Mechanical Performance of Granite Fine Fly Dust-Filled Basalt/Glass Polyurethane Polymer Hybrid Composites

Abstract

:1. Introduction

2. Experimental Procedure

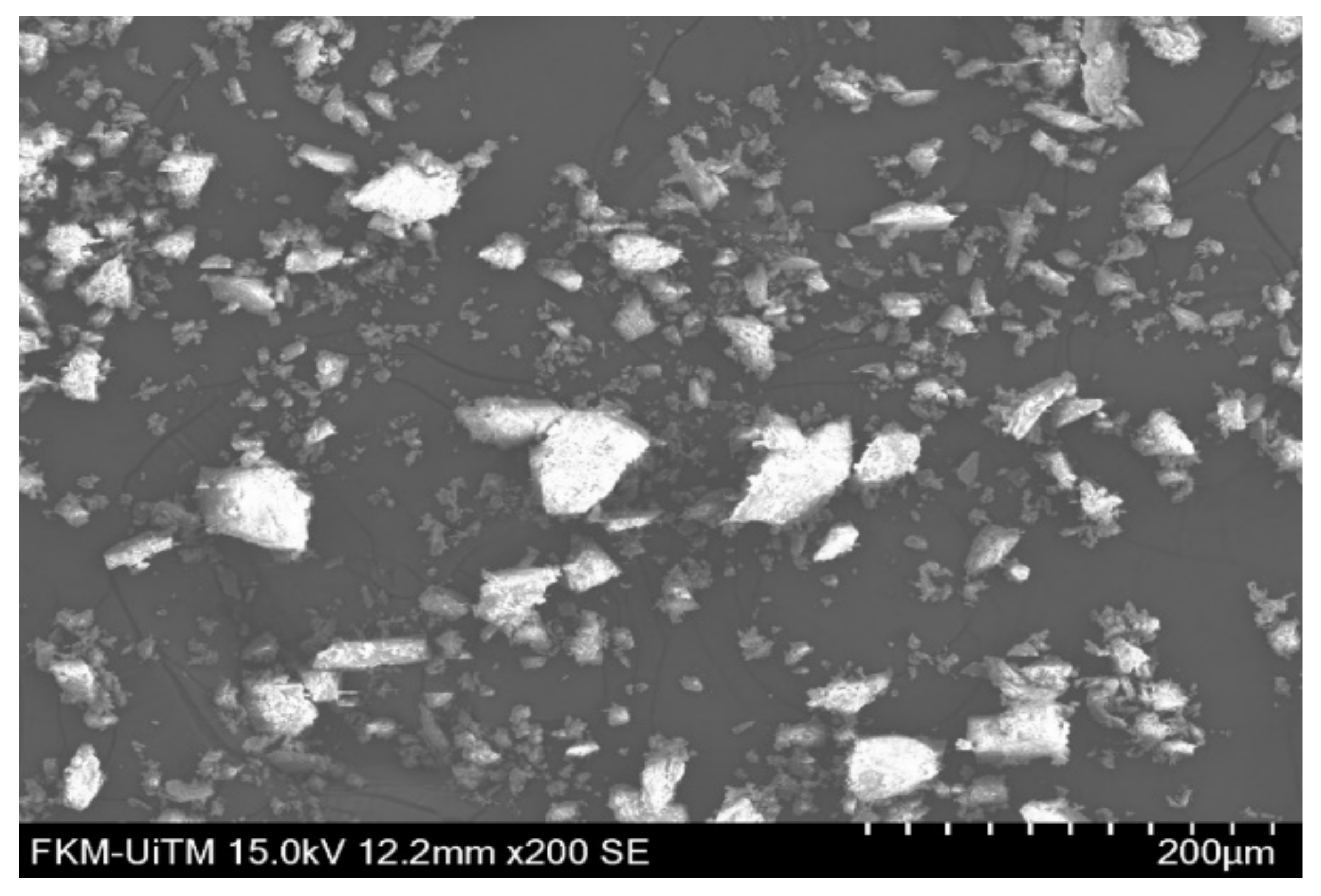

2.1. Materials

2.2. Fabrication of Composites

2.3. Mechanical Tests

2.3.1. Unhole Tensile (UHT) and Open Hole Tensile (OHT) Test

2.3.2. Low Velocity Impact (LVI) Test

2.3.3. Quasi-Static Indentation (QSI) Test

2.3.4. Flexural Test

2.3.5. Interlaminar Shear Strength (ILSS) Test

3. Results and Discussion

3.1. Unhole Tensile (UHT) and Open Hole Tensile (OHT) Properties

3.2. Low Velocity Impact (LVI) Properties

3.3. Quasi-Static Indentation (QSI) Properties

3.4. Flexural Properties

3.5. Interlaminar Shear Strength (ILSS) Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WB/GCSM | Woven Basalt/Glass Chopped Stand Mat |

