Physical, Mechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of CR and Kenaf Fiber

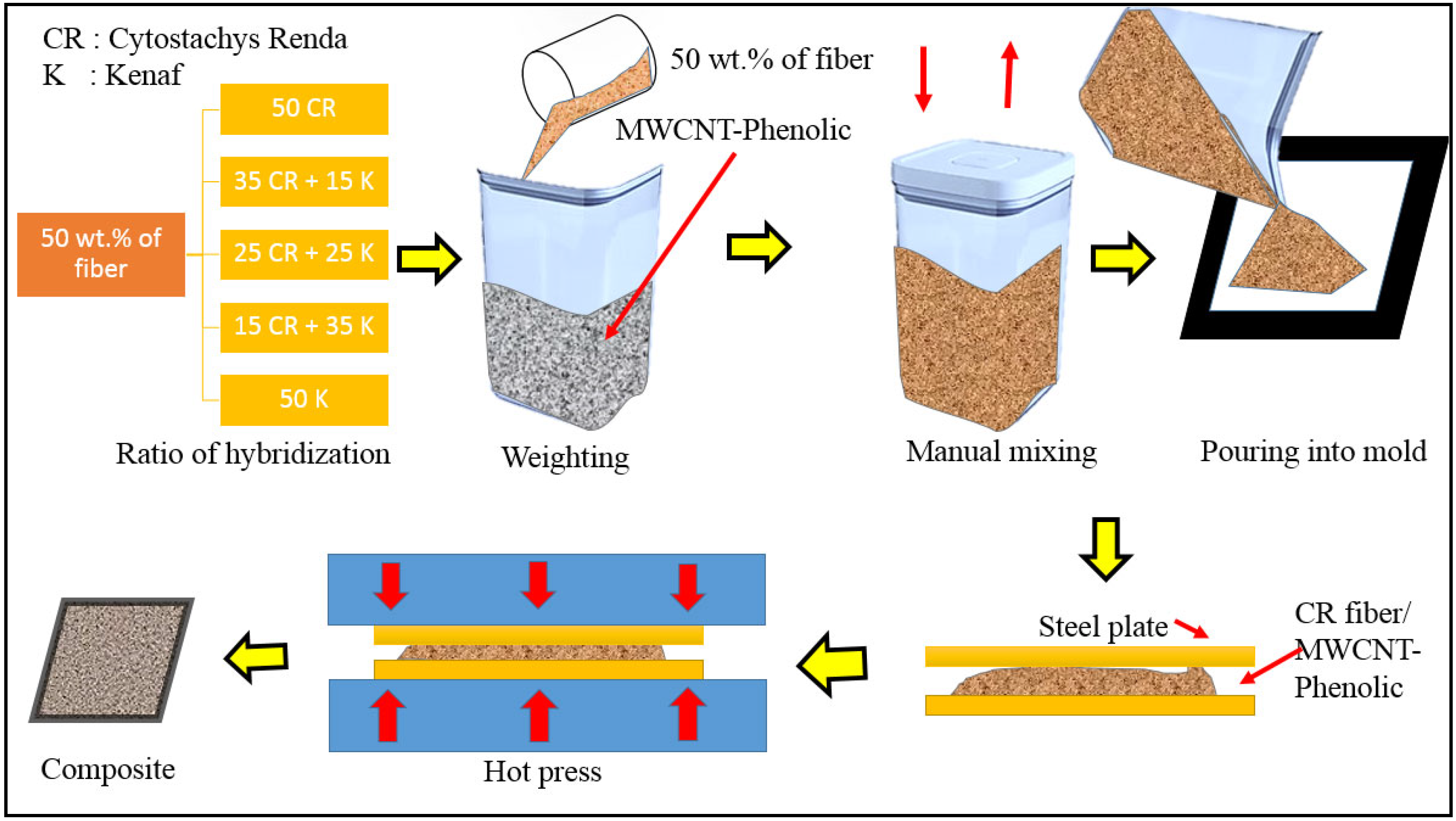

2.3. Fabricating of Composites

3. Characterization

3.1. Physical Properties

3.1.1. Density and Void Content

3.1.2. Water Absorption and Thickness Swelling

3.2. Mechanical Properties

3.2.1. Tensile

3.2.2. Morphology

3.2.3. Flexural

3.2.4. Impact

3.3. Technique for Order Preference by Similarity to the Ideal Solution (TOPSIS)

4. Results and Discussion

4.1. Physical Properties

4.1.1. Density and Void Content of CR-K Reinforced Phenolic Composites

4.1.2. Water Absorption and Thickness Swelling of CR-K Reinforced Phenolic Composites

4.2. Mechanical Properties

4.2.1. Tensile

4.2.2. Morphology

4.2.3. Flexural

4.2.4. Impact

4.3. TOPSIS Method

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Sultan, M.T.H.; Ahsan, Q.; Jawaid, M.; Naveen, J.; Shah, A.U.M.; Hua, L.S. Characterization of alkali treated new cellulosic fibre from Cyrtostachys renda. J. Mater. Res. Technol. 2020, 9, 3537–3546. [Google Scholar] [CrossRef]

- Hassan, F.; Zulkifli, R.; Ghazali, M.; Azhari, C. Kenaf fiber composite in automotive industry: An overview. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 315–321. [Google Scholar] [CrossRef]

- Bourguignon, M.; Moore, K.J.; Brown, R.C.; Kim, K.H.; Baldwin, B.S.; Hintz, R. Variety trial and pyrolysis potential of kenaf grown in Midwest United States. Bioenergy Res. 2017, 10, 36–49. [Google Scholar] [CrossRef]

- Ramesh, M.; Nijanthan, S. Mechanical property analysis of kenaf–glass fibre reinforced polymer composites using finite element analysis. Bull. Mater. Sci. 2016, 39, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Azmi, A.; Sultan, M.; Jawaid, M.; Shah, A.; Nor, A.; Majid, M.; Muhamad, S.; Talib, A. Impact properties of kenaf Fibre/X-ray films hybrid composites for structural applications. J. Mater. Res. Technol. 2019, 8, 1982–1990. [Google Scholar] [CrossRef]

- Wang, H.; Hassan, E.; Memon, H.; Elagib, T.; Abad AllaIdris, F. Characterization of natural composites fabricated from Abutilon-fiber-reinforced Poly(Lactic Acid). Processes 2019, 7, 583. [Google Scholar] [CrossRef] [Green Version]

