Improved Mechanical, Thermal, and Hydrophobic Properties of PLA Modified with Alkoxysilanes by Reactive Extrusion Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Sample Preparation

2.2.1. Reactive Extrusion

2.2.2. Flat Tape Extrusion

2.2.3. Characterization Methods

3. Results

3.1. PLA/Alkoxysilanes Reaction

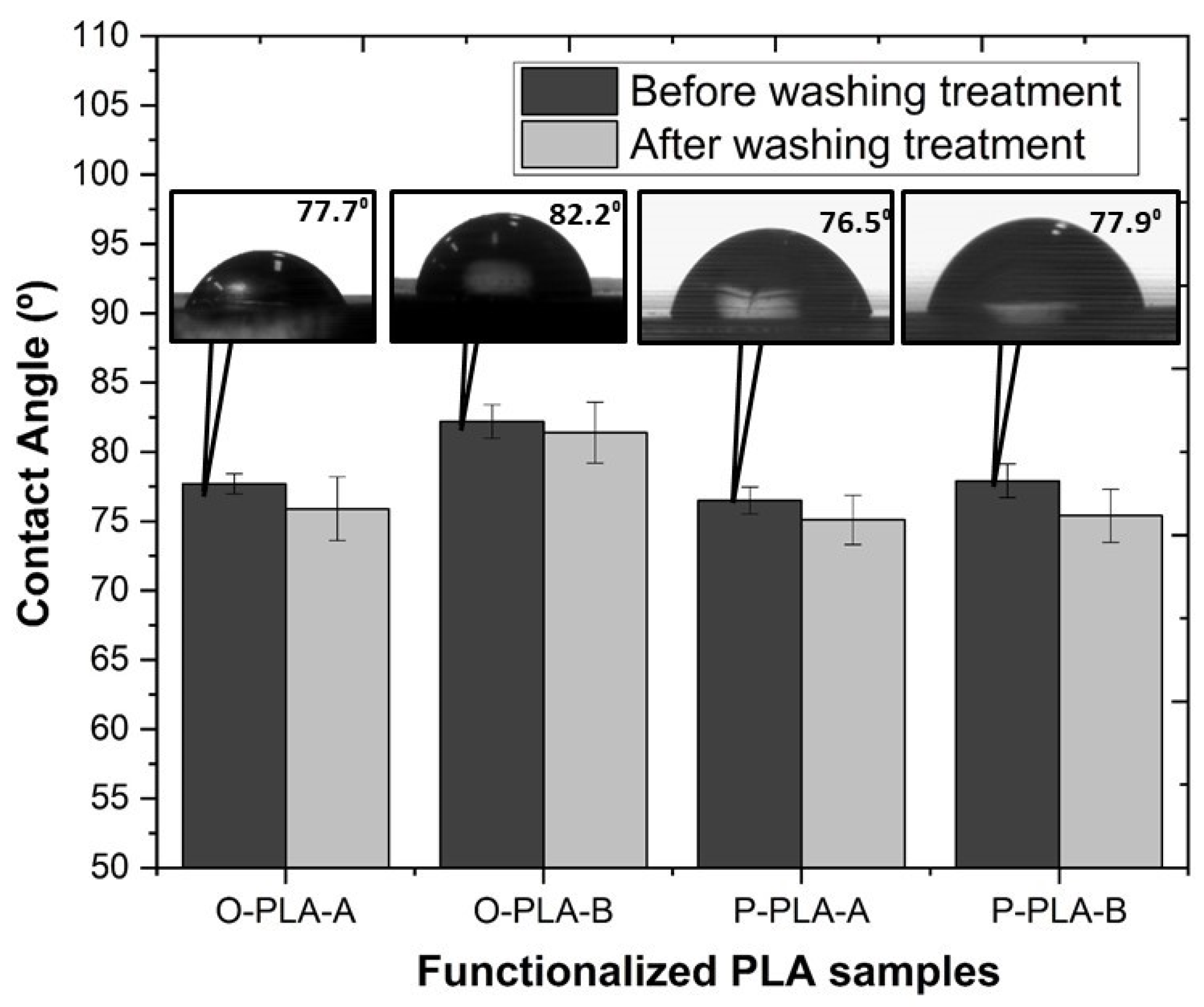

3.2. Characterization of the Functionalized Polymers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe and European Association of Plastics Recycling and Recovery Organisations (EPRO). 2019. Available online: https://www.plasticseurope.org/application/files/9715/7129/9584/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 30 April 2021).