| UHT | Unhole Tensile |

| OHT | Open Hole Tensile |

| LVI | Low Velocity Impact |

| QSI | Quasi-Static Indentations |

| ILSS | Interlaminar Shear Stress |

| GD | Granite Dust |

| TW | Twill Weave |

| CSM | Chopped Stand Mat |

| SEM | Scanning Electron Microscope |

| XRF | X-ray fluorescence |

| ASTM | American Society for Testing and Materials |

| JKR | Jabatan Kerja Raya |

References

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Michałowski, S. Basalt powder as an eco-friendly filler for epoxy composites: Thermal and thermo-mechanical properties assessment. Compos. Part B Eng. 2019, 164, 272–279. [Google Scholar] [CrossRef]

- Hashim, U.; Jumahat, A.; Mahmud, J. Improved tensile properties of basalt fibre reinforced polymer composites using silica nanoparticles. Mater. Werkst. 2019, 50, 1149–1155. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslami-Farsani, R. Enhanced mechanical properties of unidirectional basalt fiber/epoxy composites using silane-modified Na+-montmorillonite nanoclay. Polym. Test. 2016, 55, 135–142. [Google Scholar] [CrossRef]

- Bulut, M. Mechanical characterization of Basalt/epoxy composite laminates containing graphene nanopellets. Compos. Part B Eng. 2017, 122, 71–78. [Google Scholar] [CrossRef]

- Bulut, M.; Erklig, A. The investigation of quasi-static indentation effect on laminated hybrid composite plates. Mech. Mater. 2018, 117, 225–234. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Jawaid, M.; Midani, M.; Khan, A. Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites. Polymers 2020, 12, 2733. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Shaari, N.; Tahir, A. Mechanical properties of nanoclay-filled kenaf and hybrid glass/kenaf fiber composites. Mater. Today Proc. 2021, 46, 1787–1791. [Google Scholar] [CrossRef]

- Muhammad, Y.H.; Ahmad, S.; Abu Bakar, M.A.; Mamun, A.A.; Heim, H.P. Mechanical properties of hybrid glass/kenaf fibre-reinforced epoxy composite with matrix modification using liquid epoxidised natural rubber. J. Reinf. Plast. Compos. 2015, 34, 896–906. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.L.; Bougherara, H.; Zdero, R. Impact properties of a new hybrid composite material made from woven carbon fibres plus flax fibres in an epoxy matrix. Compos. Struct. 2019, 208, 346–356. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M. Magnesium hydroxide reinforced kenaf fibers/epoxy hybrid composites: Mechanical and thermomechanical properties. Constr. Build. Mater. 2019, 201, 138–148. [Google Scholar] [CrossRef]

- Vardhan, D.H.; Ramesh, A.; Reddy, B.C.M. Effect of ceramic fillers on flexural strength of the GFRP composite material. Mater. Today Proc. 2021, 37, 1739–1742. [Google Scholar] [CrossRef]

- Singh, H.; Singh, T. Effect of fillers of various sizes on mechanical characterization of natural fiber polymer hybrid composites: A review. Mater. Today Proc. 2019, 18, 5345–5350. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Manap, N.; Usoff, M.A.I. Effect of Nanofillers Dispersion on Mechanical Properties of Clay/Epoxy and Silica/Epoxy Nanocomposites. J. Teknol. 2015, 76, 107–111. [Google Scholar] [CrossRef] [Green Version]

- Napisah, S.; Aidah, J.; Mohammad, J.; Anish, K. Effect of MWCNT Surface Functionalisation and Distribution on Compressive Properties of Kenaf and Hybrid Kenaf/Glass Fibres Reinforced Polymer Composites. Polymers 2020, 12, 2522. [Google Scholar]

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos. Part A Appl. Sci. Manuf. 2016, 87, 29–45. [Google Scholar] [CrossRef]

- Jaafar, C.A.; Zainol, I.; Ishak, N.; Ilyas, R.; Sapuan, S. Effects of the liquid natural rubber (LNR) on mechanical properties and microstructure of epoxy/silica/kenaf hybrid composite for potential automotive applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Ricciardi, M.; Papa, I.; Langella, T.; Lopresto, V.; Antonucci, V. Mechanical properties of glass fibre composites based on nitrile rubber toughened modified epoxy resin. Compos. Part B Eng. 2018, 139, 259–267. [Google Scholar] [CrossRef]

