Soil Injection Technology Using an Expandable Polyurethane Resin: A Review

Abstract

:1. Introduction

- Geological (natural) reasons: summarized in a consequence of factors associated with the native state and strength of the foundation’s soil, based on various soil features such as soil types, soil formation, organic matters, weather conditions, and other natural factors that affect the soil quality. Consequently, the foundations and infrastructures, such as roads or aerodromes built on a particular soil are affected by the advent of such soil problems. As a result, it leads to the appearance of the foundation’s imperfections threatening the whole overlaying constructions status, varying from minor defects to the collapse of the construction due to the foundation’s failure. According to the following authors [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,28,39,47,48,49,50,51], these factors could be sorted as Collapsible/Metastable soil, Liquefiable Soil, Expansive soil, Slope instability, seismic impact, seasonal variation of ground water level, and other natural geological and environmental reasons [52,53,54,55,56,57,58,59,60]

- Industrial (technical) reasons: summarized as complex factors caused by engineering errors, such as inadequate preliminary design, insufficient or incorrect geotechnical investigations, poor quality of construction work, violation of building codes, and poor soil compaction during the construction process. In addition, there are aspects related to changes in the capacity concerning a particular project, the poor quality of the construction materials, reconstruction processes, cities planning and developments, the insufficient distance between the adjacent foundations, vibration effect of the neighborhood construction equipment, the changes in the groundwater level due to inappropriate seepage network, and other factors. These factors are extensively studied in the following authors’ work: [6,21,23,24,25,26,27,29,30,31,32,33,34,35,36,37,38,40,41,42,43,44,45,46,49,61,62,63] and many others.

2. Soil Injection Method Using an Expandable Polyurethane Resin

2.1. General Description

2.2. The Injection Process

- Drilling holes. The diameter of each ranges between 12–30 mm. The diameter of the holes is various according to the equipment and the injection pistol used for the injection process.

- The injection tubes (steel or copper) are inserted into the soil zones up to the depths required to be treated. The injected zones are chosen according to different aspects, such as the soil type, groundwater level, and effective foundation depth.

- The two components of an expandable polyurethane resin (with a high coefficient of expanding) are mixed in a hydraulic system and injected, using a particular injection pistol, into the soil’s massive incrementally through the small holes prepared in advance.

- The injection process is controlled and monitored until reaching the desired results using various developed procedures. The easier and most effective monitoring is using a laser level with high accuracy (0.01 mm).

2.3. The Chemical Properties of the Polyurethane Resin

2.4. The Density of the Injected Resin

2.5. The Propagation of the Polyurethane Resin

2.5.1. Cavity Expansion Theory

2.5.2. Propagation in the Hydro Fracturing Mode

2.5.3. Conclusion of the Resin Propagation in the Soil Massive

- The resin’s diffusion in a hydrofracturing mode leads to forming solid resin plates in the massive of the injected soil with a specified length, depth, and thickness. Consequently, a composite of soil-resin is formed, where the resin serves as a bearing element, strengthening the soil and lifting the overlying buildings and structures. The role of the injection pressure is to control the flow of the material in the soil’s massive. The peculiarity of the two-component injection technology is the rapid solidifying process of the resin. During the hardening process, the pores of the sand are calmed, and the injection material spreads in the form of hydraulic fracturing made by the injection pressure. Thus, the resin’s diffusion through the pores, due to the filtration of the soil, practically does not occur

- The resin diffuses through the existing pores and cracks due to the filtration of the soil; however, it is limited by a few centimeters of dendrites around the injection zone and has no significant strengthening and lifting results. However, the resin’s diffusion through voids, by the filtration of the soil, practically does not occur due to the high injection pressure.

- A cavity expansion mode, if the resin is injected at low or no injection pressure, leads to the resin expansion not along the rupture but in the form of a ball or cylinder; consequently, it leads to high resin consumption and the inability to achieve uniform distribution for lifting foundations and turns out to be ineffective.

2.6. The Consumption of the Resin

2.7. The physic-Mechanical Properties of the Soil-Resin Composite (Modified Properties): Field and Laboratory Investigations Data

2.7.1. Laboratory Investigations Data

2.7.2. Field Investigations Data

Swelling and Permeability Tests

Dynamic Cone Penetration Test

Plate Load Test

Dilatometer Tests

Pressuremeter Test

Three-Dimension Topographical Electrical Resistivity Test

Case Studies

2.7.3. Finite Element Models

2.8. Durability and Environmental Aspects

2.9. Factors Affecting the Selection of the Ground Improvement Technique for Existing Foundations

- The functions and the degree of improvement required. Different techniques exist globally and provide different functions to solve various foundations problems. Consequently, the required functions and degree of the improvement depend on several aspects, particularly for each project, and are determined by different laboratory and in-situ geotechnical investigations alongside the physical and numerical models obtained. Thereby, selecting the appropriate technology is associated directly with the functions and the degree of improvement required.

- Technical and geotechnical constraints. Such as the type, conditions, and the geological structure of the soil beneath the existing foundations. In general, selecting the appropriate technique depends substantially on the type of the treated soil, the mechanism of the technique used, the materials used for the stabilization, and other aspects. Moreover, the effective depth and extent required to be treated and the groundwater level play essential roles in selecting the efficient technique. Several stabilization methods are limited in complex geotechnical tasks where the depth of the required improvement is extended. Not all existing techniques work efficiently below the groundwater level, and in some cases, the water should be pumped to apply a particular method. The operational load of the overlying buildings and structures is another factor affecting the selection of the appropriate method since though the stresses generated in the soil layers due to the injected solutions should be transferred reliably, ensuring that the additional pressures do not lead to displacing the soil laterally, causing future adverse effects. Furthermore, over lifting risk is one of the most significant factors in selecting the appropriate compensation technique.

- Projects constraints. Such as the available cost, equipment, and materials required for the ground modification of a particular project. Besides, the specifications differ from one country to another, the scope of the constructions, and the space constraints. Different effective techniques are not applicable for small-scale constructions, due to site inaccessibility and insufficient space for construction equipment to operate safely, overhead clearance, and adjacent structures and utilities. These aspects should be considered when choosing the appropriate methods, especially in small-scale projects where the extensive labor and huge equipment might be costly and not valuable compared to the scale of the projects.

- Time constraints: The speed of the improvement technique method plays an essential role in selecting the ground improvement technology in any geotechnical project, especially in vital constructions such as airports, roads, and other infrastructures where it is necessary to choose fast techniques for soil stabilization and remediation process. The closure of such vital infrastructures for maintenance might be very costly and detrimental to these service projects and reflect negatively on the performance of other major or minor infrastructures because of the transferred momentum generated by the closure of major infrastructures.

- The possibility of adverse effects to the foundations and overlying structures. The technique used should be non-destructive to the soil, the overlying structures, and the neighborhood’s foundations. The chemical-based methods might lead to adverse effects due to the chemical reactions with the soil compositions of the minerals contained in the soil massive, leading to various problems such as the expansive soil and other problems, affecting the status of the foundations and the overlying buildings and structures. Thus, assessing the soil’s organic content is necessary to ensure the selection of the proper technique. Moreover, methods that require heavy equipment might not be an optimum solution in the residential areas where this equipment might affect the adjacent foundation due to its vibration besides the noise caused disturbing the neighborhood residents.

- The effect of the technique on the ecology. Some chemical-based methods are restricted due to their adverse effect on the environment, including the contamination of the groundwater level due to the toxicity of the chemical additives. Additionally, the seepage damage due to high pressure, applied by the technique used, is another restriction when selecting the effective method for solving geotechnical tasks. These factors should be considered when selecting the appropriate method for foundations remediation and reinforcement of the foundation’s soil.

- Other factors. Such as the durability and the quality of the injected material. Several factors affect the injected grouts, reducing their long-term performance in the soil massive, such as the groundwater level, soil mineral, and microbial contents, shrinking-swelling of the grout, due to the variation of the temperature, and others. These factors affect the quality and durability of the selected material and the technique’s efficiency, leading to prefer a technique among other techniques for solving particular foundations problems.

2.10. The Advantages of the Soil Injection Technology Using an Expanding Resin and the Limitation of Use

3. Discussion

3.1. Foundations Lifting Results

- Lifting to 20 mm of differential settlement foundations has been recorded. However, lifting to more values within the range of settlements requiring lifting to a value of which the load-bearing element is a composite (soil and resin) is possible as long as the maximum load of buildings does not exceed 10,000 kPa

- The injection is carried out in shots; thus, the over-lifting risks, due to the hydrofracturing process, are minimized.

- The optimum and most economical monitoring method is a laser level with high accuracy (0.01 mm) during the lifting process.

3.2. The Soil Modified Properties

- Indicators of the conditional dynamic resistance of the soil are increased after its injection by the expandable resin. The average increase in non-cohesive soil dynamic resistance is up to 81%.

