Dynamic Mechanical Analysis of Thermally Aged Fique Fabric-Reinforced Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

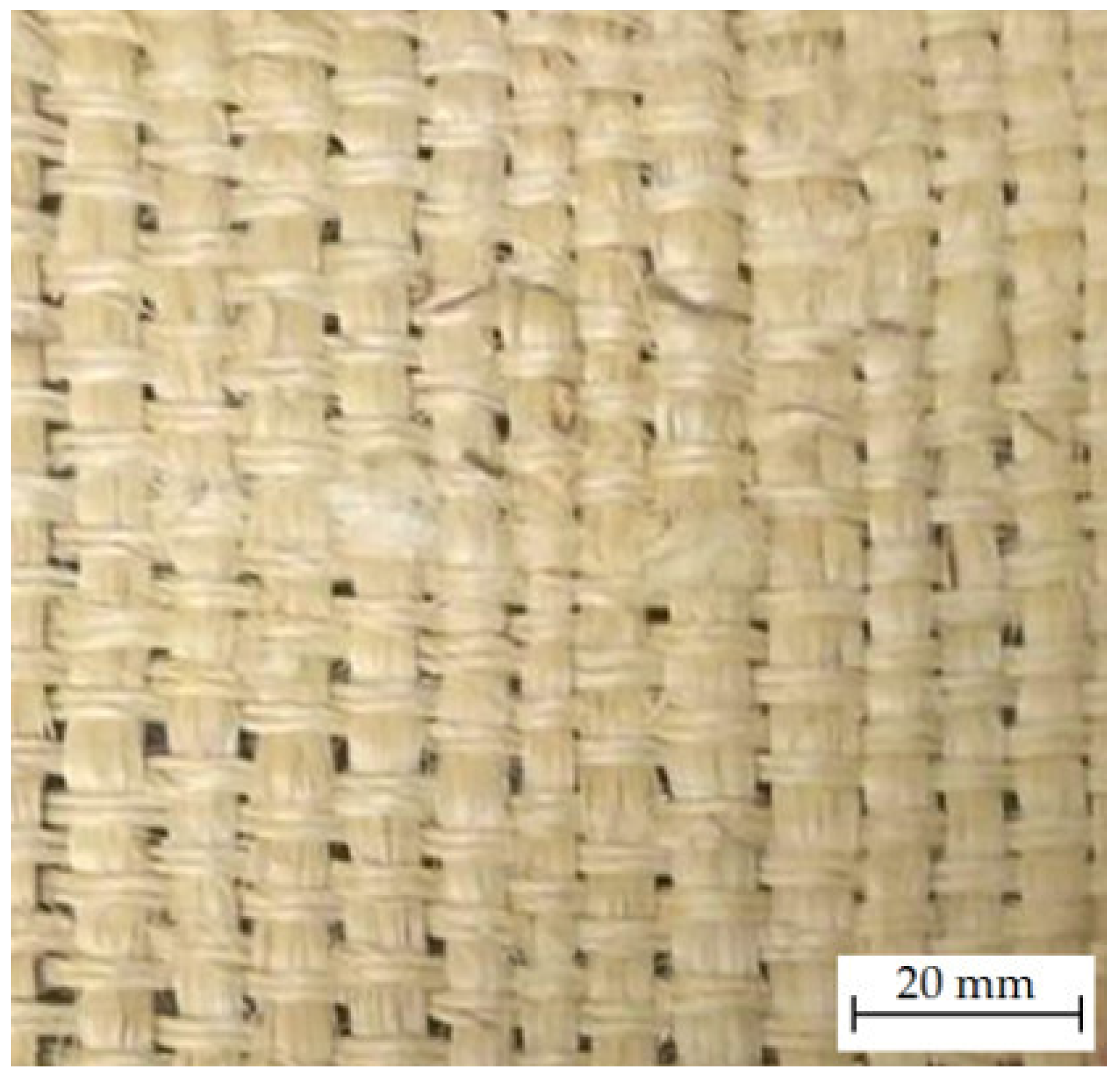

2.1. Materials

2.2. Composite Fabrication

2.3. Accelerated Aging

- 0 h (no aging): control sample;

- Aging temperature: 170 °C (T); and

- Aging time: 72, 120, 240 h.

