 8, 646–670. [Google Scholar] [CrossRef] [PubMed]

- Carlin, N.; Annamalai, K.; Sweeten, J.; Mukhtar, S. Thermo-Chemical Conversion Analysis on Dairy Manure-Based Biomass through Direct Combustion. Int. J. Green Energy 2007, 4, 133–159. [Google Scholar] [CrossRef]

- Plastics-the Facts 2020, Plastics Europe, Association of Plastics Manufacturers. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 15 June 2021).

- Buekens, A. Introduction to Feedstock Recycling of Plastics; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2006; pp. 1–41. [Google Scholar]

- Lazarevic, D.; Aoustin, E.; Buclet, N.; Brandt, N. Plastic waste management in the context of a European recycling society: Comparing results and uncertainties in a life cycle perspective. Resour. Conserv. Recycl. 2010, 55, 246–259. [Google Scholar] [CrossRef]

- Kukreja, R. Advantages and disadvantages of recycling. Conserve Energy Future. 2009. Available online: https://www.conserve-energy-future.com/advantages-and-disadvantages-of-recycling.php (accessed on 17 July 2021).

- Das, P.; Tiwari, P. The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel. Waste Manag. 2018, 79, 615–624. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Xue, Y.; Kelkar, A.; Bai, X. Catalytic co-pyrolysis of biomass and polyethylene in a tandem micropyrolyzer. Fuel 2016, 166, 227–236. [Google Scholar] [CrossRef]

- Oyedun, A.O.; Tee, C.Z.; Hanson, S.; Hui, C.W. Thermogravimetric analysis of the pyrolysis characteristics and kinetics of plastics and biomass blends. Fuel Process. Technol. 2014, 128, 471–481. [Google Scholar] [CrossRef]

- Kiran, N.; Ekinci, E.; Snape, C.E. Recyling of plastic wastes via pyrolysis. Resour. Conserv. Recycl. 2000, 29, 273–283. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass pyrolysis technologies for value-added products: a state-of-the-art review. Environ. Dev. Sustain. 2021. [Google Scholar] [CrossRef]

- Lee, X.J.; Lee, L.Y.; Gan, S.; Thangalazhy-Gopakumar, S.; Ng, H.K. Biochar potential evaluation of palm oil wastes through slow pyrolysis: Thermochemical characterization and pyrolytic kinetic studies. Bioresour. Technol. 2017, 236, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Amutio, M.; Lopez, G.; Aguado, R.; Bilbao, J.; Olazar, M. Biomass oxidative flash pyrolysis: Autothermal operation, yields and product properties. Energy Fuels 2012, 26, 1353–1362. [Google Scholar] [CrossRef]

- Caballero, J.A.; Conesa, J.A.; Font, R.; Marcilla, A. Pyrolysis kinetics of almond shells and olive stones considering their organic fractions. J. Anal. Appl. Pyrol. 1997, 42, 159–175. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M.; Sharma, D.K. Coprocessing of petroleum vacuum residue with plastics, coal, and biomass and its synergistic effects. Energy Fuels 2007, 21, 891–897. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Zhu, L.; Zhu, X.; Qian, M.; Yadavalli, G.; Wu, J.; Chen, S. Thermal behavior and kinetic study for catalytic co-pyrolysis of biomass with plastics. Bioresour. Technol. 2016, 220, 233–238. [Google Scholar] [CrossRef]

- Aboulkas, A.; El harfi, K.; El bouadili, A.; Nadifiyine, M.; Benchanaa, M.; Mokhlisse, A. Pyrolysis kinetics of olive residue/plastic mixtures by non-isothermal thermogravimetry. Fuel Process. Technol. 2009, 90, 722–728. [Google Scholar] [CrossRef]

- Alam, M.; Bhavanam, A.; Jana, A.; Viroja, J.K.S.; Peela, N.P. Co-pyrolysis of bamboo sawdust and plastic: Synergistic effects and kinetics. Renew. Energy 2020, 149, 1133–1145. [Google Scholar] [CrossRef]

- Uzoejinwa, B.B.; He, X.; Wang, S.; Abomohra, A.E.F.; Hu, Y.; Wang, Q. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide. Energy Convers. Manag. 2018, 163, 468–492. [Google Scholar] [CrossRef]

- Cai, J.; Wang, Y.; Zhou, L.; Huang, Q. Thermogravimetric analysis and kinetics of coal/plastic blends during co-pyrolysis in nitrogen atmosphere. Fuel Process. Technol. 2008, 89, 21–27. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, T.; Huang, Q. Co-pyrolysis characteristics and kinetics of coal and plastic blends. Energy Convers. Manag. 2009, 50, 705–710. [Google Scholar] [CrossRef]

- Flynn, J.H.; Wall, L.A. General treatment of the thermogravimetry of polymers. J. Res. Natl. Bur. Stand. 1966, 70, 487–523. [Google Scholar] [CrossRef] [PubMed]

