Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review

Abstract

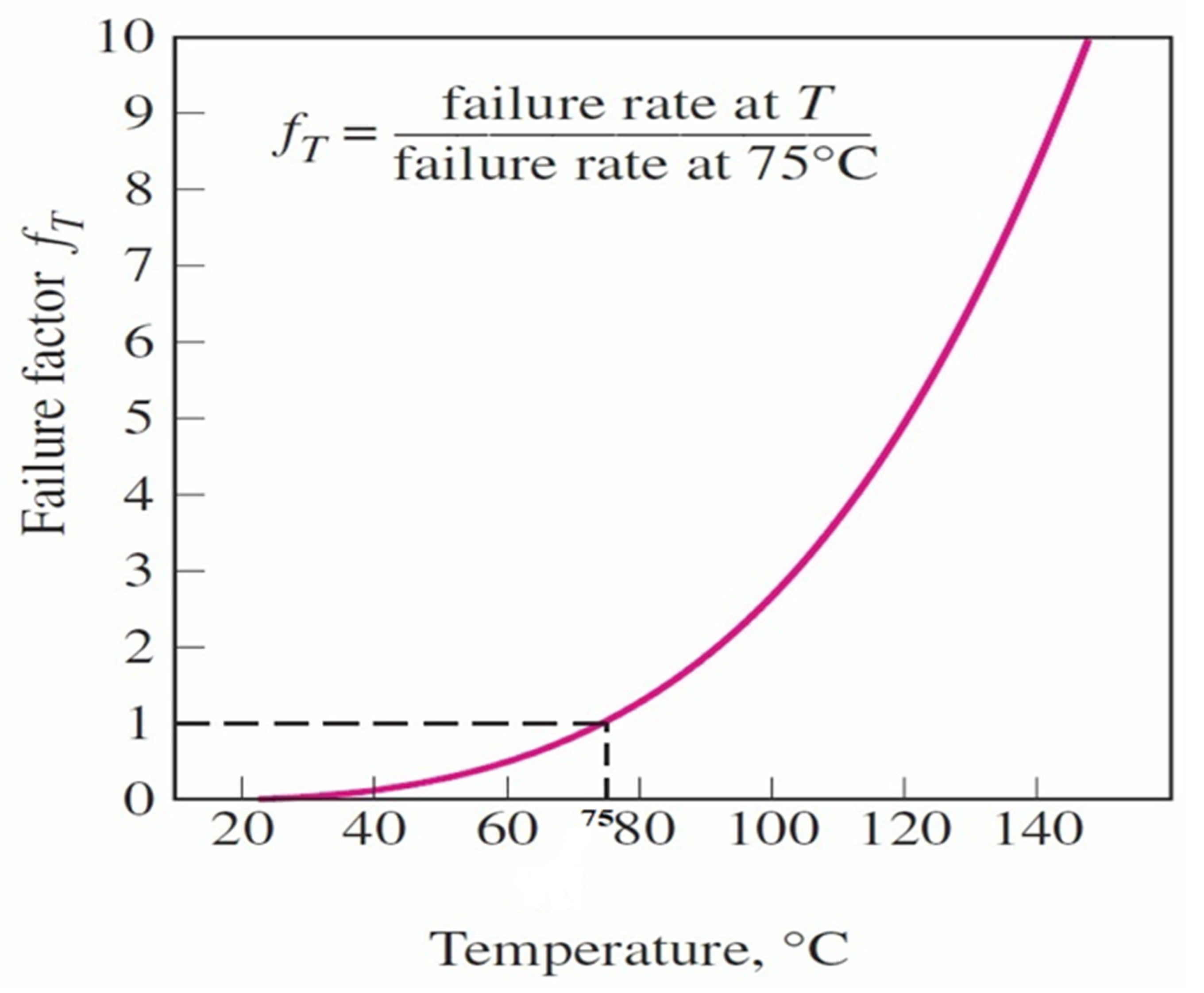

:1. Introduction

Thermally Conductive Adhesive in Electronics Packaging

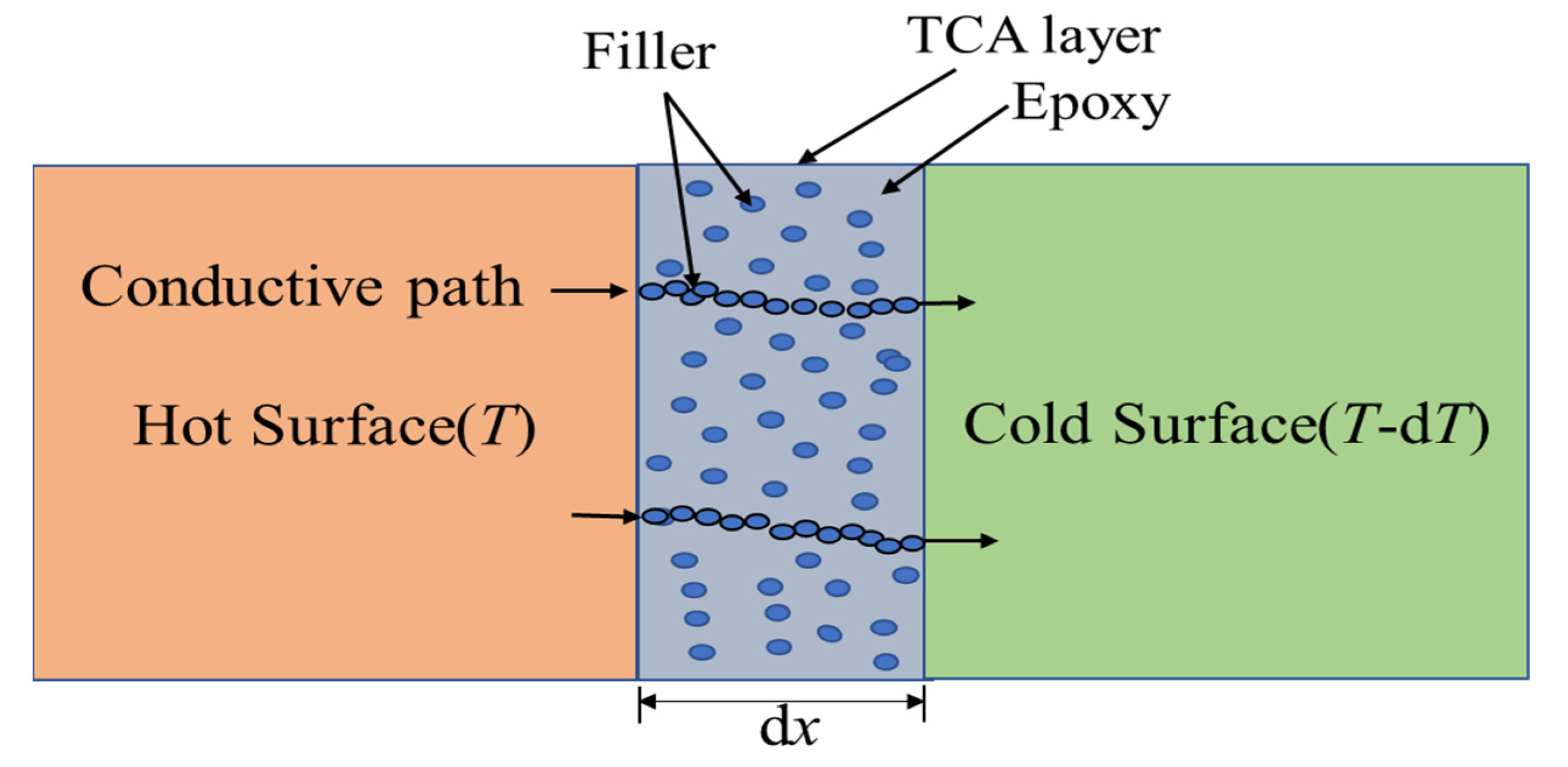

2. Formulation of Thermally Conductive Adhesive and Heat Transfer Mechanism

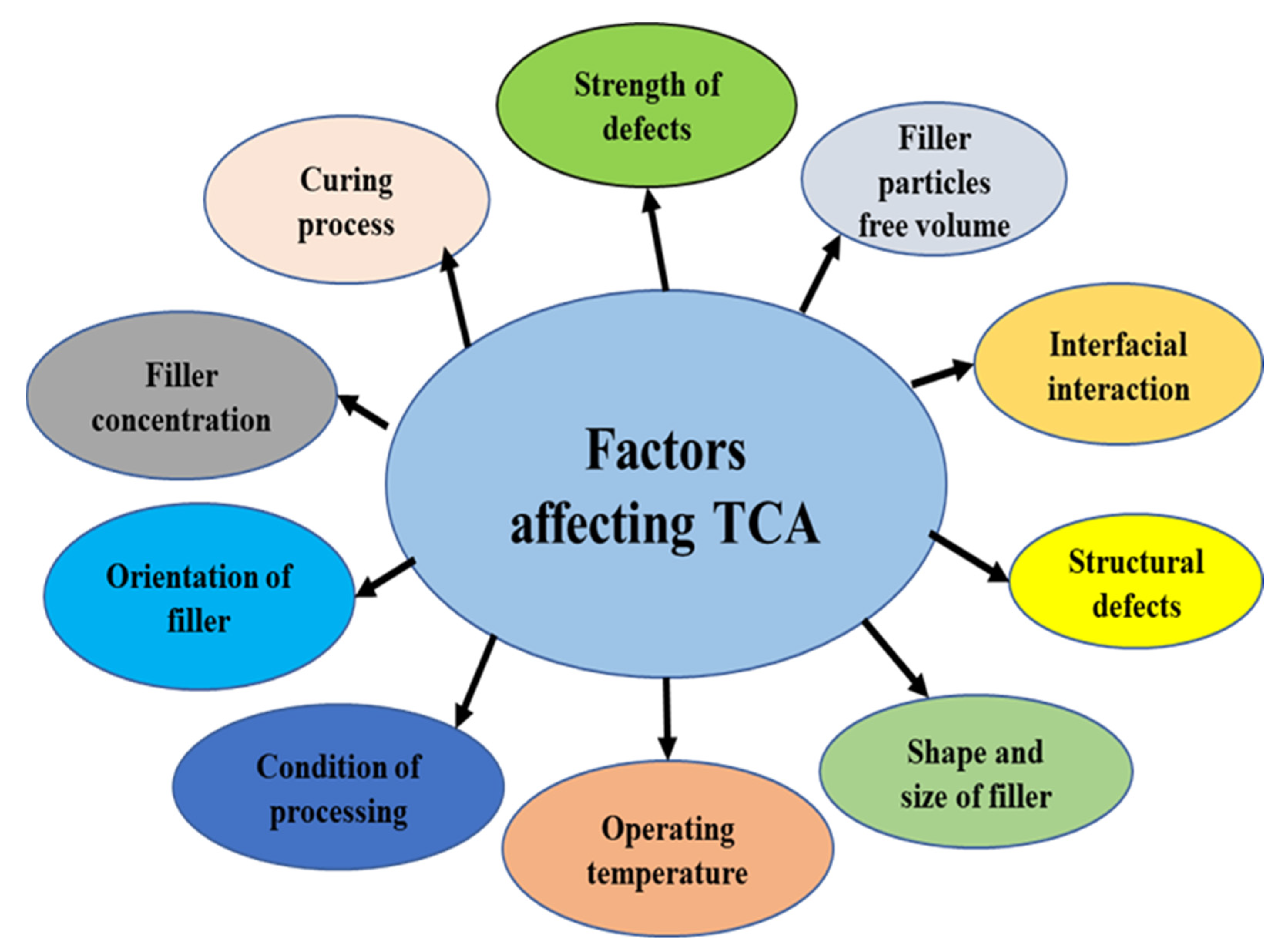

