Interfacial Transcrystallization and Mechanical Performance of 3D-Printed Fully Recyclable Continuous Fiber Self-Reinforced Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. 3D-Printing Process

2.3. Experiments

3. Results

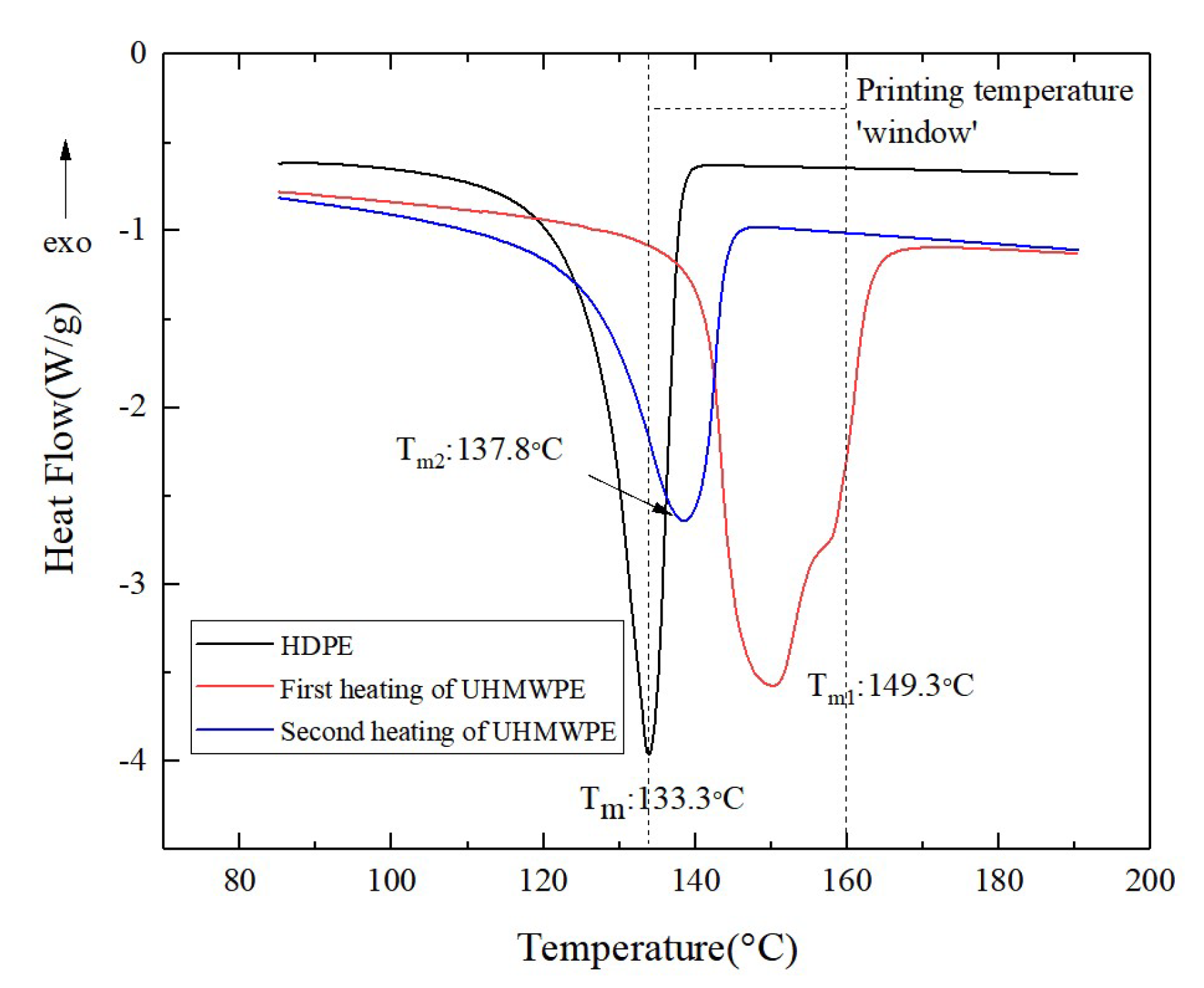

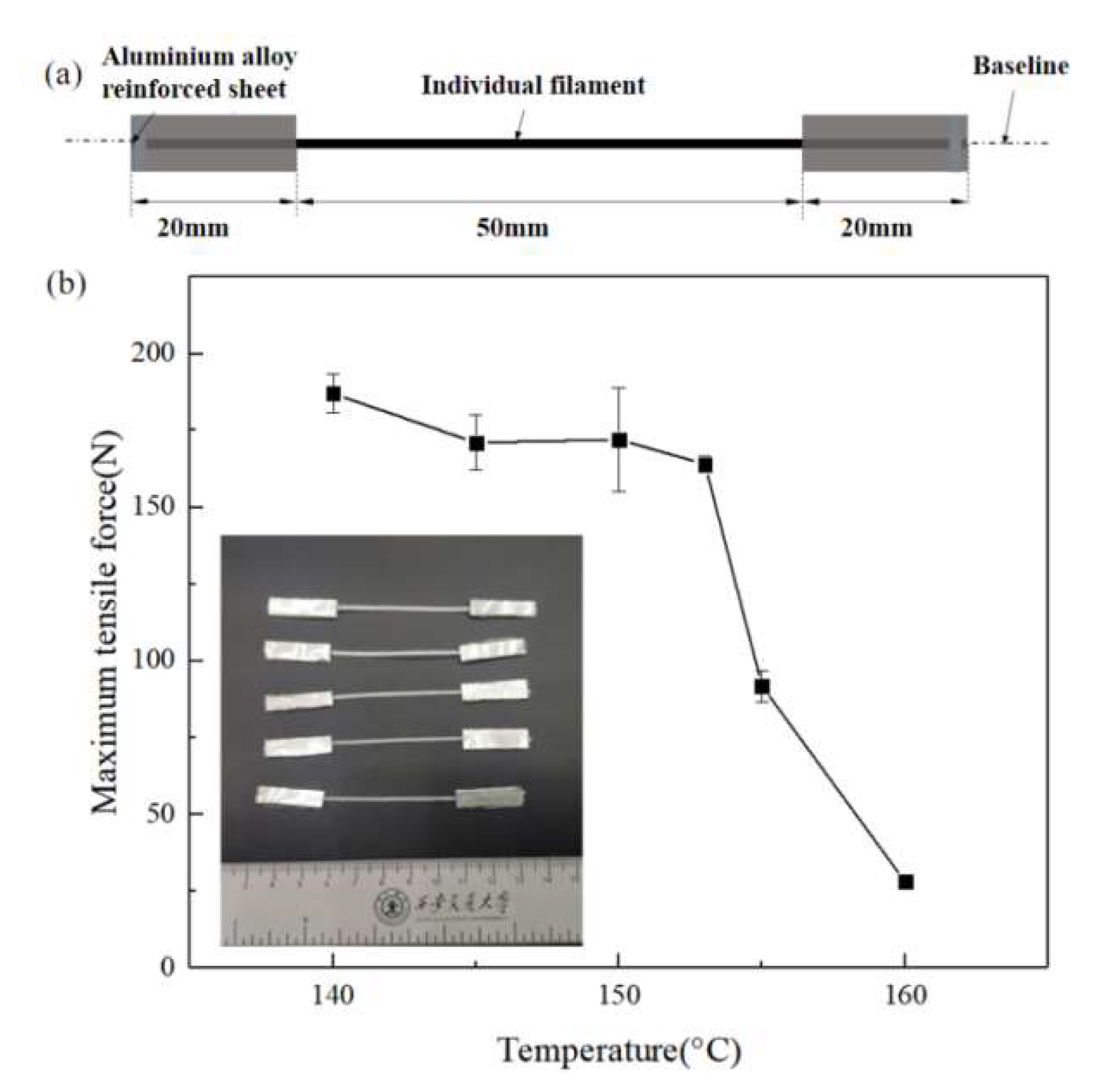

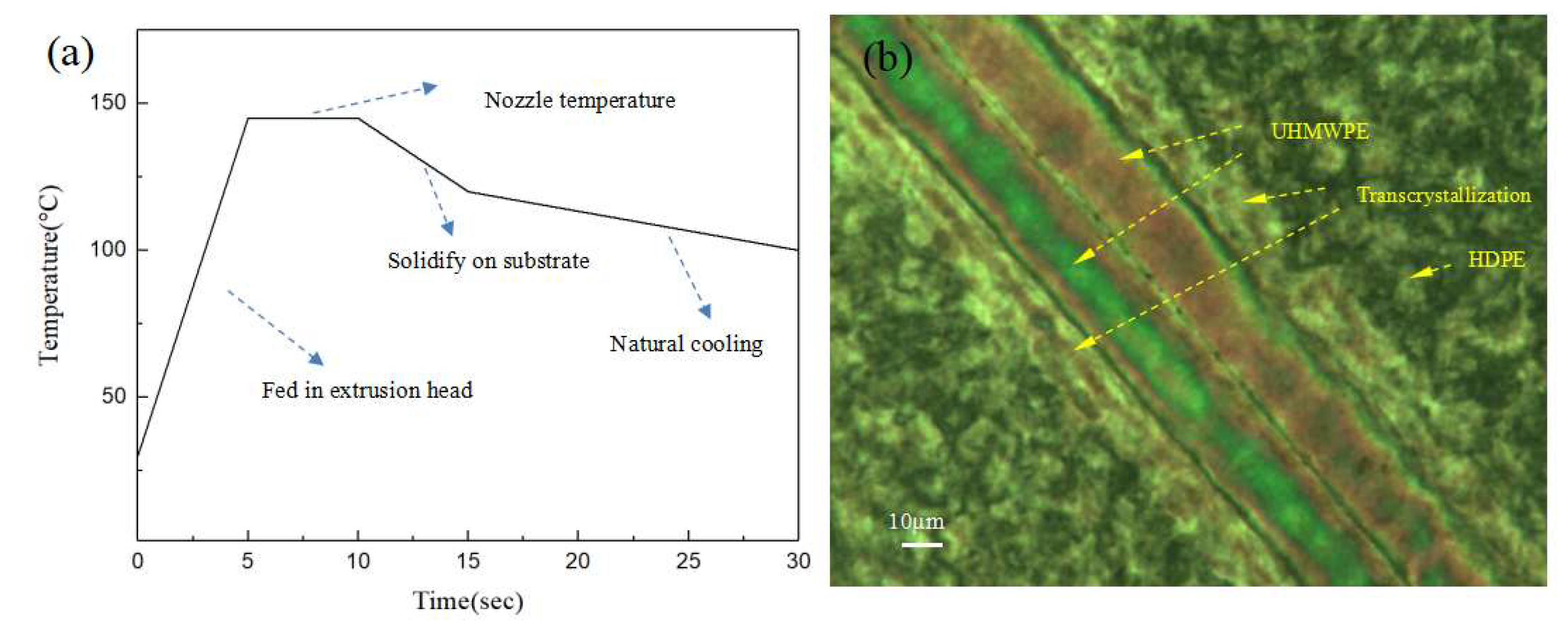

3.1. Process Temperature for 3D Printing

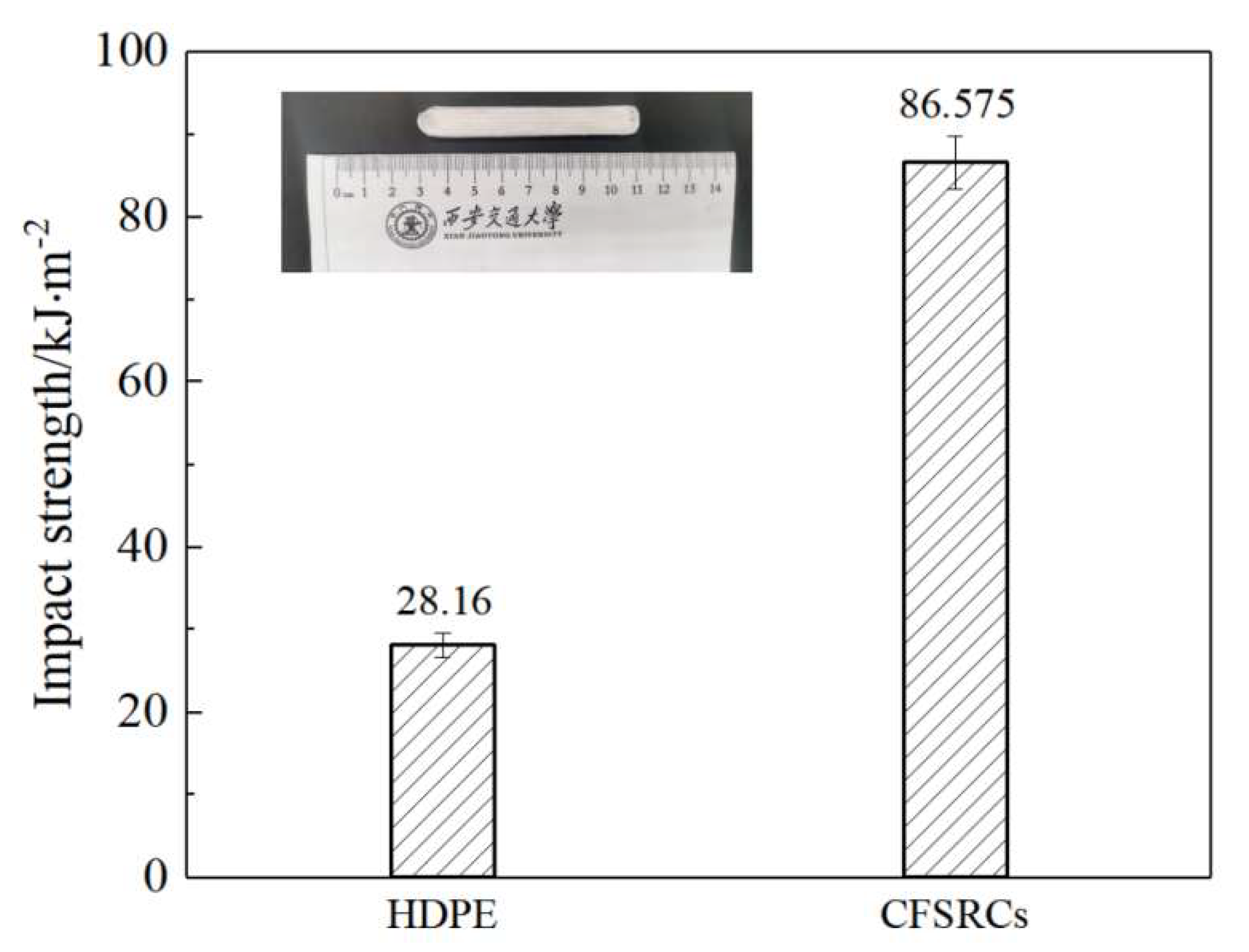

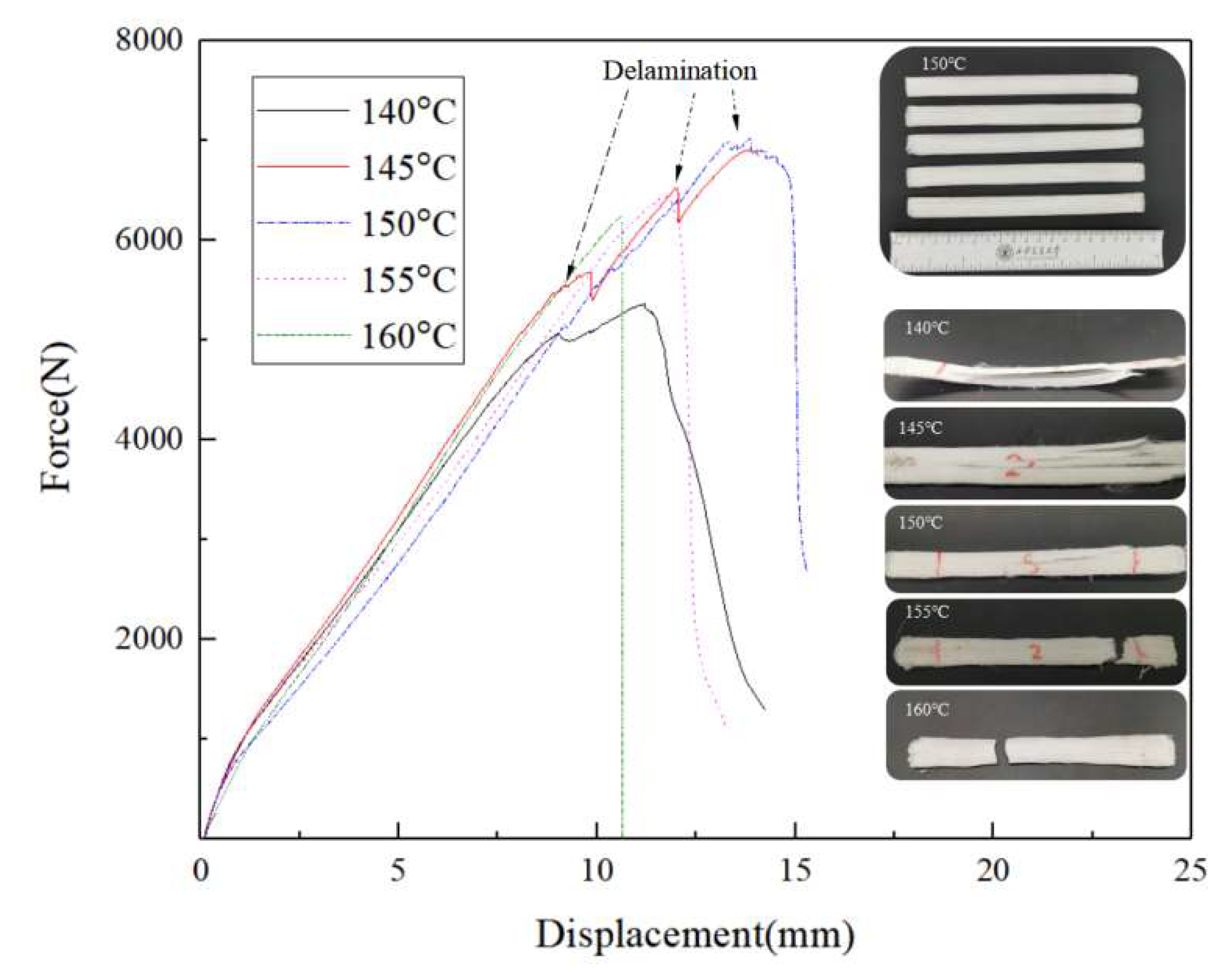

3.2. Mechanical Properties of 3D-Printed CFSRCs

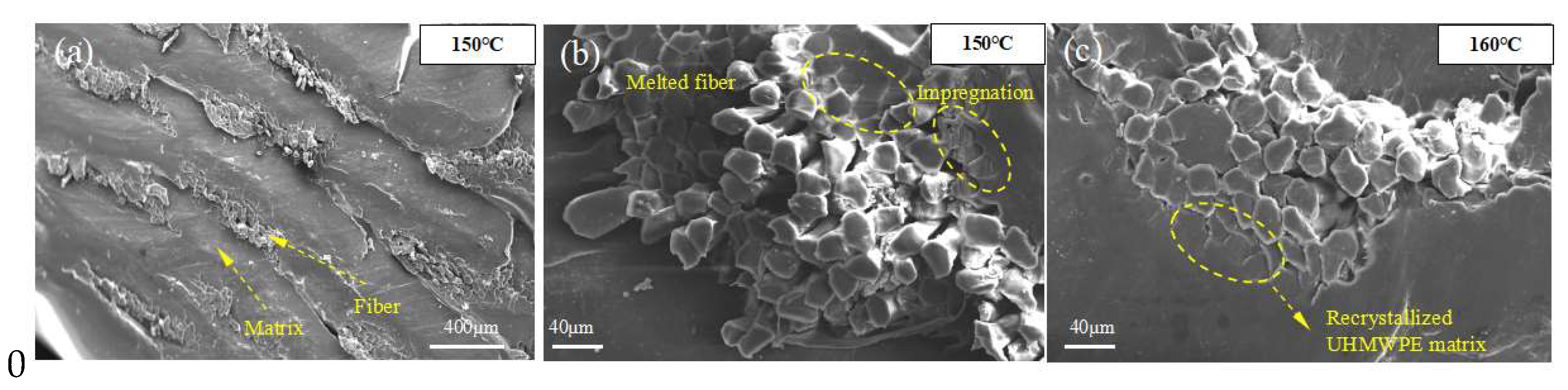

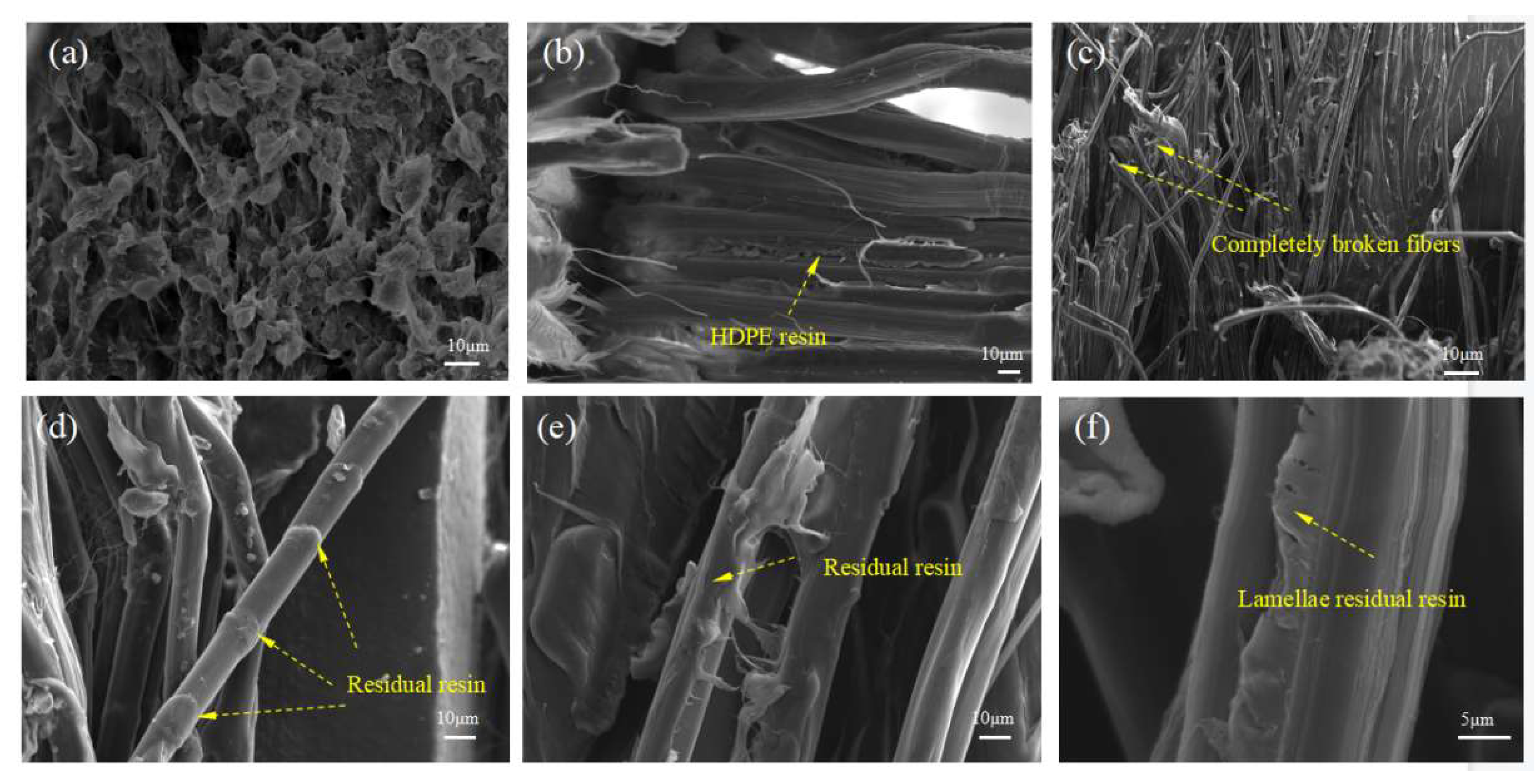

3.3. Microstructures of 3D-Printed CFSRCs

4. Discussion

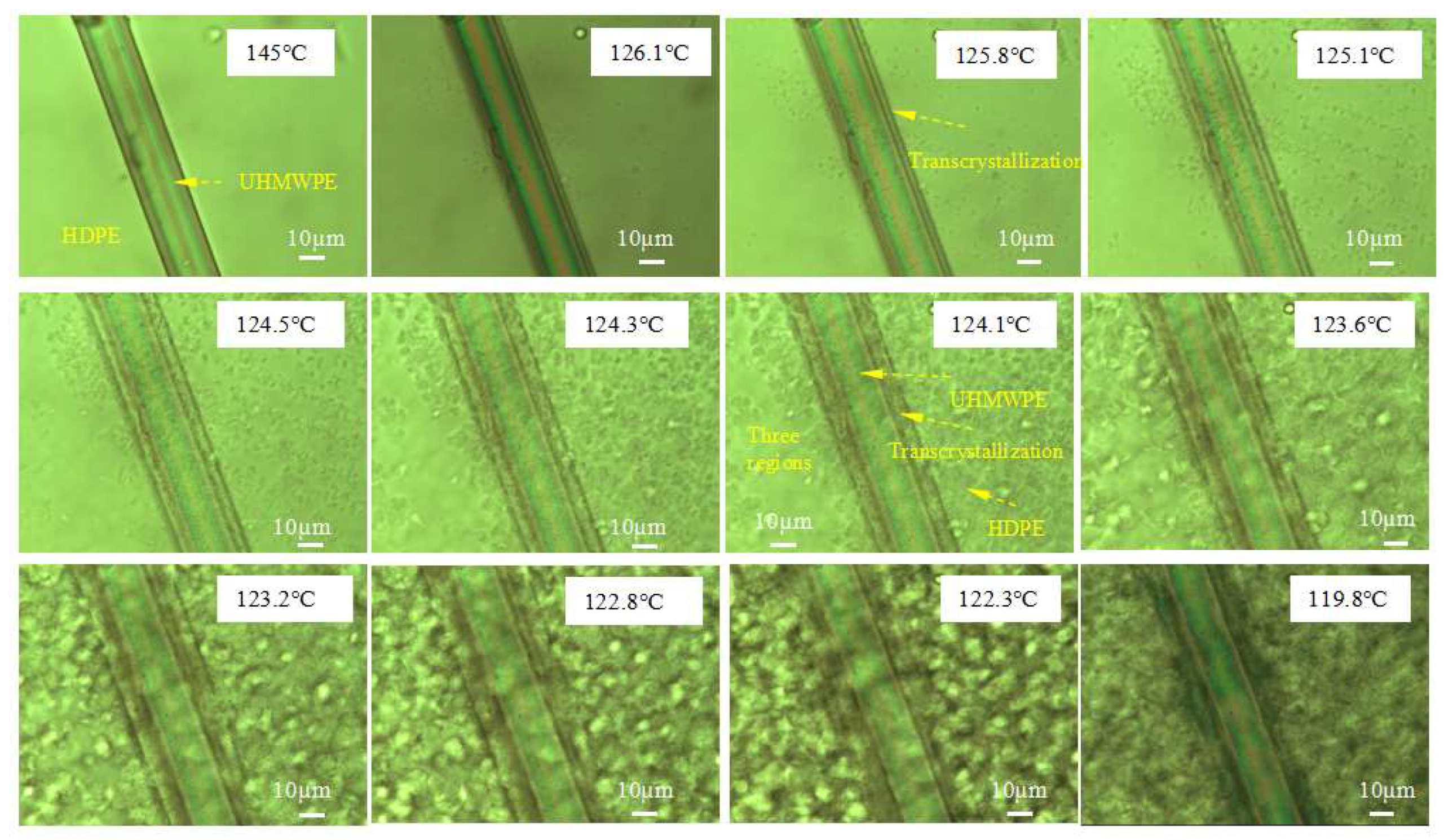

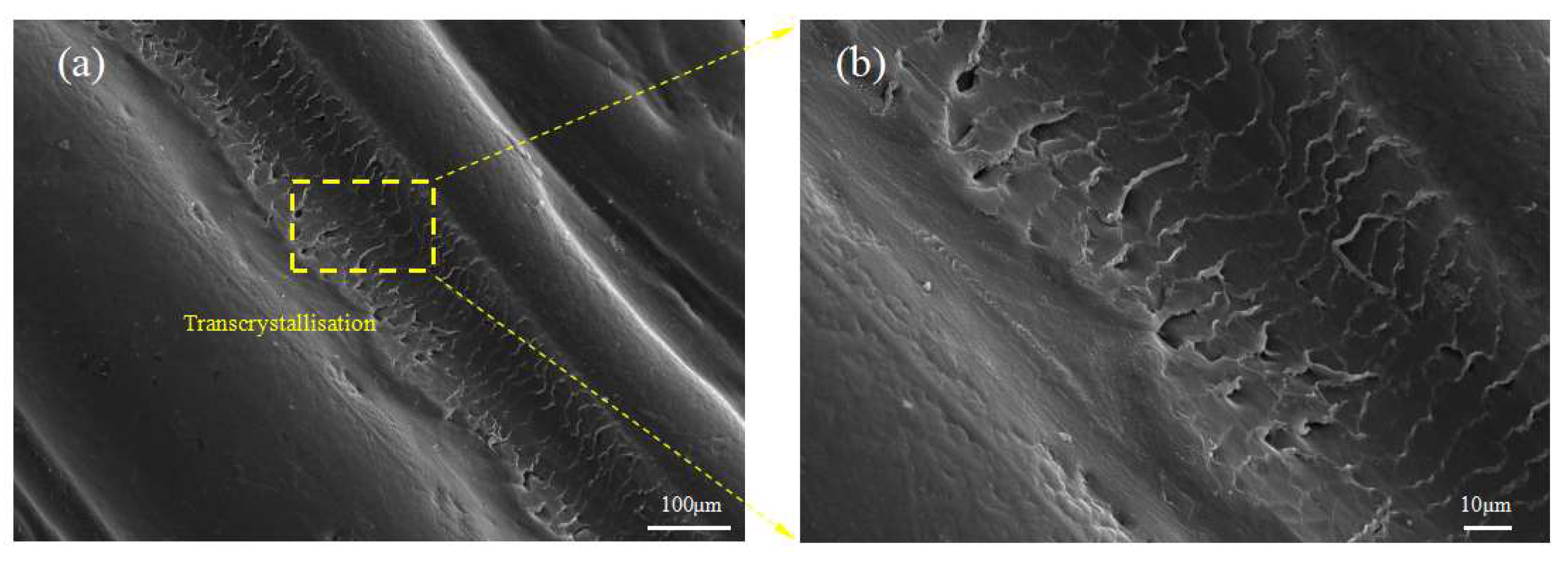