- European Environment Agency. The Plastic Waste Trade in the Circular Economy. 2019. Available online: https://www.eea.europa.eu/themes/waste/resource-efficiency/the-plastic-waste-trade-in (accessed on 31 May 2021).

- Sintim, H.; Bandopadhyay, S.; English, M.E.; Bary, A.I.; DeBruyn, J.M.; Schaeffer, S.M.; Miles, C.A.; Reganold, J.P.; Flury, M. Impacts of biodegradable plastic mulches on soil health. Agric. Ecosyst. Environ. 2018, 273, 36–49. [Google Scholar] [CrossRef]

- Haider, T.; Völker, C.; Kramm, J.; Landfester, K. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2018, 58, 50–62. [Google Scholar] [CrossRef] [PubMed]

- Formela, K.; Zedler, L.; Hejna, A.; Tercjak, A. Reactive Extrusion of Bio-Based Polymer Blends and Composites. Curr. Trends Future Dev. 2018, 12, 24–57. [Google Scholar]

- The Global Bio-Based Polymer Market 2019—A Revised View on a Turbulent and Growing Market. Bio-Based News. 2020. Available online: http://news.bio-based.eu/the-global-bio-based-polymer-market-2019-a-revised-view-on-a-turbulent-and-growing-market/ (accessed on 28 June 2021).

- European Bioplastics, Nova-Institute. 2019. Available online: https://www.european-bioplastics.org/market/ (accessed on 30 April 2021).

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef] [PubMed]

- Lunt, J. Large-scale production, properties and commercial applications of polylactic acid polymers. Polym. Degrad. Stabil. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- Bio-Sourced Biodegradable PLA Fibres Will Replace Polyester in Textiles. Bioplastics News. 2017. Available online: https://bioplasticsnews.com/2017/08/04/bio-sourced-biodegradable-pla-fibres-polyester-textiles/ (accessed on 28 June 2021).

- Radicci Company. Available online: https://www.radicigroup.com/en/products/fibres-and-nw/poy-starlight/biopolymer-cornleaf (accessed on 31 May 2021).

- Avinc, O.; Khoddami, A. Overview of Poly(Lactic Acid) (PLA) Fibre: Part I: Production, Properties, Performance, Environmental Impact, and End-Use Applications of Poly(Lactic Acid). Fibres 2009, 41, 391–401. [Google Scholar] [CrossRef]

- Zhang, J.F.; Sun, X. Poly(Lactic Acid)-Based Bioplastics; Woodhead Publishing: Cambridge, UK, 2005; pp. 251–288. [Google Scholar]

- Farrington, D.W.; Lunt, J.; Davies, S.; Blackburn, R.S. Polylactic acid fibres. In Biodegradable and Sustainable Fibres; Blackburn, R.S., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2005. [Google Scholar]

- Auras, R.A.; Lim, L.T.; Selke, S.E.; Tsuji, H. Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications. Part IV: Degradation and Environmental Issues; John Wiley Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Karst, D.; Hain, M.; Yang, Y. Care of PLA Textiles. Res. J. Text. Apparel 2009, 13, 69. [Google Scholar] [CrossRef]

- Avinc, O.; Wilding, M.; Phillips, D. Investigation of the influence of different commercial softeners on the stability of poly(lactic acid) fabrics during storage. Polym. Degrad. Stab. 2010, 95, 214. [Google Scholar] [CrossRef]

- Ma, M.; Zhou, W. Improving the hydrolysis resistance of poly(lactic acid) fiber by hydrophobic finishing. Ind. Eng. Chem. Res. 2015, 54, 2599–2605. [Google Scholar] [CrossRef]

- Patankar, N.A. Mimicking the Lotus Effect: Influence of double roughness structures and slender pillars. Langmuir 2004, 20, 8209–8213. [Google Scholar] [CrossRef]

- eCoatsolutions Company. Available online: https://www.eco-coatsolutions.com/greenhouse--solar-series-self-cleaning-nano-ceramic-coatings.html (accessed on 31 May 2021).