- Hanan, F.; Jawaid, M.; Tahir, P.M. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2018, 17, 155–167. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Ismail, M.; Rahmat, A.R.; Ogunbode, B.E. Woven hybrid Biocomposite: Mechanical properties of woven kenaf bast fibre/oil palm empty fruit bunches hybrid reinforced polyhydroxybutyrate biocomposite as non-structural building materials. Constr. Build. Mater. 2017, 154, 155–166. [Google Scholar] [CrossRef]

- Horrocks, A.; Kandola, B.K. Flammability and fire resistance of composites. In Design and Manufacture of Textile Composites; Elsevier: Amsterdam, The Netherlands, 2005; pp. 330–363. [Google Scholar]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Thariq Hameed Sultan, M.; Yahaya, R. Improved mechanical and moisture-resistant properties of woven hybrid epoxy composites by graphene nanoplatelets (GNP). Materials 2019, 12, 1249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Kudus, M.H.A.; Akil, H.M.; Thirmizir, M.Z.M. Comparative study of graphene nanoparticle and multiwall carbon nanotube filled epoxy nanocomposites based on mechanical, thermal and dielectric properties. Compos. Part B Eng. 2017, 119, 57–66. [Google Scholar] [CrossRef]

- Eslami, Z.; Yazdani, F.; Mirzapour, M.A. Thermal and mechanical properties of phenolic-based composites reinforced by carbon fibres and multiwall carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2015, 72, 22–31. [Google Scholar] [CrossRef]

- Chaiwan, P.; Pumchusak, J. Wet vs. dry dispersion methods for multiwall carbon nanotubes in the high graphite content phenolic resin composites for use as bipolar plate application. Electrochim. Acta 2015, 158, 1–6. [Google Scholar] [CrossRef]

- Li, C.; Wan, J.; Pan, Y.-T.; Zhao, P.-C.; Fan, H.; Wang, D.-Y. Sustainable, biobased silicone with layered double hydroxide hybrid and their application in natural-fiber reinforced phenolic composites with enhanced performance. Acs Sustain. Chem. Eng. 2016, 4, 3113–3121. [Google Scholar] [CrossRef]

