Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

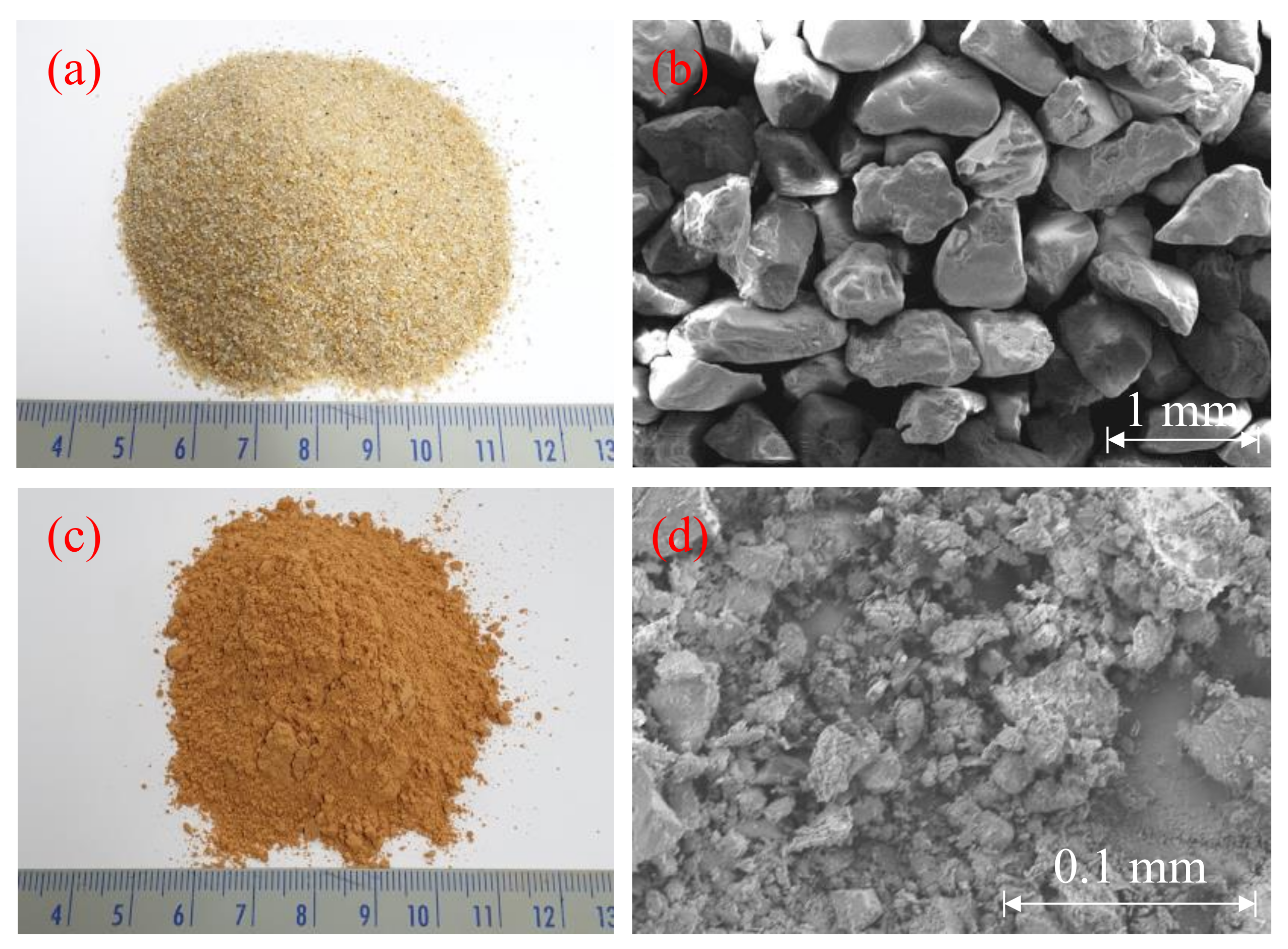

2.1.1. Sand and Red Clay

2.1.2. Epoxy and Acrylic Polymer

2.2. Method

2.2.1. Test Method

2.2.2. Sample Preparation

3. Results and Discussion

3.1. Effect of the Epoxy–Hardener Ratio

3.2. Effect of the Amount of Epoxy Emulsion

3.3. Effect of Acrylic Polymer Aqueous Solution

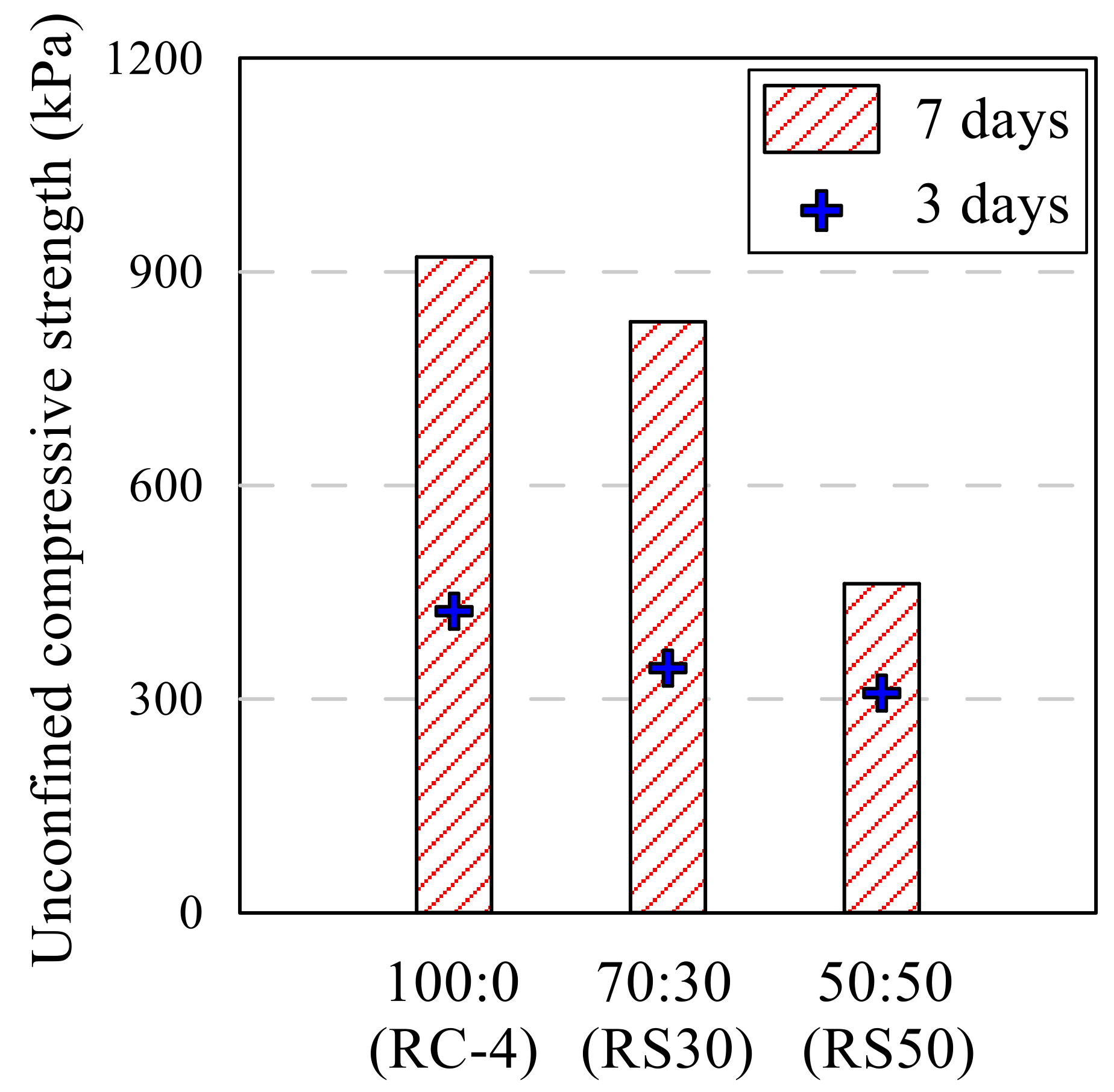

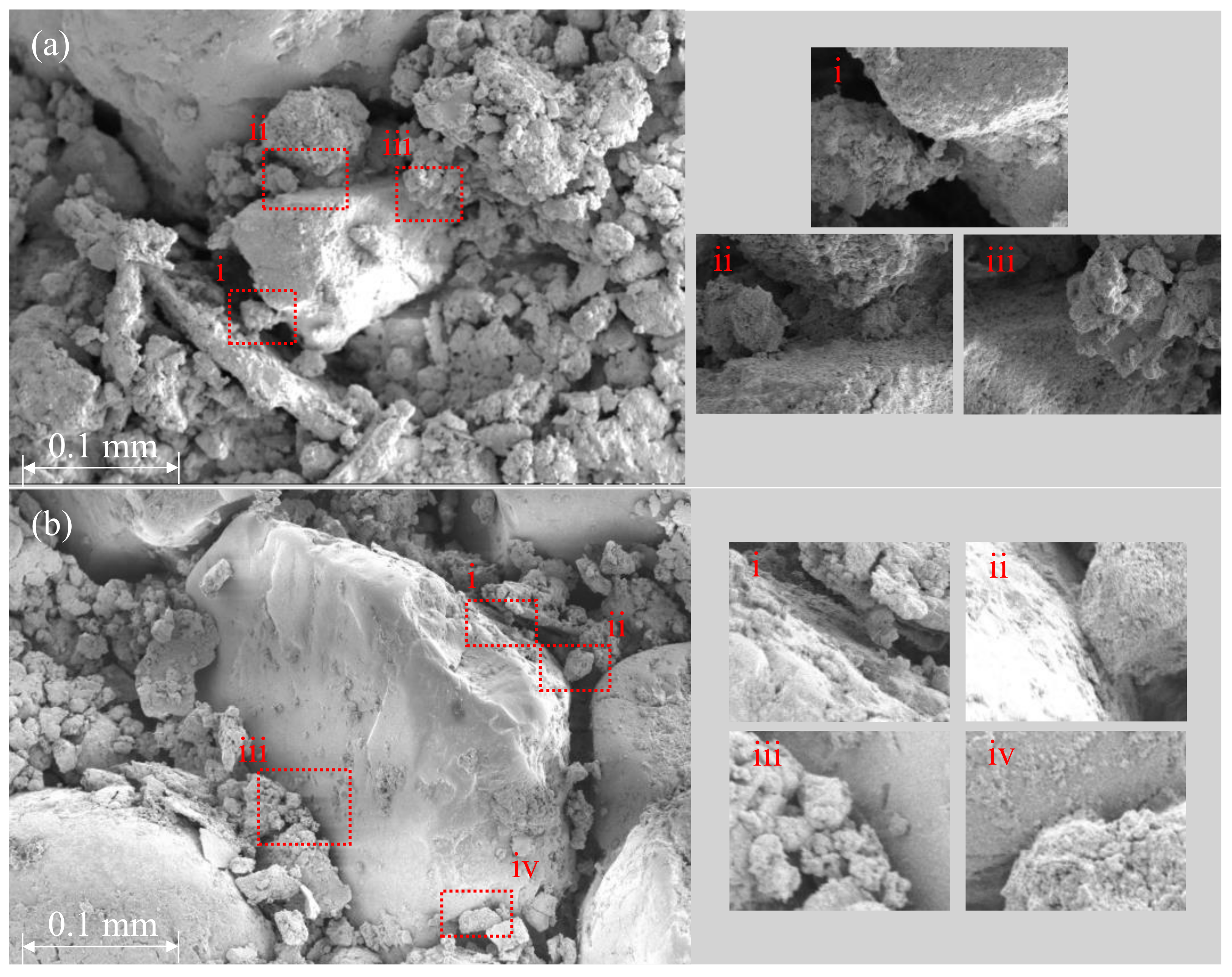