- Kaseema, M.; Fatimah, S.; Nashrah, N.; Gun Ko, Y. Recent progress in surface modification of metals coated by plasma electrolytic oxidation: Principle, structure, and performance. Prog. Mater. Sci. 2021, 117, 100735. [Google Scholar] [CrossRef]

- Hamad, K.; Gun Ko, Y.; Kaseem, M.; Deri, F. Effect of acrylonitrile–butadiene–styrene on flow behavior and mechanical properties of polylactic acid/low density polyethylene blend. Asia Pac. J. Chem. Eng. 2014, 9, 349–353. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Costas, A.V.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Giri, P.; Tambe, C.; Narayan, R. Using Reactive Extrusion to Manufacture Greener Products: From Laboratory Fundamentals to Commercial Scale. In Biomass Extrusion and Reaction Technologies: Principles to Practices and Future Potential; American Chemical Society: Washington, DC, USA, 2018; Volume 1304, pp. 1–23. [Google Scholar]

- Marinho, J.F.; Braga, N.F.; Krohn, A.; Myata, F.S.; Silveira, L.H.; Cabral Neto, A.; Fechine, G.J.M. Melt Processing of Polymer Biocomposites. Polímeros 2015, 25, 133–136. [Google Scholar] [CrossRef][Green Version]

- Formela, K.; Hejna, A.; Haponiuk, J.; Tercjak, A. In Situ Processing of Biocomposites via Reactive Extrusion; Ray, D., Ed.; Woodhead Publishing: Cambridge, UK, 2017; Volume 8, pp. 195–246. [Google Scholar]

- Liao, J.; Brosse, N.; Hoppe, S.; Du, G.; Zhou, X.; Pizzi, A. One-step compatibilization of poly(lactic acid) and tannin via reactive extrusion. Mater. Des. 2020, 191, 108603. [Google Scholar] [CrossRef]

- Nahum, T.; Dodiuk, H.; Dotan, A.; Kenig, S.; Lellouche, J.P. Superhydrophobic durable coating based on UV-photoreactive silica nanoparticles. J. Appl. Polym. Sci. 2014, 131, 41122. [Google Scholar] [CrossRef]

- Kchaou, M.; Torres, E.; Ylla, N.; Colella, M.; Da Cruz-Boisson, F.; Cassagnau, P.; Espuche, E.; Bounor-Legaré, V. Enhanced Hydrophobicity and Reduced Water Transport Properties in Alkylalkoxysilane Modified Poly(Butylene Terephthalate) Using Reactive Extrusion. Mater. Chem. Phys. 2019, 223, 597–606. [Google Scholar] [CrossRef]

- Tam, J.; Feng, B.; Ikuhara, Y.; Ohta, H.; Erb, U. Crystallographic orientation—Surface energy—Wetting property relationships of rare earth oxides. J. Mater. Chem. A 2018, 38, 1–6. [Google Scholar] [CrossRef]

- Schondelmaier, D.; Cramm, S.; Klingeler, R.; Morenzin, J.; Zilkens, C.; Eberhardt, W. Orientation and self-assembly of hydrophobic fluoroalkylsilanes. Langmuir 2002, 18, 6242–6245. [Google Scholar] [CrossRef]

- Vink, E.H.T.; Rábago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWorksTM polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Gogolewski, S.; Pennings, A. Resorbable materials of poly(L-lactide). II. Fibers spun from solutions of poly(L-lactide) in good solvents. J. Appl. Polym. Sci. 1983, 28, 1045–1061. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of Miscibility on Mechanical and Thermal Properties of Poly(Lactic Acid)/Polycaprolactone Blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane Coupling Agents used for Natural Fiber/Polymer Composites: A Review. Compos. Part A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Issa, A.A.; Luyt, A.S. Kinetics of Alkoxysilanes and Organoalkoxysilanes Polymerization: A Review. Polymers 2019, 11, 537. [Google Scholar] [CrossRef]