3. Adhesives with Improved Conductivity

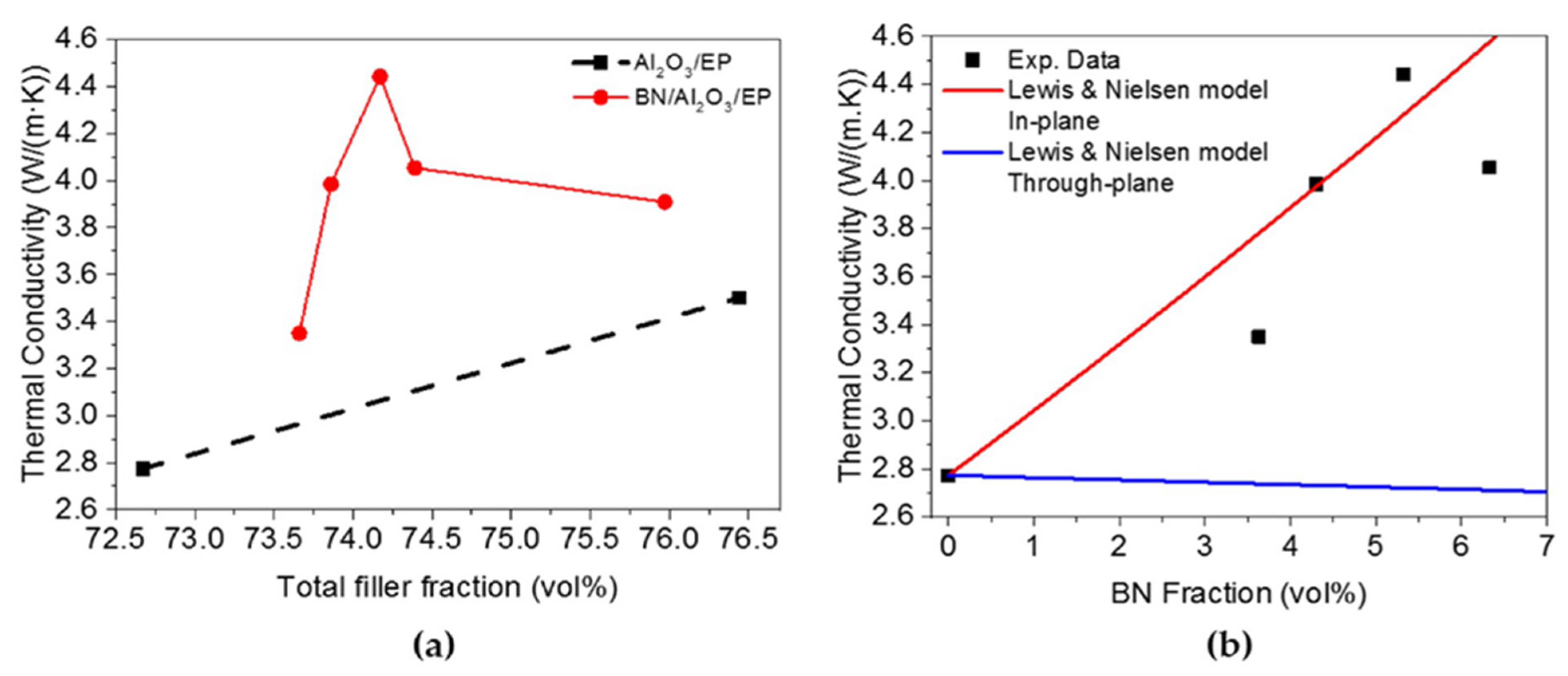

3.1. Ceramic-Based Fillers

3.1.1. Boron Nitride

3.1.2. Alumina

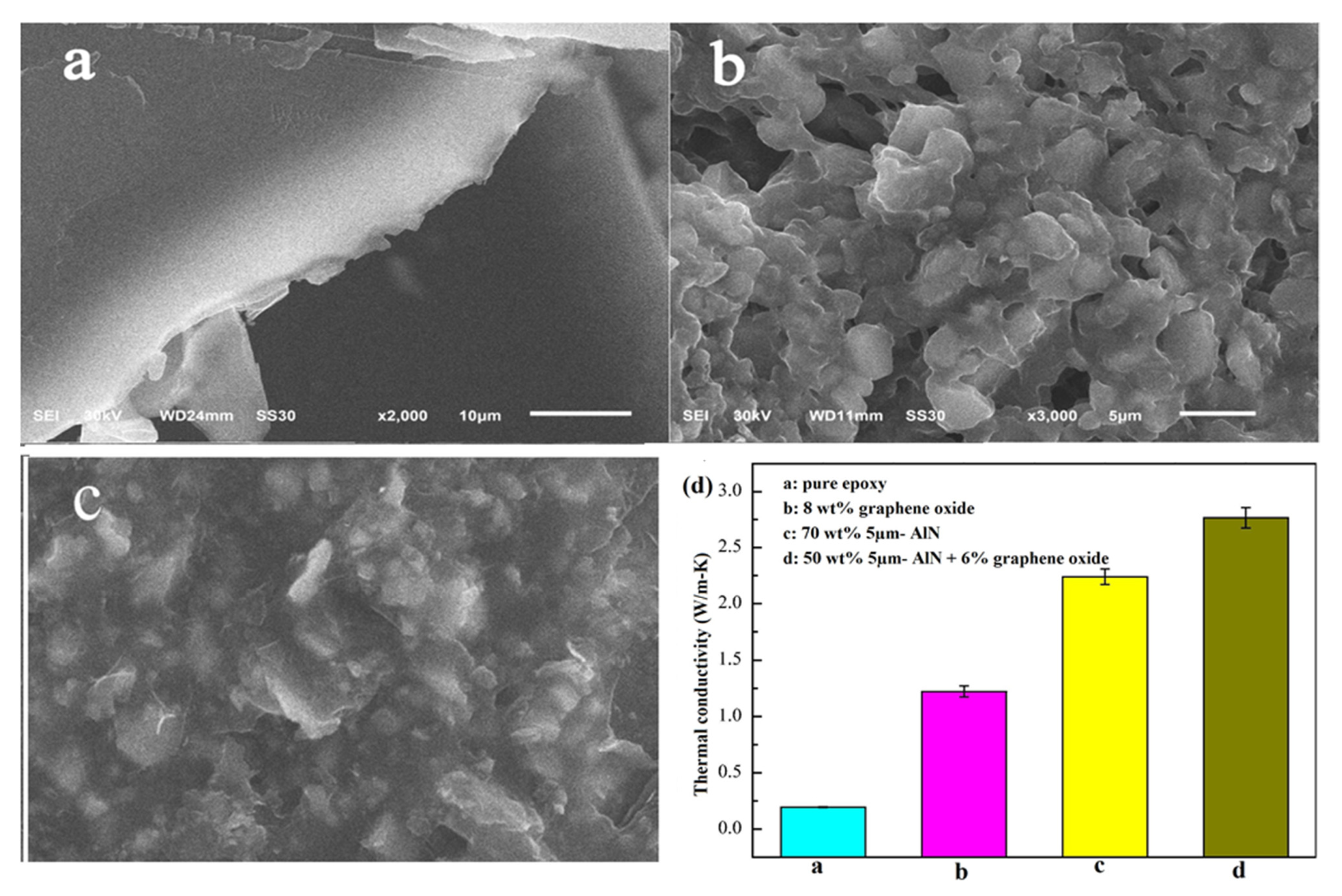

3.1.3. Aluminum Nitride

3.1.4. Silicon Carbide

3.2. Metallic Fillers

3.3. Carbon-Based Fillers

3.3.1. Carbon Nanotubes

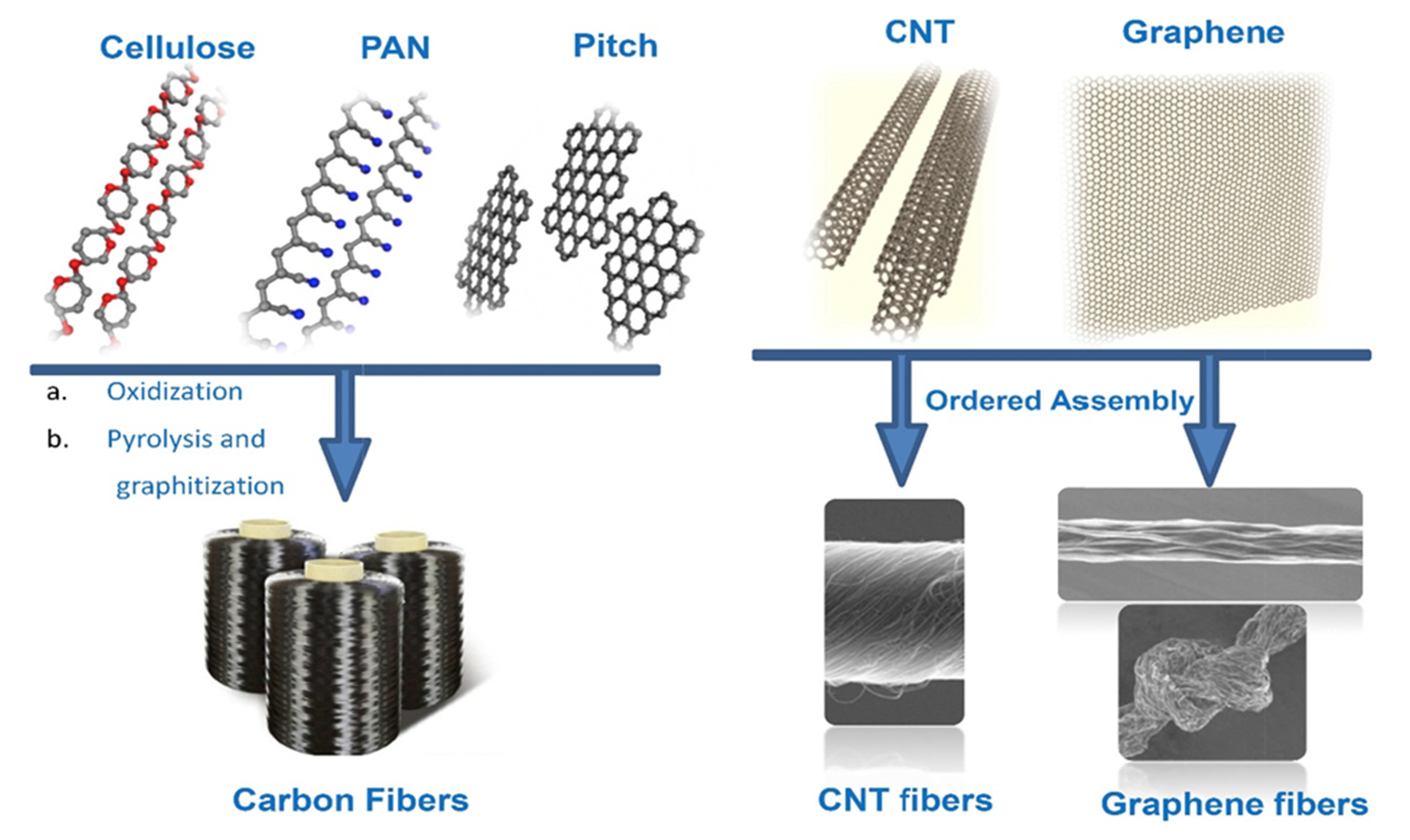

