Polymer Retention Determination in Porous Media for Polymer Flooding in Unconsolidated Reservoir

Abstract

:1. Introduction

- Viscosifying power: the polymer should provide the required in-situ viscosity (more precisely resistance factor) at a reasonable concentration at reservoir conditions;

- Retention: polymer loss in the reservoir should be as low as possible to minimize propagation issues and oil bank delay. This is the focus of this study;

- Injectivity: the polymer solution should propagate easily through the reservoir rock. This factor is directly impacted by viscosity and retention as well as the chemical composition of the polymer;

- Long-term stability: the polymer should be stable and provide enough viscosity throughout its transit in the reservoir;

- Cost.

2. Determination of Retention: Review of Procedures and Challenges

- Adsorption: the polymer molecules can “stick” to the rock via Van der Waals, ionic or hydrogen bonds. Adsorption is usually considered irreversible since the macromolecule can attach to the rock via many points;

- Mechanical entrapment: if the hydrodynamic volume of the molecule in solution is larger than the pore throat it encounters, then the polymer molecule can become physically trapped at the entrance of the pore;

- Hydrodynamic retention: in some cases, the molecules can be (temporarily) trapped in eddies or regions where the flow is stagnant.

- Polymer concentration can have a significant impact on retention, especially when displacing viscous oils [18].

- Polymer retention values can be 2 to 10 times lower in the presence of oil than without oil [19].

- The presence of sulfonated monomers in the polymers (ATBS) can help decrease the retention of polymers [20].

- The mineralogy of the reservoir, and especially clay and iron content, greatly impacts polymer retention [21].

- Polymer characteristics such as chemical composition, concentration, and molecular weight impact retention [22].

- Retention values vary if the experiments are conducted in aerobic vs. anaerobic conditions [23].

- The packing and ageing methodology have a significant impact on the overall results [24].

- The correlation between retention values and inaccessible pore volume in the core is still unclear [18].