- Chumeka, W.; Pasetto, P.; Pilard, J.-F. Bio-based triblock copolymers from natural rubber and poly(lactic acid): Synthesis and application in polymer blending. Polymer 2014, 55, 4478–4487. [Google Scholar] [CrossRef]

- He, Z.; Jiang, L.; Chuan, Y.; Li, H.; Yuan, M. Ring-Opening Polymerization of L-Lactic Acid O-Carboxyanhydrides Initiated by Alkoxy Rare Earth Compounds. Molecules 2013, 18, 12768–12776. [Google Scholar] [CrossRef]

- Kricheldorf, A.R.; Hachmann-Thiessen, H.; Schwarz, G. Telechelic and Star-Shaped Poly(L-lactide)s by Means of Bismuth(III) Acetate as Initiator. Biomacromolecules 2004, 5, 492–496. [Google Scholar] [CrossRef] [PubMed]

- Popelka, S.; Rypácek, F. Synthesis of polylactide with thiol end groups. Collect. Czech. Chem. Commun. 2003, 68, 1131–1140. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Taubner, V.; Shishoo, R. Influence of processing parameters on the degradation of poly(L-lactide) during extrusion. J. Appl. Polym. Sci. 2001, 79, 2128–2135. [Google Scholar] [CrossRef]

- Meng, X.; Nguyen, N.; Tekinalp, H.; Lara-Curzio, E.; Ozcan, S. Supertough PLA-silane nanohybrids by in situ condensation and grafting. ACS Sustain. Chem. Eng. 2018, 6, 1289–1298. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Tsuji, H.; Noda, I.; Ozaki, Y. Structural Changes and Crystallization Dynamics of Poly(l-lactide) during the Cold-Crystallization Process Investigated by Infrared and Two-Dimensional Infrared Correlation Spectroscopy. Macromolecules 2004, 37, 6433–6439. [Google Scholar] [CrossRef]

- Xu, R.; Xie, J.; Lei, C. Influence of Melt-Draw Ratio on the Crystalline Behaviour of a Polylactic Acid Cast Film with a Chi Structure. RSC Adv. 2017, 7, 39914–39921. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Mallegni, N.; Rizzo, S.; Cinelli, P. Improved Impact Properties in Poly(lactic acid) (PLA) Blends Containing Cellulose Acetate (CA) Prepared by Reactive Extrusion. Materials 2019, 12, 270. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.Q.; Qu, J.P. Mechanical and rheological properties of epoxidized soybean oil plasticized poly (lactic acid). J. Appl. Polym. Sci. 2009, 112, 3185–3191. [Google Scholar] [CrossRef]

- Lee, J.C.; Choi, M.-C.; Choi, D.-H.; Ha, C.-S. Toughness Enhancement of Poly(Lactic Acid) through Hybridisation with Epoxide-Functionalized Silane via Reactive Extrusion. Polym. Degrad. Stab. 2019, 160, 195–202. [Google Scholar] [CrossRef]

- Ku Marsilla, K.I.; Verbeek, C.J.R. Modification of poly(lactic acid) using itaconic anhydride by reactive extrusion. Eur. Polym. J. 2015, 67, 213–223. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Gil-Castell, O.; Badia, J.; Kittikorn, T.; Strömberg, E.; Martínez-Felipe, A.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Hydrothermal ageing of polylactide/sisal biocomposites. Studies of water absorption behaviour and Physico-Chemical performance. Polym. Degrad. Stab. 2014, 108, 212–222. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Ogami, A.; Okamoto, M.; Ueda, K. New Polylactide/Layered Silicate Nanocomposite: Nanoscale Control Over Multiple Properties. Macromol. Rapid Commun. 2002, 23, 943–947. [Google Scholar] [CrossRef]