3.3.2. Carbon Fiber

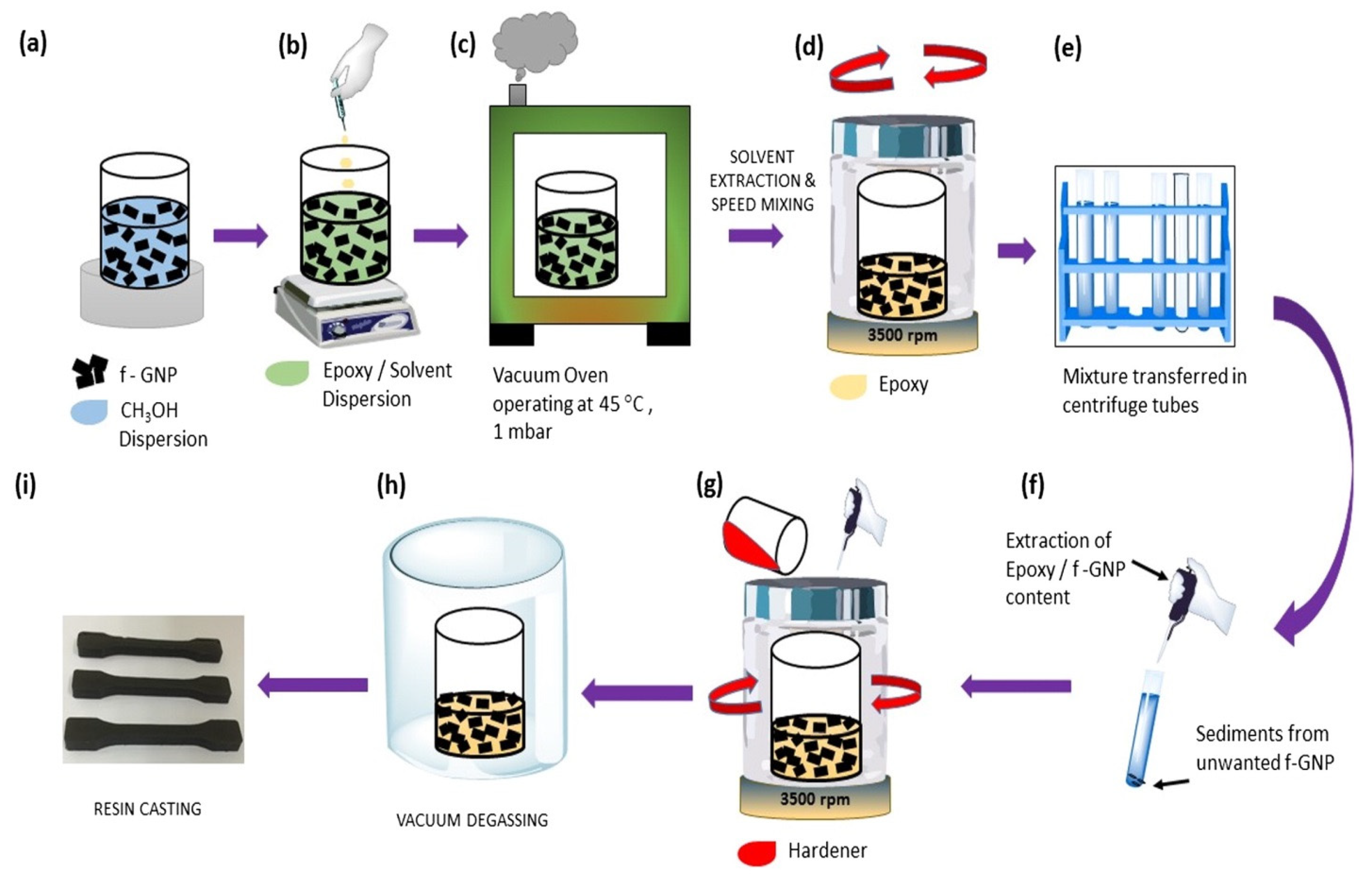

3.3.3. Graphene

4. Economic Perspective of TCA

5. Challenges and Research Potential

- (1)

- The improvement of nanomaterial preparation techniques and process parameters can contribute to the development of an efficient three-dimensional thermal conductive network in matrix.