2.4. Experimental Procedures

2.4.1. Scanning Electron Microscopy (SEM) Analysis

2.4.2. Thermogravimetric Analysis (TGA)

2.4.3. Dynamic Mechanical Analysis (DMA)

3. Results and Discussions

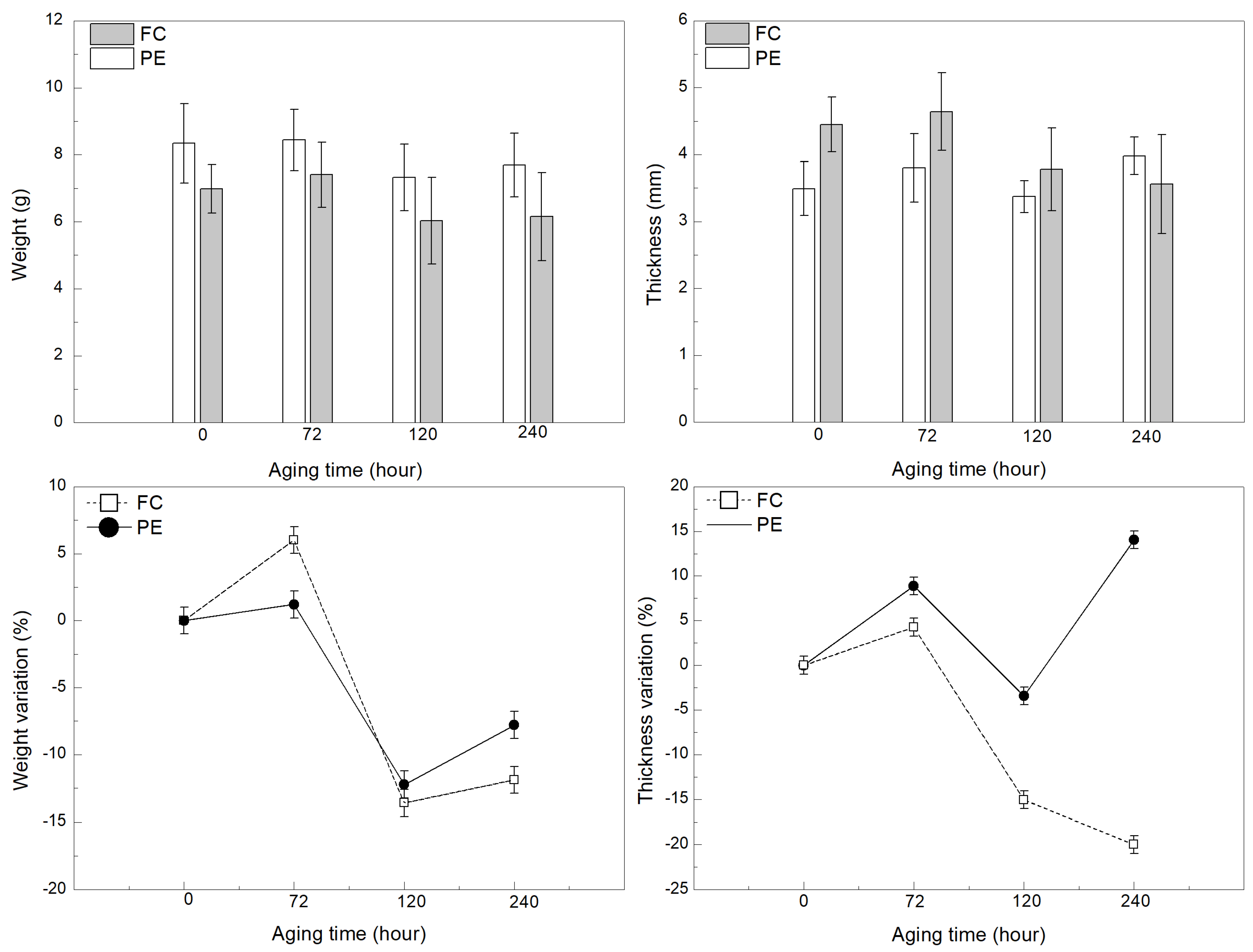

3.1. Mass and Thickness Variations

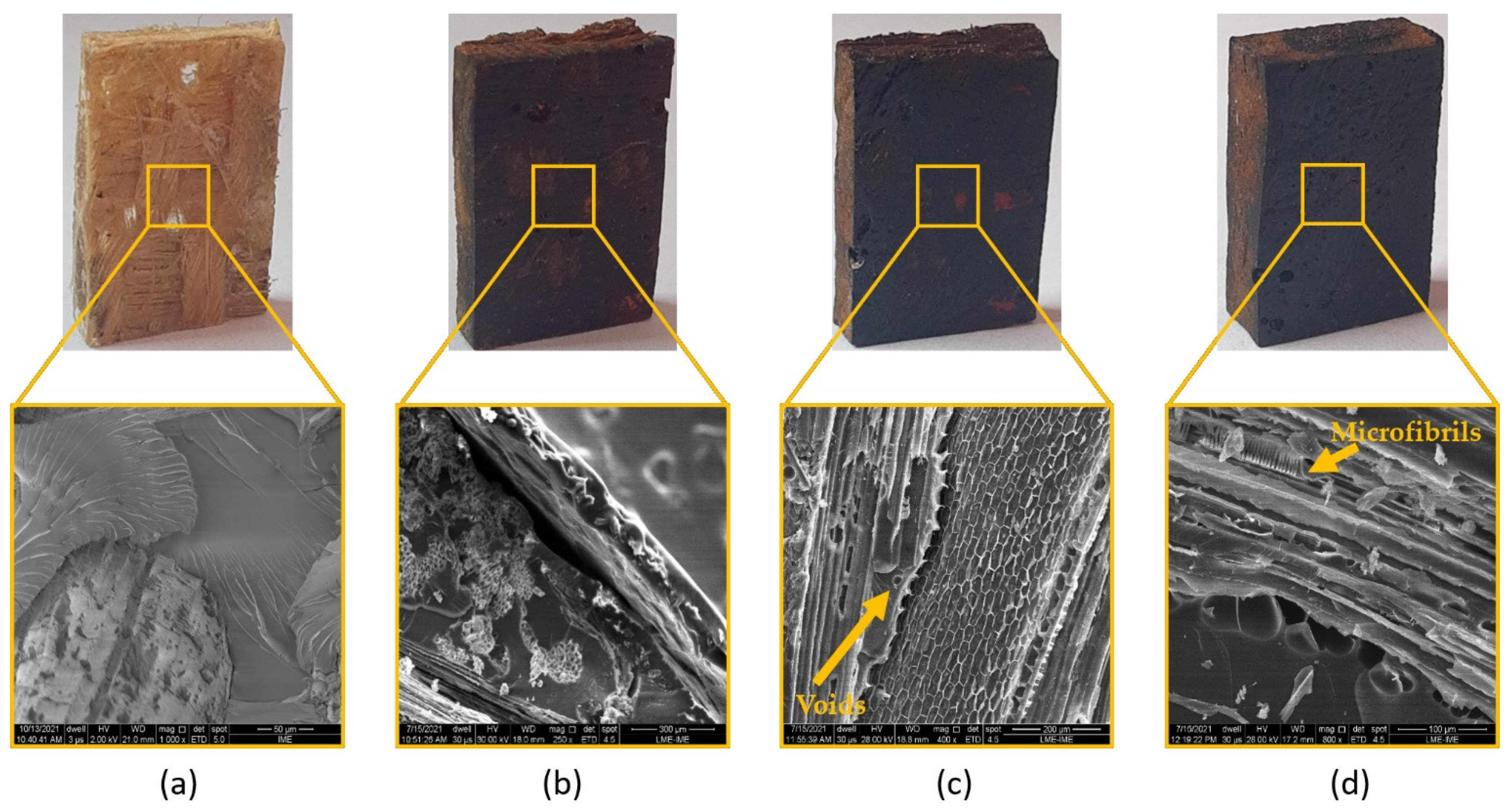

3.2. Effects of Thermal Aging on Fique Fabric

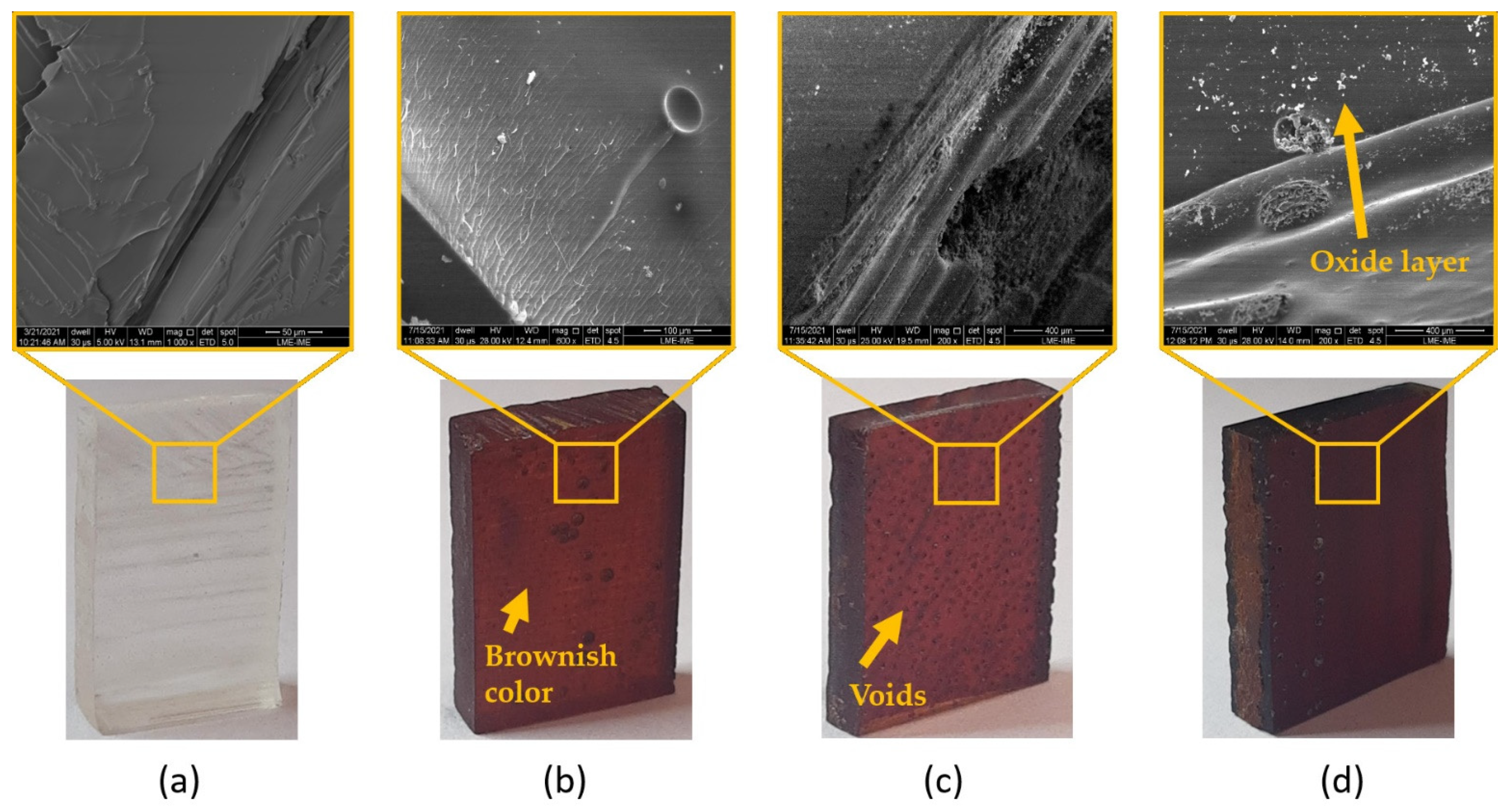

3.3. Effects of Thermal Aging on Plain Epoxy

3.4. Effects of Thermal Aging on Fique Fabric-Reinforced Epoxy Composite

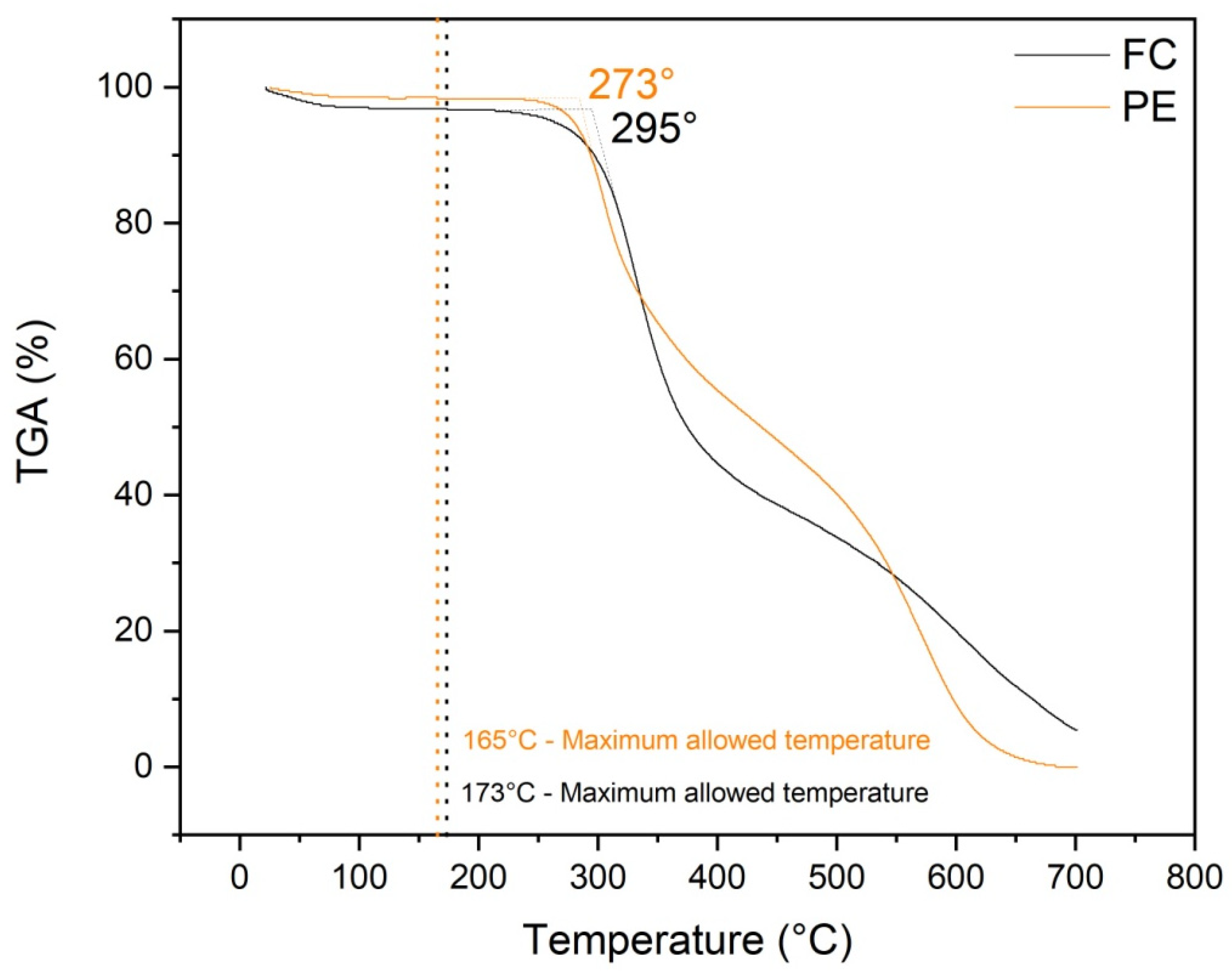

3.5. TGA of Unaged Epoxy and Composite

3.6. Effects of Thermal Aging on DMA

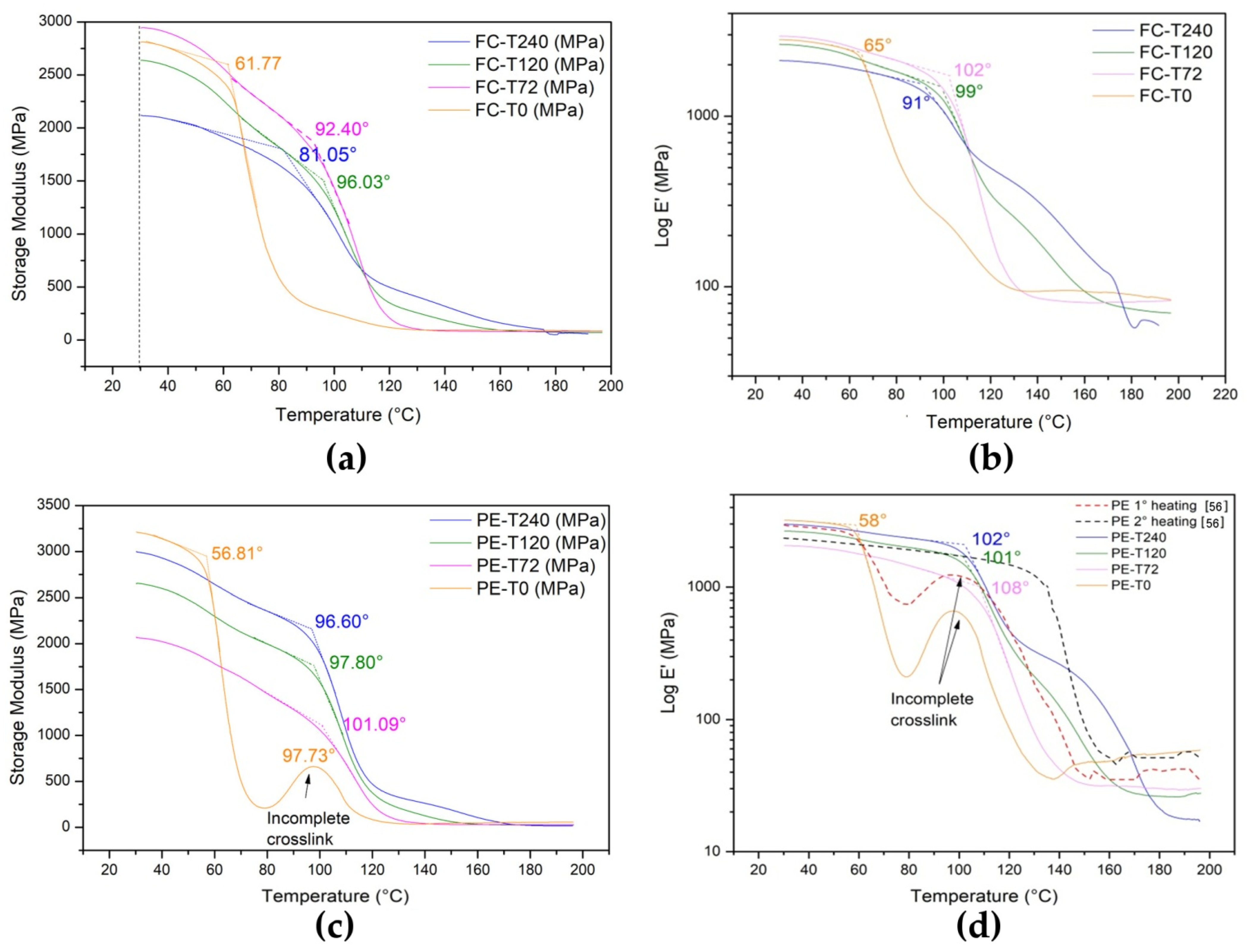

3.6.1. Storage Modulus

3.6.2. Loss Modulus

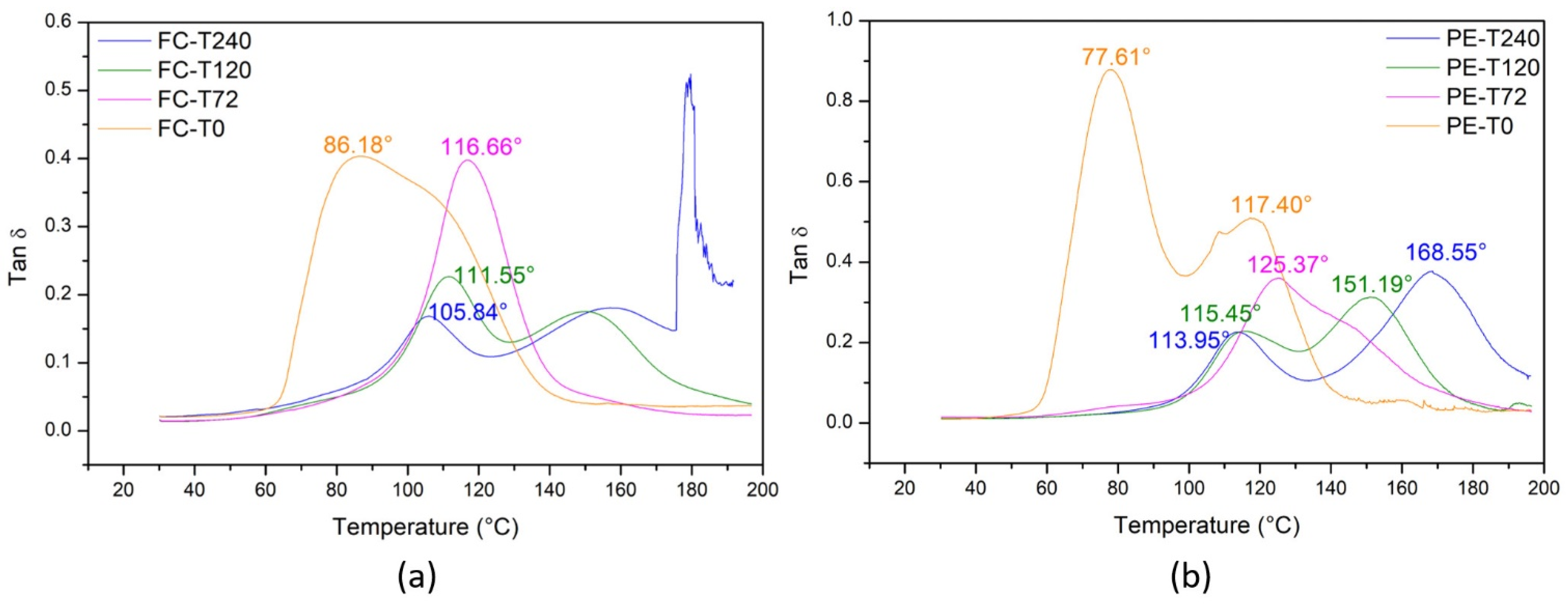

3.6.3. Tan Delta

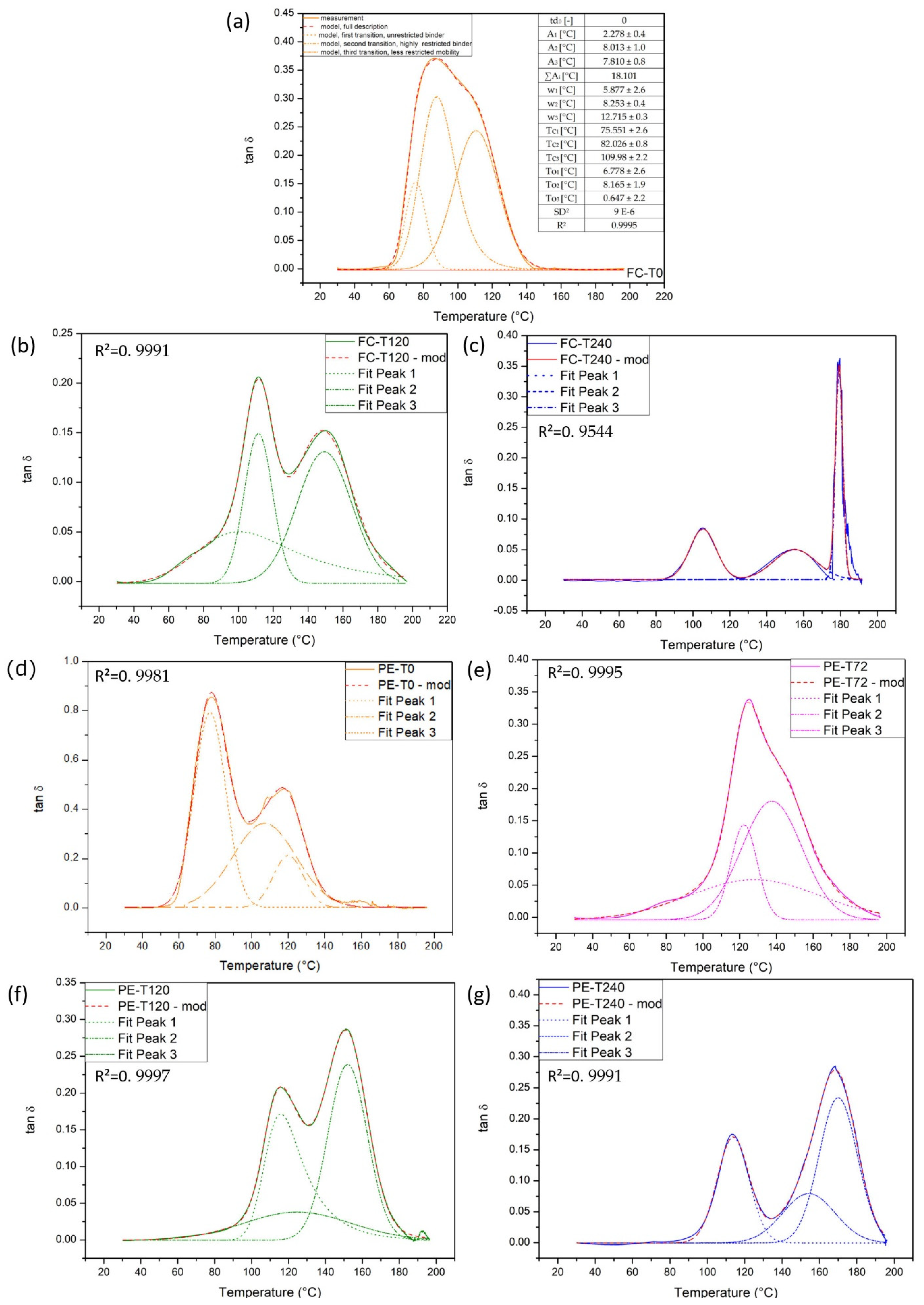

3.6.4. Modeling of the Loss Factor Curve: Evaluation with Exponentially Modified Gauss (EMG) Distribution Functions

4. Summary and Conclusions