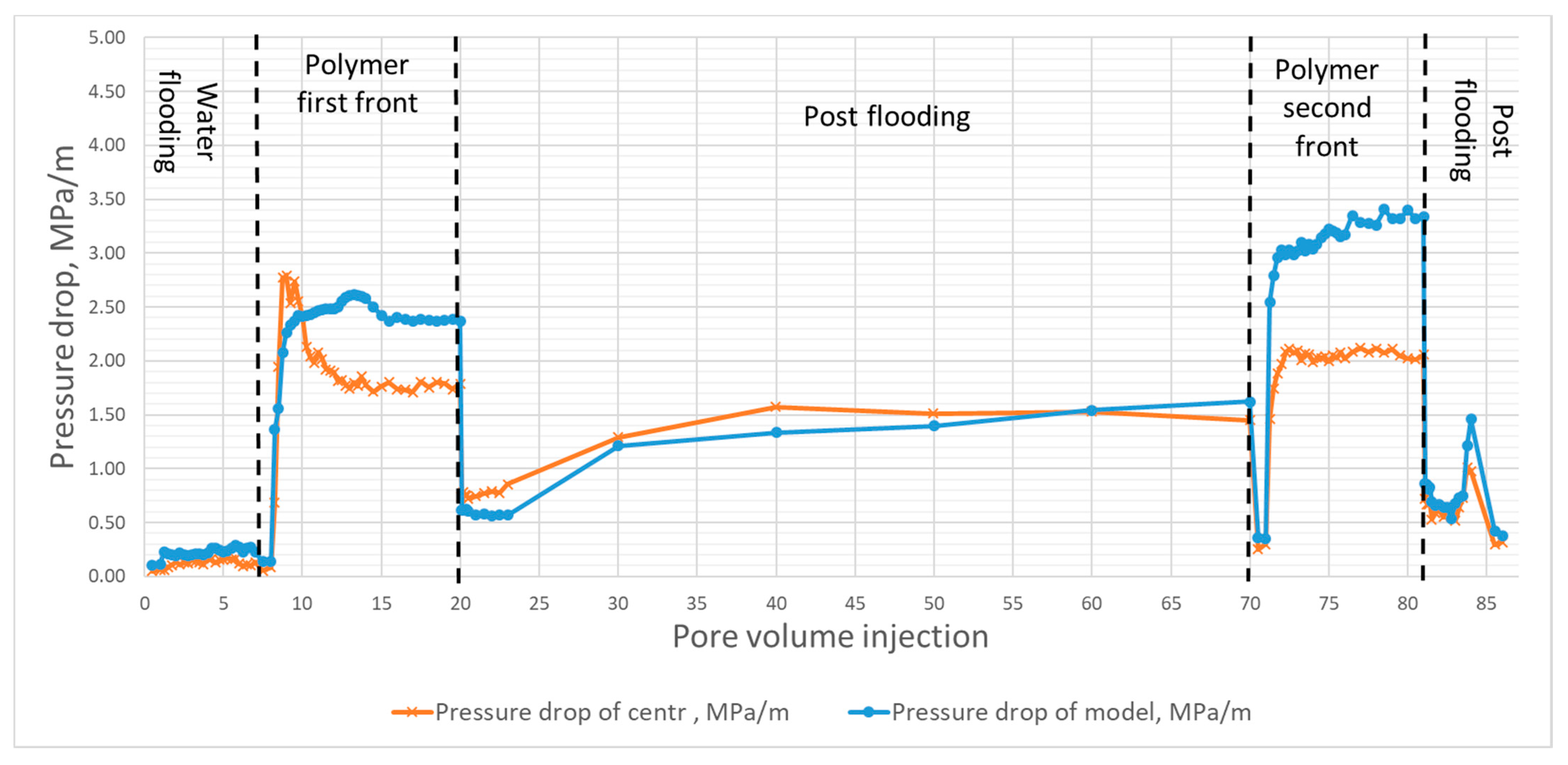

- The dynamic retention method with 2 polymer fronts was used as a standard.

- The method was improved for unconsolidated rocks and technical abilities of the laboratory which conducted the tests.

- The retention values were obtained in cores at residual oil saturation, to mimic real field conditions.

- The retention studies compared polymers at iso-viscosity (0.01 Pa·s) to get as close as possible from the injection conditions.

- Effluent concentration of polymers was determined via total nitrogen concentration (TNb method).

- Polymers with different molecular weights and chemistries (with or without Acyrlamido Tertiary Butyl Sulfonate or ATBS) were compared to determine the retention trends.

- Core with different permeabilities were used to represent the heterogeneity in the field.

3. Materials

3.1. Core

3.2. Polymers and Solutions

4. Methods

4.1. Set up of Filtration Test

4.2. Determination of Polymer Retention

- Testing of polymer compositions should be performed on composite models of 5 cylindrical core samples having permeabilities of class 1 of clastic reservoirs (helium permeability of 1150–1850 md) and class 2–3 (helium permeability of 300–700 md) to simulate different sections of the reservoir. It was not possible to cover the whole permeability range, mentioned above, especially with high permeability more than 1.5 d.

- Fix weakly cemented specimens with PTFE film (polytetrafluoroethylene), without a brass mesh at the ends: using a mesh is not recommended as it can affect polymer retention at the ends of the specimens.

- Samples shall be cleaned in a Soxhlet apparatus with an alcohol and benzene mixture. The core shall be dried at a temperature not exceeding 70 °C to prevent decomposition of clay minerals.

- Samples shall be saturated with synthetic multicomponent water, its composition being as close to that of formation water as possible.

- Forming the residual water saturation (Krw) and initial oil saturation (Kio), restoring wettability of samples and all subsequent preparations shall be performed in a filtration unit to avoid a mechanical impact and destruction of core samples.

- At all stages of testing, the linear fluid injection rate should not exceed 2 m/day to ensure reproducing the actual filtration rate and capillary impregnation in actual development of the formation under study.