4.1. Transcrystallization in the 3D-Printed CFSRCs

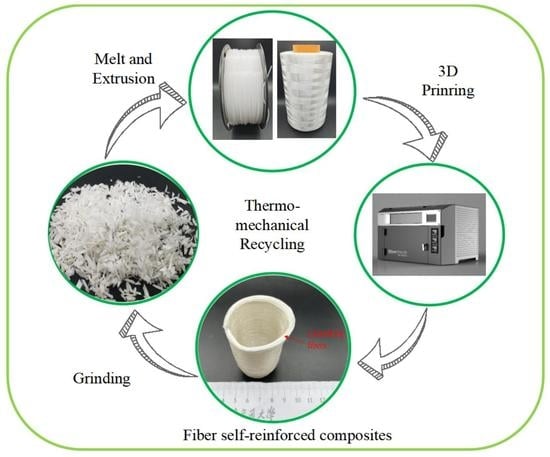

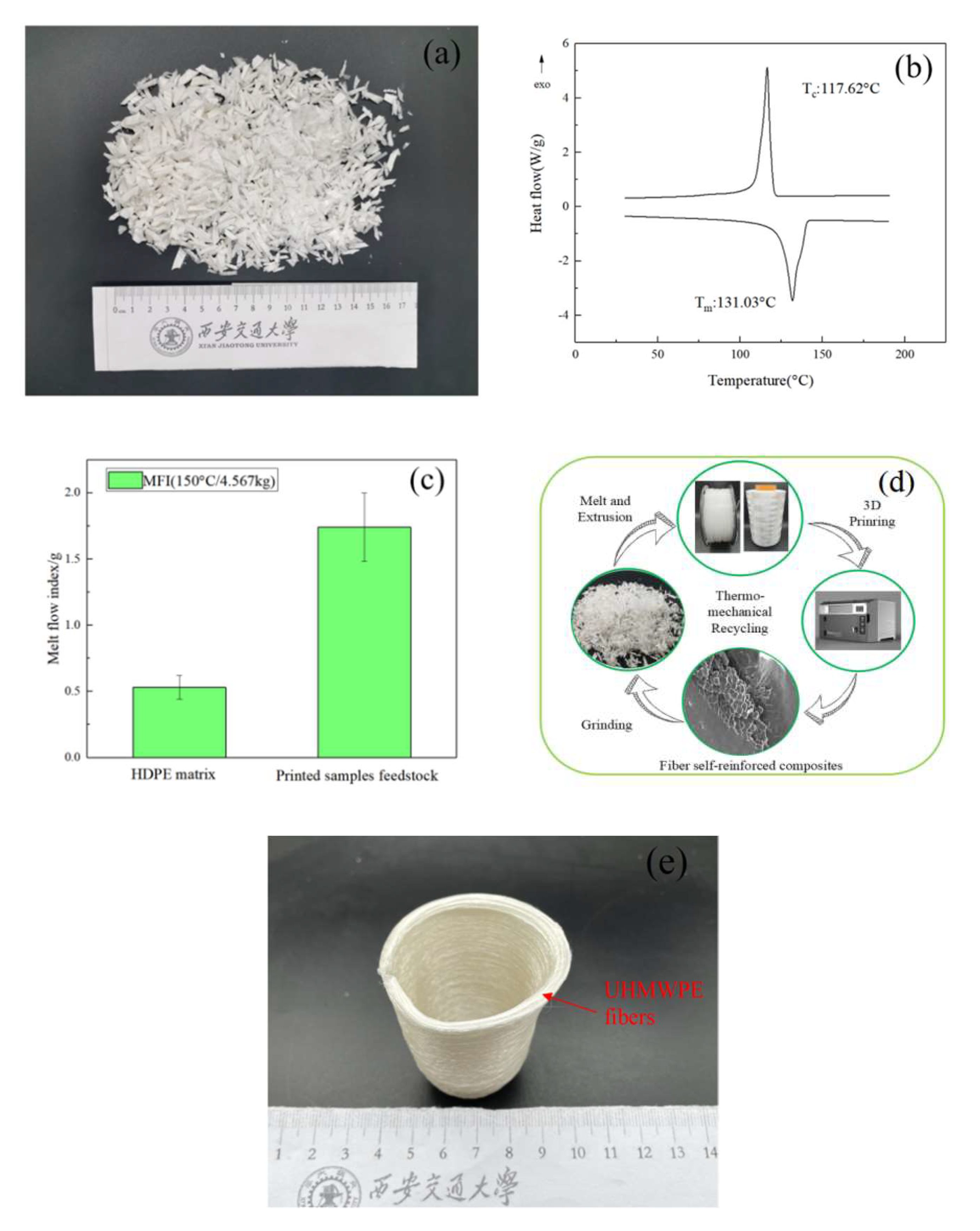

4.2. Recoverability of 3D-Printed CFSRC Material

4.3. Potential Application Areas

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Botelho, E.C.; Silva, R.A.; Pardini, L.C. A Review on the Development and Properties of Continuous Fiber/epoxy/aluminum Hybrid Composites for Aircraft Structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- Ma, Q.; Gu, Y.; Li, M.; Wang, S.; Zhang, Z. Effects of surface treating methods of high-strength carbon fibers on interfacial properties of epoxy resin matrix composite. Appl. Surf. Sci. 2016, 379, 199–205. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev. 2013, 53, 185–218. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Li, C. Polyamide 6 composite with highly improved mechanical properties by PEI-CNT grafted glass fibers through interface wetting, infiltration and crystallization. Polymer 2019, 172, 253–264. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Matabola, K.P.; De Vries, A.R.; Moolman, F.S.; Luyt, A.S. Single polymer composites: A review. J. Mater. Sci. 2009, 44, 6213–6222. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Ferrando, H.E.; Velasco, J.I. Characterisation of filled and recycled PA6. Macromol. Symp. 2003, 194, 295–304. [Google Scholar] [CrossRef]

- Houshyar, S.; Shanks, R.A.; Hodzic, A. The effect of fiber concentration on mechanical and thermal properties of fiber-reinforced polypropylene composites. Appl. Polym. 2005, 96, 2260–2272. [Google Scholar] [CrossRef]

- Yao, D.; Li, R.; Nagarajan, P. Single-polymer composites based on slowly crystallizing polymers. Polym. Eng. Sci. 2010, 46, 1223–1230. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Capiati, N.J.; Porter, R.S. Concept of one polymer composites modeled with high density polyethylene. J. Mater. Sci. 1975, 10, 1671–1677. [Google Scholar] [CrossRef]

- Zherebtsov, D.; Chukov, D.; Torokhov, V.; Statnik, E. Manufacturing of Single-Polymer Composite Materials Based on Ultra-High Molecular Weight Polyethylene Fibers by Hot Compaction. J. Mater. Eng. Perform. 2020, 12, 1522–1527. [Google Scholar] [CrossRef]