- Hemicellulose loss and oxidation are believed to be the main mechanisms for the microstructure changes that occur during thermal aging of fique fabric-reinforced epoxy composites. All samples of fique fabric, plain epoxy, and fique fabric composites revealed physical aspect changes at the macrostructural level, exhibiting a formation of a brownish layer at the sample surface.

- Mass loss rapidly increased at the initial stage of thermal aging, mainly due to the evaporation of moisture and the volatilization of residual low-molecular-weight substances. The samples thermally exposed for 120 h showed the higher mass loss, ∼14%, and high shrinkage, ~15%, which might be associated with the outgassing of resin oxidation by-products.

- In DMA analyses, we observed significant property changes after aging. The most notable changes occurred in the storage modulus (E’) curves. For samples aged for 72 h, a significant decrease in E’ modulus was observed for both the plain epoxy and the fique fabric composite. In addition, an increase of Tg was observed for the samples aged up to 120 h.

- By contrast, the fique fabric composite aged with 240-h aging time exhibited a lower E’ modulus, which indicated the degradation at the fiber–matrix interface, also verified in the SEM analyses.

- Additionally, it is worth mentioning the presence of a broad peak around 98 °C for the unaged plain epoxy, which was attributed to the post-curing reaction given by the incomplete crosslinking.

- The loss factor results were modeled with three exponentially modified Gauss functions in order to get a molecular interpretation of the involved phenomena, which can be analyzed by the areas of the second and third transition peaks or the corresponding temperature values of the assigned Gauss peaks. The fique fabric composites presented smaller peak areas compared to the plain epoxy, which might be explained by the higher hindrance in mobility, an increase of stiffness, and an increase of crosslinking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eaton, M.D.; Brinson, L.C.; Shull, K.R. Temperature dependent fracture behavior in model epoxy networks with nanoscale heterogeneity. Polymer 2021, 221, 123560. [Google Scholar] [CrossRef]

- Henriques, I.R.; Borges, L.A.; Costa, M.F.; Soares, B.G.; Castello, D.A. Comparisons of complex modulus provided by different DMA. Polym. Test. 2018, 72, 394–406. [Google Scholar] [CrossRef]

- Proia, A.; Matthys, S. Influence of environmental conditions on the glass transition temperature of epoxy used for strengthening applications. Polym. Test. 2019, 79, 106012. [Google Scholar] [CrossRef]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J. Effect of thermal ageing on the impact and flexural damage behaviour of carbon fibre-reinforced epoxy laminates. Polymers 2019, 11, 80. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, J.; Osenbach, J. Processability and reliability of epoxy adhesive used in microelectronic devices linked to effects of degree of cure and damp heat aging. Microelectron. Reliab. 2006, 46, 503–511. [Google Scholar] [CrossRef]

- Ma, X.; Guo, W.; Xu, Z.; Chen, S.; Cheng, J.; Zhang, J.; Miao, M.; Zhang, D. Synthesis of degradable hyperbranched epoxy resins with high tensile, elongation, modulus and low-temperature resistance. Compos. B Eng. 2020, 192, 108005. [Google Scholar] [CrossRef]

- Lemos, M.F.; Bohn, M.A. DMA of polyester-based polyurethane elastomers for composite rocket propellants containing different energetic plasticizers. J. Therm. Anal. Calorim. 2016, 131, 595–600. [Google Scholar] [CrossRef]