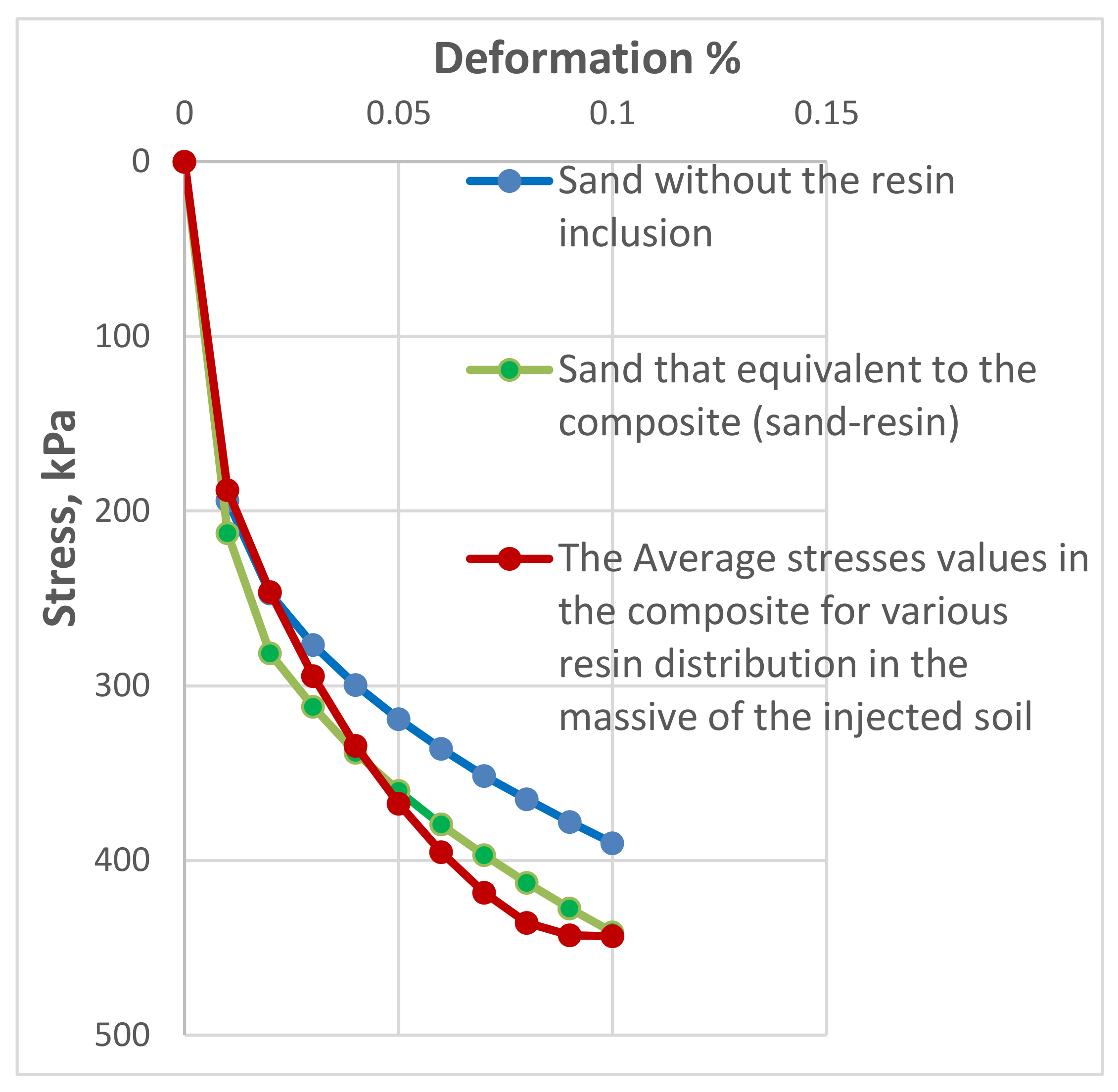

- The average bearing capacity of resin-strengthened soil increases by 67–400%, and the calculated modulus of deformation of the resin-strengthened soil increases by 55–203%. The variation in the soil-resin composite’s final characteristics is justified by the variation in the treated depth, soil type, and other factors.

- Although, the deformation modulus of the composite soil-resin is depth-dependent. Nevertheless, the main advantage of this technology is the possibility of settling sediment, that is, using it as a “liquid jack.” In light of this consideration, settlements are excluded due to the lifting of the foundations by the presence of the resin, and not due to the changes in the deformation modulus.

- The effective distances interval is 1–1.5 m, within which a considerable increase in the soil properties is noticed.

- A 68% reduction in the clay peak swelling pressure has been recorded for soil with as little as 1% macro voids in its total volume.

- The liquefaction potential of the sand is remarkably decreased after the injection of the resin. The evaluation of the dynamic properties of polyurethane resin indicates that this material can be considered a potential alternative for reducing seismic earth pressures. Dilatometer test showed an increase in horizontal stress index KD from 50 to 150% after the resin injection. Shear waves velocity increased around 50%, the relative density increased by 30 %, and the Modulus of Subgrade Reaction (k) increased around 50 to 90% at different injection locations.

- The soil’s shear resistance is noticeably increased up to 257% after the injection of the resin. However, this increase depends on the final formed density of the injected resin.

- The moisture content, the particle size distribution, and the specific gravity are improved due to the resin inclusion, accompanied by an impressive reduction in the existing voids and swelling index after the injection.

- The soil cohesion increases by 187–260% in non-cohesive soils due to the resin inclusion into the soil massive. However, the modified properties of cohesive soils are not yet determined.

- The injected resin is non-toxic, and there is no possibility for any chemical reaction with the soil’s expansive minerals.

3.3. The Resin Propagation

- Although some conducted research stated that the flow and propagation of the PU expandable foam are subjected to the cavity expansion theory when injected into the soil massive, this theory is considered if the resin is injected at low injection pressure. In this case, the resin expands not along the fracture but in the form of a ball or cylinder. Consequently, it leads to high resin consumption and the inability to achieve a uniform distribution for the foundations lifting and turns out to be ineffective.

- In the practical applications, the injected resin diffuses in both non-cohesive and cohesive soils, forming identical continuous walls of foam plates along the whole injected depth, surrounding the injected soil from all sides, connecting at the edges of the resin within a distance interval around 30–50 cm, and the average thickness of the resin is 0.8–25 mm, approximately, as measured. Figure 2, Figure 3 and Figure 4 show different sections of the resin propagation in the massive of various investigated soils.

- The peculiarity of the two-component injection technology is the rapid solidifying process of the resin. During the hardening process, the pores of the sand are calmed, and the injection material spreads in the form of hydraulic fracturing made by the injection pressure. Thus, the resin’s diffusion through the pores, due to the filtration of the soil, practically does not occur.