- More exact determination of optimum polymer slug size, formation water model, and pumping rates. Slug sizes are selected based on the heterogeneity of the reservoir, oil to polymer solution viscosity ratio and the degree of polymer adsorption to pore space. The optimum pumping volumes and rates were experimentally determined during the first experiment, as shown in Table 4.

4.3. Detection of Polymer Concentration

4.4. Determination of Tracer Concentration

5. Results and Discussion

5.1. Coreflooding Results

5.2. Polymer and Tracers Measurements

5.3. Polymer Retention Values

- The retention values are similar to other cases described in the literature for unconsolidated heavy oil formations.

- Retention decreases with the increase in permeability and the decrease in molecular weight.

- However, it was not possible to measure retention for permeabilities more than 1.2 d, which represents the majority of permeability range. So, the retention values in the reservoir should be much lower.

- The addition of ATBS in the polymer macromolecule reduces polymer retention in the studied cores. For instance, a 12 MDa (million g/mol) polymer with ATBS displays similar retention values than a 7 MDa conventional polyacrylamide in rocks with comparable permeabilities.

- Discrepancies exist between both measurements’ methods with reasons still unclear at this stage. Investigations are on-going to get a better understanding of these results.

5.4. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| °C | degree Celsius |

| ATBS | Acrylamido Tertiary Butyl Sulfonate |

| C | concentration |

| cP | centipoise |

| d | Darcy |

| Da | Dalton |

| EOR | enhanced oil recovery |

| g/cm3 | gram per cubic centimeter |

| g/l | gram per liter |

| IAPV | inaccessible pore volume |

| Kio | relative permeability at 100% oil saturation |

| Kro | relative permeability to oil |

| Krw | relative permeability to water |

| m/day | meter per day |

| md | milli Darcy |

| MDa | Million Dalton = million g/mol |

| min | minute |

| MPa | Million Pascal |

| p | Pressure |

| PFTE | polytetrafluoroethylene |

| ppm | part per million = mg/kg |

| PV | pore volume |

| rpm | rotation per minute |

| s−1 | reciprocal second |

| t | time |

| TNb | Total nitrogen analyzer |

| TOC | Total organic carbon analyzer |

| μg/g | micro gram per gram |

| µL | micro liter |

References

- Willhite, G.P.; Green, D.W. Enhanced Oil Recovery, 2nd ed.; SPE Textbook Series; SPE: Richardson, TX, USA, 2018; Volume 6, p. 896. ISBN 978-1-61399-494-8. [Google Scholar]

- Ilyasov, I.; Podkorytov, A.; Gudz, A.; Komarov, V.; Glushchenko, N. Waterflooding East-Messoyakhskoe heavy oil field in unconsolidated reservoir—challenges and proactivity. In Proceedings of the SPE Russian Petroleum Technology Conference, SPE 196752, Moscow, Russia, 22–24 October 2019. [Google Scholar] [CrossRef]

- Ilyasov, I.; Gudz, A.; Podkorytov, A.; Komarov, V.; Glushchenko, N. Results of the first polymer flooding pilot at East-Messoyakhskoe oil field. In Proceedings of the SPE Russian Petroleum Technology Conference, Virtual Online, 26–29 October 2020. SPE 201822. [Google Scholar] [CrossRef]

- Manichand, R.N.; Seright, R.S. Field vs. Laboratory Polymer Retention Values for a Polymer Flood in the Tambaredjo Field. SPE Res. Eval. Eng. 2014, 17, 314–325. [Google Scholar] [CrossRef] [Green Version]

- Van der Heyden, F.H.J.; Mikhaylenko, E.; de Reus, A.J.; van Batendurg, D.W.; Karpan, V.M.; Volotikin, Y. Injectivity Experiences and its Surveillance in the West Salym ASP Pilot. In Proceedings of the IOR 2017—19th European Symposium on Improved Oil Recovery, Stavanger, Norway, 24–27 April 2017. Paper EAGE ThB07. [Google Scholar] [CrossRef]