3.4. Red Clay Sample Containing the Sand and Lime

4. Conclusions

- The strength of the RC sample decreased when the epoxy–hardener ratio was higher or lower based on 11:6. The UCS of the RC sample was a 1376 kPa at 11:6 ratio. In the case of the JS sample, the total amount of polymer aqueous solution and epoxy emulsion affected the UCS more than the ratio of epoxy–hardener.

- The RC sample which contained 8% of the epoxy emulsion showed as 1601 kPa of UCS. In contrast, the JS sample that contained 2% of the epoxy emulsion showed 1020 kPa as the UCS. As the epoxy emulsion was included from 2% to 8% in the sample, the strength of RC sample increased, but the strength of JS sample decreased.

- The RC sample showed the highest UCS as 2243 kPa with 50 g of polymer aqueous solution, and the JS sample showed the highest UCS as 1493 kPa at 10 g of the solution. Adjusting the amount of the polymer aqueous solution was the most efficient method to get the highest strength.

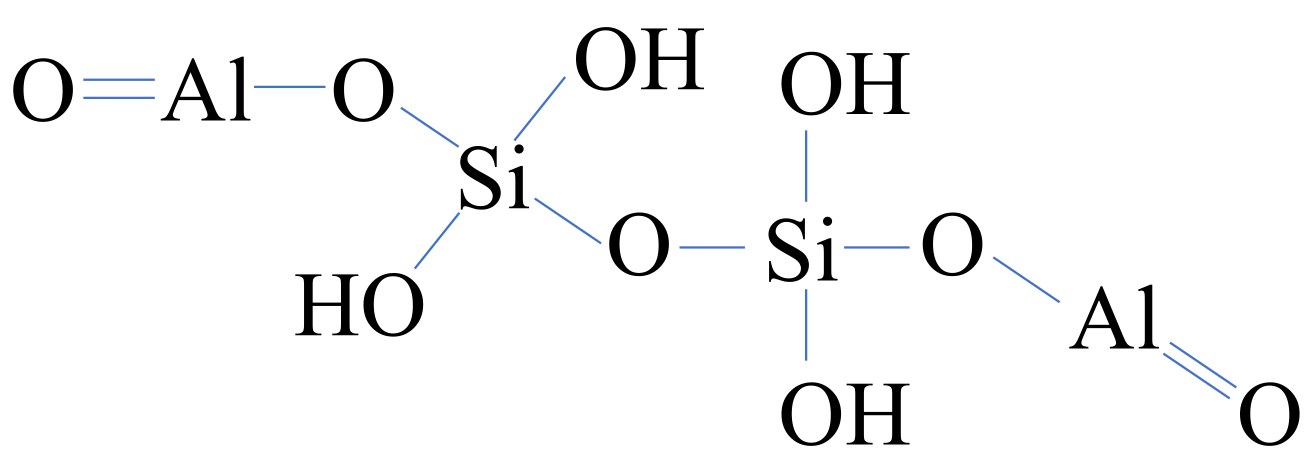

- When the red clay mixed with the sand, the strength of sample decreased. However, when the lime was added, the strength of the sample increased more than RC samples. The lime reacted chemically with the silicate of the sand and formed thread-shaped crystals between the soil particles. The 10% of lime and 5% of lime were the best content to the clay sample and clay–sand sample, respectively.

