Flame Retardancy and Excellent Electrical Insulation Performance of RTV Silicone Rubber

Abstract

:1. Introduction

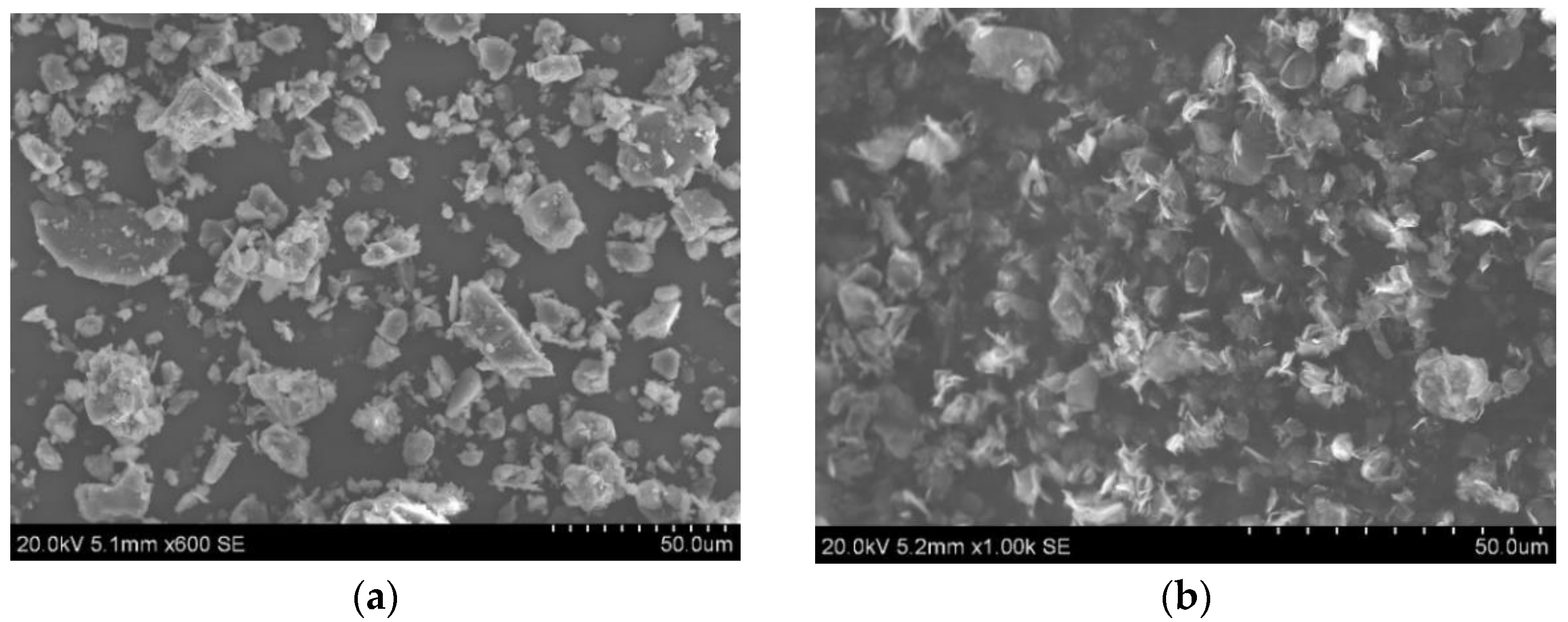

2. Materials and Methods

3. Results and Discussion

3.1. Combustibility and Release of Smoke

3.2. Limiting Oxygen Index (LOI)

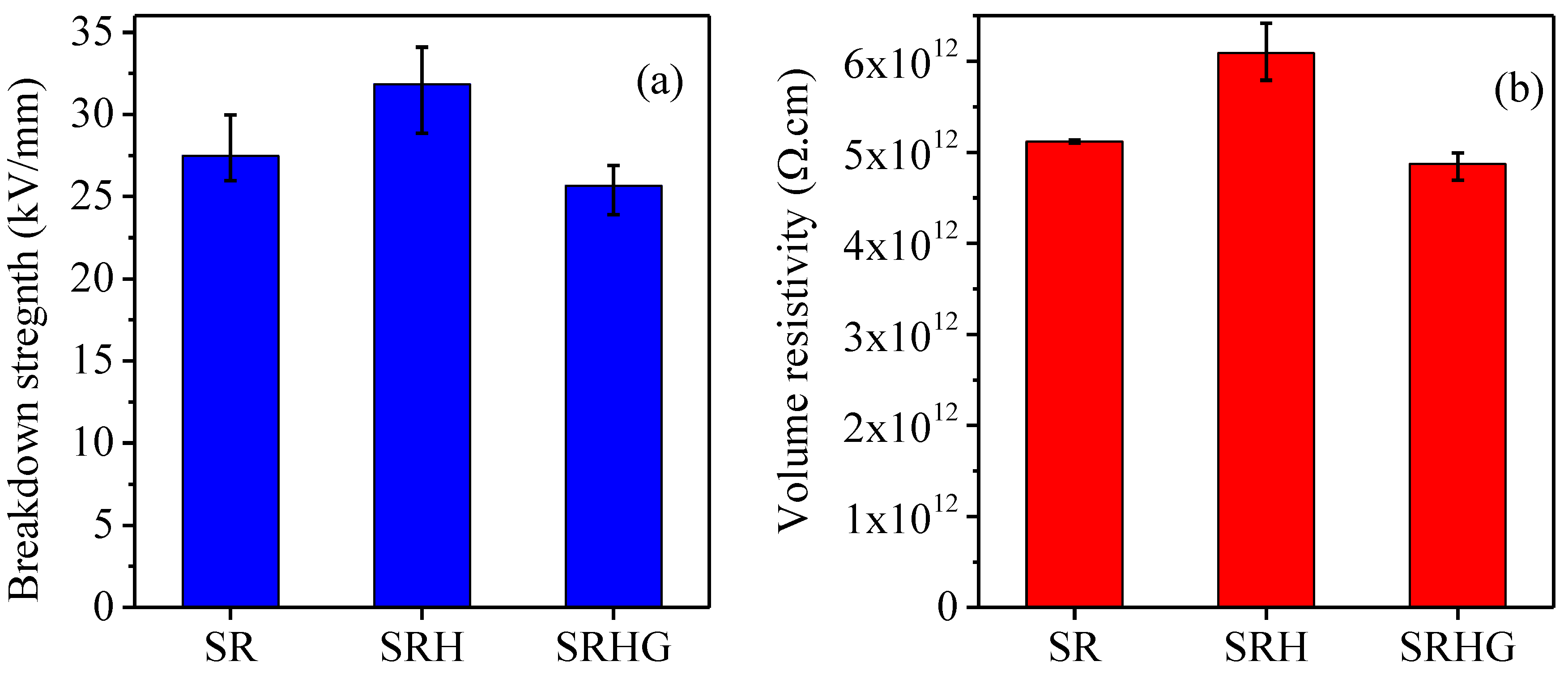

3.3. Dielectric Breakdown Strength and Volume Resistivity (DC)

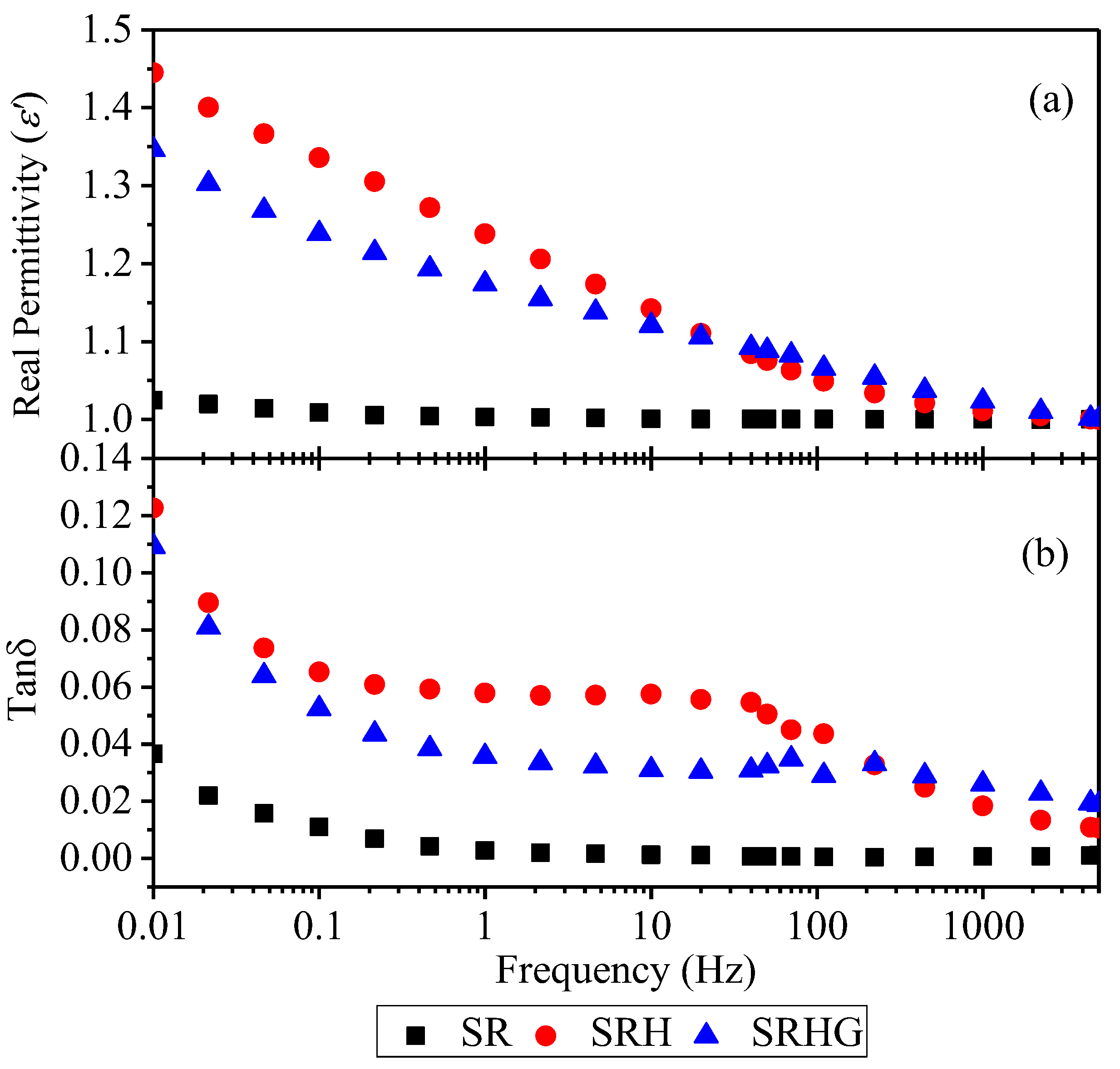

3.4. Permittivity and Dielectric Loss

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jia, Z.; Fang, S.; Gao, H.; Guan, Z.; Wang, L.; Xu, Z. Development of RTV silicone coatings in China: Overview and bibliography [feature article]. IEEE Electr. Insul. Mag. 2008, 24, 28–41. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T. AC corona resistance of micro-ATH/nano-Al2O3 filled silicone rubber composites. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Li, S. Erosion resistance of micro-AlN and nano-SiO2 hybrid filled silicone rubber composites. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017; pp. 370–373. [Google Scholar] [CrossRef]

- IEEE Guide for the Application, Maintenance, and Evaluation of Room-Temperature Vulcanizing (RTV) Silicone Rubber Coatings for Outdoor Ceramic Insulators. In IEEE Std 1523-2018 (Revision of IEEE Std 1523-2002); IEEE: New York, NY, USA, 2018; pp. 1–25.

- Stoliarov, S.I.; Safronava, N.; Lyon, R.E. The effect of variation in polymer properties on the rate of burning. Fire Mater. Int. J. 2009, 33, 257–271. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Song, S. Preparation of a novel type of flame retardant diatomite and its application in silicone rubber composites. Adv. Powder Technol. 2019, 30, 1567–1575. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Yu, S.; Li, S. Effects of thermal properties on tracking and erosion resistance of micro-ATH/AlN/BN filled silicone rubber composites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2076–2085. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Yu, S.; Zhang, Y.; Li, S. Tracking, erosion and thermal distribution of micro-AlN+ nano-SiO2 co-filled silicone rubber for high-voltage outdoor insulation. High Volt. 2018, 3, 289–294. [Google Scholar] [CrossRef]

- El-Hag, A.H.; Simon, L.C.; Jayaram, S.H.; Cherney, E.A. Erosion resistance of nano-filled silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 122–128. [Google Scholar] [CrossRef]

- Ghunem, R.A.; Jayaram, S.H.; Cherney, E.A. Suppression of silicone rubber erosion by alumina trihydrate and silica fillers from dry-band arcing under DC. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 14–20. [Google Scholar] [CrossRef]