3.4. The Resin Properties

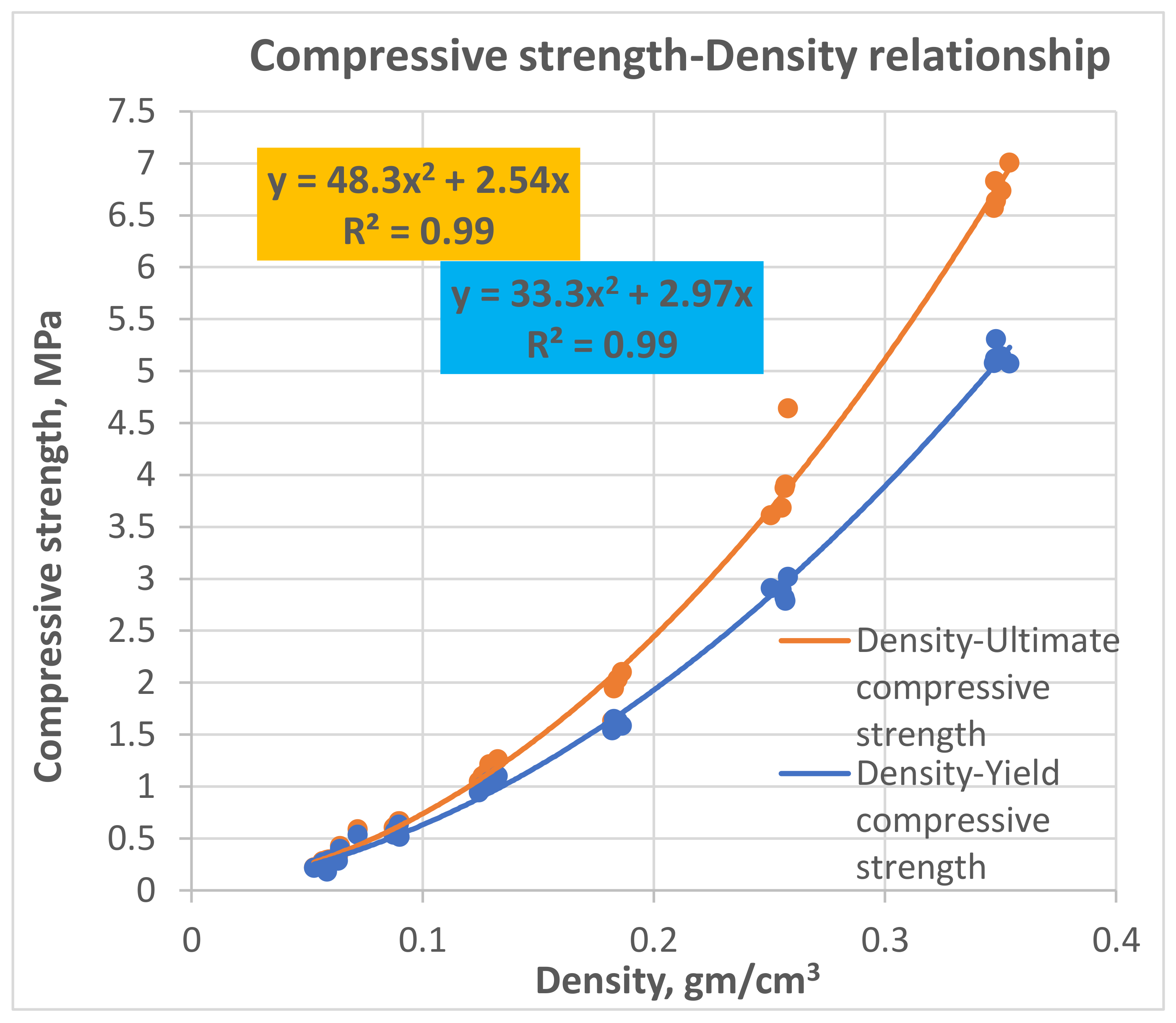

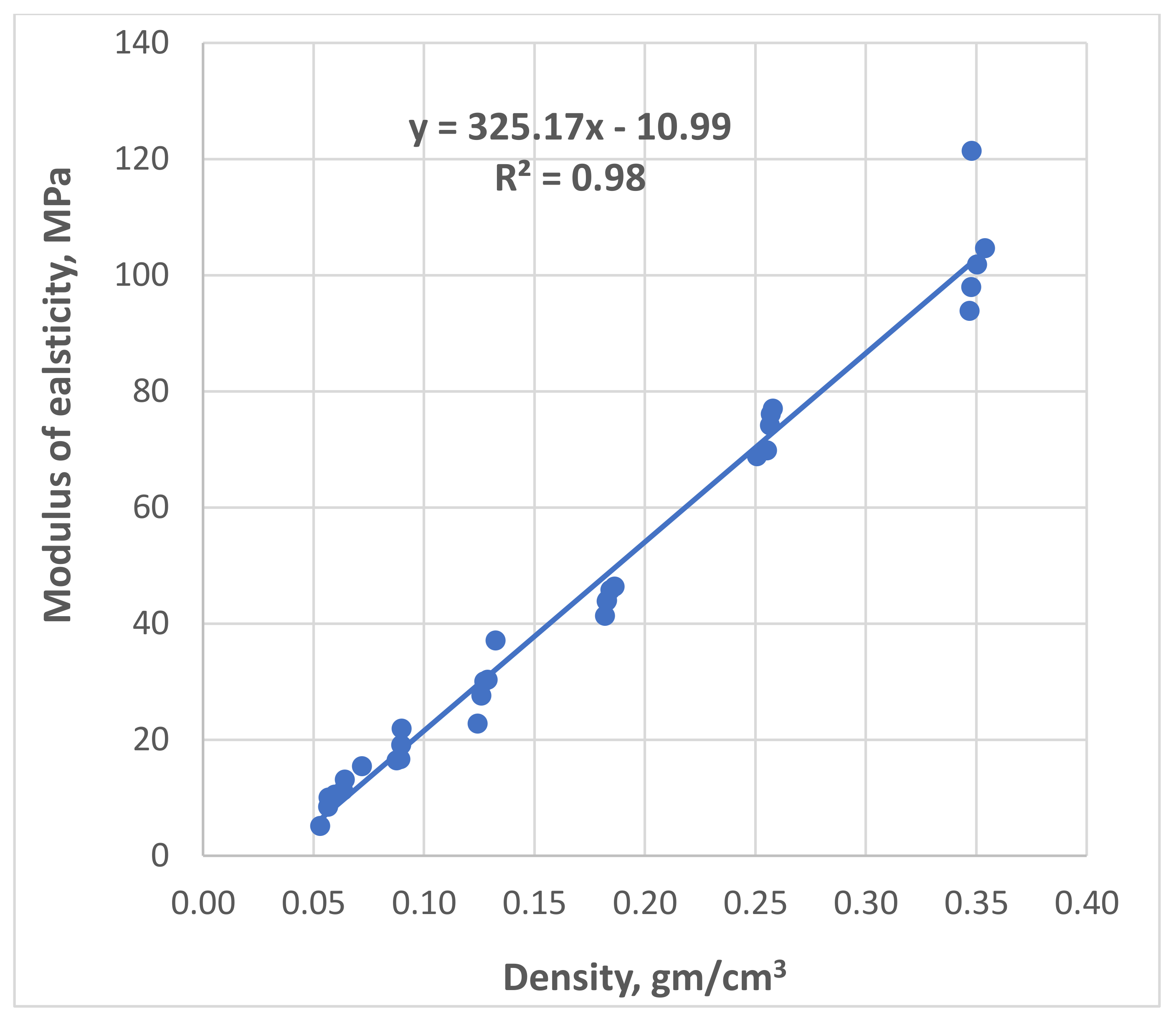

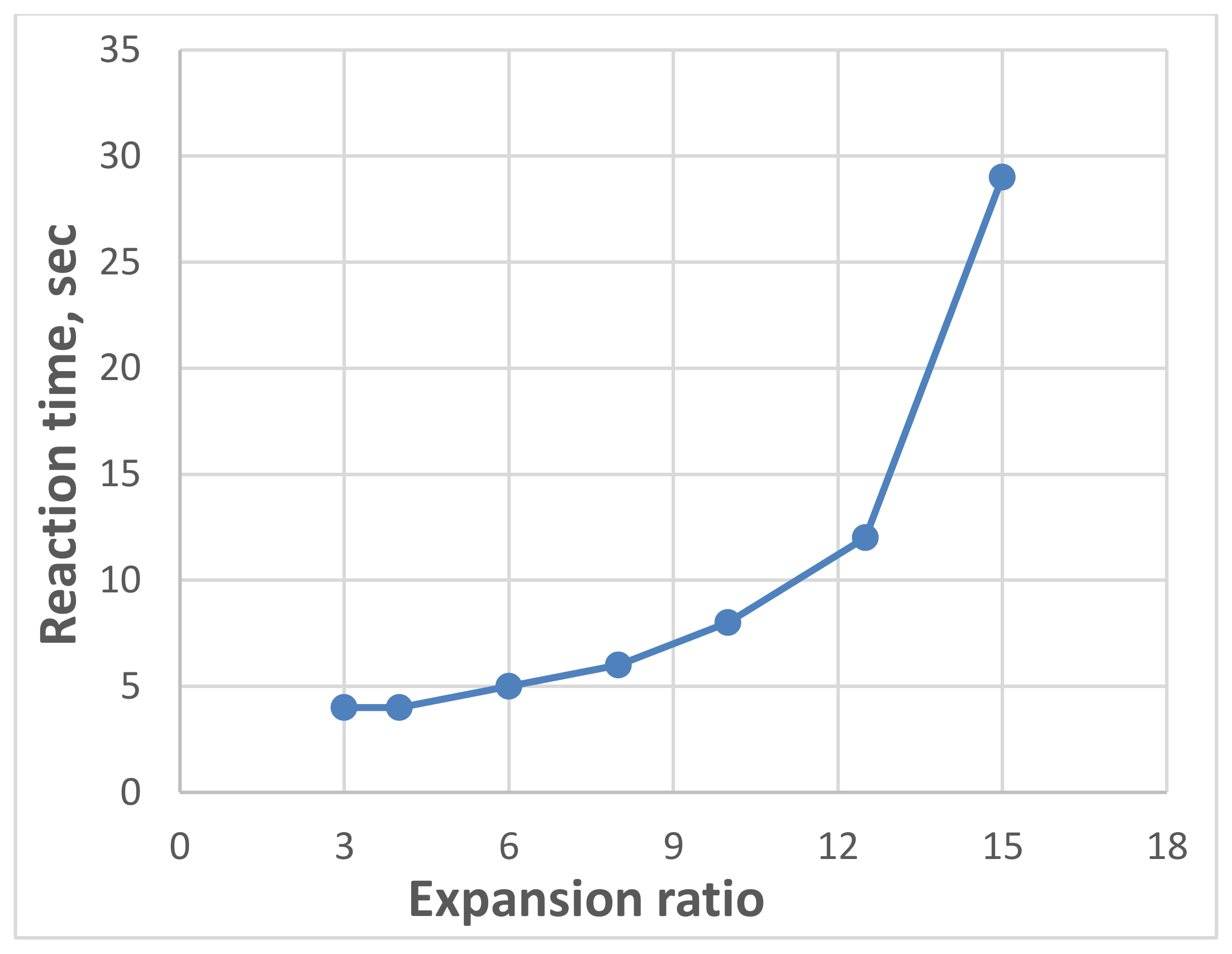

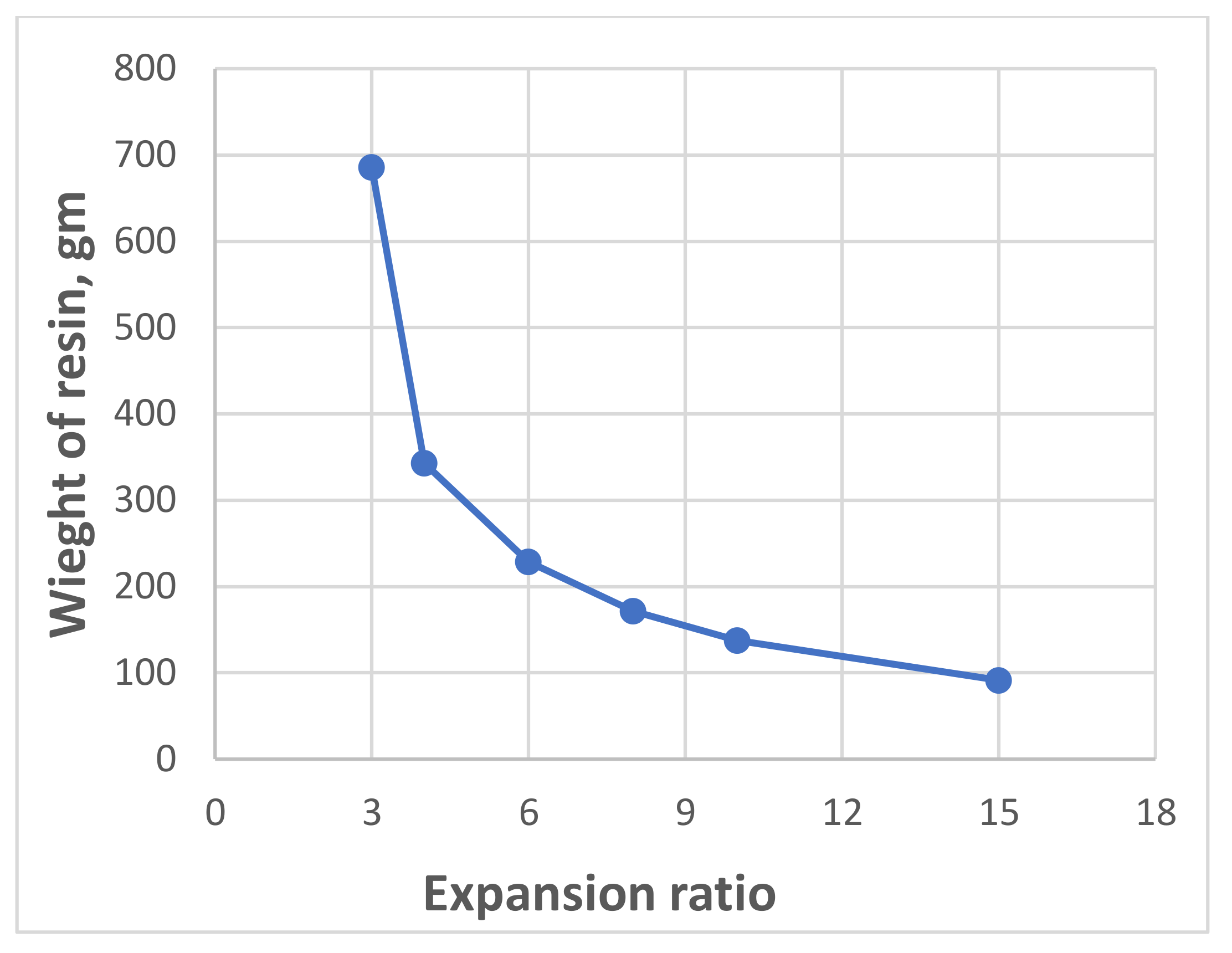

- The relationship between density and ultimate strength (σ = 48.3 ρ2 + 2.54ρ) and the relationship between density and modulus of elasticity (E = 325.17 ρ − 10.99) of the expandable resin within the density range (from 0.053 up to 0.354 gm/cm3) and the volumetric expansion coefficients of the resin (from 3 to 15), respectively.

- The average density of the resin formed in the non-cohesive soils is 0.184 gm/cm3 at an injection pressure of 100 bar and a temperature of 15 °C. There is no comparative registered data in the cohesive soils.

- The resin can be formed in various densities, allowing a high spectrum of the mechanical properties in the soil massive up to (E = 8–73 MPa, σ = 0.5–4.6 MPa), respectively, at expanding ratios ranges (3–15 times). Consequently, this resin is considered a high-strength injected material compared to various injection materials used for soil stabilization, considering the rapid lifting and strengthening processes.

3.5. The Optimum Resin Consumption

3.6. Finite Element Models

4. Future Work

- A calculation method of the settlement and the bearing capacity of the modified composite (soil-resin) properties has been developed and validated [72]. However, generalization and validation of this method for other soil types are still required.

- The solidified resin’s density formed in the soil’s massive after the injection process is the most significant factor that affects its mechanical properties, thereby identifying the degree of the soil strengthening required after the treatment. The resin’s density varies due to its expansion properties, and the volumetric amount of the resin used plays a role in the final density formed. Therefore, a developed method that accurately predicts the resin’s density after the injection process is necessary for the practical applications

- The deformation modulus of the composite (soil-resin) is varied along with the depth of the soil. Further investigations of the changes patterns in the composite’s deformation modulus at different depths are required.

- To investigate the effect of the component compositions ratios variation on the modified properties of the composite is necessary.

- Since it was established, this technology has been used for shallow foundations due to various limitations. The development of equipment and procedure for using this technology to remediate and strengthen deep foundations (below 10 m) is a significant task for future technology applications.

- The variation of the surcharge load applied to the soil significantly influences the resin’s physic mechanical properties and consumption. Investigating this effect using large-scale field and laboratory experiments can improve the practical applications of this technology and reduce resin consumption.