- Rojo, E.; Alonso, M.V.; Oliet, M.; Del Saz-Orozco, B.; Rodriguez, F. Effect of fiber loading on the properties of treated cellulose fiber-reinforced phenolic composites. Compos. Part B Eng. 2015, 68, 185–192. [Google Scholar] [CrossRef]

- Trindade, W.G.; Hoareau, W.; Razera, I.A.; Ruggiero, R.; Frollini, E.; Castellan, A. Phenolic thermoset matrix reinforced with sugar cane bagasse fibers: Attempt to develop a new fiber surface chemical modification involving formation of quinones followed by reaction with furfuryl alcohol. Macromol. Mater. Eng. 2004, 289, 728–736. [Google Scholar] [CrossRef]

- Ramires, E.C.; Megiatto, J.D., Jr.; Gardrat, C.; Castellan, A.; Frollini, E. Biobased composites from glyoxal–phenolic resins and sisal fibers. Bioresour. Technol. 2010, 101, 1998–2006. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Jawaid, M.; Zainudin, E.S.; Yamani, S.A.K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 2019, 8, 3466–3474. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef] [Green Version]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.; Alothman, O. Effect of hybridization on the mechanical properties of pineapple leaf fiber/kenaf phenolic hybrid composites. J. Renew. Mater. 2018, 6, 38–46. [Google Scholar] [CrossRef]

- Chang, H.; Smith, R.; Li, S.; Neumann, A. Wettability of reinforcing fibers. In Molecular Characterization of Composite Interfaces; Springer: Berlin/Heidelberg, Germany, 1985; pp. 413–421. [Google Scholar]

- Jawaid, M.; Khalil, H.A.; Bakar, A.A.; Khanam, P.N. Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater. Des. 2011, 32, 1014–1019. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites. Int. J. Polym. Sci. 2015, 2015, 390275. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. Text. 2018, 47, 2153–2183. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Nevestenko, M.; Bryuzgina, E.; Tuzhikov, O.; Bryuzgin, E.; Tarasova, Y.S. Study of Properties of Film Materials Based on Cellulose and Polyurethane Rubbers for Drainage of Oils. Russ. J. Appl. Chem. 2020, 93, 564–571. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.; Jawaid, M.; Nasir, M.; Saba, N. Physical and flammability properties of kenaf and pineapple leaf fibre hybrid composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018; IOP Publishing: Bristol, UK, 2018; Volume 368, p. 012018. [Google Scholar]

- Ibrahim, N.; Hashim, N.; Rahman, M.A.; Yunus, W.Z.W. Mechanical properties and morphology of oil palm empty fruit bunch—polypropylene composites: Effect of adding ENGAGETM 7467. J. Thermoplast. Compos. Mater. 2011, 24, 713–732. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

- Yusuff, I.; Sarifuddin, N.; Ali, A.M. A review on kenaf fiber hybrid composites: Mechanical properties, potentials, and challenges in engineering applications. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 66–83. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Khan, A.; Asiri, A.M.; Malik, M.A. Effects of Date Palm fibres loading on mechanical, and thermal properties of Date Palm reinforced phenolic composites. J. Mater. Res. Technol. 2020, 9, 3614–3621. [Google Scholar] [CrossRef]

- Abdullah, S.; Zuhudi, N.; Anuar, N.; Isa, M. Mechanical and thermal characterization of alkali treated kenaf fibers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 24–26 February 2018; p. 012048. [Google Scholar]

- Izani, M.A.N.; Paridah, M.T.; Anwar, U.M.K.; Nor, M.Y.M.; H’ng, P.S. Effects of fiber treatment on morphology, tensile and thermogravimetric analysis of oil palm empty fruit bunches fibers. Compos. Part B Eng. 2013, 45, 1251–1257. [Google Scholar] [CrossRef] [Green Version]

- Symington, M.C.; Banks, W.M.; West, O.D.; Pethrick, R. Tensile testing of cellulose based natural fibers for structural composite applications. J. Compos. Mater. 2009, 43, 1083–1108. [Google Scholar] [CrossRef] [Green Version]

- Rozman, H.; Ahmadhilmi, K.; Abubakar, A. Polyurethane (PU)—oil palm empty fruit bunch (EFB) composites: The effect of EFBG reinforcement in mat form and isocyanate treatment on the mechanical properties. Polym. Test. 2004, 23, 559–565. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Bakar, A.A. Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- Yusoff, M.Z.M.; Salit, M.S.; Ismail, N.; Wirawan, R. Mechanical properties of short random oil palm fibre reinforced epoxy composites. Sains Malays. 2010, 39, 87–92. [Google Scholar]