- Balart, J.F.; Montanes, N.; Fombuena, V.; Boronat, T.; Sánchez-Nacher, L. Disintegration in Compost Conditions and Water Uptake of Green Composites from Poly(Lactic Acid) and Hazelnut Shell Flour. J. Polym. Environ. 2017, 26, 701–715. [Google Scholar] [CrossRef]

- Dominguez-Candela, I.; Ferri, J.M.; Cardona, S.C.; Lora, J.; Fombuena, V. Dual Plasticizer/Thermal Stabilizer Effect of Epoxidized Chia Seed Oil (Salvia hispanica L.) to Improve Ductility and Thermal Properties of Poly(Lactic Acid). Polymers 2021, 13, 1283. [Google Scholar] [CrossRef]

- Garlotta, D.A. Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stabil. 2012, 10, 1898–1914. [Google Scholar] [CrossRef]

- McNeill, I.C.; Leiper, H.A. Degradation studies of some polyesters and polycarbonates. 1. Polylactide: Degradation under isothermal conditions, thermal degradation mechanism and photolysis of the polymer. Polym. Degrad. Stabil. 1985, 11, 309–326. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, M.; Ju, Z.; Tam, P.Y.; Hua, T.; Younas, M.W.; Kamrul, H.; Hu, H. Poly(lactic acid) fibers, yarns and fabrics: Manufacturing, properties and applications. Text. Res. J. 2020, 91, 1–29. [Google Scholar]

- Liv, S.; Tan, H.; Gu, J.; Zhang, Y. Silane Modified Wood Flour Blended with Poly(Lactic Acid) and Its Effects on Composite Performance. Bioresources 2015, 10, 5426–5439. [Google Scholar] [CrossRef]

- Jordá-Vilaplana, A.; Fombuena, V.; García-García, D.; Samper, M.D.; Sánchez-Nácher, L. Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment. Eur. Polym. J. 2014, 58, 23–33. [Google Scholar] [CrossRef]

- Fombuena, V.; Balart, J.; Boronat, T.; Sánchez-Nácher, L.; Garcia-Sanoguera, D. Improving mechanical performance of thermoplastic adhesion joints by atmospheric plasma. Mater. Des. 2013, 47, 49–56. [Google Scholar] [CrossRef]

| Sample | Functional Molecule (R’) | Concentration (wt%) | Molar Concentration (mol/h) |

|---|---|---|---|

| PLA (control) | ------- | ------- | 0.031 |

| O-PLA-A | Oct-Si(OEt)3 | 1.5 | 0.167 |

| O-PLA-B | Oct-Si(OEt)3 | 3.0 | 0.337 |

| P-PLA-A | Ph-Si(OEt)3 | 1.3 | 0.167 |

| P-PLA-B | Ph-Si(OEt)3 | 2.7 | 0.337 |

| Sample | Vgodet1 (m/min) | Vgodet4 (m/min) | Draw Ratio (DR) | Dimensions (Width × Thickness, mm) |