- Cerri, S.; Bohn, M.A.; Menke, K.; Galfetti, L. Aging of HTPB/Al/AP Rocket Propellant Formulations Investigated by DMA Measurements. Propellants Explos. Pyrotech. 2013, 38, 190–198. [Google Scholar] [CrossRef]

- Lemos, M.F.; Mussbach, G.; Bohn, M.A. Evaluation of filler effects on the dynamic mechanical behavior of HTPB-elastomer used as binder in exemplary composite formulations. J. Aerosp. Technol. Manag. 2017, 9, 379–388. [Google Scholar] [CrossRef]

- Oliveira, J.L.; Skilbred, A.W.B.; Loken, A.; Henriques, R.R.; Soares, B.G. Effect of accelerated ageing procedures and flash rust inhibitors on the anti-corrosive performance of epoxy coatings: EIS and dynamic-mechanical analysis. Prog. Org. Coat. 2021, 159, 106387. [Google Scholar] [CrossRef]

- Peng, X.; Liu, Q.; Wang, D.; Liu, C.; Zhao, Y.; Wang, R.; Zheng, P. A hyperbranched structure formed by in-situ crosslinking of additive flame retardant endows epoxy resins with great flame retardancy improvement. Compos. B Eng. 2021, 224, 109162. [Google Scholar] [CrossRef]

- Zhang, M.; Bareille, O.; Salvia, M. Cure and damage monitoring of flax fiber-reinforced epoxy composite repairs for civil engineering structures using embedded piezo micro-patches. Constr. Build. Mater. 2019, 225, 196–203. [Google Scholar] [CrossRef]

- de Paula, A.C.; Uliana, F.; da Silva Filho, E.A.; Soares, K.; Luz, P.P. Use of DMA-Material Pocket to Determine the Glass Transition Temperature of Nitrocellulose Blends in Film Form. Carbohydr. Polym. 2019, 226, 115288. [Google Scholar]

- Zheng, N.; Liu, H.-Y.; Gao, J.; Mai, Y.-W. Synergetic improvement of interlaminar fracture energy in carbon fiber/epoxy composites with nylon nanofiber/polycaprolactone blend interleaves. Compos. B Eng. 2019, 171, 320–328. [Google Scholar] [CrossRef]

- Gobin, M.; Loulergue, P.; Audic, J.-L.; Lemiègre, L. Synthesis and characterisation of bio-based polyester materials from vegetable oil and short to long chain dicarboxylic acids. Ind. Crops. Prod. 2015, 70, 213–220. [Google Scholar] [CrossRef]

- Karakaya, N.; Papila, M.; Özkoç, G. Effects of hot melt adhesives on the interfacial properties of overmolded hybrid structures of polyamide-6 on continuous carbon fiber/epoxy composites. Compos. A Appl. Sci. Manuf. 2020, 139, 106106. [Google Scholar] [CrossRef]

- da Costa Garcia Filho, F.; da Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- Dujardin, N.; Fois, M.; Grimau, M.; Poilâne, C. Soft interface dynamics in flax-fabrics/epoxy composites. Compos. Struct. 2018, 202, 389–396. [Google Scholar] [CrossRef]

- da Luz, F.S.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Thermal Behavior of Polyester Composites Reinforced with Green Sugarcane Bagasse Fiber. JOM 2018, 70, 1965–1971. [Google Scholar] [CrossRef]

- Oliveira, M.S.; da Costa Garcia Filho, F.; da Luz, F.S.; da Cruz Demosthenes, L.C.; Pereira, A.C.; Colorado, H.A.; Nascimento, L.F.C.; Monteiro, S.N. Evaluation of Dynamic Mechanical Properties of Fique Fabric/Epoxy Composites. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- da Luz, F.S.; Monteiro, S.N.; Tommasini, F.J. Evaluation of Dynamic Mechanical Properties of PALF and Coir Fiber Reinforcing Epoxy Composites. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Monteiro, S.N.; de Assis, F.S.; Ferreira, C.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Colorado, H.; Pereira, A.C. Fique Fabric: A Promising Reinforcement for Polymer Composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Xun, L.; Huang, S.; Ren, C.; Sun, B.; Gu, B. Crack spatial distributions and dynamic thermomechanical properties of 3D braided composites during thermal oxygen ageing. Compos. A Appl. Sci. Manuf. 2021, 144, 106355. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Sans, A.; Jiménez-Suárez, A.; Prolongo, S.G. The addition of graphene nanoplatelets into epoxy/polycaprolactone composites for autonomous self-healing activation by Joule’s heating effect. Compos. Sci. Technol. 2021, 213, 108950. [Google Scholar] [CrossRef]

- Mayandi, K.; Rajini, N.; Ayrilmis, N.; Indira Devi, M.P.; Siengchin, S.; Mohammad, F.; Al-Lohedan, H.A. An overview of endurance and ageing performance under various environmental conditions of hybrid polymer composites. J. Mater. Res. Technol. 2020, 9, 15962–15988. [Google Scholar] [CrossRef]

- Fejdyś, M.; Kucharska-Jastrząbek, A.; Kośla, K. Effect of Accelerated Ageing on the Ballistic Resistance of Hybrid Composite Armour with Advanced Ceramics and UHMWPE Fibers. Fibres Text. East. Eur. 2020, 28, 71–80. [Google Scholar] [CrossRef]

- Raji, M.; Zari, N.; Bouhfid, R.; el Kacem Qaiss, A. Durability of composite materials during hydrothermal and environmental aging. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 1st ed.; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead: Serdang, Malaysia, 2019; Volume 1, pp. 83–119. [Google Scholar]

- Monteiro, S.N.; Lopes, F.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural-fiber polymer-matrix composites: Cheaper, tougher, and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Odesanya, K.O.; Ahmad, R.; Jawaid, M.; Bingol, S.; Adebayo, G.O.; Wong, Y.H. Natural fibre-reinforced composite for ballistic applications: A review. J. Polym. Environ. 2021, 10, 1–18. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, A.; et al. A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of natural fibers in composites for ballistic applications–A review. J. Nat. Fibers 2021, 44, 1–11. [Google Scholar] [CrossRef]

- Gañan, P.; Mondragon, I. Surface modification on fique fibers: Effects on their physico-mechanical properties. Polym. Compos. 2002, 383, 94. [Google Scholar] [CrossRef]

- Teles, M.C.A.; Altoé, G.R.; Netto, P.A.; Colorado, H.A.; Margem, F.M.; Monteiro, S.N. Fique fiber tensile elastic modulus dependence with diameter using the Weibull statistical analysis. Mater. Res. 2015, 18, 193–199. [Google Scholar] [CrossRef] [Green Version]

- Netto, P.A.; Altoé, G.R.; Margem, F.M.; Braga, F.O.; Monteiro, S.N.; Margem, J.I. Correlation between the density and the diameter of fique fibers. Mater. Sci. Forum. 2016, 869, 377–383. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Luz, F.S.; Pereira, A.C.; Demosthenes, L.C.C.; Nascimento, L.F.C.; Monteiro, S.N. Tensile properties of epoxy matrix reinforced with fique fabric. Mater. Sci. Forum. 2020, 1012, 14–19. [Google Scholar] [CrossRef]