- Toro, M.; Khisametdinov, M.; Nuriev, D.; Lutfullin, A.; Daminov, A.; Gaifullin, A.; Puskas, S.; Ordog, T. Initiation of a surfactant-polymer flooding project at PJSC Tatneft: From laboratory studies to test injection. In Proceedings of the European Association of Geoscientists & Engineers, Conference Proceedings, IOR 2021, Online Event, 19–22 April 2021; Volume 2021, pp. 1–15. [Google Scholar] [CrossRef]

- Delamaide, E.; Bazin, B.; Rousseau, D.; Degre, G. Chemical EOR for Heavy Oil: The Canadian Experience. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. Paper SPE 169715. [Google Scholar] [CrossRef]

- Juri, J.; Ruiz, A.; Pedersen, G.; Pagliero, P.; Blanco, H.; Eguia, V.; Serrano, V. Grimbeek: First Successful Application Polymer Flooding in Multilayer Reservoir at YPF. Interpretation of Polymer Flooding Response. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, 17–19 May 2017. Paper SPE 185487. [Google Scholar] [CrossRef]

- Juri, J.; Ruiz, A.; Serrano, V.; Guillen, P.; Thill, M.; Kichick, L.; Ojeda, N. A Successful 18%STOOIP 4-Injector Polymer Pilot Expands to 80 New Injectors in 6 Years Adopting A Modular Concept in Grimbeek Fluvial Reservoirs. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. Paper IPTC-20285. [Google Scholar] [CrossRef]

- Buciak, J.; Fondevilla Sancet, G.; Del Pozo, L. Polymer Flooding Pilot Learning Curve: 5+ Years Experience to Reduce Cost per Incremental Oil Barrel. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. Paper SPE 166255. [Google Scholar] [CrossRef]

- Kumar, P.; Raj, R.; Koduru, N.; Kumar, S.; Pandey, A. Field Implementation of Mangala Polymer Flood: Initial Challenges, Mitigation and Management. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21–23 March 2016. Paper SPE 179820. [Google Scholar] [CrossRef]

- Pandey, A.; Jain, S.; Prasad, D.; Koduru, N.; Raj, R. Planning for Large Scale ASP Flood Implementation in Mangala Oil Field. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual Online, 31 August–4 September 2020. Paper SPE 200445. [Google Scholar] [CrossRef]

- Shankar, V.; Jain, S.; Mishra, A.; Seth, S.; Rautela, C.; Jha, B. Polymer Injection Pilots in Bhagyam Oil Field and Full Field Polymer Development Planning. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018. Paper SPE 190472. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery; CRC Press, Inc.: Boca Raton, FL, USA, 1991; ISBN 978-94-011-3044-8. [Google Scholar]

- Rashidi, M.; Sandvik, S.; Blokhus, A.; Skauge, A. Static and dynamic adsorption of salt tolerant polymers. In Proceedings of the IOR 2009-15th European Symposium on Improved Oil Recovery, Paris, France, 27–29 April 2009. [Google Scholar]

- Li, Q.; Pu, W.; Wei, B.; Jin, F.; Li, K. Static adsorption and dynamic retention of an anti-salinity polymer in low permeability sandstone core. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Osterloh, W.T.; Law, E.J. Polymer Transport and Rheological Properties for Polymer Flooding in the North Sea Captain Field. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 19–22 April 1998. Paper SPE 39694. [Google Scholar] [CrossRef]

- Seright, R.S.; Wavrik, K.E.; Zhang, G. Polymer Retention Evaluation in a Heavy Oil Sand for a Polymer Flooding Application on Alaska’s North Slope; University of Alaska: Fairbanks, AK, USA, 2020; Paper SPE 200324. [Google Scholar] [CrossRef]