- The application of acrylic polymer and epoxy as a ground stabilization binder outperforms in strength. Notably, addition of small amount of lime increases the strength dramatically. However, it is necessary to evaluate several dimensions such as impact of the environment, duration of the strength maintenance, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nader, H.; Reyhaneh, J. Effect of Fine-Grain Percent on Soil Strength Properties Improved by Biological Method. Geomicrobiol. J. 2018, 35, 695–703. [Google Scholar] [CrossRef]

- Alkhanbashi, A.; Abdalla, S.W. Evaluation of three waterborne polymers as stabilizers for sandy soil. Geotech. Geol. Eng. 2006, 24, 1603–1625. [Google Scholar] [CrossRef]

- McDowell, C. Stabilization of soils with lime, lime-flyash, and other lime reactive materials. Highw. Res. Board Bull. 1959, 231, 60–66. [Google Scholar]

- Karol, R.H. Chemical Grouting and Soil Stabilization, Revised and Expanded, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Degirmenci, N.; Okucu, A.; Turabi, A. Application of phosphogypsum in soil stabilization. Build. Environ. 2007, 42, 3393–3398. [Google Scholar] [CrossRef]

- Yi, Y.; Liska, M.; Unluer, C.; Al-Tabbaa, A. Carbonating magnesia for soil stabilization. Can. Geotech. J. 2013, 50, 899–905. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Ouston, M. Polymers for stabilization of soft clay soils. Procedia Eng. 2017, 189, 25–32. [Google Scholar] [CrossRef]

- Slaný, M.; Jankovič, Ľ.; Madejová, J. Structural characterization of organo-montmorillonites prepared from a series of primary alkylamines salts: Mid-IR and near-IR study. Appl. Clay Sci. 2019, 176, 11–20. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Rashid, A.S.A. Xanthan gum biopolymer: An eco-friendly additive for stabilization of tropical organic peat. Environ. Earth Sci. 2016, 75, 825. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—an environmentally friendly soil stabilizer. J. Mater. Civil. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Kolay, P.K.; Dhakal, B.; Kumar, S.; Puri, B.K. Effect of liquid acrylic polymer on geotechnical properties of fine-grained soils. Int. J. Geosynth. Ground Eng. 2016, 2, 1–9. [Google Scholar] [CrossRef]

- Georgees, R.N.; Hassan, R.A.; Evans, R.P.; Jegatheesan, P. Effect of the use of a polymeric stabilizing additive on unconfined compressive strength of soils. Transp. Res. Rec. 2015, 2473, 200–208. [Google Scholar] [CrossRef]

- Rye, H.M.; Son, N.R.; Park, J.Y.; Yi, C.Y.; Lee, D.E.; Yoon, K.B. Acrylic Copolymer as Soil Stabilzer for Improving Compresive Strength of Red Clay Soil. In Proceedings of the ICCEPM2019, Hong Kong, 8–10 December 2019. [Google Scholar]

- Kim, J.S.; Choi, H.G.; Rye, H.M.; Yoon, K.B.; Lee, D.E. A Study on the Red Clay Binder Stabilized with a Polymer Aqueous Solution. Polymers 2021, 13, 54. [Google Scholar] [CrossRef]

- Ajayi, M.A.; Grissom, W.A.; Smith, L.S.; Jones, E.E. Epoxy–resin–based chemical stabilization of a fine, poorly graded soil system. Transp. Res. Rec. 1991, 1295, 95–108. [Google Scholar]

- Anagnostopoulos, C.A. Strength properties of an epoxy resin and cement-stabilized silty clay soil. Appl. Clay Sci. 2015, 114, 517–529. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Sapidis, G.; Papastergiadis, E. Fundamental properties of epoxy resin-modified cement grouts. Constr. Build. Mater. 2016, 125, 184–195. [Google Scholar] [CrossRef]

- Yasmin, A.; Luo, J.J.; Abot, J.L.; Daniel, I.M. Mechanical and thermal behavior of clay/epoxy nanocomposites. Compos. Sci. Technol. 2006, 66, 2415–2422. [Google Scholar] [CrossRef]