- The optimum resin consumption in the sand has been determined. However, further research on the optimum resin’s volumetric consumption rate, for strengthening the cohesive soils, is still obligatory for generalizing the results.

5. Conclusions

- Various techniques are used for soil strengthening and compensation of the foundation’s settlements of the existing buildings and structures. Each technique has an application field based on its functions and the accessibility of use under different project conditions. Some of the significant limitations for most of the traditional techniques are the type of treated soil, the project constraints, and the time constraints fundamentally in vital infrastructures which require a rapid reconstruction process as the traditional materials composition used in most of the existing techniques have a long curing process and require tremendous preparation prior the treatment.

- The soil injection, using an expandable polyurethane resin, provides a vast solution for foundation lifting and settlement compensation, strengthening the soil beneath. However, very few experimental investigations regarding this technology have been conducted worldwide.

- The effectiveness of the reviewed technology for fast foundations, lifting and compensation of the differential settlement of buildings and structures, has been practically confirmed in different soil types (Section 2.7).

- Analyses of the modified properties of different soil types (Section 2.7) have revealed that the injection of the soil by an expandable resin leads to significant improvements of the physic-mechanical and hydraulic properties of the treated soil. Besides that, the soil-resin acts as a composite material where the resin serves as a bearing element.

- The analysis of the resin propagation in the soil massive has shown that the resin propagates in the soil massive through the fractures made by the hydrofracturing mode rather than the cavity expansion (Section 2.5).

- The optimum resin consumption in the sandy soils is 10 L per 1 m3, equal to 1% of the total soil volume (Section 2.6). Changing the consumption rate leads to changes in the resin density in a homogeneous injection environment. Consequently, the resin properties are changed, affecting the final modified soil-resin composite properties.

- A practically confirmed method for calculating the bearing capacity and assessing the settlement of the foundations after the injection process in the hydrofracturing mode has been developed (Section 2.8). The calculation method considers the average resin diffusion under a homogenous injection environment. In turn, it improves the application of this technology and increases its efficiency and operational reliability.

- The relationships between mechanical properties of the expandable resin and its density, based on its volumetric expansion properties varied out by the amount of the injected resin have been established (Section 2.7). Further, the density of the resin, under a certain injection environment, has been determined and fixed by 0.184 gm/cm3 (Section 2.4).