- Mijares, J.L.; Agaliotis, E.; Bernal, C.R.; Mollo, M. Self-reinforced polypropylene composites based on low-cost commercial woven and non-woven fabrics. Polym. Adv. Technol. 2018, 29, 111–120. [Google Scholar] [CrossRef]

- Rojanapitayakorn, P.; Mather, P.T.; Goldberg, A.; Weiss, R. Optically transparent self-reinforced poly (ethylene terephthalate) composites: Molecular orientation and mechanical properties. Polymer 2005, 46, 761–773. [Google Scholar] [CrossRef]

- Gilbert, J.L.; Ney, D.S.; Lautenschlager, E.P. Self-reinforced composite poly (methyl methacrylate): Static and fatigue properties. Biomaterials 1995, 16, 1043–1055. [Google Scholar] [CrossRef]

- Kmetty, Á.; Bárány, T.; Karger-Kocsis, J. Self-reinforced polymeric materials: A review. Prog. Polym. Sci. 2010, 35, 1288–1310. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Zhang, M.; Dilmurat, A.; Li, D.; Ziegmann, G. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 368–376. [Google Scholar]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D printing of continuous carbon fibre reinforced thermos-plastic (CFRTP) tensile test specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Fakirov, S. Nano-and Microfibrillar Single-Polymer Composites: A Review. Macromol. Mater. Eng. 2013, 298, 9–32. [Google Scholar] [CrossRef]

- GB/T447-2005. Fiber-Reinforced Plastics Composites-Determination of Tensile Properties[S]; SAC (Standardization Administration of China): Beijing, China, 2005.