- Ozawa, T. A new method of analyzing thermogravimetric data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Yang, R.; Cheng, Z.; Yan, B.; Ma, W. Nitric oxide formation during corn straw/sewage sludge co-pyrolysis/gasification. J Clean. Prod. 2018, 197, 97–105. [Google Scholar] [CrossRef]

- Kai, X.; Yang, T.; Shen, S.; Li, R. TG-FTIR-MS study of synergistic effects during co-pyrolysis of corn stalk and high-density polyethylene (HDPE). Energy Convers. Manag. 2019, 181, 202–213. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sust. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Valorization of packaging plastic waste by slow pyrolysis. Resour. Conserv. Recycl. 2018, 128, 69–77. [Google Scholar] [CrossRef]

- Yu, X.; Wang, S.; Zhang, J. Preparation of high adsorption performance activated carbon by pyrolysis of waste polyester. J. Mater. Sci. 2018, 53, 5458–5466. [Google Scholar] [CrossRef]

- Chandrasekaran, A.; Ramachandran, S.; Subbiah, S. Determination of kinetic parameters in the pyrolysis operation and thermal behavior of Prosopis juliflora using thermogravimetric analysis. Bioresour. Technol. 2017, 223, 413–422. [Google Scholar] [CrossRef] [PubMed]

- Samuelsson, L.N.; Babler, M.U.; Moriana, R. A single model-free rate expression describing both non-isothermal and isothermal pyrolysis of Norway Spruce. Fuel 2015, 161, 59–67. [Google Scholar] [CrossRef]

- Akyürek, Z. Sustainable Valorization of Animal Manure and Recycled Polyester: Co-pyrolysis Synergy. Sustainability 2019, 11, 2280. [Google Scholar] [CrossRef] [Green Version]

- Mishra, R.K.; Sahoo, A.; Mohanty, K. Pyrolysis kinetics and synergistic effect in co-pyrolysis of Samanea saman seeds and polyethylene terephthalate using thermogravimetric analyser. Bioresour. Technol. 2019, 289, 121608. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohanty, K. Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 2018, 251, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Ma, X.; Li, L. The synergistic effect of co-pyrolysis of oil shale and microalgae to produce syngas. J. Energy Inst. 2016, 89, 447–455. [Google Scholar] [CrossRef]

- Xu, X.; Pan, R.; Chen, R. Combustion Characteristics, Kinetics, and Thermodynamics of Pine Wood through Thermogravimetric Analysis. Appl. Biochem. Biotechnol. 2021, 193, 1427–1446. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; He, T.; Cao, H.; Yuan, Q. Cattle manure pyrolysis process: Kinetic and thermodynamic analysis with isoconversional methods. Renew. Energy 2017, 107, 489–496. [Google Scholar] [CrossRef]

- Mortari, D.A.; Torquato, L.D.M.; Crespi, M.S.; Crnkovic, P.M. Co-firing of blends of sugarcane bagasse and coal. J. Therm. Anal. Calorim. 2018, 132, 1333–1345. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.S.; Man, Z.; Bustam, M.A.; Kait, C.F.; Ullah, Z.; Nasrullah, A.; Khan, M.I.; Gonfa, G.; Ahmad, P.; Muhammad, N. Kinetics and thermodynamic parameters of ionic liquid pretreated rubber wood biomass. J. Mol. Liq. 2016, 223, 754–762. [Google Scholar] [CrossRef]

- Mehmood, M.A.; Ye, G.; Luo, H.; Liu, C.; Malik, S.; Afzal, I.; Xu, J.; Ahmad, M.S. Pyrolysis and kinetic analyses of Camel grass (Cymbopogon schoenanthus) for bioenergy. Bioresour. Technol. 2017, 228, 18–24. [Google Scholar] [CrossRef]

- Turmanova, S.C.; Genieva, S.; Dimitrova, A.; Vlaev, L. Non-isothermal degradation kinetics of filled with rise husk ash polypropene composites. Express Polym. Lett. 2008, 2, 133–146. [Google Scholar] [CrossRef]

- Ruvolo-Filho, A.; Curti, P.S. Chemical kinetic model and thermodynamic compensation effect of alkaline hydrolysis of waste poly(ethylene terepftalate) in nonaqueous ethylene glycol solution. Ind. Eng. Chem. Res. 2006, 45, 7985–7996. [Google Scholar] [CrossRef]

| Proximate Analysis (As Received Basis) | ||

|---|---|---|

| SM | PET | |

| Moisture, % | 19.42 | 0.65 |

| Volatile Matter, % | 38.78 | 86.12 |

| Fixed Carbon, % | 12.88 | 13.19 |

| Ash, % | 28.92 | 0.04 |

| Ultimate Analysis (Dry Basis) | ||

| C, % | 22.50 | 63.5 |

| H, % | 3.48 | 4.7 |

| N, % | 3.09 | 0.05 |

| S, % | 0.50 | 0.03 |

| O, % (by difference) | 32.73 | 31.68 |

| LHV (kJ/kg) | 13.55 | 20.32 |

| SM | PET | Blend | |||||||

|---|---|---|---|---|---|---|---|---|---|

| β (°C/min) | 10 | 30 | 50 | 10 | 30 | 50 | 10 | 30 | 50 |

| Ti (°C) | 210.65 | 217.49 | 229.72 | 386.05 | 403.50 | 409.86 | 370.85 | 390.07 | 400.15 |