- (2)

- Surface modification seems to be an effective method of reducing the thermal resistance at the interface; however, it leads to reduction in the low-dimensional materials’ intrinsic thermal conductivity.

- (3)

- Metallic and carbon based (graphene and carbon nanotubes) fillers have high thermal conductivity but possess high electron mobility. The ceramic fillers (BN, AlN, SiC, and Al2O3) are highly thermally conductive but electrically insulated. Therefore, the hybridization of the filler can be a new research direction.

- (4)

- The wonder material graphene oxide (GO) appears to be a potential choice because of its solution processability and controllable deposition on the substrate. GO has been used on various substrates, but there is still room for development in terms of adhesion and heat transmission.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, T.; Wang, M.; Fu, L.; Duan, Z.; Chen, Y.; Hou, X.; Wu, Y.; Li, S.; Guo, L.; Kang, R.; et al. Enhanced Thermal Conductivity of Polyimide Composites with Boron Nitride Nanosheets. Sci. Rep. 2018, 8, 1557. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Park, M.; Park, S.-J. Implication of thermally conductive nanodiamond-interspersed graphite nanoplatelet hybrids in thermoset composites with superior thermal management capability. Sci. Rep. 2019, 9, 2893. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; Zhou, J.; Li, B. Thermal Conductivity of Polymers and Their Nanocomposites. Adv. Mater. 2018, 30, 1705544. [Google Scholar] [CrossRef] [Green Version]

- Almubarak, A.A. The Effects of Heat on Electronic Components. Int. J. Eng. Res. Appl. 2017, 7, 52–57. [Google Scholar] [CrossRef]

- Saidina, D.S.; Abdullah, M.Z.; Hussin, M. Metal oxide nanofluids in electronic cooling: A review. J. Mater. Sci. Mater. Electron. 2020, 31, 4381–4398. [Google Scholar] [CrossRef]

- Khan, J.; Momin, S.A.; Mariatti, M. A review on advanced carbon-based thermal interface materials for electronic devices. Carbon 2020, 168, 65–112. [Google Scholar] [CrossRef]

- Vahabi, H.; Jouyandeh, M.; Cochez, M.; Khalili, R.; Vagner, C.; Ferriol, M.; Movahedifar, E.; Ramezanzadeh, B.; Rostami, M.; Ranjbar, Z.; et al. Short-lasting fire in partially and completely cured epoxy coatings containing expandable graphite and halloysite nanotube additives. Prog. Org. Coat. 2018, 123, 160–167. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Clayton, M. Epoxy Resins: Chemistry and Technology; Routledge: London, UK, 2018; p. 1288. [Google Scholar]

- Ahmadi, Z. Nanostructured epoxy adhesives: A review. Prog. Org. Coat. 2019, 135, 449–453. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M. Recent Advances and Trends of Nanofilled/Nanostructured Epoxies. Materials 2020, 13, 3415. [Google Scholar] [CrossRef]

- Zhao, Z.; Ye, J. Design key points for high power LED encapsulation. Adv. Mater. Res. 2013, 651, 705–709. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, T.; Ma, A. Recent Advances in Design and Preparation of Polymer-Based Thermal Management Material. Polymers 2021, 13, 2797. [Google Scholar] [CrossRef] [PubMed]

- Nie, S.; Hao, N.; Zhang, K.; Xing, C.; Wang, S. Cellulose nanofibrils-based thermally conductive composites for flexible electronics: A mini review. Cellulose 2020, 27, 4173–4187. [Google Scholar] [CrossRef]

- Kausar, A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review. Polym. Technol. Mater. 2020, 59, 895–909. [Google Scholar] [CrossRef]

- Ren, Q.; Guo, P.; Zhu, J. Thermal management of electronic devices using pin-fin based cascade microencapsulated PCM/expanded graphite composite. Int. J. Heat Mass Transf. 2020, 149, 119199. [Google Scholar] [CrossRef]

- Wan, Y.J.; Li, G.; Yao, Y.M.; Zeng, X.L.; Zhu, P.L.; Sun, R. Recent advances in polymer-based electronic packaging materials. Compos. Commun. 2020, 19, 154–167. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; Yuen, M.M.F. Enhanced conductivity induced by attractive capillary force in ternary conductive adhesive. Compos. Sci. Technol. 2016, 137, 109–117. [Google Scholar] [CrossRef]

- Shen, Z.; Fanini, O. Die-Attach Materials for Extreme Conditions and Harsh Environments. In Die-Attach Mater. High Temp. Appl. Microelectron. Packag. Mater. Process. Equipment, Reliab; Springer: Berlin/Heidelberg, Germany, 2019; pp. 251–274. [Google Scholar] [CrossRef]

- Zhang, H.; Minter, J.; Lee, N.-C. A Brief Review on High-Temperature, Pb-Free Die-Attach Materials. J. Electron. Mater. 2018, 48, 201–210. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Gautam, S.; Shu, C.M. Inconsistencies of e-waste management in developing nations—Facts and plausible solutions. J. Environ. Manag. 2020, 261, 110234. [Google Scholar] [CrossRef]

- Derakhshankhah, H.; Mohammad-Rezaei, R.; Massoumi, B.; Abbasian, M.; Rezaei, A.; Samadian, H.; Jaymand, M. Conducting polymer-based electrically conductive adhesive materials: Design, fabrication, properties, and applications. J. Mater. Sci. Mater. Electron. 2020, 31, 10947–10961. [Google Scholar] [CrossRef]

- Jouyandeh, M.; Paran, S.M.R.; Jannesari, A.; Puglia, D.; Saeb, M.R. Protocol for nonisothermal cure analysis of thermoset composites. Prog. Org. Coat. 2019, 131, 333–339. [Google Scholar] [CrossRef]

- Jouyandeh, M.; Rahmati, N.; Movahedifar, E.; Hadavand, B.S.; Karami, Z.; Ghaffari, M.; Taheri, P.; Bakhshandeh, E.; Vahabi, H.; Ganjali, M.R.; et al. Properties of nano-Fe3O4 incorporated epoxy coatings from Cure Index perspective. Prog. Org. Coat. 2019, 133, 220–228. [Google Scholar] [CrossRef]

- Kim, J.; Yim, B.; Kim, J.; Kim, J. The effects of functionalized graphene nanosheets on the thermal and mechanical properties of epoxy composites for anisotropic conductive adhesives (ACAs). Microelectron. Reliab. 2012, 52, 595–602. [Google Scholar] [CrossRef]

- Zhao, J.; Du, F.; Zhou, X.; Cui, W.; Wang, X.; Zhu, H.; Xie, X. Thermal conductive and electrical properties of polyurethane/hyperbranched poly (urea-urethane)-grafted multi-walled carbon nanotube composites. Compos. Part B Eng. 2011, 42, 2111–2116. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Ighalo, J.O.; Abdulkareem, S.A. Al, Fe and Cu waste metallic particles in conductive polystyrene composites. Int. J. Sustain. Eng. 2021, 14, 893–898. [Google Scholar] [CrossRef]

- Huang, X.; Iizuka, T.; Jiang, P.; Ohki, Y.; Tanaka, T. Role of Interface on the Thermal Conductivity of Highly Filled Dielectric Epoxy/AlN Composites. J. Phys. Chem. C 2012, 116, 13629–13639. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, P.; Tanaka, T. A Review of Dielectric Polymer Composites with High Thermal. IEEE Electr. Insul. Mag. 2011, 27, 8–16. [Google Scholar] [CrossRef]

- Felba, J. Thermally conductive adhesives in electronics. Adv. Adhes. Electron. Mater. Prop. Appl. 2011, 15–52. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Liaghat, G.; Vahid, S.; Spacie, C.; Paton, K.R.; Sainsbury, T. Improving the fracture toughness properties of epoxy using graphene nanoplatelets at low filler content. Nanocomposites 2017, 3, 85–96. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, X.; Zhang, J.; Guo, X.; Huang, W. Effect of curing condition on bonding quality of scarf-repaired composite laminates. Chin. J. Aeronaut. 2020, 33, 2257–2267. [Google Scholar] [CrossRef]

- Lee, J.-H.; Koh, C.Y.; Singer, J.P.; Jeon, S.-J.; Maldovan, M.; Stein, O.; Thomas, E.L. 25th Anniversary Article: Ordered Polymer Structures for the Engineering of Photons and Phonons. Adv. Mater. 2014, 26, 532–569. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Wu, K.; Lu, M.; Jiao, E.; Zhang, H.; Shi, J.; Lu, M. Highly thermal conductivity and flame retardant flexible graphene/MXene paper based on an optimized interface and nacre laminated structure. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106227. [Google Scholar] [CrossRef]