- This technology has many advantages, such as the rapid and highly controlled foundations remediation process, due to the rapid curing of the injectable resin, and the ability to use in almost all soil types. The proposed resin does not contain any particles that the soil porosity can restrict. Moreover, the ease to use, the high mobility, the lightweight of the injectable expandable resin and its non-toxic features, and the independence of the resin physic-mechanical properties, from the groundwater level, allows the application of this technology under different geotechnical constraints and projects conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manfred, R.H. Engineering Principles of Ground Modification: International Addition; McGraw-Hill College: NewYork, NY, USA, 1990; ISBN 0071007407. [Google Scholar]

- Schaefer, V.R.; Berg, R.R.; Collin, J.G.; Christopher, B.R.; DiMaggio, J.A.; Filz, G.M.; Bruce, D.A.; Ayala, D. Ground Modification Methods-Reference Manual-Volume II; U.S. Department of Transportation Federal Highway Administration: Washington, DC, USA, 2017.

- Nicholson, P.G. Soil Improvement and Ground Modification Methods; Elsevier Inc.: Amsterdam, The Netherlands, 2014; ISBN 9780124078994. [Google Scholar]

- Townsend, F.C.; Anderson, J.B. Compendium of Ground Modification Techniques Final Report; Florida Department of Transportation, Research Management Center: Tallahassee, FL, USA, 2004; Volume 1.

- Nazarzadeh, M.; Sarbishe-ee, S. Probabilistic Analysis of Shallow Foundation Settlement considering Soil Parameters Uncertainty Effects. Open J. Geol. 2017, 7, 731–743. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Goyal, C.R.; Jain, A. Review of Causes of Foundation Failures and their Possible Preventive and Remedial Measures. In Proceedings of the 4th KKU-International Engineering Conference (KKU-IENC2012), Khon Kaen, Thailand, 10–11 May 2012; pp. 1–6. [Google Scholar]

- Boulanger, R.W.; Idriss, I.M. Liquefaction Susceptibility Criteria for Silts and Clays. J. Geotech. Geoenviron. Eng. 2006, 132, 1413–1426. [Google Scholar] [CrossRef]

- Quintero, J.; Saldanha, S.; Millen, M.; da Fonseca, A.V.; Sargin, S.; Oztoprak, S.; Kelesoglu, M.K. Investigation into the Settlement of a Case Study Building on Liquefiable Soil in Adapazari, Turkey. In Proceedings of the Geotechnical Earthquake Engineering and Soil Dynamics V, Austin, TX, USA, 10–13 June 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 321–336. [Google Scholar]

- Kalantari, B. Foundations on collapsible soils: A review. Proc. Inst. Civ. Eng.-Forensic Eng. 2013, 166, 57–63. [Google Scholar] [CrossRef]

- Beck, B.F. Sinkholes: Their Geology, Engineering and Environmental Impact. In Proceedings of the First Multidisciplinary Conferente, Orlando, FL, USA, 15–17 October 1984; pp. 117–121. [Google Scholar] [CrossRef]

- Kramer, S.L.; Holtz, R.D. Soil Improvement and Foundation Remediation: With Emphasis on Seismic Hazards; University of Washington, Department of Civil Engineering: Seattle, WA, USA, 1991. [Google Scholar]

- Gaaver, K.E. Geotechnical properties of Egyptian collapsible soils. Alexandria Eng. J. 2012, 51, 205–210. [Google Scholar] [CrossRef] [Green Version]

- Jefferies, M.; Been, K. Soil Liquefaction: A Critical State Approach; CRC Press: Boca Raton, FL, USA, 2006; p. 512. [Google Scholar]

- Baker Jr, C.N.; Steinberg, S.B.; Lam, W. Building Design and Construction over Organic Soil. In Proceedings of the Second International Conference on Case Histories in Geotechnical Engineering, St. Louis, MO, USA, 1–5 June 1988; Missouri University of Science and Technology: Rolla, MO, USA, 1988; pp. 1389–1393. [Google Scholar]

- Derbyshire, E.; Dijkstra, T.A.; Smalley, I.J. (Eds.) Genesis and Properties of Collapsible Soils; Springer: Dordrecht, The Netherlands, 1995; ISBN 978-94-010-4047-1. [Google Scholar]

- Al-Sanad, H.A.; Shaqour, F.M.; Hencher, S.R.; Lumsden, A.C. The influence of changing groundwater levels on the geotechnical behaviour of desert sands. Q. J. Eng. Geol. Hydrogeol. 1990, 23, 357–364. [Google Scholar] [CrossRef]

- Sudhakar, J.M. Foundations on collapsible and Expansive Soils: An Overview. Int. J. Tech. Innov. Mod. Eng. Sci. 2017, 3, 60–67. [Google Scholar]

- Kakoli, S.T.N.; Hanna, A.M. Causes of foundation failure and sudden volume reduction of collapsible soil during inundation. In Proceedings of the 4th Annual Paper Meet and 1st Civil Engineering Congress, Dhaka, Bangladesh, 22–24 December 2011; pp. 109–116. [Google Scholar]

- Liquefaction Potential of Cohesionless Soils; State of New York, Department of Transportation Geotechnical Engineering Bureau: New York, NY, USA, 2015.

- Di Maio, C.; Vassallo, R.; Vallario, M. Plastic and viscous shear displacements of a deep and very slow landslide in stiff clay formation. Eng. Geol. 2013, 162, 53–66. [Google Scholar] [CrossRef]

- Wilkinson, W.B. Rising groundwater levels in London and possible effects on engineering structures. In Proceedings of the 18th Congress, International Association of Hydrogeologists, Cambridge, UK, 1 January 1985; pp. 145–157. [Google Scholar]

- Kryzhanovskii, A.L.; Kulikov, O.V. Computation of slope stability. Hydrotechnical Constr. 1977, 11, 504–513. [Google Scholar] [CrossRef]

- Lizzi, F. The Static Restoration of Monuments: Basic Criteria, Case Histories: Strengthening of Buildings Damaged by Earthquakes; Sagep: Genova, Italy, 1982; ISBN 8870580253. [Google Scholar]

- Lourenço, P.B. Structural restoration of monuments: Recommendations and advances in research and practice. In Proceedings of the 1st International Conference on Restoration of Heritage Masonry Structures, Cairo, Egypt, 24–27 April 2006; pp. 1–16. [Google Scholar]

- Tokimatsu, K.; Mizuno, H.; Kakurai, M. Building damage associated with geotechnical problems. Soils Found. 1996, 36, 219–234. [Google Scholar] [CrossRef] [Green Version]

- Doǧangün, A. Performance of reinforced concrete buildings during the May 1, 2003 Bingöl Earthquake in Turkey. Eng. Struct. 2004, 26, 841–856. [Google Scholar] [CrossRef]

- Indraratna, B.; Heitor, A.; Rujikiatkamjorn, C. Ground improvement methods for port infrastructure expansion. Geotech. Eng. 2015, 46, 125–130. [Google Scholar]

- Sowers, G.F. Review of Building on Sinkholes: Design and Construction of Foundations in Karst Terrain by George F. Sowers; ASCE Press: New York, NY, USA, 1996; Volume 3, ISBN 0-7844-0176-4. [Google Scholar]

- Tapan, M.; Comert, M.; Demir, C.; Sayan, Y.; Orakcal, K.; Ilki, A. Failures of structures during the October 23, 2011 Tabanlı (Van) and November 9, 2011 Edremit (Van) earthquakes in Turkey. Eng. Fail. Anal. 2013, 34, 606–628. [Google Scholar] [CrossRef]

- Carter, N.T. Protecting new orleans: From hurricane barriers to floodwalls. In Flood Risk Management; Nova Science Publishers, Inc.: NewYork, NY, USA, 2009; pp. 51–67. ISBN 9781606921470. [Google Scholar]

- Gupta, Y.; Kaur, S.; Dindorkar, N. Bridge Failure Due to Inadequate Design of Bed Protection. J. Inst. Eng. Ser. A 2017, 98, 555–560. [Google Scholar] [CrossRef]

- Feld, J.; Carper, K.L. Construction Failure. A Wiley Interscience Publication, 2nd ed; Wiley: New York, NY, USA, 1996; ISBN 0471574775. [Google Scholar]

- Liao, P.-C.; Ma, Z.; Chong, H.-Y. Identifying Effective Management Factors Across Human Errors—A Case in Elevator Installation. KSCE J. Civ. Eng. 2018, 22, 3204–3214. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.; Zhu, Y. Complex engineering system learning through study of engineering failure cases using 3D animations. In Proceedings of the ASEE Annual Conference and Exposition, Vancouver, BC, Canada, 26–29 June 2011. [Google Scholar]

- Bekdaş, G.; Sayin, B.; Çelik Sola, Ö.; Güner, A. Assessment of the Material Quality of Damaged Structures after Earthquake in Van, Turkey. J. Mater. Civ. Eng. 2016, 28, 04016110. [Google Scholar] [CrossRef]

- Gana, A.; Engr, O. The Costs and Effects of Buildings Structure Failures in a Developing Society (the Nigerian experience). Int. J. Eng. Sci. Res. Technol. 2015, 4, 566–574. [Google Scholar]

- Okuntade, T. Effects of Faulty Construction On Building Maintenance. Int. J. Technol. Enhanc. Emerg. Eng. Res. 2014, 2, 73–79. [Google Scholar]

- Goldsworthy, J.S.; Jaksa, M.B.; Fenton, G.A.; Griffiths, D.V.; Kaggwa, W.S.; Poulos, H.G. Measuring the Risk of Geotechnical Site Investigations. In Proceedings of the Geo-Denver: Probabilistic Applications in Geotechnical Engineering, Denver, CO, USA, 18–21 February 2007; American Society of Civil Engineers: Reston, VA, USA, 2007; pp. 1–12. [Google Scholar]

- Knodel, P.C. Characteristics and Problems of Collapsible Soils; U.S. Department of the Interior Bureau of Reclamation: Washington, DC, USA, 1992.