- Ma, H.; Aravand, M.A.; Falzon, B.G. Synergistic enhancement of fracture toughness in multiphase epoxy matrices modified by thermoplastic and carbon nanotubes. Compos. Sci. Technol. 2021, 201, 108523. [Google Scholar] [CrossRef]

- Dzul-Cervantes, M.; Pacheco-Salazar, O.; Can-Herrera, L.; Moreno-Chulim, M.; Cauich-Cupul, J.; Herrera-Franco, P.; Valadez-González, A. Effect of moisture content and carbon fiber surface treatments on the interfacial shear strength of a thermoplastic-modified epoxy resin composites. J. Mater. Res. Technol. 2020, 9, 15739–15749. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V. A review on Properties of Sustainable Concrete using granite dust as replacement for river sand. J. Clean. Prod. 2016, 126, 74–87. [Google Scholar] [CrossRef]

- Pai, A.; Sharma, S.S.; D’Silva, R.E.; Nikhil, R.G. Effect of graphite and granite dust particulates as micro-fillers on tribological performance of Al 6061-T6 hybrid composites. Tribiology Int. 2015, 92, 462–471. [Google Scholar] [CrossRef]

- Cheah, C.B.; Lim, J.S.; Ramli, M.B. The mechanical strength and durability properties of ternary blended cementitious composites containing granite quarry dust (GQD) as natural sand replacement. Constr. Build. Mater. 2019, 197, 291–306. [Google Scholar] [CrossRef]

- Awad, A.; El-Gamasy, R.; El-Wahab, A.A.A.; Abdellatif, M.H. Assessment of mechanical properties of HDPE composite with addition of marble and granite dust. Ain Shams Eng. J. 2020, 11, 1211–1217. [Google Scholar] [CrossRef]

- Ghorbani, S.; Taji, I.; de Brito, J.; Negahban, M.; Ghorbani, S.; Tavakkolizadeh, M.; Davoodi, A. Mechanical and durability behaviour of concrete with granite waste dust as partial cement replacement under adverse exposure conditions. Constr. Build. Mater. 2019, 194, 143–152. [Google Scholar] [CrossRef]

- Subhash, C.; Krishna, M.R.; Raj, M.S.; Sai, B.H.; Rao, S.R. Development of granite powder reinforced epoxy composites. Mater. Today Proc. 2018, 5, 13010–13014. [Google Scholar] [CrossRef]

- Bakar, N.H.; Hyie, K.M.; Mardziah, C.; Roselina, N.N.; Masdek, N.R.N. Impact Energy and Ductility Index of Kevlar Reinforcement with Kenaf Polyester Composite. J. Teknol. 2015, 76, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Bulut, M.; Erklig, A.; Yeter, E. Hybridization effects on quasi-static penetration resistance in fiber reinforced hybrid composite laminates. Compos. Part B Eng. 2016, 98, 9–22. [Google Scholar] [CrossRef]

- Yudhanto, A.; Wafai, H.; Lubineau, G.; Yaldiz, R.; Verghese, N. Characterizing the influence of matrix ductility on damage phenomenology in continuous fiber-reinforced thermoplastic laminates undergoing quasi-static indentation. Compos. Struct. 2018, 186, 324–334. [Google Scholar] [CrossRef] [Green Version]

- Saravanakumar, K.; Arumugam, V. Effect of milled glass fibers on quasi-static indentation and tensile behavior of tapered laminates under acoustic emission monitoring. Eng. Fract. Mech. 2018, 201, 36–46. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | K2O | CaCo3 | Fe2O3 | MnO | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|

| Percentage (%) | 78.91 | 10.52 | 6.07 | 2.07 | 1.73 | 0.18 | 0.10 | 0.08 |

| Composites | Tensile Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Tensile Strength, σt (MPa) | Tensile Modulus, Et (GPa) | Tensile Strain at Break, εf (%) | Damage Tolerance σhole/σunhole (%) | Strength Reduction (100 − σhole/σunhole) (%) | ||||