|---|---|---|---|---|

| PLA | 10 | 45 | 4.5 | 2.70 × 0.14 |

| O-PLA-A | 10 | 55 | 5.5 | 2.34 × 0.13 |

| O-PLA-B | 10 | 66 | 6.6 | 2.40 × 0.14 |

| P-PLA-A | 10 | 55 | 5.5 | 2.32 × 0.13 |

| P-PLA-B | 10 | 62 | 6.2 | 2.20 × 0.14 |

| Sample | Concentration (ppm) | Si (%) | Incorporation (%) a |

|---|---|---|---|

| O-PLA-A | 259 ± 16 | 0.026 | 16.6 |

| O-PLA-B | 364 ± 22 | 0.036 | 12.2 |

| P-PLA-A | 727 ± 55 | 0.073 | 48.2 |

| P-PLA-B | 1594 ± 410 | 0.159 | 50.4 |

| Sample ID | Assignment | Chemical Signal (ppm) | Integration a |

|---|---|---|---|

| O-PLA-A | d’ | 3.7 | 1 |

| p | 1.21 | 9.58 | |

| O-PLA-B | d’ | 3.7 | 1 |

| p | 1.21 | 12.61 | |

| P-PLA-A | d’ | 3.7 | 1 |

| p | 1.21 | 3.45 | |

| P-PLA-B | d’ | 3.7 | 1 |

| p | 1.21 | 6.59 |

| Sample | Mn (g·mol−1) | Mw (g·mol−1) | D |

|---|---|---|---|

| Neat PLA | 97,000 ± 20,000 | 173,000 ± 20,000 | 1.85 |

| Extruded PLA | 75,000 ± 20,000 | 116,000 ± 20,000 | 1.56 |

| O-PLA-A | 48,000 ± 6000 | 94,000 ± 6000 | 1.96 |

| O-PLA-B | 45,000 ± 9000 | 90,000 ± 15,000 | 1.99 |

| P-PLA-A | 61,000 ± 6000 | 101,000 ± 4000 | 1.66 |

| P-PLA-B | 66,000 ± 4000 | 117,000 ± 2000 | 1.62 |