- Messina, E.; Leone, N.; Foti, A.; Di Marco, G.; Riccucci, C.; Di Carlo, G.; Di Maggio, F.; Cassata, A.; Gargano, L.; D’Andrea, C.; et al. Double-wall nanotubes and graphene nanoplatelets for hybrid conductive adhesives with enhanced thermal and electrical conductivity. ACS Appl. Mater. Interfaces 2016, 8, 23244–23259. [Google Scholar] [CrossRef]

- Singh, A.K.; Panda, B.P.; Mohanty, S.; Nayak, S.K.; Gupta, M.K. Synergistic effect of hybrid graphene and boron nitride on the cure kinetics and thermal conductivity of epoxy adhesives. Polym. Adv. Technol. 2017, 28, 1851–1864. [Google Scholar] [CrossRef]

- Chung, D.D.L. Review: Electrical application of carbon materials. J. Mater. Sci. 2004, 39, 2645–2661. [Google Scholar] [CrossRef]

- Luo, R.; Liu, T.; Li, J.; Zhang, H.; Chen, Z.; Tian, G. Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity. Carbon 2004, 42, 2887–2895. [Google Scholar] [CrossRef]

- Chung, D.D.L. Applied Materials Science; CRC Press: Boca Raton, FL, USA, 2001; ISBN 9781420040975. [Google Scholar]

- Román-Manso, B.; Chevillotte, Y.; Osendi, M.I.; Belmonte, M.; Miranzo, P. Thermal conductivity of silicon carbide composites with highly oriented graphene nanoplatelets. J. Eur. Ceram. Soc. 2016, 36, 3987–3993. [Google Scholar] [CrossRef]

- Maldovan, M. Sound and heat revolutions in phononics. Nature 2013, 503, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Heo, Y.J.; Son, Y.R.; In, I.; An, K.H.; Kim, B.J.; Park, S.J. Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials. Carbon 2019, 142, 445–460. [Google Scholar] [CrossRef]

- Chen, L.; Shen, Y.; Yi, H.; Liu, Z.; Song, Q. Mathematical modeling of heat transfer in GO-doped reinforce polymer for anti-/deicing of wind turbines. Int. Commun. Heat Mass Transf. 2021, 123, 105235. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Fang, Z.; Huang, Y.; Xu, H.; Liu, Y.; Wu, D.; Zhuang, J.; Sun, J. Recent advances in preparation, mechanisms, and applications of thermally conductive polymer composites: A review. J. Compos. Sci. 2020, 4, 180. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Gong, Y.; Wang, K.; Chen, Y.; Song, X.; Lin, J.; Shen, B.; He, S.; Bian, X. Analysis of the Electrical and Thermal Properties for Magnetic Fe3O4-Coated SiC-Filled Epoxy Composites. Polymers 2021, 13, 3028. [Google Scholar] [CrossRef]

- Mora, M.; Amaveda, H.; Porta-Velilla, L.; de la Fuente, G.F.; Martínez, E.; Angurel, L.A. Improved Copper–Epoxy Adhesion by Laser Micro- and Nano-Structuring of Copper Surface for Thermal Applications. Polymers 2021, 13, 1721. [Google Scholar] [CrossRef] [PubMed]

- Naresh, K.; Khan, K.A.; Umer, R. Experimental Characterization and Modeling Multifunctional Properties of Epoxy/Graphene Oxide Nanocomposites. Polymers 2021, 13, 2831. [Google Scholar] [CrossRef] [PubMed]

- Turner, R.C.; Fuierer, P.A.; Newnham, R.E.; Shrout, T.R. Materials for high temperature acoustic and vibration sensors: A review. Appl. Acoust. 1994, 41, 299–324. [Google Scholar] [CrossRef]

- Zweben, C. Advances in composite materials for thermal management in electronic packaging. Jom 1998, 50, 47–51. [Google Scholar] [CrossRef]

- Guerra, V.; Wan, C.; McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 2019, 100, 170–186. [Google Scholar] [CrossRef]

- Jo, I.; Pettes, M.T.; Kim, J.; Watanabe, K.; Taniguchi, T.; Yao, Z.; Shi, L. Thermal conductivity and phonon transport in suspended few-layer hexagonal boron nitride. Nano Lett. 2013, 13, 550–554. [Google Scholar] [CrossRef] [Green Version]

- Geng, D.; Dong, J.; Kee Ang, L.; Ding, F.; Yang, H.Y. In situ epitaxial engineering of graphene and h-BN lateral heterostructure with a tunable morphology comprising h-BN domains. NPG Asia Mater. 2019, 11, 56. [Google Scholar] [CrossRef]

- Shen, W.; Shen, S.; Liu, S.; Li, H.; Gan, Z.; Zhang, Q. Monolayer Cubic Boron Nitride Terminated Diamond (111) Surfaces for Quantum Sensing and Electron Emission Applications. ACS Appl. Mater. Interfaces 2020, 12, 33336–33345. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Y.; Yin, D.; Song, S.; Lin, L.; Qi, X.; Zhang, M.; Yao, J. Large-scale generation and characterization of amorphous boron nitride and its mechanical properties in atomistic simulations. J. Non-Cryst. Solids 2021, 558, 120664. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, W.; Li, Y.; Zhao, D.; Yin, H. Hybrid fillers of hexagonal and cubic boron nitride in epoxy composites for thermal management applications. RSC Adv. 2019, 9, 7388–7399. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Li, L.; Wang, L.; Huang, T.; Yao, Y.; Xu, W. Effects of 2D boron nitride (BN) nanoplates filler on the thermal, electrical, mechanical and dielectric properties of high temperature vulcanized silicone rubber for composite insulators. J. Alloys Compd. 2019, 774, 396–404. [Google Scholar] [CrossRef]

- Xiao, C.; Tang, Y.; Chen, L.; Zhang, X.; Zheng, K.; Tian, X. Preparation of highly thermally conductive epoxy resin composites via hollow boron nitride microbeads with segregated structure. Compos. Part A Appl. Sci. Manuf. 2019, 121, 330–340. [Google Scholar] [CrossRef]

- Sim, L.C.; Lee, C.K.; Ramanan, S.R.; Ismail, H.; Seetharamu, K.N. Cure characteristics, mechanical and thermal properties of Al2O3 and ZnO reinforced silicone rubber. Polym.-Plast. Technol. Eng. 2006, 45, 301–307. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. The role of alumina nanoparticles in epoxy adhesives. J. Nanop. Res. 2011, 13, 2429–2441. [Google Scholar] [CrossRef]

- Chen, C.; Xue, Y.; Li, X.; Wen, Y.; Liu, J.; Xue, Z.; Shi, D.; Zhou, X.; Xie, X.; Mai, Y.W. High-performance epoxy/binary spherical alumina composite as underfill material for electronic packaging. Compos. Part A Appl. Sci. Manuf. 2019, 118, 67–74. [Google Scholar] [CrossRef]

- Mai, V.D.; Lee, D., II; Park, J.H.; Lee, D.S. Rheological properties and thermal conductivity of epoxy resins filled with a mixture of alumina and boron nitride. Polymers 2019, 11, 597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, K.T.; Dao, T.D.; Jeong, H.M.; Anjanapura, R.V.; Aminabhavi, T.M. Graphene coated with alumina and its utilization as a thermal conductivity enhancer for alumina sphere/thermoplastic polyurethane composite. Mater. Chem. Phys. 2015, 153, 291–300. [Google Scholar] [CrossRef]

- Bae, J.W.; Kim, W.; Cho, S.H.; Lee, S.H. Properties of AlN-filled epoxy molding compounds by the effects of filler size distribution. J. Mater. Sci. 2000, 35, 5907–5913. [Google Scholar] [CrossRef]

- Dai, C.; Chen, X.; Jiang, T.; Paramane, A.; Tanaka, Y. Improvement of electrical and material properties of epoxy resin/ aluminum nitride nanocomposites for packaging materials. Polym. Test. 2020, 86, 106502. [Google Scholar] [CrossRef]

- Yuan, W.; Xiao, Q.; Li, L.; Xu, T. Thermal conductivity of epoxy adhesive enhanced by hybrid graphene oxide/AlN particles. Appl. Therm. Eng. 2016, 106, 1067–1074. [Google Scholar] [CrossRef]

- Choi, S.; Im, H.; Kim, J. The thermal conductivity of embedded nano-aluminum nitride-doped multi-walled carbon nanotubes in epoxy composites containing micro-aluminum nitride particles. Nanotechnology 2012, 23, 065303. [Google Scholar] [CrossRef] [PubMed]

- Alim, M.A.; Abdullah, M.Z.; Aziz, M.S.A.; Kamarudin, R.; Irawan, A.P.; Siahaan, E. Experimental study on luminous intensity of white LEDs of different configurations. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1007, 012145. [Google Scholar] [CrossRef]