- Gil-Martín, L.M.; Rodríguez-Suesca, A.E.; Fernández-Ruiz, M.A.; Hernández-Montes, E. Cyclic behavior of RC beam-column joints with epoxy resin and ground tire rubber as partial cement replacement. Constr. Build. Mater. 2019, 211, 659–674. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Papaliangas, T.T. Experimental investigation of epoxy resin and sand mixes. J. Geotech. Geoenviron. Eng. 2012, 138, 841–849. [Google Scholar] [CrossRef] [Green Version]

- Anagnostopoulos, C.A.; Kandiliotis, P.; Lola, M.; Karavatos, S. Improving properties of sand using epoxy resin and electrokinetics. Geotech. Geol. Eng. 2014, 32, 859–872. [Google Scholar] [CrossRef]

- D’Almeida, J.R.M.; Monteiro, S.N. The effect of the resin/hardener ratio on the compressive behavior of an epoxy system. Polym. Test. 1996, 15, 329–339. [Google Scholar] [CrossRef]

- Rahmannejad, M.; Toufigh, V. Influence of curing time and water content on unconfined compressive strength of sand stabilized using epoxy resin. Int. J. Eng. 2018, 31, 1187–1195. [Google Scholar] [CrossRef]

- Lisuzzo, L.; Cavallaro, G.; Milioto, S.; Lazzara, G. Halloysite nanotubes filled with MgO for paper reinforcement and deacidification. Appl. Clay Sci. 2021, 213, 106231. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Modified Nanoclays/Straw Fillers as Functional Additives of Natural Rubber Biocomposites. Polymers 2021, 13, 799. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Al Hawat, W.; Keshawarz, M. Durability and Mechanical Properties of Concrete Reinforced with Basalt Fiber-Reinforced Polymer (BFRP) Bars: Towards Sustainable Infrastructure. Polymers 2021, 13, 1402. [Google Scholar] [CrossRef]

- Lee, K.C.; Her, J.H.; Kwon, S.K. Red clay composites reinforced with polymeric binders. Constr. Build. Mater. 2008, 22, 2292–2298. [Google Scholar] [CrossRef]

- Yoon, K.B.; Ryu, H.M.; Lee, G.H.; Gopalan, A.I.; Sai-anand, G.; Lee, D.E. Enhanced compressive strength of rammed earth walls stabilized with eco-friendly multi-functional polymeric system. Renew. Sustain. Energy Rev. 2021, 152, 111681. [Google Scholar] [CrossRef]

- Du, W.; Slaný, M.; Wang, X.; Chen, G.; Zhang, J. The inhibition property and mechanism of a novel low molecular weight zwitterionic copolymer for improving wellbore stability. Polymers 2020, 12, 708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ASTM D2166. Standard Test. Method for Unconfined Compressive Strength of Cohesive Soil; Annual Book of ASTM Standards: Montgomery County, MD, USA, 2000. [Google Scholar]

- KS F 2314. Standard Test Method for Unconfined Compression Test of Soils; Korean Standards Association: Chungcheongbuk-do, Korea, 2018.

- Ladd, R.S. Preparing test specimens using Undercompaction. Geotech. Test. J. 1978, 1, 16–23. [Google Scholar] [CrossRef]

- Aziz, M.E. A Study on the Effect of Hardener on the Mechanical Properties of Epoxy Resin. Ph.D. Thesis, University of Technology, Baghdad, Republic of Iraq, 2010. [Google Scholar]

- D’Almeida, J.R.M.; Monteiro, S.N. The influence of the amount of hardener on the tensile mechanical behavior of an epoxy system. Polym. Adv. Technol. 1998, 9, 216–221. [Google Scholar] [CrossRef]

- Galvánková, L.; Másilko, J.; Solný, T.; Štěpánková, E. Tobermorite synthesis under hydrothermal conditions. Procedia Eng. 2016, 151, 100–107. [Google Scholar] [CrossRef]