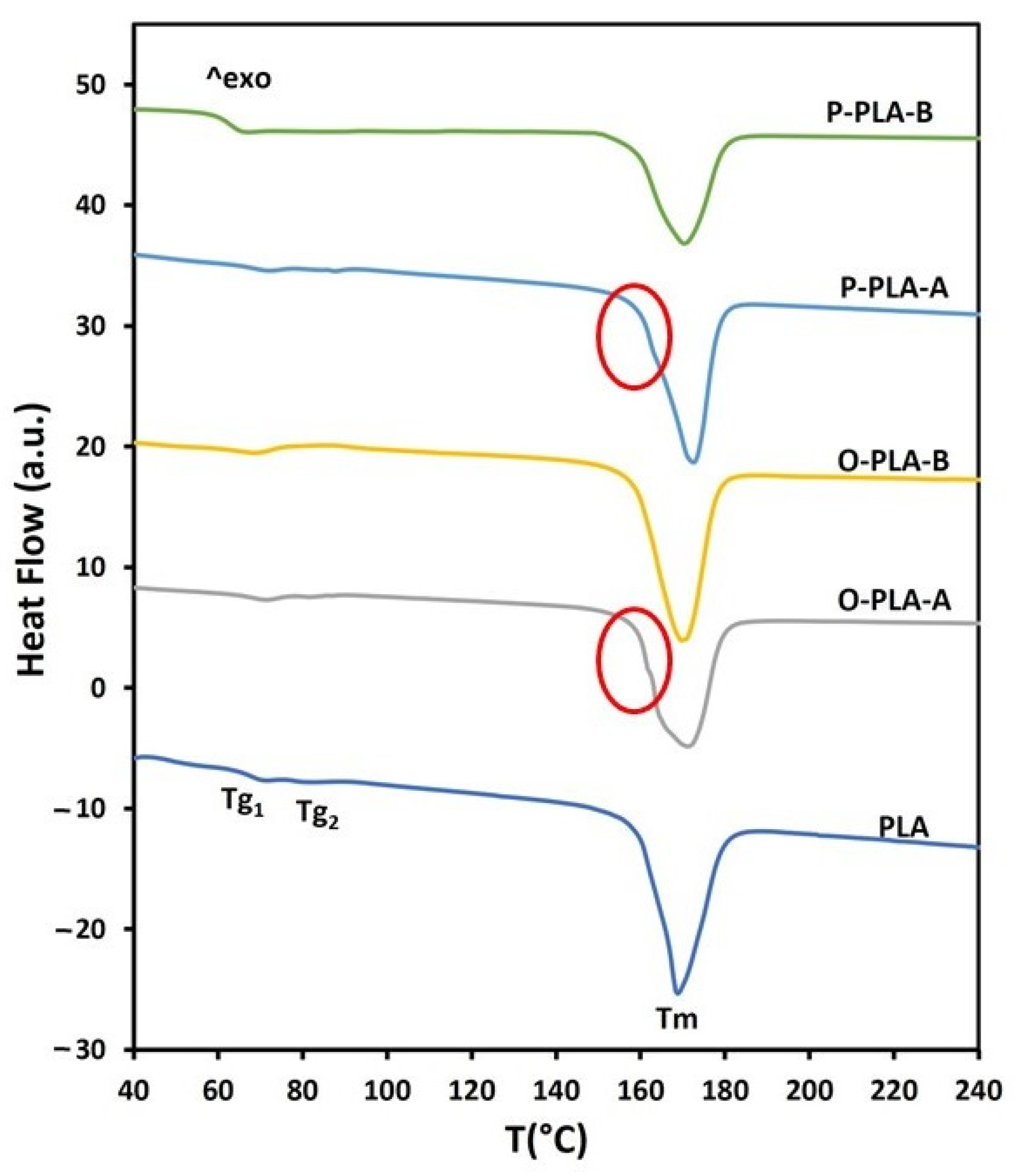

| Sample | Tg1 (°C) | Tg2 (°C) | Tm (°C) | ∆Hm (J·g−1) | Xc (%) a |

|---|---|---|---|---|---|

| PLA | 71 | 82 | 168 | 43.8 | 47 |

| O-PLA-A | 72 | 88 | 170 | 48.4 | 52 |

| O-PLA-B | 67 | ---- | 169 | 52.6 | 56 |

| P-PLA-A | 72 | 82 | 171 | 48.1 | 51 |

| P-PLA-B | 69 | ---- | 170 | 48.4 | 52 |

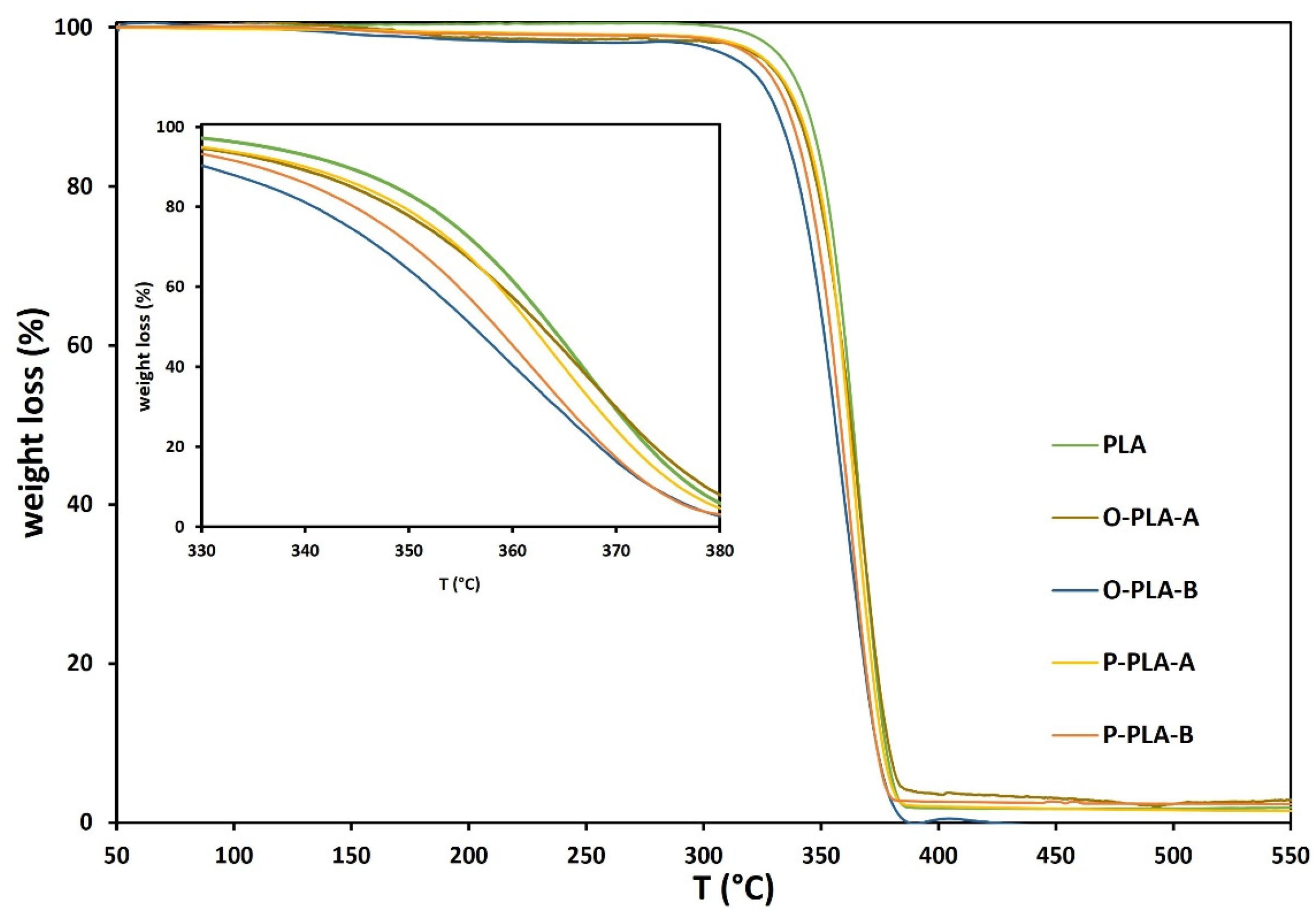

| Sample | T0 (°C) | T50 (°C) | Tf (°C) |

|---|---|---|---|

| PLA | 292 | 364 | 385 |

| O-PLA-A | 294 | 363 | 385 |

| O-PLA-B | 292 | 356 | 387 |

| P-PLA-A | 298 | 362 | 385 |

| P-PLA-B | 298 | 358 | 380 |

| Sample | DR | Dimensions (mm) (Width × Thickness) | Tensile Strength at Break (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| PLA | 4.5 | 2.70 × 0.14 | 157 ± 10 | 4.6 ± 0.1 | 40.2 ± 2.6 |

| O-PLA-A | 5.5 | 2.34 × 0.13 | 238 ± 5 | 5.1 ± 0.1 | 30.9 ± 1.0 |

| O-PLA-B | 6.6 | 2.40 × 0.14 | 215 ± 10 | 4.8 ± 0.2 | 31.9 ± 2.7 |

| P-PLA-A | 5.5 | 2.32 × 0.13 | 212 ± 15 | 5.1 ± 0.1 | 29.4 ± 3.9 |