- Shen, D.; Zhan, Z.; Liu, Z.; Cao, Y.; Zhou, L.; Liu, Y.; Dai, W.; Nishimura, K.; Li, C.; Lin, C.-T.; et al. Enhanced thermal conductivity of epoxy composites filled with silicon carbide nanowires. Sci. Rep. 2017, 7, 2606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, C.; Chen, L.; Tang, Y.; Zhang, X.; Zheng, K.; Tian, X. Enhanced thermal conductivity of silicon carbide nanowires (SiCw)/epoxy resin composite with segregated structure. Compos. Part A Appl. Sci. Manuf. 2019, 116, 98–105. [Google Scholar] [CrossRef]

- Kim, K.; Ju, H.; Kim, J. Vertical particle alignment of boron nitride and silicon carbide binary filler system for thermal conductivity enhancement. Compos. Sci. Technol. 2016, 123, 99–105. [Google Scholar] [CrossRef]

- Xiao, C.; Guo, Y.; Tang, Y.; Ding, J.; Zhang, X.; Zheng, K.; Tian, X. Epoxy composite with significantly improved thermal conductivity by constructing a vertically aligned three-dimensional network of silicon carbide nanowires/boron nitride nanosheets. Compos. Part B Eng. 2020, 187, 107855. [Google Scholar] [CrossRef]

- Mun, S.Y.; Lim, H.M.; Lee, D.J. Thermal conductivity of a silicon carbide/pitch-based carbon fiber-epoxy composite. Thermochim. Acta 2015, 619, 16–19. [Google Scholar] [CrossRef]

- Li, K.S.; Wang, Q. Thermal conductivity of filled polymer composites. Gaofenzi Cailiao Kexue Yu Gongcheng/Polym. Mater. Sci. Eng. 2002, 18, 10–15. [Google Scholar]

- Xiao, M.; Du, B.X. Review of high thermal conductivity polymer dielectrics for electrical insulation. High Volt. 2016, 1, 34–42. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.; Yang, N.; Qin, L.; Grami, M.E.; Zhang, Q.; Wang, N.; Qu, X. Preparation and characterization of surface modified boron nitride epoxy composites with enhanced thermal conductivity. RSC Adv. 2014, 4, 44282–44290. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, J.; Li, Z.; Tian, W.; Wang, L.; Luo, J.; Li, Q.; Fan, X.; Yao, Y. Enhanced through-plane thermal conductivity of boron nitride/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 25–31. [Google Scholar] [CrossRef]

- Wang, Z.; Iizuka, T.; Kozako, M.; Ohki, Y.; Tanaka, T. Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength part I—Sample preparations and thermal conductivity. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1963–1972. [Google Scholar] [CrossRef]

- Zheng, J.C.; Zhang, L.; Kretinin, A.V.; Morozov, S.V.; Wang, Y.B.; Wang, T.; Li, X.; Ren, F.; Zhang, J.; Lu, C.Y.; et al. High thermal conductivity of hexagonal boron nitride laminates. 2D Mater. 2016, 3, 011004. [Google Scholar] [CrossRef]

- Wattanakul, K.; Manuspiya, H.; Yanumet, N. The adsorption of cationic surfactants on BN surface: Its effects on the thermal conductivity and mechanical properties of BN-epoxy composite. Colloids Surf. A Physicochem. Eng. Asp. 2010, 369, 203–210. [Google Scholar] [CrossRef]

- Ishida, H.; Rimdusit, S. Very high thermal conductivity obtained by boron nitride-filled polybenzoxazine. Thermochim. Acta 1998, 320, 177–186. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J. Thermal conductivity of epoxy composites with a binary-particle system of aluminum oxide and aluminum nitride fillers. Compos. Part B Eng. 2013, 51, 140–147. [Google Scholar] [CrossRef]

- Ma, A.-J.; Chen, W.; Hou, Y. Enhanced Thermal Conductivity of Epoxy Composites with MWCNTs/AlN Hybrid Filler. Polym.-Plast. Technol. Eng. 2012, 51, 1578–1582. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J. Magnetic aligned AlN/epoxy composite for thermal conductivity enhancement at low filler content. Compos. Part B Eng. 2016, 93, 67–74. [Google Scholar] [CrossRef]

- Hsieh, C.Y.; Chung, S.L. High thermal conductivity epoxy molding compound filled with a combustion synthesized AIN powder. J. Appl. Polym. Sci. 2006, 102, 4734–4740. [Google Scholar] [CrossRef]

- Yu, J.H.; Duan, J.K.; Peng, W.Y.; Wang, L.C.; Peng, P.; Jiang, P.K. Influence of nano-ALN particles on thermal conductivity, thermal stability and cure behavior of cycloaliphatic epoxy/trimethacrylate system. Express Polym. Lett. 2011, 5, 132–141. [Google Scholar] [CrossRef]

- Shi, Z.; Radwan, M.; Kirihara, S.; Miyamoto, Y.; Jin, Z. Enhanced thermal conductivity of polymer composites filled with three-dimensional brushlike AlN nanowhiskers. Appl. Phys. Lett. 2009, 95, 176–179. [Google Scholar] [CrossRef]

- Heo, Y.; Im, H.; Kim, J.; Kim, J. The influence of Al(OH)3-coated graphene oxide on improved thermal conductivity and maintained electrical resistivity of Al2O3/epoxy composites. J. Nanop. Res. 2012, 14, 1–10. [Google Scholar] [CrossRef]

- Kozako, M.; Okazaki, Y.; Hikita, M.; Tanaka, T. Preparation and evaluation of epoxy composite insulating materials toward high thermal conductivity. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Yang, K.; Gu, M. Enhanced thermal conductivity of epoxy nanocomposites filled with hybrid filler system of triethylenetetramine-functionalized multi-walled carbon nanotube/silane-modified nano-sized silicon carbide. Compos. Part A Appl. Sci. Manuf. 2010, 41, 215–221. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.; Kim, J.; Kim, J. Magnetic filler alignment of paramagnetic Fe3O4 coated SiC/epoxy composite for thermal conductivity improvement. Ceram. Int. 2015, 41, 12280–12287. [Google Scholar] [CrossRef]

- Yan, J. A Review of Sintering-Bonding Technology Using Ag Nanoparticles for Electronic Packaging. Nanomaterials 2021, 11, 927. [Google Scholar] [CrossRef] [PubMed]

- Janzen, J. On the critical conductive filler loading in antistatic composites. J. Appl. Phys. 1975, 46, 966–969. [Google Scholar] [CrossRef]

- Kim, J.; Lee, B.; Koo, J.M.; Gan, C.L. Copper nanoparticle paste on different metallic substrates for low temperature bonded interconnection. In Proceedings of the 2017 IEEE 19th Electronics Packaging Technology Conference (EPTC), Singapore, 6–9 December 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Li, G.; Fana, J.; Liao, S.; Zhua, P.; Zhang, B.; Zhao, T.; Sun, R.; Wong, C.P. Low temperature sintering of dendritic cu based pastes for power semiconductor device interconnection. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 81–86. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Xuan, Y. Thermal contact resistance of epoxy composites incorporated with nano-copper particles and the multi-walled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2014, 57, 1196. [Google Scholar] [CrossRef]

- Ahn, K.; Kim, K.; Kim, J. Thermal conductivity and electric properties of epoxy composites filled with TiO2-coated copper nanowire. Polymer 2015, 76, 313–320. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Zhi, C.; Zhang, W. High thermal conductivity and temperature probing of copper nanowire/upconversion nanoparticles/epoxy composite. Compos. Sci. Technol. 2016, 130, 63–69. [Google Scholar] [CrossRef]

- Fortunati, E.; D’Angelo, F.; Martino, S.; Orlacchio, A.; Kenny, J.M.; Armentano, I. Carbon nanotubes and silver nanoparticles for multifunctional conductive biopolymer composites. Carbon 2011, 49, 2370–2379. [Google Scholar] [CrossRef]

- Choi, J.R.; Rhee, K.Y.; Park, S.J. Influence of electrolessly silver-plated multi-walled carbon nanotubes on thermal conductivity of epoxy matrix nanocomposites. Compos. Part B Eng. 2015, 80, 379–384. [Google Scholar] [CrossRef]

- Wang, F.; Zeng, X.; Yao, Y.; Sun, R.; Xu, J.; Wong, C.P. Silver Nanoparticle-Deposited Boron Nitride Nanosheets as Fillers for Polymeric Composites with High Thermal Conductivity. Sci. Rep. 2016, 6, 19394. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, A.K.; Panda, B.P.; Mohanty, S.; Nayak, S.K.; Gupta, M.K. Study on metal decorated oxidized multiwalled carbon nanotube (MWCNT)—Epoxy adhesive for thermal conductivity applications. J. Mater. Sci. Mater. Electron. 2017, 28, 8908–8920. [Google Scholar] [CrossRef]

- Choi, J.; Sil, Y.; Park, S. Journal of Industrial and Engineering Chemistry A study on thermal conductivity of electroless Ni—B plated multi-walled carbon nanotubes-reinforced composites. J. Ind. Eng. Chem. 2014, 20, 3421–3424. [Google Scholar] [CrossRef]