- Pereira, A.C.; Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Lima, E.S.; Lopera, H.A.C.; Monteiro, S.N. Evaluation of the projectile’s loss of energy in polyester composite reinforced with fique fiber and fabric. Mat. Res. 2019, 22 (Suppl. 1). [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.C.; Pereira, A.C.; Nunes, L.F.; Luz, F.S.; Braga, F.O.; Colorado, H.A.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the Weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.; Lopera, H.A.C.; Nascimento, L.F.C.; Garcia Filho, F.C.; Monteiro, S.N. Energy absorption and limit velocity of epoxy composites incorporated with fique fabric as ballistic armor—A brief report. Polymers 2021, 13, 2727. [Google Scholar] [CrossRef] [PubMed]

- Inamdar, A.; Yang, Y.-H.; Prisacaru, A.; Gromala, P.; Han, B. High temperature aging of epoxy-based molding compound and its effect on mechanical behavior of molded electronic package. Polym. Degrad. Stab. 2021, 188, 109572. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, K.; Zhan, M.; Xu, W.; Ding, X. Thermal-oxidative aging of DGEBA/EPN/LMPA epoxy system: Chemical structure and thermal–mechanical properties. Polym. Degrad. Stab. 2011, 96, 1179–1186. [Google Scholar] [CrossRef]

- Hinkley, J.A.; Connell, J.W. Resin systems and chemistry: Degradation mechanisms and durability. In Long-Term Durability of Polymeric Matrix Composites; Springer: Boston, MA, USA, 2012; pp. 1–37. [Google Scholar] [CrossRef]

- Ernault, E.; Richaud, E.; Fayolle, B. Origin of epoxies embrittlement during oxidative ageing. Polym. Test. 2017, 63, 448–454. [Google Scholar] [CrossRef]

- Schoeppner, G.A.; Tandon, G.P.; Ripberger, E.R. Anisotropic oxidation and weight loss in PMR-15 composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 890–904. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym. Degrad. Stab. 2013, 98, 2752–2759. [Google Scholar] [CrossRef]

- Ezekiel, N.; Ndazi, B.; Nyahumwa, C.; Karlsson, S. Effect of temperature and durations of heating on coir fibers. Ind. Crops. Prod. 2011, 33, 638–643. [Google Scholar] [CrossRef]

- Ching, Y.C.; Gunathilake, T.U.; Ching, K.Y.; Chuah, C.H.; Sandu, V.; Singh, R.; Liou, N.-S. Effects of high temperature and ultraviolet radiation on polymer composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 407–426. [Google Scholar]

- Yang, D.G.; Wan, F.F.; Shou, Z.Y.; van Driel, W.D.; Scholten, H.; Goumans, L.; Faria, R. Effect of high temperature aging on reliability of automotive electronics. Microelectron. Reliab. 2011, 51, 1938–1942. [Google Scholar] [CrossRef]

- Behera, A.; Thawre, M.M.; Ballal, A. Hygrothermal aging effect on physical and mechanical properties of carbon fiber/epoxy cross-ply composite laminate. Mater. Today: Proc. 2020, 28, 940–943. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Richardson, M. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Ugochukwu, S.; Ridzuan, M.J.M.; Abdul Majid, M.S.; Cheng, E.M.; Razlan, Z.M.; Marsi, N. Effect of thermal ageing on the scratch resistance of natural-fibre-reinforced epoxy composites. Compos. Struct. 2021, 261, 113586. [Google Scholar] [CrossRef]

- Krauklis, A.; Echtermeyer, A. Mechanism of yellowing: Carbonyl formation during hygrothermal aging in a common amine epoxy. Polymers 2018, 10, 1017. [Google Scholar] [CrossRef] [Green Version]

- Fan, W.; Li, J.; Zheng, Y.; Liu, T.; Tian, X.; Sun, R. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites. Polym. Degrad. Stab. 2016, 123, 162–169. [Google Scholar] [CrossRef]

- Margem, F.M.; Monteiro, S.N.; Bravo Neto, J.; Rodriguez, R.J.S.; Soares, B.G. The dynamic-mechanical behavior of epoxy matrix composites reinforced with ramie fibers. Matéria 2010, 15, 164–171. [Google Scholar] [CrossRef] [Green Version]

- Rocha, M.L.; Leite, M.C.O.; Ferreira, E.P.C.; Melo, J.D.D.; Barbosa, A.P.C. Accelerated aging effects in composites used as repair for pipes in oil industry. Polym. Compos. 2021, 42, 5918–5929. [Google Scholar] [CrossRef]

- Stark, W. Investigation of the curing behaviour of carbon fibre epoxy prepreg by Dynamic Mechanical Analysis DMA. Polym. Test. 2013, 32, 231–239. [Google Scholar] [CrossRef]

- Kumar, D.S.; Shukla, M.J.; Mahato, K.K.; Rathore, D.K.; Prusty, R.K.; Ray, B.C. Effect of post-curing on thermal and mechanical behavior of GFRP composites. IOP Conf. Ser. Mater. Sci. Eng. 2015, 75, 012012. [Google Scholar] [CrossRef] [Green Version]

- Chateauminois, A.; Vincent, L.; Chabert, B.; Soulier, J.P. Study of the interfacial degradation of a glass-epoxy composite during hygrothermal ageing using water diffusion measurements and dynamic mechanical thermal analysis. Polymer 1994, 35, 4766–4774. [Google Scholar] [CrossRef]

- Cucos, A.; Budrugeac, P.; Miu, L.; Mitrea, S.; Sbarcea, G. Dynamic mechanical analysis (DMA) of new and historical parchments and leathers: Correlations with DSC and XRD. Thermochim. Acta 2011, 516, 19–28. [Google Scholar] [CrossRef]

| Material | Aging Times (Hours at 170° C) | |||

|---|---|---|---|---|

| 0 | 72 | 120 | 240 | |

| Plain epoxy | PE-T0 | PE-T72 | PE-T120 | PE-T240 |

| Composite | FC-T0 | FC-T72 | FC-T120 | FC-T240 |

| Material | E’30 | E” | Tan δ | |||

|---|---|---|---|---|---|---|

| Storage Modulus at 30 °C (GPa) | Lower Limit of Tg (°C) | Loss Modulus Peak (GPa) | Peak Temperature (°C) | Tan δ Peak (GPa) | Peak Temperature (°C) | |