- Albatal, A.; Mohammad, H.; Elrazik, M. Effect of inadequate site investigation on the cost and time of a construction project. In Proceedings of the 4th International Symposium on Geotechnical Safety and Risk, Hong Kong, China, 4–6 December 2013; pp. 331–336. [Google Scholar]

- Muthukkumaran, K.; Keerthi Raaj, S.; Vinoth Kumar, M. Assessment of pile failures due to excessive settlement during pile load test. Japanese Geotech. Soc. Spec. Pub. 2016, 2, 2520–2524. [Google Scholar] [CrossRef] [Green Version]

- Zumrawi, M. Effects of Inadequate Geotechnical Investigation on Civil Engineering Projects. Int. J. Sci. Res. 2014, 3, 927–931. [Google Scholar]

- Anon Inadequate Site Analysis Caused Dam Failure. World Constr. Engl. Ed. 1985, 38, 38–39. [CrossRef] [Green Version]

- Forth, R. Groundwater and geotechnical aspects of deep excavations in Hong Kong. Eng. Geol. 2004, 72, 253–260. [Google Scholar] [CrossRef]

- Cho, S.E. Probabilistic analysis of seepage that considers the spatial variability of permeability for an embankment on soil foundation. Eng. Geol. 2012, 133–134, 30–39. [Google Scholar] [CrossRef]

- Li, Y.; Chai, J.; Xu, Z. Analysis of influence of seepage on stability of foundation pit. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Busan, Korea, 25–27 August 2017; Volume 207, pp. 1–6. [Google Scholar]

- Usmanov, R.; Rakočević, M.; Murgul, V.; Vatin, N. Problems of Sub-Mountain Area Development Associated with Collapsing Loess Soils (Case of Tajikistan). Appl. Mech. Mater. 2014, 633–634, 927–931. [Google Scholar] [CrossRef]

- Hanna, A.; Soliman, S. Experimental investigation of foundation on collapsible soils. J. Geotech. Geoenviron. Eng. 2017, 143, 1–12. [Google Scholar] [CrossRef]

- Conte, E.; Troncone, A.; Donato, A. A Simple Approach for Evaluating Slope Movements Induced by Groundwater Variations. Procedia Eng. 2016, 158, 200–205. [Google Scholar] [CrossRef] [Green Version]

- Janalizadeh, A.; Zahmatkesh, A. Lateral response of pile foundations in liquefiable soils. J. Rock Mech. Geotech. Eng. 2015, 7, 532–539. [Google Scholar] [CrossRef] [Green Version]

- Bishop, A.W.; Bjerrum, L. The relevance of the triaxial test to the solution of stability problems. Geotech. Spec. Publ. 2002, 690–754. [Google Scholar]

- Rad, A.R.; Banazadeh, M. Probabilistic risk-based performance evaluation of seismically base-isolated steel structures subjected to far-field earthquakes. Buildings 2018, 8, 128. [Google Scholar] [CrossRef] [Green Version]

- Couto, R.; Bento, R.; Gomes, R.C. Seismic performance and fragility curves of historical residential buildings in Lisbon downtown affected by settlements. Bull. Earthq. Eng. 2020, 18, 5281–5307. [Google Scholar] [CrossRef]

- Cantagallo, C.; Spacone, E.; Perrucci, D.; Liguori, N.; Verazzo, C. A multilevel approach for the cultural heritage vulnerability and strengthening: Application to the melfi castle. Buildings 2020, 10, 158. [Google Scholar] [CrossRef]

- Hosamo, H.; Sliteen, I.; Ding, S. Numerical analysis of bearing capacity of a ring footing on geogrid reinforced sand. Buildings 2021, 11, 68. [Google Scholar] [CrossRef]

- Diz-Mellado, E.; Mascort-Albea, E.J.; Romero-Hernández, R.; Galán-Marín, C.; Rivera-Gómez, C.; Ruiz-Jaramillo, J.; Jaramillo-Morilla, A. Non-destructive testing and Finite Element Method integrated procedure for heritage diagnosis: The Seville Cathedral case study. J. Build. Eng. 2021, 37, 102134. [Google Scholar] [CrossRef]

- Brand, A.S.; Singhvi, P.; Fanijo, E.O.; Tutumluer, E. Stabilization of a clayey soil with ladle metallurgy furnace slag fines. Materials 2020, 13, 4251. [Google Scholar] [CrossRef]

- Shen, J.; Xu, Y.; Chen, J.; Wang, Y. Study on the stabilization of a new type of waste solidifying agent for soft soil. Materials 2019, 12, 826. [Google Scholar] [CrossRef] [Green Version]

- Rosales, J.; Agrela, F.; Marcobal, J.R.; Diaz-López, J.L.; Cuenca-Moyano, G.M.; Caballero, Á.; Cabrera, M. Use of nanomaterials in the stabilization of expansive soils into a road real-scale application. Materials 2020, 13, 3058. [Google Scholar] [CrossRef]

- Almajed, A.; Srirama, D.; Moghal, A.A.B. Response surface method analysis of chemically stabilized fiber-reinforced soil. Materials 2021, 14, 1535. [Google Scholar] [CrossRef]

- Abdila, S.R.; Abdullah, M.M.A.B.; Ahmad, R.; Rahim, S.Z.A.; Rychta, M.; Wnuk, I.; Nabiałek, M.; Muskalski, K.; Tahir, M.F.M.; Syafwandi; et al. Evaluation on the mechanical properties of ground granulated blast slag (GGBS) and fly ash stabilized soil via geopolymer process. Materials 2021, 14, 2833. [Google Scholar] [CrossRef] [PubMed]

- Al-Barqawi, M.; Aqel, R.; Wayne, M.; Titi, H.; Elhajjar, R. Polymer Geogrids: A Review of Material, Design and Structure Relationships. Materials 2021, 14, 4745. [Google Scholar] [CrossRef] [PubMed]

- Maichin, P.; Jitsangiam, P.; Nongnuang, T.; Boonserm, K.; Nusit, K.; Pra-Ai, S.; Binaree, T.; Aryupong, C. Stabilized high clay content lateritic soil using cement-fgd gypsum mixtures for road subbase applications. Materials 2021, 14, 1858. [Google Scholar] [CrossRef] [PubMed]

- Sabri, M.M.; Shashkin, K.G.; Zakharin, E.; Ulybin, A.V. Soil stabilization and foundation restoration using an expandable polyurethane resin. Mag. Civ. Eng. 2018, 82, 68–80. [Google Scholar] [CrossRef]

- Sabri, M.M.; Shashkin, K.G. Shashkin Improvement of the soil deformation modulus using an expandable polyurethane resin. Mag. Civ. Eng. 2018, 83, 222–234. [Google Scholar] [CrossRef]

- Sabri, M.M.; Bugrov, A.; Panov, S.; Davidenko, V. Ground improvement using an expandable polyurethane resin. MATEC Web Conf. 2018, 245, 1–4. [Google Scholar] [CrossRef]

- Sabri, M.M.; Shashkin, K.G. The mechanical properties of the expandable polyurethane resin based on its volumetric expansion nature. Mag. Civ. Eng. 2020, 98, 9811. [Google Scholar] [CrossRef]

- Sabri, M.M.; Shashkin, K.G. Subsoil stabilized by polyurethane resin injection: FEM calculation. Constr. Unique Build. Struct. 2020, 91, 9108. [Google Scholar] [CrossRef]

- Buzzi, O.; Fityus, S.; Sasaki, Y.; Sloan, S. Structure and properties of expanding polyurethane foam in the context of foundation remediation in expansive soil. Mech. Mater. 2008, 40, 1012–1021. [Google Scholar] [CrossRef]

- Buzzi, O.; Fityus, S.; Sloan, S.W. Use of expanding polyurethane resin to remediate expansive soil foundations. Can. Geotech. J. 2010, 47, 623–634. [Google Scholar] [CrossRef] [Green Version]

- Fityus, S.G.; Buzzi, O.; Imre, E. Large scale tests on the expansiveness of resin-injected clay. In Proceedings of the 5th Asia-Pacific Conference on Unsaturated Soils, Pattaya, Thailand, 29 February–2 March 2012; Volume 2, pp. 445–450. [Google Scholar]

- Popik, M.; Trout, M.; Icr, U.; Brown, R.W. Improving soil stiffness beneath pavements using polyurethane injection. In Proceedings of the TAC/ATC 2010 Annual Conference and Exhibition of the Transportation Association of Canada: Adjusting to New Realities, Halifax, NS, Canada, 26–29 September 2010. [Google Scholar]

- Sabri, M.M. Reinforcement of Foundations and Regulation of Buildings Settlement with an Expandable Polyurethane Resin. Ph.D. Thesis, Peter the Great St.Petersburg Polytechnic University, Saint Petersburg, Russia, 2020. Available online: https://www.dissercat.com/content/usilenie-osnovanii-i-regulirovanie-osadok-zdanii-rasshiryaemoi-poliuretanovoi-smoloi/read (accessed on 15 October 2021).