- Ekrem, M.; Ataberk, N.; Avcı, A.; Akdemir, A. Improving electrical and mechanical properties of a conductive nano adhesive. J. Adhes. Sci. Technol. 2017, 31, 699–712. [Google Scholar] [CrossRef]

- Jiang, H.; Moon, K.S.; Lu, J.; Wong, C.P. Conductivity enhancement of nano silver-filled conductive adhesives by particle surface functionalization. J. Electron. Mater. 2005, 34, 1432–1439. [Google Scholar] [CrossRef]

- Peighambardoust, S.J.; Rikhtegar, H.; Mohammadzadeh Pakdel, P.; Mirmohseni, A. Electrically conductive epoxy-based nanocomposite adhesives loaded with silver-coated copper and silver-coated reduced graphene oxide nanoparticles. Polym. Adv. Technol. 2019, 30, 1996–2004. [Google Scholar] [CrossRef]

- Fu, Y.X.; He, Z.X.; Mo, D.C.; Lu, S.S. Thermal conductivity enhancement with different fillers for epoxy resin adhesives. Appl. Therm. Eng. 2014, 66, 493–498. [Google Scholar] [CrossRef]

- Huang, D.; Liu, Q.; Zhang, Y.; Ye, C.; Zhu, S.; Fan, Z.; Han, F.; Liu, H.; Liu, J. Ablation behavior and thermal conduction mechanism of 3D ZrC–SiC-modified carbon/carbon composite having high thermal conductivity using mesophase-pitch-based carbon fibers and pyrocarbon as heat transfer channels. Compos. Part B Eng. 2021, 224, 109201. [Google Scholar] [CrossRef]

- Kausar, A. A review of high performance polymer nanocomposites for packaging applications in electronics and food industries. J. Plast. Film Sheeting 2020, 36, 94–112. [Google Scholar] [CrossRef]

- Bregar, T.; An, D.; Gharavian, S.; Burda, M.; Durazo-Cardenas, I.; Thakur, V.K.; Ayre, D.; Słoma, M.; Hardiman, M.; McCarthy, C.; et al. Carbon nanotube embedded adhesives for real-time monitoring of adhesion failure in high performance adhesively bonded joints. Sci. Rep. 2020, 10, 16833. [Google Scholar] [CrossRef] [PubMed]

- Syama, S.; Mohanan, P.V. Comprehensive Application of Graphene: Emphasis on Biomedical Concerns; Springer: Berlin/Heidelberg, Germany, 2019; Volume 11, ISBN 0123456789. [Google Scholar]

- Morris, J.E. Nanopackaging: Nanotechnologies and Electronics Packaging; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783319903620. [Google Scholar]

- Liu, X.; Deng, H.L.; Zheng, J.H.; Sun, M.; Cui, H.; Zhang, X.H.; Song, G.S. Mechanical and thermal conduction properties of carbon/carbon composites with different carbon matrix microstructures. New Carbon Mater. 2020, 35, 576–584. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. Graphene fiber: A new trend in carbon fibers. Mater. Today 2015, 18, 480–492. [Google Scholar] [CrossRef]

- Rakhi, R.B. Preparation and properties of manipulated carbon nanotube composites and applications. Nanocarbon Its Compos. Prep. Prop. Appl. 2019, 489–520. [Google Scholar] [CrossRef]

- Peng, L.-M.; Zhang, Z.; Qiu, C. Carbon nanotube digital electronics. Nat. Electron. 2019, 2, 499–505. [Google Scholar] [CrossRef]

- Shi, H.; Ding, L.; Zhong, D.; Han, J.; Liu, L.; Xu, L.; Sun, P.; Wang, H.; Zhou, J.; Fang, L.; et al. Radiofrequency transistors based on aligned carbon nanotube arrays. Nat. Electron. 2021, 4, 405–415. [Google Scholar] [CrossRef]

- Venkata Ramana, G.; Padya, B.; Naresh Kumar, R.; Prabhakar, K.P.V.; Jain, P.K. Mechanical properties of multi-walled carbon nanotubes reinforced polymer nanocomposites. Indian J. Eng. Mater. Sci. 2010, 17, 331–337. [Google Scholar]

- Mazov, I.N.; Ilinykh, I.A.; Kuznetsov, V.L.; Stepashkin, A.A.; Ergin, K.S.; Muratov, D.S.; Tcherdyntsev, V.V.; Kuznetsov, D.V.; Issi, J.P. Thermal conductivity of polypropylene-based composites with multiwall carbon nanotubes with different diameter and morphology. J. Alloys Compd. 2014, 586, 2012–2014. [Google Scholar] [CrossRef]

- Gonnet, P.; Liang, Z.; Choi, E.S.; Kadambala, R.S.; Zhang, C.; Brooks, J.S.; Wang, B.; Kramer, L. Thermal conductivity of magnetically aligned carbon nanotube buckypapers and nanocomposites. Curr. Appl. Phys. 2006, 6, 119–122. [Google Scholar] [CrossRef]

- Zhang, P.; Ding, X.; Wang, Y.; Gong, Y.; Zheng, K.; Chen, L.; Tian, X.; Zhang, X. Segregated double network enabled effective electromagnetic shielding composites with extraordinary electrical insulation and thermal conductivity. Compos. Part A Appl. Sci. Manuf. 2019, 117, 56–64. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 2009, 47, 2–22. [Google Scholar] [CrossRef]

- Kamarian, S.; Bodaghi, M.; Isfahani, R.B.; Shakeri, M.; Yas, M.H. Influence of carbon nanotubes on thermal expansion coefficient and thermal buckling of polymer composite plates: Experimental and numerical investigations. Mech. Based Des. Struct. Mach. 2019, 49, 217–232. [Google Scholar] [CrossRef]

- Han, S.; Chung, D.D.L. Increasing the through-thickness thermal conductivity of carbon fiber polymer-matrix composite by curing pressure increase and filler incorporation. Compos. Sci. Technol. 2011, 71, 1944–1952. [Google Scholar] [CrossRef]

- Zheng, X.; Fei, J.; Gu, Y.; Li, M.; Huang, J. Constructing interfacial path for enhancing mechanical and thermal performances of carbon fiber/cyanate ester resin composite. Colloids Surf. A Physicochem. Eng. Asp. 2021, 617, 126311. [Google Scholar] [CrossRef]

- Gerstner, E. Nobel Prize 2010: Andre Geim & Konstantin Novoselov. Nat. Phys. 2010, 6, 836. [Google Scholar] [CrossRef]

- Wang, T.Y.; Tsai, J.L. Investigating thermal conductivities of functionalized graphene and graphene/epoxy nanocomposites. Comput. Mater. Sci. 2016, 122, 272–280. [Google Scholar] [CrossRef]

- Omar, G.; Salim, M.A.; Mizah, B.R.; Kamarolzaman, A.A.; Nadlene, R. Electronic Applications of Functionalized Graphene Nanocomposites. Funct. Graphene Nanocomposites Deriv. Synth. Process. Appl. 2019, 245–263. [Google Scholar] [CrossRef]

- Yang, G.; Yi, H.; Yao, Y.; Li, C.; Li, Z. Thermally Conductive Graphene Films for Heat Dissipation. ACS Appl. Nano Mater. 2020. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X.; Song, W. Effect of various carbon nanofillers and different filler aspect ratios on the thermal conductivity of epoxy matrix nanocomposites. Results Phys. 2019, 15, 102771. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Li, J.; Weng, G.J.; Su, Y. A multiscale study of the filler-size and temperature dependence of the thermal conductivity of graphene-polymer nanocomposites. Carbon 2021, 175, 259–270. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Development of Graphene-Based Polymeric Nanocomposites: A Brief Overview. Polymers 2021, 13, 2978. [Google Scholar] [CrossRef]

- Khan, J.; Mariatti, M. The Influence of Substrate Functionalization for Enhancing the Interfacial Bonding between Graphene Oxide and Nonwoven Polyester. Fibers Polym. 2021, 1–11. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, Z.A. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef]

- Yang, S.Y.; Ma, C.C.M.; Teng, C.C.; Huang, Y.W.; Liao, S.H.; Huang, Y.L.; Tien, H.W.; Lee, T.M.; Chiou, K.C. Effect of functionalized carbon nanotubes on the thermal conductivity of epoxy composites. Carbon 2010, 48, 592–603. [Google Scholar] [CrossRef]

- Marconnet, A.M.; Yamamoto, N.; Panzer, M.A.; Wardle, B.L.; Goodson, K.E. Thermal conduction in aligned carbon nanotube-polymer nanocomposites with high packing density. ACS Nano 2011, 5, 4818–4825. [Google Scholar] [CrossRef] [Green Version]

- Qin, M.; Feng, Y.; Ji, T.; Feng, W. Enhancement of cross-plane thermal conductivity and mechanical strength via vertical aligned carbon nanotube@graphite architecture. Carbon 2016, 104, 157–168. [Google Scholar] [CrossRef]

- Chen, Y.M.; Ting, J.M. Ultra high thermal conductivity polymer composites. Carbon 2002, 40, 359–362. [Google Scholar] [CrossRef]