| Tmax(°C) | 314.94 | 329.05 | 336.20 | 435.70 | 459.80 | 465.91 | 430.50 | 450.46 | 470.50 |

| Tf (°C) | 486.63 | 502.36 | 536.29 | 469.05 | 495.86 | 523.45 | 489.50 | 540.96 | 560.00 |

| Total Weight Loss, % | 61.83 | 60.13 | 53.45 | 98.63 | 93.50 | 91.32 | 77.94 | 74.77 | 73.56 |

| α | Ea (kJ/mol) | A (s−1) | R2 | ΔH (kJ/mol) | ΔG (kJ/mol) | ΔS (J/mol K) |

|---|---|---|---|---|---|---|

| SM | ||||||

| 0.2 | 126.64 | 1.30 × 10+09 | 0.9915 | 121.75 | 171.38 | −84.39 |

| 0.3 | 91.83 | 7.63 × 10+05 | 0.9957 | 86.94 | 172.95 | −146.26 |

| 0.4 | 86.29 | 2.31 × 10+05 | 0.9932 | 81.40 | 173.26 | −156.19 |

| 0.5 | 80.37 | 6.41 × 10+04 | 0.9990 | 75.48 | 173.60 | −166.86 |

| 0.6 | 85.08 | 1.78 × 10+05 | 0.9965 | 80.19 | 173.32 | −158.36 |

| 0.7 | 70.30 | 7.15 × 10+03 | 0.9955 | 65.41 | 174.26 | −185.09 |

| 0.8 | 63.39 | 1.57 × 10+03 | 0.9941 | 58.50 | 174.76 | −197.70 |

| Average | 86.27 | 81.38 | 173.36 | |||

| PET | ||||||

| 0.2 | 246.50 | 1.44 × 10+16 | 0.9990 | 240.61 | 205.95 | 48.90 |

| 0.3 | 255.84 | 7.28 × 10+16 | 1.0000 | 249.94 | 205.73 | 62.37 |

| 0.4 | 251.89 | 3.67 × 10+16 | 0.9975 | 246.00 | 205.82 | 56.68 |

| 0.5 | 260.83 | 1.73 × 10+17 | 0.9978 | 254.94 | 205.62 | 69.58 |

| 0.6 | 239.19 | 4.04 × 10+15 | 1.0000 | 233.30 | 206.13 | 38.34 |

| 0.7 | 244.90 | 1.09 × 10+16 | 0.9947 | 239.01 | 205.99 | 46.58 |

| 0.8 | 191.53 | 9.94 × 10+11 | 0.9752 | 185.64 | 207.44 | −30.75 |

| Average | 241.53 | 235.63 | 206.09 | |||

| Blend (1:1 wt%) | ||||||

| 0.2 | 244.14 | 2.47 × 10+16 | 0.9980 | 238.37 | 201.21 | 53.57 |

| 0.3 | 250.40 | 7.50 × 10+16 | 0.9987 | 244.63 | 201.07 | 62.81 |

| 0.4 | 248.42 | 5.28 × 10+16 | 0.9985 | 242.66 | 201.11 | 59.89 |

| 0.5 | 245.89 | 3.37 × 10+16 | 0.9977 | 240.12 | 201.17 | 56.15 |

| 0.6 | 241.63 | 1.58 × 10+16 | 0.9965 | 235.86 | 201.27 | 49.86 |

| 0.7 | 231.66 | 2.69 × 10+15 | 0.9973 | 225.89 | 201.52 | 35.15 |

| 0.8 | 179.44 | 2.44 × 10+11 | 0.9901 | 173.67 | 202.99 | −42.26 |

| Average | 234.51 | 228.74 | 201.48 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akyürek, Z. Synergetic Effects during Co-Pyrolysis of Sheep Manure and Recycled Polyethylene Terephthalate. Polymers 2021, 13, 2363. https://doi.org/10.3390/polym13142363

Akyürek Z. Synergetic Effects during Co-Pyrolysis of Sheep Manure and Recycled Polyethylene Terephthalate. Polymers. 2021; 13(14):2363. https://doi.org/10.3390/polym13142363

Chicago/Turabian StyleAkyürek, Zuhal. 2021. "Synergetic Effects during Co-Pyrolysis of Sheep Manure and Recycled Polyethylene Terephthalate" Polymers 13, no. 14: 2363. https://doi.org/10.3390/polym13142363

APA StyleAkyürek, Z. (2021). Synergetic Effects during Co-Pyrolysis of Sheep Manure and Recycled Polyethylene Terephthalate. Polymers, 13(14), 2363. https://doi.org/10.3390/polym13142363