- Lat, D.C.; Ali, N.; Jais, I.B.M.; Yunus, N.Z.M.; Razali, R.; Talip, A.R.A. A review of polyurethane as a ground improvement method. Malaysian J. Fundam. Appl. Sci. 2020, 16, 70–74. [Google Scholar] [CrossRef]

- Al-Atroush, M.E.; Sebaey, T.A. Stabilization of expansive soil using hydrophobic polyurethane foam: A review. Transp. Geotech. 2021, 27, 100494. [Google Scholar] [CrossRef]

- Guo, C.; Sun, B.; Hu, D.; Wang, F.; Shi, M.; Li, X. A Field Experimental Study on the Diffusion Behavior of Expanding Polymer Grouting Material in Soil. Soil Mech. Found. Eng. 2019, 56, 171–177. [Google Scholar] [CrossRef]

- Niederbrucker, R.; Wu, W.; Pasquetto, A. Flat Dilatometer Tests for verification of Uretek’s Resin-Injektions. 2015. Available online: https://www.semanticscholar.org/paper/Flat-Dilatometer-Tests-for-verification-of-Uretek’s-Niederbrucker/281cad2e975ed785c6fe823a1225a05cc8f3e59 (accessed on 15 October 2021).

- Dei Svaldi, A.; Favaretti, M.; Pasquetto, A.; Vinco, G. Analytical modelling of the soil improvement by injections of high expansion pressure resin. Bull. fuer Angew. Geol. 2005, 10, 71–81. [Google Scholar]

- Sánchez, F.E.; de la Serna, A.M.; Lavín, J.R.S.; del Campo Yagüe, J.M. Underpinning of shallow foundations by expansive polyurethane resin injections. Case study: Cardinal Diego de Espinosa Palace in Segovia (Spain). Rev. la Constr. 2017, 16, 420–430. [Google Scholar] [CrossRef] [Green Version]

- Lavín, J.R.S.; Sánchez, F.E.; de la Serna, A.M. Chemical injections realized with null pressure for underpinning the foundation of an 18th Century Building located in the historical city of Cuenca (Spain). Appl. Sci. 2018, 8, 1117. [Google Scholar] [CrossRef] [Green Version]

- Sidek, N.; Bakar, I.A.A.; Azman, A.A.; Rahman, A.S.A.; Austin, W.A. Strength characteristic of polyurethane with variation of polyol to isocyanate mix ratio: A numerical analysis. In Proceedings of the 2017 IEEE 2nd International Conference on Automatic Control and Intelligent Systems (I2CACIS 2017), Kota Kinabalu, Malaysia, 21 October 2017. [Google Scholar] [CrossRef]

- Chun, B.-S.; Ryu, D.-S. A study on applications of polyurethane injection material for ground improvement. KSCE J. Civ. Eng. 2000, 4, 113–118. [Google Scholar] [CrossRef]

- Jais, I.B.M. Rapid remediation using polyurethane foam/resin grout in Malaysia. Geotech. Res. 2017, 4, 107–117. [Google Scholar] [CrossRef] [Green Version]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Sharmin, E.; Zafar, F. Polyurethane: An Introduction; IntechOpen: London, UK, 2012; pp. 3–16. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Nelson, A.M.; Talley, S.J.; Chen, M.; Margaretta, E.; Hudson, A.G.; Moore, R.B.; Long, T.E. Non-isocyanate poly(amide-hydroxyurethane)s from sustainable resources. Green Chem. 2016, 18, 4667–4681. [Google Scholar] [CrossRef] [Green Version]

- Delebecq, E.; Pascault, J.-P.; Boutevin, B.; Ganachaud, F. On the Versatility of Urethane/Urea Bonds: Reversibility, Blocked Isocyanate, and Non-isocyanate Polyurethane. Chem. Rev. 2013, 113, 80–118. [Google Scholar] [CrossRef]

- Tejaswi, S.L.; Aswathi, T.S.; Poongothai, A. Rectification of settled foundations. In Proceedings of the 6th IRF International Conference, Chennai, India, 10 May 2014; pp. 68–72. [Google Scholar]

- Keene, A.K.; Tinjum, J.M.; Edil, T.B. Mechanical Properties of Polyurethane-Stabilized Ballast Mechanical Properties of Polyurethane-Stabilized Ballast. Geotech. Eng. J. 2014, 45, 66–73. [Google Scholar]

- Valentino, R.; Romeo, E.; Stevanoni, D. An experimental study on the mechanical behaviour of two polyurethane resins used for geotechnical applications. Mech. Mater. 2014, 71, 101–113. [Google Scholar] [CrossRef]

- Saha, M.C.; Mahfuz, H.; Chakravarty, U.K.; Uddin, M.; Kabir, M.E.; Jeelani, S. Effect of density, microstructure, and strain rate on compression behavior of polymeric foams. Mater. Sci. Eng. A 2005, 406, 328–336. [Google Scholar] [CrossRef]

- Golpazir, I.; Ghalandarzadeh, A.; Jafari, M.K.; Mahdavi, M. Dynamic properties of polyurethane foam-sand mixtures using cyclic triaxial tests. Constr. Build. Mater. 2016, 118, 104–115. [Google Scholar] [CrossRef]

- Nowamooz, H. Resin injection in clays with high plasticity. C. R. Mécanique 2016, 344, 797–806. [Google Scholar] [CrossRef] [Green Version]

- Mitani, T.; Hamada, H. Prediction of flow patterns in the polyurethane foaming process by numerical simulation considering foam expansion. Polym. Eng. Sci. 2003, 43, 1603–1612. [Google Scholar] [CrossRef]

- Valentino, R.; Romeo, E.; Misra, A. Mechanical Aspects of Micropiles Made of Reinforced Polyurethane Resins. Geotech. Geol. Eng. 2013, 31, 463–478. [Google Scholar] [CrossRef]

- Sidek, N.; Mohamed, K.; Jais, I.B.M.; Abu Bakar, I.A. Strength Characteristics of Polyurethane (PU) With Modified Sand. Appl. Mech. Mater. 2015, 773–774, 1508–1512. [Google Scholar] [CrossRef] [Green Version]

- Fakhar, A.M.M.; Asmaniza, A. Road Maintenance Experience Using Polyurethane (PU) Foam Injection System and Geocrete Soil Stabilization as Ground Rehabilitation. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Adithya, H.; Amith, K.; Akshar, S.; Rakshitha, A. Experimental Investigation on the effect of polyurethane foam on black cotton soil. In Trends in Civil Engineering and Challenges for Sustainability; Springer Nature Singapore Pte Ltd.: Singapore, 2019; pp. 421–430. ISBN 9789811568275. [Google Scholar]

- Tannoury, G.A.; Schrock, S.D. Introduction to chemical stabilization of unstable trackbeds. In Proceedings of the 2016 Joint Rail Conference, Columbia, SC, USA, 12–15 April 2016; pp. 1–5. [Google Scholar]

- Mohamed Jais, I.B.; Che Lat, D.; Tengku Endut, T.N.D. Compressiblity of peat soil improved with polyurethane. Malaysian J. Civ. Eng. 2019, 31, 35–41. [Google Scholar] [CrossRef]

- Al-Atroush, M.E.; Shabbir, O.; Almeshari, B.; Waly, M.; Sebaey, T.A. A Novel Application of the Hydrophobic Polyurethane Foam: Expansive Soil Stabilization. Polymers 2021, 13, 1335. [Google Scholar] [CrossRef] [PubMed]

- Hellmeier, E.S.W.W.; Hellmeier, P.; Soranzo, E.; Wu, W.; Niederbrucker, R.; Pasquetto, A. An experimental investigation into the performance of polyurethane grouting in soil. In Proceedings of the 14th Pan-American Conference on Soil Mechanics and Geotechnical Engineering, Toronto, ON, Canada, 1–7 October 2011; Volume 54, pp. 209–223. [Google Scholar]