- Dashtizadeh, Z.; Khalina, A.; Cardona, F.; Lee, C.H. Mechanical Characteristics of Green Composites of Short Kenaf Bast Fiber Reinforced in Cardanol. Adv. Mater. Sci. Eng. 2019, 2019, 8645429. [Google Scholar] [CrossRef] [Green Version]

- Aji, I.; Zainudin, E.; Abdan, K.; Sapuan, S.; Khairul, M. Mechanical properties and water absorption behavior of hybridized kenaf/pineapple leaf fibre-reinforced high-density polyethylene composite. J. Compos. Mater. 2013, 47, 979–990. [Google Scholar] [CrossRef]

- He, H.; Tay, T.E.; Wang, Z.; Duan, Z. The strengthening of woven jute fiber/polylactide biocomposite without loss of ductility using rigid core–soft shell nanoparticles. J. Mater. Sci. 2019, 54, 4984–4996. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Burhan, I.; Abdullah, S.K.B.; Sultan, M.T.H.; Singh, S.; Singh, L.K.; Amran, U. Physical, Mechanical, Thermal Properties of Bio-phenolic Based Composites. In Phenolic Polymers Based Composite Materials; Springer: Berlin/Heidelberg, Germany, 2020; pp. 169–190. [Google Scholar]

- Sanjay, M.; Jawaid, M.; Naidu, N.; Yogesha, B. TOPSIS method for selection of best composite laminate. In Modelling of Damage Processes in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 199–209. [Google Scholar]

| Properties | CR | K |

|---|---|---|

| Density (g/cm3) | 1.4 | 1.5 |

| Tensile strength (MPa) | 119 | 223–930 |

| Tensile Modulus (GPa) | 1.5 | 11–53 |

| Elongation at break (%) | 3.13 | 1.6–10 |

| Cellulose (%) | 45.42 | 31–39 |

| Hemicellulose (%) | 18.97 | 8–13 |

| Lignin | 20.70 | 12.1 |

| Designation Ratio of Hybrid Composites | 0.5 wt.% MWCNT + Phenolic Resin (wt%) | CR (wt%) | K (wt%) |

|---|---|---|---|

| 10C:0K | 50 | 50 | 0 |

| 7C:3K | 50 | 35 | 15 |

| 5C:5K | 50 | 25 | 25 |

| 3C:7K | 50 | 15 | 35 |

| 0C:10K | 50 | 0 | 50 |

| Properties | Type | Weight |

|---|---|---|

| Density | − | 0.1 |

| Water absorption | − | 0.1 |

| Tensile | + | 0.25 |

| Flexural | + | 0.25 |

| Impact | + | 0.3 |

| Composites | Theoretical Density (g/cm3) | Measured Density (g/cm3) | Void Content (%) |

|---|---|---|---|

| 10C:0K | 1.39 | 1.22 | 12.23% |

| 7C:3K | 1.39 | 1.26 | 9.35% |

| 5C:5K | 1.38 | 1.27 | 7.97% |

| 3C:7K | 1.37 | 1.27 | 7.30% |

| 0C:10K | 1.37 | 1.28 | 6.57% |

| Hybrid Fibers | Tensile Strength (MPa) | Tensile Modulus (GPa) | Ref. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 wt.% | Proportion of Fiber 1:Fiber 2 | Proportion of Fiber 1:Fiber 2 | ||||||||||

| Fiber 1 | Fiber 2 | 10:0 | 7:3 | 5:5 | 3:7 | 0:10 | 10:0 | 7:3 | 5:5 | 3:7 | 0:10 | |

| oil palm empty fruit bunch (OP) | sugarcane bagasse (SB) | 4.95 | 5.56 | 5.23 | 5.34 | 4.51 | 0.58 | 0.66 | 0.63 | 0.64 | 0.52 | [21] |

| pineapple leaf fiber (PALF) | 6% NaOH treated kenaf | 33.15 | 42.60 | 42.80 | 46.96 | 48.00 | 6.85 | 6.57 | 6.50 | 6.84 | 6.80 | [23] |