- Arabi, N.; Jauberthie, R.; Chelghoum, N.; Molez, L. Formation of CSH in calcium hydroxide–blast furnace slag–quartz–water system in autoclaving conditions. Adv. Cem. Res. 2015, 27, 153–162. [Google Scholar] [CrossRef] [Green Version]

| SiO2 | Al2O3 | K2O | NA2O | Fe2O3 | CaO | BaO | Cl | L.O.I. | |

|---|---|---|---|---|---|---|---|---|---|

| Component (%) | 87.70 | 6.61 | 4.03 | 0.76 | 0.25 | 0.11 | 0.09 | 0.07 | 0.38 |

| SiO2 | Al2O3 | K2O | Fe2O3 | TiO2 | MgO | CaO | Pd | Ru | ZrO2 | L.O.I. | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Component (%) | 58.79 | 25.87 | 1.63 | 3.99 | 0.74 | 0.62 | 0.13 | 0.07 | 0.06 | 0.04 | 0.38 |

| Model | EEW * (g/eq) | Viscosity (cps@25 °C) | Non-Volatile Content (wt%) |

|---|---|---|---|

| KEM-101-50 | 450–550 | 1000–10000 | 47 |

| Model | TAV * (mgKOH/g) | Viscosity (cps@25 °C) | AHEW ** (g/eq) | Non-Volatile Content (wt%) |

|---|---|---|---|---|

| KH-700 | 190–250 | 3000–10000 | 170 | 80 |

| ID | Polymer Aqueous Solution (g) | Epoxy (g) | Hardener (g) | Water (g) |

|---|---|---|---|---|

| RC-1 | - | - | - | 40 |

| RC-2 | - | - | - | 50 |

| RC-3 | 40 | 11 | 1.5 | - |

| RC-4 | 40 | 11 | 3 | - |

| RC-5 | 40 | 11 | 6 | - |

| RC-6 | 40 | 11 | 9 | - |

| RC-7 | 40 | 5.5 | 1.5 | - |

| RC-8 | 40 | 22 | 6 | |

| RC-9 | 20 | 11 | 3 | - |

| RC-10 | 30 | 11 | 3 | |

| RC-11 | 50 | 11 | 3 | - |

| ID | Polymer Aueous Solution (g) | Epoxy (g) | Hardener (g) |

|---|---|---|---|

| JS-1 | 20 | 11 | 1.5 |

| JS-2 | 20 | 11 | 3 |

| JS-3 | 20 | 11 | 6 |

| JS-4 | 20 | 11 | 9 |

| JS-5 | 20 | 5.5 | 1.5 |

| JS-6 | 20 | 22 | 6 |

| JS-7 | 10 | 11 | 3 |

| JS-8 | 30 | 11 | 3 |

| JS-9 | 40 | 11 | 3 |

| ID | Polymer Solution(g)–Epoxy(g)–Hardener(g) | Red Clay (g) | Sand (g) | Lime (g (%)) |