- Wever, D.A.Z.; Bartlema, H.; ten Berge, A.B.G.M. The Effect of the Presence of Oil on Polymer Retention in Porous Media from Clastic Reservoirs in the Sultanate of Oman. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018. Paper SPE190430. [Google Scholar] [CrossRef]

- Rashidi, M.; Blokhus, A.M.; Skauge, A. Viscosity and retention of sulfonated polyacrylamide polymers at high temperature. J. Appl. Polym. Sci. 2011, 119, 3623–3629. [Google Scholar] [CrossRef]

- Theng, B.K.G. Chapter 2: Polymer Behaviour at Clay and Solid Surfaces. In Developments in Soil Science, Formation and Properties of Clay-Polymer Complexes; Elsivier Science, B.V.: Amsterdam, The Netherlands, 1979. [Google Scholar]

- Zhang, G.; Seright, R.S. Effect of Concentration on HPAM Retention in Porous Media, SPE-166256-PA. SPE J. 2014, 19, 373–380. [Google Scholar] [CrossRef] [Green Version]

- Wan, H.; Seright, R.S. Is Polymer Retention Different Under Anaerobic vs. Aerobic Conditions? SPE-179538-PA. SPE J. 2017, 22, 431–437. [Google Scholar] [CrossRef]

- Wang, D.; Li, C.; Seright, R.S. Laboratory Evaluation of Polymer Retention in a Heavy Oil Sand for a Polymer Flooding Application on Alaska’s North Slope. SPE J. 2020, 25, 1842–1856. [Google Scholar] [CrossRef]

- Chen, Z.; Du, C.; Kurnia, I. A Study of Factors Influencing Polymer Hydrodynamic Retention in Porous Media. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. Paper SPE 179607. [Google Scholar] [CrossRef]

- Taylor, K.C. Spectrophotometric Determination of Acrylamide Polymers by Flow Injection Analysis. SPE Adv. Technol. Ser. 1993, 1, 130–133. [Google Scholar] [CrossRef]

- Lentz, R.D.; Sojka, R.E.; Foerster, J.A. Estimating Polyacrylamide Concentration in Irrigation Water. J. Environ. Qual. 1996, 25, 1015–1024. [Google Scholar] [CrossRef]

- Ueno, K.; Kina, K. Colloid Titration—A Rapid Method for the Determination of Charged Colloid. J. Chem. Educ. 1985, 62, 627–629. [Google Scholar] [CrossRef]

- Kuehne, D.L.; Shaw, D.W. Manual and Automated Turbidimetric Methods for the Determination of Polyacrylamides in the Presence of Sulfonates, SPE 11784. SPE J. 1985, 25, 687–692. [Google Scholar] [CrossRef]

- Han, A.; Fuseni, M.; Zahrani, B.; Wang, J. Laboratory Study on Polymers for Chemical Flooding in Carbonate Reservoirs. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. SPE 169724. [Google Scholar] [CrossRef]

- Akbaria, S.; Mahmoodb, S.S. A critical review of concept and methods related to accessible pore volume during polymer-enhanced oil recovery. J. Pet. Sci. Eng. 2019, 182, 106263. [Google Scholar] [CrossRef]

- Hall, H.N. How to Analyze Waterflood Injection Well Performance. World Oil 1963, 157, 128–130. [Google Scholar]

| Salt | Concentration, g/L |

|---|---|

| NaHCO3 | 1.239 |

| NaCl | 14.118 |

| KCl | 0.592 |

| MgCl2 | 0.594 |

| CaCl2 | 0.833 |

| Water salinity, g/L | 17.38 |

| Experiment No. | Average Permeability, md (Helium) | Polymer | Mol. Weight Mean, MDa | Sulfate Degree, % | Concentration at 10 cP @ 7.3 s−1, ppm |