- Ilhan, S.; Cherney, E.A. Comparative tests on RTV silicone rubber coated porcelain suspension insulators in a salt-fog chamber. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 947–953. [Google Scholar] [CrossRef]

- Lan, L.; Mu, L.; Wang, Y.; Yuan, X.; Wang, W.; Li, Z. The influence of pollution accumulation on coating aging of UHV line insulators with different suspension height in coal-ash polluted area. Arch. Electr. Eng. 2020, 69. [Google Scholar] [CrossRef]

- Kabir, I.I.; Fu, Y.; de Souza, N.; Nazir, M.T.; Baena, J.C.; Yuen, A.C.Y.; Yeoh, G.H. Improved flame-retardant properties of polydimethylsiloxane/multi-walled carbon nanotube nanocomposites. J. Mater. Sci. 2021, 56, 2192–2211. [Google Scholar] [CrossRef]

- Chen, X.; Song, W.; Liu, J.; Jiao, C.; Qian, Y. Synergistic flame-retardant effects between aluminum hypophosphite and expandable graphite in silicone rubber composites. J. Therm. Anal. Calorim. 2015, 120, 1819–1826. [Google Scholar] [CrossRef]

- Liu, L.; Zhuo, J.; Chen, X.; Li, S.; Gu, Y. Influence of ferric hydroxide on smoke suppression properties and combustion behavior of intumescent flame retardant silicone rubber composites. J. Therm. Anal. Calorim. 2015, 119, 487–497. [Google Scholar] [CrossRef]

- Alumina Trihydrate. Available online: https://redox.com/products/alumina-trihydrate/ (accessed on 1 August 2021).

- Graphene Nanoplatelets. Available online: https://firstgraphene.net/puregraph/ (accessed on 1 August 2021).

- Nazir, M.T.; Phung, B.T.; Yu, S.; Li, S.; Xie, D.; Zhang, Y. Thermal distribution analysis and suppression mechanism of carbonized tracking and erosion in silicone rubber/SiO2 nanocomposites. Polym. Test. 2018, 70, 226–233. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Y.; Dong, W.; Wang, P. Enhanced fire retardancy of polyethylene/alumina trihydrate composites by graphene nanoplatelets. Mater. Lett. 2014, 128, 275–278. [Google Scholar] [CrossRef]

| Composition | RTV 615 | ATH | Graphene Nanoplatelets | Acronym |

|---|---|---|---|---|

| Pristine RTV silicone rubber | 100% | 0 | 0 | SR |

| RTV Silicone rubber/ATH | 70% | 30% | 0 | SRH |

| RTV Silicone rubber/ATH/Graphene nanoplatelets | 69% | 30% | 1% | SRHG |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazir, M.T.; Khalid, A.; Kabir, I.; Wang, C.; Baena, J.-C.; Akram, S.; Bhutta, M.S.; Yasin, G.; Phung, B.T.; Yeoh, G.H. Flame Retardancy and Excellent Electrical Insulation Performance of RTV Silicone Rubber. Polymers 2021, 13, 2854. https://doi.org/10.3390/polym13172854

Nazir MT, Khalid A, Kabir I, Wang C, Baena J-C, Akram S, Bhutta MS, Yasin G, Phung BT, Yeoh GH. Flame Retardancy and Excellent Electrical Insulation Performance of RTV Silicone Rubber. Polymers. 2021; 13(17):2854. https://doi.org/10.3390/polym13172854

Chicago/Turabian StyleNazir, Muhammad Tariq, Arslan Khalid, Imrana Kabir, Cheng Wang, Juan-Carlos Baena, Shakeel Akram, Muhammad Shoaib Bhutta, Ghulam Yasin, Bao Toan Phung, and Guan Heng Yeoh. 2021. "Flame Retardancy and Excellent Electrical Insulation Performance of RTV Silicone Rubber" Polymers 13, no. 17: 2854. https://doi.org/10.3390/polym13172854

APA StyleNazir, M. T., Khalid, A., Kabir, I., Wang, C., Baena, J.-C., Akram, S., Bhutta, M. S., Yasin, G., Phung, B. T., & Yeoh, G. H. (2021). Flame Retardancy and Excellent Electrical Insulation Performance of RTV Silicone Rubber. Polymers, 13(17), 2854. https://doi.org/10.3390/polym13172854