- Traylen, N.J.; Wentz, F.J.; Van Ballegooy, S.; Wotherspoon, L.M.; Hnat, T.; Deller, R. A Study into Resin Injection as a Ground Improvement Technique for Seismic Liquefaction Mitigation. In Proceedings of the Geotechnical Earthquake Engineering and Soil Dynamics V Conference, Austin, TX, USA, 10–13 June 2018; pp. 60–70. [Google Scholar]

- Apuani, T.; Giani, G.P.; D’Attoli, M.; Fischanger, F.; Morelli, G.; Ranieri, G.; Santarato, G. Assessment of the Efficiency of Consolidation Treatment through Injections of Expanding Resins by Geotechnical Tests and 3D Electrical Resistivity Tomography. Sci. World J. 2015, 2015, 1–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Warren, B. Field Application of Expanding Rigid Polyurethane Stabilization of Railway Track Substructure; University of Wisconsin-Madison: Madison, WI, USA, 2015. [Google Scholar]

- Alsabhan, A.; Tinjum, J.; Fratta, D.; Edil, T. Field Validation of Polyurethane Technology in Remediating Rail Substructure and Enhancing Rail Freight Capacity: Report; University of Wisconsin–Madison: Madison, WI, USA, 2016; pp. 1–55. [Google Scholar]

- Shi, M.S.; Xu, P.; Wang, F.M. Application of uretek polymer material to uplift workshop floor. Electron. J. Geotech. Eng. 2013, 18, 1809–1816. [Google Scholar]

- Hess, J. In-Situ Testing of Uretek’ s Injectable Barrier SM as a Mechanism for Groundwater Control. Master’s Thesis, University of South Florida , Tampa, FL, USA, 2016. [Google Scholar]

- Vennapusa, P.K.R.; Zhang, Y.; White, D.J. Comparison of Pavement Slab Stabilization Using Cementitious Grout and Injected Polyurethane Foam. J. Perform. Constr. Facil. 2016, 30, 1–14. [Google Scholar] [CrossRef]

- Che Lat, D.; Jais, I.B.M.; Ali, N.; Baharom, B.; Salleh, S.M.; Omar, A. Performance Comparison between Polyurethane Foam and Cement Grouting Slab Replacement for Soft Ground Improvement at Shallow Depth Using Finite Element Model. Key Eng. Mater. 2020, 844, 1–8. [Google Scholar] [CrossRef]

- Davies, P.; Evrard, G. Accelerated ageing of polyurethanes for marine applications. Polym. Degrad. Stab. 2007, 92, 1455–1464. [Google Scholar] [CrossRef] [Green Version]

- Rutkowska, M.; Krasowska, K.; Heimowska, A.; Steinka, I.; Janik, H. Degradation of polyurethanes in sea water. Polym. Degrad. Stab. 2002, 76, 233–239. [Google Scholar] [CrossRef]

- Campion, R.P.; Thomson, B.; Harris, J.A. Elastomers for Fluid Containment in Offshore Oil and Gas Production: Guidelines and Review, Research Report 320; Health and Safety Executive: Caerphilly, UK, 2005.

- Howard, G.T. Polyurethane Biodegradation. In Environmental Science and Engineering; Singh, S.N., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 371–394. ISBN 978-3-642-23788-1. [Google Scholar]

- Huntsman Elastomers. A Guide to Thermoplastic Polyurethanes (TPU), July 10, 2013. 2021. Available online: http://www.huntsman.com (accessed on 15 October 2021).

- Cosgrove, L.; McGeechan, P.L.; Robson, G.D.; Handley, P.S. Fungal communities associated with degradation of polyester polyurethane in soil. Appl. Environ. Microbiol. 2007, 73, 5817–5824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crabbe, J.R.; Campbell, J.R.; Thompson, L.; Walz, S.L.; Schultz, W.W. Biodegradation of a colloidal ester-based polyurethane by soil fungi. Int. Biodeterior. Biodegrad. 1994, 33, 103–113. [Google Scholar] [CrossRef]

- Kay, M.J.; Morton, L.H.G.; Prince, E.L. Bacterial degradation of polyester polyurethane. Int. Biodeterior. 1991, 27, 205–222. [Google Scholar] [CrossRef]

- Kay, M.J.; McCabe, R.W.; Morton, L.H.G. Chemical and physical changes occurring in polyester polyurethane during biodegradation. Int. Biodeterior. Biodegrad. 1993, 31, 209–225. [Google Scholar] [CrossRef]

- Mitchell, J.K. Soil improvement-state-of-the-art. In Proceedings of the 10th International Conference of Soil Mechanics and Foundation Engineering, Stockholm, Sweden, 15–19 June 1981; pp. 509–565. [Google Scholar]

- Karol, R.H. Chemical Grouting and Soil Stabilization, 3rd ed.; CRC Press: Boca Raton, NJ, USA, 2003; ISBN 9780203911815. [Google Scholar]

- Korneeva, E.; Sabri Mohanad, M.S.; Babanina, A.; Zaytsev, E.; Poberezhskii, S. Operational characteristics of limestone and methods to increase its strength. E3S Web Conf. 2019, 91, 02028. [Google Scholar] [CrossRef]

- Sabri, M.; Korneeva, E. Strengthening the historical constructions made of limestone by treating with silicic acid based material. MATEC Web Conf. 2018, 245, 10–13. [Google Scholar] [CrossRef]

- Grebneva, V.; Utkina, K.; Sabri, M.; Stolyarov, O. Application of Stepped Isothermal Method for Prediction the Creep Behavior of Extruded Polypropylene Geogrid. Appl. Mech. Mater. 2015, 725–726, 611–616. [Google Scholar] [CrossRef]

- Korneeva, E.; Sabri, S.M.M. The water absorption of Crimean limestone treated with silicic acid based material. MATEC Web Conf. 2018, 245, 03001. [Google Scholar] [CrossRef] [Green Version]

- Santarato, G.; Albertini, A.; d’Attoli, M.; Navi, F.; Occhi, M.; Fischanger, F.; Morelli, G.; Leoni, M.; Apuani, T.; Loddo, F.; et al. The consolidation and stabilization of foundation soils through the injection of expanding polyurethane resin under a non-invasive diagnostic check by 3D-4D-ERT. In Soil Stabilization: Types, Methods and Applications; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2017; pp. 165–230. ISBN1 978-153612528-3. ISBN2 978-153612507-8. [Google Scholar]

- Gatto, M.P.A.; Lentini, V.; Castelli, F.; Montrasio, L.; Grassi, D. The Use of Polyurethane Injection as a Geotechnical Seismic Isolation Method in Large-Scale Applications: A Numerical Study. Geosciences 2021, 11, 201. [Google Scholar] [CrossRef]

- Yenco, A. Decision Tree for Ground Improvement in Transportation Applications. Master’s Thesis, University of Akron, Akron, OH, USA, 2013. [Google Scholar]

- Lat, D.C.; Mohamed, I.R.K. Performance Comparisonbetwee Polyurethane Injection Pile and Slab System against Lightweight Concrete as a Ground Improvement Using Finite Element Analysis. J. Appl. Sci. Res. 2015, 11, 11–16. [Google Scholar]

| The Injection Point | The Consumption Required for the Strengthening, (Liters) | The Consumption Required for Lifting, (Liters) | The Looses (Liters) |

|---|---|---|---|

| Point 1 | 22 | 9 | 3 |

| Point 2 | 19 | 7 | 2 |

| Point 3 | 37 | 17 | 7 |

| Point 4 | 17 | 13 | 3 |

| Point 5 | 28 | 11 | 5 |

| Total | 123 | 57 | 20 |

| Advantages [64,66,68,70,71,76,78,83,93,95,97,103,104,105,106,110,126,127,128,129]. | Limitations [64,65,67,70,72,74,83,128]. |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

| |

| |

| |

| |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabri, M.M.S.; Vatin, N.I.; Alsaffar, K.A.M. Soil Injection Technology Using an Expandable Polyurethane Resin: A Review. Polymers 2021, 13, 3666. https://doi.org/10.3390/polym13213666

Sabri MMS, Vatin NI, Alsaffar KAM. Soil Injection Technology Using an Expandable Polyurethane Resin: A Review. Polymers. 2021; 13(21):3666. https://doi.org/10.3390/polym13213666

Chicago/Turabian StyleSabri, Mohanad Muayad Sabri, Nikolai Ivanovich Vatin, and Kifayah Abood Mohammed Alsaffar. 2021. "Soil Injection Technology Using an Expandable Polyurethane Resin: A Review" Polymers 13, no. 21: 3666. https://doi.org/10.3390/polym13213666

APA StyleSabri, M. M. S., Vatin, N. I., & Alsaffar, K. A. M. (2021). Soil Injection Technology Using an Expandable Polyurethane Resin: A Review. Polymers, 13(21), 3666. https://doi.org/10.3390/polym13213666