| 3% NaOH treated CR | 3% NaOH treated Kenaf | 35.17 | 40.55 | 47.96 | 38.91 | 36.67 | 11.94 | 12.67 | 14.79 | 12.52 | 11.59 | Present study |

| Density | Water Absorption | Tensile | Flexural | Impact | |

|---|---|---|---|---|---|

| 10C:0K | 1.22 | 35.71 | 35.17 | 74.16 | 5.17 |

| 7C:3K | 1.26 | 33.15 | 40.55 | 77.08 | 6.37 |

| 5C:5K | 1.27 | 26.93 | 47.96 | 84.61 | 7.28 |

| 3C:7K | 1.27 | 26.93 | 38.91 | 90.89 | 8.13 |

| 0C:10K | 1.28 | 29.16 | 36.67 | 80.72 | 9.56 |

| Density | Water Absorption | Tensile | Flexural | Impact | |

|---|---|---|---|---|---|

| 10C:0K | 0.430 | 0.617 | 0.363 | 0.354 | 0.367 |

| 7C:3K | 0.448 | 0.447 | 0.461 | 0.376 | 0.396 |

| 5C:5K | 0.451 | 0.363 | 0.600 | 0.489 | 0.414 |

| 3C:7K | 0.451 | 0.363 | 0.399 | 0.526 | 0.455 |

| 0C:10K | 0.455 | 0.394 | 0.369 | 0.467 | 0.574 |

| Density | Water Absorption | Tensile | Flexural | Impact | |

|---|---|---|---|---|---|

| 10C:0K | 0.043 | 0.062 | 0.091 | 0.088 | 0.110 |

| 7C:3K | 0.045 | 0.045 | 0.115 | 0.094 | 0.119 |

| 5C:5K | 0.045 | 0.036 | 0.150 | 0.122 | 0.124 |

| 3C:7K | 0.045 | 0.036 | 0.100 | 0.131 | 0.137 |

| 0C:10K | 0.045 | 0.039 | 0.092 | 0.117 | 0.172 |

| Positive Ideal | Negative Ideal | |

|---|---|---|

| Density | 0.043 | 0.045 |

| Water absorption | 0.036 | 0.062 |

| Tensile | 0.150 | 0.091 |

| Flexural | 0.131 | 0.088 |

| Impact | 0.172 | 0.110 |

| Composites | Distance to Positive and Negative Ideal Points | The Relative Closeness Value and Ranking | ||

|---|---|---|---|---|

| Distance to Positive Ideal | Distance to Negative Ideal | Relative Closeness, Ci | Rank | |

| 10C:0K | 0.099 | 0.002 | 0.024 | 5 |

| 7C:3K | 0.074 | 0.032 | 0.299 | 4 |

| 5C:5K | 0.049 | 0.074 | 0.603 | 1 |

| 3C:7K | 0.062 | 0.057 | 0.481 | 3 |

| 0C:10K | 0.006 | 0.072 | 0.547 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loganathan, T.M.; Hameed Sultan, M.T.; Jawaid, M.; Ahsan, Q.; Naveen, J.; Shah, A.U.M.; Abu Talib, A.R.; Basri, A.A. Physical, Mechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites. Polymers 2021, 13, 3448. https://doi.org/10.3390/polym13193448

Loganathan TM, Hameed Sultan MT, Jawaid M, Ahsan Q, Naveen J, Shah AUM, Abu Talib AR, Basri AA. Physical, Mechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites. Polymers. 2021; 13(19):3448. https://doi.org/10.3390/polym13193448

Chicago/Turabian StyleLoganathan, Tamil Moli, Mohamed Thariq Hameed Sultan, Mohammad Jawaid, Qumrul Ahsan, Jesuarockiam Naveen, Ain Umaira Md Shah, Abd. Rahim Abu Talib, and Adi Azriff Basri. 2021. "Physical, Mechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites" Polymers 13, no. 19: 3448. https://doi.org/10.3390/polym13193448

APA StyleLoganathan, T. M., Hameed Sultan, M. T., Jawaid, M., Ahsan, Q., Naveen, J., Shah, A. U. M., Abu Talib, A. R., & Basri, A. A. (2021). Physical, Mechanical, and Morphological Properties of Hybrid Cyrtostachys renda/Kenaf Fiber Reinforced with Multi-Walled Carbon Nanotubes (MWCNT)-Phenolic Composites. Polymers, 13(19), 3448. https://doi.org/10.3390/polym13193448