| Unhole | Hole | Unhole | Hole | Unhole | Hole | |||

| [WB/GCSM] | 84.40 ± 5.92 | 58.46 ± 12.74 | 2.30 ± 0.06 | 1.95 ± 0.34 | 3.99 ± 0.36 | 3.19 ± 0.02 | 69.27 | 30.73 |

| [WB/GCSM/1GD] | 87.54 ± 6.35 | 73.23 ± 2.33 | 2.33 ± 0.14 | 2.14 ± 0.45 | 3.51 ± 0.37 | 3.19 ± 0.24 | 83.65 | 16.35 |

| [WB/GCSM/3GD] | 86.66 ± 10.93 | 71.16 ± 4.33 | 2.11 ± 0.11 | 2.01 ± 0.34 | 3.20 ± 0.02 | 2.98 ± 0.17 | 82.11 | 17.89 |

| [WB/GCSM/5GD] | 73.68 ± 22.58 | 65.28 ± 1.51 | 2.04 ± 0.24 | 1.64 ± 0.68 | 3.00 ± 0.47 | 3.56 ± 0.45 | 88.60 | 11.40 |

| Composites | Impact Properties | |||||

|---|---|---|---|---|---|---|

| Peak Load (N) | Deflection at Peak Load (mm) | Total Energy Absorbed, Et (J) | Initiation Energy, Em (J) | Propagation Energy, Ep (J) | Ductility Index, Ep/Em | |

| [WB/GCSM] | 2623.7 ± 221.73 | 5.41 ± 0.18 | 20.37 ± 1.26 | 8.63 ± 0.67 | 11.74 | 1.36 |

| [WB/GCSM/1GD] | 3010.7 ± 249.44 | 4.29 ± 0.18 | 23.33 ± 1.43 | 6.75 ± 0.12 | 16.58 | 2.46 |

| [WB/GCSM/3GD] | 2763.8 ± 144.20 | 4.12 ± 0.71 | 22.34 ± 1.06 | 6.46 ± 1.06 | 15.88 | 2.46 |

| [WB/GCSM/5GD] | 2820.6 ± 350.90 | 4.21 ± 0.65 | 20.96 ± 4.83 | 5.98 ± 0.62 | 14.98 | 2.51 |

| Composites | Quasi-static Indentation Properties | ||

|---|---|---|---|

| Maximum Load (kN) | Displacement (mm) | Energy Absorbed (J) | |

| [WB/GCSM] | 1.46 ± 0.29 | 3.84 ± 0.60 | 8.58 ± 0.31 |

| [WB/GCSM/1GD] | 1.71 ± 0.06 | 2.99 ± 0.22 | 9.04 ± 0.08 |

| [WB/GCSM/3GD] | 1.58 ± 0.03 | 3.64 ± 0.67 | 9.40 ± 0.02 |

| [WB/GCSM/5GD] | 1.37 ± 0.07 | 2.71 ± 0.57 | 8.38 ± 0.50 |

| Composites | Flexural Properties | ||

|---|---|---|---|

| Flexural Modulus (GPa) | Flexural Strength (MPa) | Flexural Strain at Break (%) | |

| [WB/GCSM] | 5.76 ± 0.62 | 78.23 ± 10.95 | 1.57 ± 1.52 |

| [WB/GCSM/1GD] | 6.47 ± 0.51 | 109.07 ± 8.72 | 2.04 ± 0.01 |

| [WB/GCSM/3GD] | 6.24 ± 0.43 | 83.13 ± 11.43 | 2.15 ± 0.20 |

| [WB/GCSM/5GD] | 4.28 ± 0.45 | 65.66 ± 2.36 | 2.36 ± 0.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapiai, N.; Jumahat, A.; Jawaid, M.; Abu, M.Z.; Chalid, M. Mechanical Performance of Granite Fine Fly Dust-Filled Basalt/Glass Polyurethane Polymer Hybrid Composites. Polymers 2021, 13, 3032. https://doi.org/10.3390/polym13183032

Sapiai N, Jumahat A, Jawaid M, Abu MZ, Chalid M. Mechanical Performance of Granite Fine Fly Dust-Filled Basalt/Glass Polyurethane Polymer Hybrid Composites. Polymers. 2021; 13(18):3032. https://doi.org/10.3390/polym13183032

Chicago/Turabian StyleSapiai, Napisah, Aidah Jumahat, Mohammad Jawaid, Md Zin Abu, and Mochamad Chalid. 2021. "Mechanical Performance of Granite Fine Fly Dust-Filled Basalt/Glass Polyurethane Polymer Hybrid Composites" Polymers 13, no. 18: 3032. https://doi.org/10.3390/polym13183032

APA StyleSapiai, N., Jumahat, A., Jawaid, M., Abu, M. Z., & Chalid, M. (2021). Mechanical Performance of Granite Fine Fly Dust-Filled Basalt/Glass Polyurethane Polymer Hybrid Composites. Polymers, 13(18), 3032. https://doi.org/10.3390/polym13183032