| P-PLA-B | 6.2 | 2.37 × 0.14 | 177 ± 8 | 4.9 ± 0.1 | 23.4 ± 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres, E.; Gaona, A.; García-Bosch, N.; Muñoz, M.; Fombuena, V.; Moriana, R.; Vallés-Lluch, A. Improved Mechanical, Thermal, and Hydrophobic Properties of PLA Modified with Alkoxysilanes by Reactive Extrusion Process. Polymers 2021, 13, 2475. https://doi.org/10.3390/polym13152475

Torres E, Gaona A, García-Bosch N, Muñoz M, Fombuena V, Moriana R, Vallés-Lluch A. Improved Mechanical, Thermal, and Hydrophobic Properties of PLA Modified with Alkoxysilanes by Reactive Extrusion Process. Polymers. 2021; 13(15):2475. https://doi.org/10.3390/polym13152475

Chicago/Turabian StyleTorres, Elena, Aide Gaona, Nadia García-Bosch, Miguel Muñoz, Vicent Fombuena, Rosana Moriana, and Ana Vallés-Lluch. 2021. "Improved Mechanical, Thermal, and Hydrophobic Properties of PLA Modified with Alkoxysilanes by Reactive Extrusion Process" Polymers 13, no. 15: 2475. https://doi.org/10.3390/polym13152475

APA StyleTorres, E., Gaona, A., García-Bosch, N., Muñoz, M., Fombuena, V., Moriana, R., & Vallés-Lluch, A. (2021). Improved Mechanical, Thermal, and Hydrophobic Properties of PLA Modified with Alkoxysilanes by Reactive Extrusion Process. Polymers, 13(15), 2475. https://doi.org/10.3390/polym13152475