| FC-T0 | 2.81 | 61.77 | 0.29 | 72.95 | 0.40 | 86.82 |

| FC-T72 | 2.94 | 92.40 | 0.22 | 107.55 | 0.40 | 116.71 |

| FC-T120 | 2.64 | 96.03 | 0.17 | 105.14 | 0.18 | 150.19 |

| FC-T240 | 2.12 | 81.05 | 0.15 | 101.39 | 0.58 | 179.71 |

| Material | E’glassy(30 °C) | E” | Tan δ | |||

|---|---|---|---|---|---|---|

| Storage Modulus at 30°C (GPa) | Lower Limit of Tg (°C) | Loss Modulus Peak (GPa) | Peak Temperature (°C) | Tan δ Peak (GPa) | Peak Temperature (°C) | |

| PE-T0 | 3.21 | 97.97 | 0.25 | 93.61 | 0.51 | 117.81 |

| PE-T72 | 2.07 | 102.37 | 0.11 | 112.86 | 0.24 | 145.29 |

| PE-T120 | 2.65 | 99.82 | 0.28 | 142.88 | 0.31 | 151.29 |

| PE-T240 | 2.99 | 97.04 | 0.37 | 151.88 | 0.38 | 169.13 |

| Plain Epoxy | ||||||

|---|---|---|---|---|---|---|

| Aging Time | 0 | 72 | 120 | 240 | Change | Trend with Aging |

| A1 | 17.239 ± 0.1 | 5.538 ± 0.2 | 5.157 ± 0.1 | 3.647 ± 0.0 | 0.21 | decrease |

| A2 | 4.379 ± 0.1 | 2.661 ± 0.1 | 6.393 ± 0.0 | 6.011 ± 1.0 | 1.37 | increase |

| A3 | 14.874 ± 0.2 | 7.596 ± 0.3 | 2.785 ± 0.1 | 2.791 ± 1.1 | 0.19 | decrease |

| ∑Ai | 36.492 | 15.795 | 14.335 | 12.449 | 0.34 | - |

| w1 | 8.691 ± 0.0 | 34.950 ± 3.1 | 6.857 ± 0.0 | 8.500 ± 0.2 | 0.98 | nearly constant |

| w2 | 8.230 ± 0.5 | 7.190 ±0.1 | 10.645 ± 0.0 | 10.212 ±0.3 | 1.24 | increase |

| w3 | 17.356 ± 0.0 | 16.442 ± 5.1 | 29.004 ± 0.4 | 13.963 ± 3.5 | 0.80 | nearly constant |

| Tc1 | 77.095 ± 0.1 | 122.156 ± 22.3 | 108.58 ± 0.1 | 113.10 ± 5.2 | 1.47 | increase |

| Tc2 | 119.28 ± 8.4 | 122.20 ± 0.0 | 152.00 ± 0.1 | 169.52 ± 0.4 | 1.42 | increase |

| Tc3 | 106.13 ± 0.2 | 137.42 ± 0.4 | 124.80 ± 2.46 | 153.57 ± 1.2 | 1.45 | increase |

| To1 | 3.18 × 10−12 ± 0.1 | 5.993 ± 0.2 | 14.800 ± 0.3 | 0.733 ± 0.5 | - | decrease |

| To2 | 0.793 ± 0.8 | 0.181 ± 0.0 | 4.5 × 10−12 ± 0.0 | 0.509 ± 0.3 | 0.64 | decrease |

| To3 | 0.790 ± 0.0 | 0.164 ± 0.4 | 8.5 × 10−11 ± 0.0 | 0.770 ± 0.0 | 0.97 | nearly constant |

| R2 | 0.9981 | 0.9995 | 0.9997 | 0.99905 | - | - |

| Fique Fabric Reinforcing Epoxy Composite (°C) | |||||

|---|---|---|---|---|---|

| Aging Time | 0 | 120 | 240 | Changes | Trend with Aging |

| A1 | 2.278 ± 0.4 | 4.226 ± 0.0 | 1.483 ± 0.0 | 0.65 | decrease |

| A2 | 8.013 ± 1.0 | 3.097 ± 0.0 | 1.408 ± 0.0 | 0.18 | decrease |

| A3 | 7.810 ± 0.8 | 5.220 ± 0.0 | 1.716 ± 0.0 | 0.22 | decrease |

| ∑Ai | 18.101 | 12.543 | 4.607 | 0.25 | - |

| w1 | 5.877 ± 2.6 | 19.017 ± 0.4 | 7.175 ± 0.2 | 1.22 | increase |

| w2 | 8.253 ± 0.4 | 8.182 ± 0.0 | 11.475 ± 0.4 | 1.39 | increase |

| w3 | 12.715 ± 0.3 | 15.686 ± 0.0 | 1.984 ± 0.0 | 0.16 | decrease |

| Tc1 | 75.551 ± 2.6 | 80.883 ± 0.7 | 105.42 ± 0.1 | 1.40 | increase |

| Tc2 | 82.026 ± 0.8 | 111.46 ± 0.0 | 155.20 ± 0.3 | 1.89 | increase |

| Tc3 | 109.98 ± 2.2 | 148.97 ± 0.1 | 179.20 ± 0.0 | 1.63 | increase |

| To1 | 6.78 × 10−11 ± 2.6 | 39.103 ± 1.2 | 4.65 × 10−18 ± 0.0 | - | increase |

| To2 | 8.165 ± 1.9 | 3.56 × 10−13 ± 0.0 | 2.35 × 10−17± 0.0 | - | decrease |

| To3 | 0.647 ± 2.2 | 0.411 ± 0.0 | 4.15 × 10−15 ± 0.0 | - | increase |

| R2 | 0.9995 | 0.9991 | 0.9544 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, M.S.; da Luz, F.S.; da Costa Garcia Filho, F.; Pereira, A.C.; de Oliveira Aguiar, V.; Lopera, H.A.C.; Monteiro, S.N. Dynamic Mechanical Analysis of Thermally Aged Fique Fabric-Reinforced Epoxy Composites. Polymers 2021, 13, 4037. https://doi.org/10.3390/polym13224037

Oliveira MS, da Luz FS, da Costa Garcia Filho F, Pereira AC, de Oliveira Aguiar V, Lopera HAC, Monteiro SN. Dynamic Mechanical Analysis of Thermally Aged Fique Fabric-Reinforced Epoxy Composites. Polymers. 2021; 13(22):4037. https://doi.org/10.3390/polym13224037

Chicago/Turabian StyleOliveira, Michelle Souza, Fernanda Santos da Luz, Fabio da Costa Garcia Filho, Artur Camposo Pereira, Vinícius de Oliveira Aguiar, Henry Alonso Colorado Lopera, and Sergio Neves Monteiro. 2021. "Dynamic Mechanical Analysis of Thermally Aged Fique Fabric-Reinforced Epoxy Composites" Polymers 13, no. 22: 4037. https://doi.org/10.3390/polym13224037

APA StyleOliveira, M. S., da Luz, F. S., da Costa Garcia Filho, F., Pereira, A. C., de Oliveira Aguiar, V., Lopera, H. A. C., & Monteiro, S. N. (2021). Dynamic Mechanical Analysis of Thermally Aged Fique Fabric-Reinforced Epoxy Composites. Polymers, 13(22), 4037. https://doi.org/10.3390/polym13224037