|---|---|---|---|---|

| RC-4 | 40-11-3 | 350 | - | - |

| RS30 | 245 | 105 | ||

| RS50 | 175 | 175 | ||

| RCL-1 | 350 | - | 10.5 (3) | |

| RCL-2 | 17.5 (5) | |||

| RCL-3 | 35.0 (10) | |||

| RCL-4 | 52.5 (15) | |||

| RS30L-1 | 245 | 105 | 10.5 (3) | |

| RS30L-2 | 17.5 (5) | |||

| RS30L-3 | 35.0 (10) | |||

| RS30L-4 | 52.5 (15) | |||

| RS50L-1 | 175 | 175 | 10.5 (3) | |

| RS50L-2 | 17.5 (5) | |||

| RS50L-3 | 35.0 (10) | |||

| RS50L-4 | 52.5 (15) |

| ID | Polymer Aqueous Solution–Epoxy–Hardener | 3 Days | 7 Days | ||

|---|---|---|---|---|---|

| UCS * (kPa) | εucs * (%) | UCS * (kPa) | εucs * (%) | ||

| RC-1 | Water 40 | N.A. | |||

| RC-2 | Water 50 | 647 | 1.18 | 868 | 1.01 |

| RC-3 | 40–11–1.5 | 179 | 1.29 | 472 | 1.07 |

| RC-4 | 40–11–3 | 418 | 1.51 | 921 | 1.58 |

| RC-5 | 40–11–6 | 843 | 1.81 | 1376 | 1.48 |

| RC-6 | 40–11–9 | 654 | 1.77 | 820 | 1.67 |

| RC-7 | 40–5.5–1.5 | 387 | 0.95 | 540 | 0.84 |

| RC-8 | 40–22–6 | 1027 | 1.92 | 1601 | 1.86 |

| RC-9 | 20–11–3 | N.A. | |||

| RC-10 | 30–11–3 | N.A. | |||

| RC-11 | 50–11–3 | 1786 | 1.89 | 2243 | 1.82 |

| JS-1 | 20–11–1.5 | 40 | 2.21 | 81 | 2.11 |

| JS-2 | 20–11–3 | 29 | 2.54 | 108 | 1.97 |

| JS-3 | 20–11–6 | 30 | 2.48 | 96 | 2.04 |

| JS-4 | 20–11–9 | 54 | 2.17 | 132 | 2.15 |

| JS-5 | 20–5.5–1.5 | 829 | 1.87 | 1020 | 1.74 |

| JS-6 | 20–22–6 | N.A. | |||

| JS-7 | 10–11–3 | 1074 | 1.94 | 1493 | 1.81 |

| JS-8 | 30–11–3 | N.A. | |||

| JS-9 | 40–11–3 | N.A. | |||

| ID | Soil Ratio (Red Clay:Sand) | Lime (%) | 3 Days | 7 Days | ||

|---|---|---|---|---|---|---|

| UCS * (kPa) | εucs * (%) | UCS * (kPa) | εucs * (%) | |||

| RC-4 | 100:0 | - | 432 | 1.63 | 921 | 1.58 |

| RS30 | 70:30 | 352 | 1.85 | 830 | 1.65 | |

| RS50 | 50:50 | 317 | 1.75 | 462 | 1.74 | |

| RCL-1 | 100:0 | 3 | 584 | 0.75 | 1173 | 1.87 |

| RCL-2 | 5 | 795 | 1.51 | 1265 | 1.55 | |

| RCL-3 | 10 | 858 | 1.23 | 1343 | 1.77 | |

| RCL-4 | 15 | 591 | 1.21 | 858 | 1.43 | |

| RS30L-1 | 70:30 | 3 | 667 | 1.71 | 1364 | 1.60 |

| RS30L-2 | 5 | 1433 | 1.41 | 2671 | 2.03 | |

| RS30L-3 | 10 | 633 | 1.47 | 1075 | 1.47 | |

| RS30L-4 | 15 | 401 | 1.28 | 802 | 1.13 | |

| RS50L-1 | 50:50 | 3 | 893 | 1.29 | 1490 | 1.73 |

| RS50L-2 | 5 | 788 | 2.32 | 1250 | 1.92 | |

| RS50L-3 | 10 | 717 | 2.54 | 914 | 1.88 | |

| RS50L-4 | 15 | 717 | 3.07 | 879 | 2.73 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-S.; Lee, J.-S.; Yoon, K.-B.; Woo, S.-W.; Lee, D.-E. Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand. Polymers 2021, 13, 3410. https://doi.org/10.3390/polym13193410

Park S-S, Lee J-S, Yoon K-B, Woo S-W, Lee D-E. Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand. Polymers. 2021; 13(19):3410. https://doi.org/10.3390/polym13193410

Chicago/Turabian StylePark, Sung-Sik, Jung-Shin Lee, Keun-Byoung Yoon, Seung-Wook Woo, and Dong-Eun Lee. 2021. "Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand" Polymers 13, no. 19: 3410. https://doi.org/10.3390/polym13193410

APA StylePark, S.-S., Lee, J.-S., Yoon, K.-B., Woo, S.-W., & Lee, D.-E. (2021). Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand. Polymers, 13(19), 3410. https://doi.org/10.3390/polym13193410