- GB/T1043-1993. Plastics-Determination Charpy Impact Strength of Rigid Materials[S]; SAC (Standardization Administration of China): Beijing, China, 1993.

- Loos, J.; Schimanski, T.; Hofman, J.; Peijs, T.; Lemstra, P.J. Morphological Investigations of Polypropylene Single-Fibre Reinforced Polypropylene Model Composites. Polymer 2001, 42, 3827–3834. [Google Scholar] [CrossRef]

- Vaisman, L.; González, M.F.; Marom, G. Transcrystallinity in brominated UHMWPE fiber reinforced HDPE composites: Morphology and dielectric properties. Polymer 2003, 44, 1229–1235. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Tian, X.; Li, D. Interfacial Transcrystallization and Mechanical Performance of 3D-Printed Fully Recyclable Continuous Fiber Self-Reinforced Composites. Polymers 2021, 13, 3176. https://doi.org/10.3390/polym13183176

Zhang M, Tian X, Li D. Interfacial Transcrystallization and Mechanical Performance of 3D-Printed Fully Recyclable Continuous Fiber Self-Reinforced Composites. Polymers. 2021; 13(18):3176. https://doi.org/10.3390/polym13183176

Chicago/Turabian StyleZhang, Manyu, Xiaoyong Tian, and Dichen Li. 2021. "Interfacial Transcrystallization and Mechanical Performance of 3D-Printed Fully Recyclable Continuous Fiber Self-Reinforced Composites" Polymers 13, no. 18: 3176. https://doi.org/10.3390/polym13183176

APA StyleZhang, M., Tian, X., & Li, D. (2021). Interfacial Transcrystallization and Mechanical Performance of 3D-Printed Fully Recyclable Continuous Fiber Self-Reinforced Composites. Polymers, 13(18), 3176. https://doi.org/10.3390/polym13183176