|---|---|---|---|---|---|

| 1 | 346 | A | 18 | - | 900 |

| 2 | 361 | A | 18 | - | 900 |

| 3 | 424 | B | 12 | - | 1320 |

| 4 | 460 | D | 7 | - | 1250 |

| 5 | 552 | C | 12 | 5 | 1050 |

| 6 | 1229 | C | 12 | 5 | 1050 |

| Formation | PK1-3 |

|---|---|

| Temperature, °C | 16 |

| Rock pressure, MPa | 19 |

| Formation pressure, MPa | 7.9 |

| Water salinity, g/L | multicomponent composition |

| Oil density in atmospheric conditions, g/cm3 | 0.945 |

| Oil density in formation conditions, g/cm3 | 0.922 |

| Oil viscosity in formation conditions, MPa·s | 111.15 |

| Pumping Stages/Parameters | Experiment No. | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| Absolute permeability, md, average | 346 | 361 | 424 | 460 | 552 | 1229 | |

| Polymer, first front | Linear injection rate, m/day | 1 | 2 | 2 | 2 | 2 | 2 |

| Injected volume, PV | 3 | 12 | 12 | 12 | 12 | 12 | |

| Formation water injection | Linear injection rate, m/day | 2 | 2 (10PV) and 4 (40PV) | 2 (10PV) and 4 (40PV) | 2 (10PV) and 4 (40PV) | 2 (10PV) and 4 (40PV) | 2 (10PV) and 4 (40PV) |

| Injected volume, PV | 50 | 50 | 50 | 50 | 50 | 50 | |

| Polymer, second front | Linear injection rate, m/day | 1 | 2 | 2 | 2 | 2 | 2 |

| Injected volume, PV | 10 | 10 | 10 | 10 | 10 | 10 | |

| Formation water injection | Injected volume, PV | 3 | 3 | 3 | 3 | 3 | 3 |

| Linear injection rate, m/day | 1 | 2 (2PV) and 4 (1PV) | 2 (2PV) and 4 (1PV) | 2 (2PV) and 4 (1PV) | 2 (2PV) and 4 (1PV) | 2 (2PV) and 4 (1PV) | |

| Experiment No. | Polymer | Permeability, md | Mol. Mass, MDa | Sulfate Degree, % | Retention (Method 1), µg/g | Retention (Method 2), µg/g | Average Retention, µg/g |

|---|---|---|---|---|---|---|---|

| 1 | A | 346 | 18 | - | NA | NA | NA |

| 2 | A | 361 | 18 | - | 444 | 436 | 440 |

| 3 | B | 424 | 12 | - | 385 | 321 | 353 |

| 4 | D | 460 | 7 | - | 152 | 292 | 222 |

| 5 | C | 552 | 12 | 5 | 124 | 290 | 207 |

| 6 | C | 1229 | 12 | 5 | 212 | 93 | 153 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilyasov, I.; Koltsov, I.; Golub, P.; Tretyakov, N.; Cheban, A.; Thomas, A. Polymer Retention Determination in Porous Media for Polymer Flooding in Unconsolidated Reservoir. Polymers 2021, 13, 2737. https://doi.org/10.3390/polym13162737

Ilyasov I, Koltsov I, Golub P, Tretyakov N, Cheban A, Thomas A. Polymer Retention Determination in Porous Media for Polymer Flooding in Unconsolidated Reservoir. Polymers. 2021; 13(16):2737. https://doi.org/10.3390/polym13162737

Chicago/Turabian StyleIlyasov, Ilnur, Igor Koltsov, Pavel Golub, Nikolay Tretyakov, Andrei Cheban, and Antoine Thomas. 2021. "Polymer Retention Determination in Porous Media for Polymer Flooding in Unconsolidated Reservoir" Polymers 13, no. 16: 2737. https://doi.org/10.3390/polym13162737

APA StyleIlyasov, I., Koltsov, I., Golub, P., Tretyakov, N., Cheban, A., & Thomas, A. (2021). Polymer Retention Determination in Porous Media for Polymer Flooding in Unconsolidated Reservoir. Polymers, 13(16), 2737. https://doi.org/10.3390/polym13162737