- Fan, W.; Li, J.L.; Zheng, Y.Y.; Liu, T.J.; Tian, X.; Sun, R.J. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites. Polym. Degrad. Stab. 2016, 123, 162–169. [Google Scholar] [CrossRef]

- Li, Q.; Guo, Y.; Li, W.; Qiu, S.; Zhu, C.; Wei, X.; Chen, M.; Liu, C.; Liao, S.; Gong, Y.; et al. Ultrahigh thermal conductivity of assembled aligned multilayer graphene/epoxy composite. Chem. Mater. 2014, 26, 4459–4465. [Google Scholar] [CrossRef]

- Meng, Q.; Han, S.; Araby, S.; Zhao, Y.; Liu, Z.; Lu, S. Mechanically robust, electrically and thermally conductive graphene-based epoxy adhesives. J. Adhes. Sci. Technol. 2019, 33, 1337–1356. [Google Scholar] [CrossRef]

- Shtein, M.; Nadiv, R.; Buzaglo, M.; Kahil, K.; Regev, O. Thermally conductive graphene-polymer composites: Size, percolation, and synergy effects. Chem. Mater. 2015, 27, 2100–2106. [Google Scholar] [CrossRef]

- Kim, H.S.; Bae, H.S.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef] [Green Version]

- Song, N.; Jiao, D.; Cui, S.; Hou, X.; Ding, P.; Shi, L. Highly anisotropic thermal conductivity of layer-by-layer assembled nanofibrillated cellulose/graphene nanosheets hybrid films for thermal management. ACS Appl. Mater. Interfaces 2017, 9, 2924–2932. [Google Scholar] [CrossRef]

- Conductive Adhesive Market Size, Share 2021 Analysis, Overview, Growth, Demand and Forecast Research Report to 2030—MarketWatch. Available online: https://www.marketwatch.com/press-release/conductive-adhesive-market-size-share-2021-analysis-overview-growth-demand-and-forecast-research-report-to-2030-2021-08-09?tesla=y (accessed on 16 September 2021).

- Thermal Conductive Adhesives Market Outlook 2021–2027: Top Compa—WRDE Coast TV. Available online: https://www.wrde.com/story/44479091/thermal-conductive-adhesives-market-outlook-2021-2027--top-companies--trends-and-future-prospects-details-for-business-development (accessed on 16 September 2021).

- Global Conductive Adhesive Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025—Market Study Report. Available online: https://www.marketstudyreport.com/reports/global-conductive-adhesive-market-2020-by-manufacturers-regions-type-and-application-forecast-to-2025?gclid=Cj0KCQjw1ouKBhC5ARIsAHXNMI_yLDzvbJRXoaSNO8HZPsqzTCNG_AOMH5l6An49fmZPspaaePzY1-saAisoEALw_wcB (accessed on 16 September 2021).

- Abdullah, A.; Abdullah, A.Z.; Ahmed, M.; Okoye, P.U.; Shahadat, M. A review on bi/multifunctional catalytic oxydehydration of bioglycerol to acrylic acid: Catalyst type, kinetics, and reaction mechanism. Can. J. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Khan, J.; Jaafar, M. Reduction efficiencies of natural substances for reduced graphene oxide synthesis. J. Mater. Sci. 2021, 1–16. [Google Scholar] [CrossRef]

- Htwe, Y.Z.N.; Mariatti, M.; Chin, S.Y. Fabrication of Graphene by Electrochemical Intercalation Method and Performance of Graphene/PVA Composites as Stretchable Strain Sensor. Arab. J. Sci. Eng. 2020, 45, 7677–7689. [Google Scholar] [CrossRef]

| Material | TC (Wm−1 K−1) | Material | TC (Wm−1 K−1) |

|---|---|---|---|

| Aluminum oxide | 20–30 | Graphite | 100–400 (on plane) |

| Molybdenum | 142 | Silver | 450 |

| Tungsten | 155 | Copper | 401 |

| Nickel | 158 | Silicon carbide (SiC) | 490 |

| Aluminum | 204 | Diamond | 2000 |

| Beryllium oxide | 260 | Boron nitride | ~2000 (in-plane); ~380 (out-of-plane) |

| Carbon fiber | 260 | Multiwalled carbon nanotube (MWCNT) | ~3000 |

| Aluminum nitride (AlN) | 200–320 | Graphene | ~5300 |

| Gold | 345 | Single-walled carbon nanotube (SWCNT) | ~6000 |

| Filler | Conditions/Process | TC (Wm−1 K−1) | References |

|---|---|---|---|

| BN | Platelet-shaped Boron Nitride(BN) particles | 3.5 | [73] |

| BN | At 70 wt% functionalized and mix with epoxy resin | 2.8 | [50] |

| BN | Admicellar-treated BN particles. | 2.7 | [74] |

| BN | 30 wt% of BN particles modified by 3-aminopropyl triethoxysilane | 1.178 | [75] |

| BN | Hexagonal BN/epoxy composites at 44 vol% (densely packed and vertically aligned). | 9 | [76] |

| BN | Hexagonal, cubic, and conglomerated -BN. | 2.91, 3.95, and 10.1 | [77] |

| BN | Hexagonal boron nitride laminates | 20 | [78] |

| BN | Untreated and OTAB-treated BN/epoxy composites. | 1.9 and 3.4 | [79] |

| BN | 88 wt% of BN loading. | 32.5 | [80] |

| AlN | 58.4 vol% of large-sized Aluminum nitride (AlN) with small-sized Al2O3 | 2.842 and 3.4 | [81] |

| AlN | 29 wt% of MWCNTs/AlN | 1.04 | [82] |

| AlN | 20 vol% AlN particles (magnetically aligned) | 1.8 | [83] |

| AlN | 50 wt% of 5 μm-AlN particles and 6 wt% of GO | 2.77 | [65] |

| AlN | 67 vol% of AlN particles (large-sized silane-coated). | 14 | [84] |

| AlN | Cycloaliphatic epoxy/trimethacrylate system | 0.47 | [85] |

| AlN | At 47 vol% nano-whiskers AlN | 4.2 | [86] |

| Al2O3 | At 80 wt% of Alumina (Al2O3)/epoxy, filled with 5 wt% of graphene oxide (GO) and 5 wt% of Al(OH)3-coated GO | 3.5 and 3.1 | [87] |

| Al2O3 | Al2O3/GFRP (amino group grafted) | 1.07 | [17] |

| Al2O3 | At 60 vol% of micron-sized alumina | 4.3 | [88] |

| SiC | Magnetically aligned BN and Silicon Carbide (SiC) filler system | 5.77 | [70] |

| SiC | Nano-sized SiC particles with triethylenetetramine (TETA) functionalized MWCNTs, (at 30% vol%) | 2.00 | [89] |

| SiC | At 20 vol% of SiC particles (magnetically aligned Fe3O4 coated) | 1.681 | [90] |

| Filler | Conditions/Process | TC (Wm−1 K−1) | References |

|---|---|---|---|

| CNT | 1–5 vol% BTC-MWCNTs | 0.96 | [134] |

| CNT | At 14.8 vol% of CNT (axial and transverse direction) | 1.85 and 2.41 | [135] |

| CNT | At 1 wt% of double walled CNT and 0.01 wt% of graphene. | ∼12 | [35] |

| CNT | 3D CNT reinforced exfoliated graphite block | ∼38 | [136] |

| Carbon fiber | At 56 vol% of carbon fiber | 291 | [137] |

| Carbon fiber | carbon fiber/epoxy composites | 1.329 | [138] |

| Carbon fiber | vapor grown carbon fiber (VGCF)/epoxy | ∼695 | [137] |

| Graphene | Aligned MLG/epoxy composite system | 33.54 | [139] |

| Graphene | at 6 vol% with epoxy | 2.13 | [140] |

| Graphene | GNPs reinforced polymer composites. | 12.4 | [141] |

| Graphene | At 20 wt% of GNP with different particle size | 1.8 and 7.3 | [142] |

| Graphene | Layer-by-layer assembly of (GO) on a flexible NFC substrate. | 12.6 | [143] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alim, M.A.; Abdullah, M.Z.; Aziz, M.S.A.; Kamarudin, R.; Gunnasegaran, P. Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review. Polymers 2021, 13, 3337. https://doi.org/10.3390/polym13193337

Alim MA, Abdullah MZ, Aziz MSA, Kamarudin R, Gunnasegaran P. Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review. Polymers. 2021; 13(19):3337. https://doi.org/10.3390/polym13193337

Chicago/Turabian StyleAlim, Md. Abdul, Mohd Zulkifly Abdullah, Mohd Sharizal Abdul Aziz, R. Kamarudin, and Prem Gunnasegaran. 2021. "Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review" Polymers 13, no. 19: 3337. https://doi.org/10.3390/polym13193337

APA StyleAlim, M. A., Abdullah, M. Z., Aziz, M. S. A., Kamarudin, R., & Gunnasegaran, P. (2021). Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review. Polymers, 13(19), 3337. https://doi.org/10.3390/polym13193337