Improvement of Polytetrafluoroethylene Membrane High-Efficiency Particulate Air Filter Performance with Melt-Blown Media

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

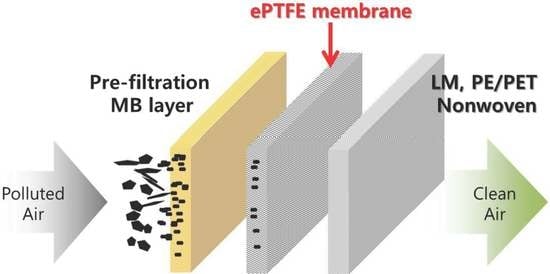

2.2. Preparation of the High-Efficiency Particulate Air Filter with Melt-Blown Nonwoven

2.3. Characterization

2.4. Filtration Test

3. Results and Discussion

3.1. Effect of Melt-Blown Physical Properties for High-Efficiency Particulate Air Filter

3.1.1. Morphology Structure

3.1.2. Contact Angle

3.1.3. Pore Size

3.1.4. Air Permeability

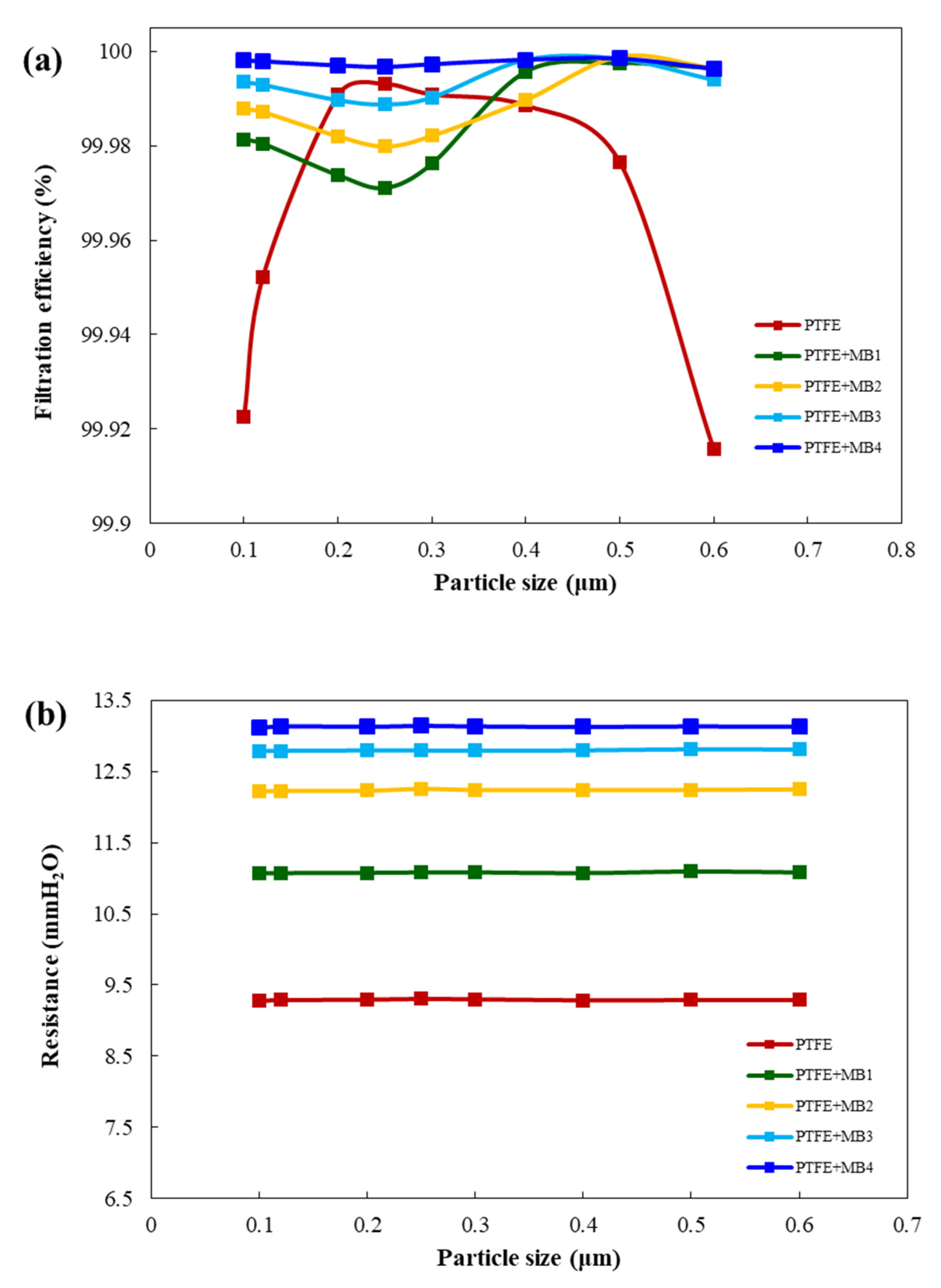

3.2. Filtration Performance

3.3. Dust Loading Test

3.4. Filter Performance Evaluation in Heating, Ventilation, and Air Conditioning System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brande, D. Cleanroom certification and particulate testing. In Environmental Monitoring for Cleanrooms and Controlled Environments; CRC Press: Boca Raton, FL, USA, 2016; pp. 65–82. [Google Scholar]

- Xu, T.; Lan, C.H.; Jeng, M.S. Performance of large fan-filter units for cleanroom applications. Build. Environ. 2007, 42, 2299–2304. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, S.; Wang, Y.; Lin, Z. Dust loading performance of the PTFE HEPA media and its comparison with the glass fibre HEPA media. Aerosol. Air Qual. Res. 2018, 18, 1921–1931. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Deng, S.; Wang, Y.; Lin, Z. Modeling the surface filtration pressure drop of PTFE HEPA filter media for low load applications. Build. Environ. 2020, 177, 106905. [Google Scholar] [CrossRef]

- Feng, S.; Zhong, Z.; Wang, Y.; Xing, W.; Drioli, E. Progress and perspectives in PTFE membrane: Preparation, modification, and applications. J. Membr. Sci. 2018, 549, 332–349. [Google Scholar] [CrossRef]

- Wikol, M.; Hartmann, B.; Brendle, J.; Crane, M.; Beuscher, U.; Brake, J.; Shickel, T.; Gore, W.L. Expanded polytetrafluoroethylene membranes and their applications. Drugs Pharm. Sci. 2008, 174, 619. [Google Scholar]

- Galka, N.; Saxena, A. High efficiency air filtration: The growing impact of membranes. Filtr. Sep. 2009, 46, 22–25. [Google Scholar] [CrossRef]

- Song, J.; Liu, Z.; Li, Z.; Wu, H. Continuous production and properties of mutil-level nanofiber air filters by blow spinning. RSC Adv. 2020, 10, 19615–19620. [Google Scholar] [CrossRef]

- Long, J.; Tang, M.; Sun, Z.; Liang, Y.; Hu, J. Dust loading performance of a novel submicro-fiber composite filter medium for engine. Materials 2018, 11, 2038. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.S.; Hasolli, N.; Jeon, S.M.; Lee, J.R.; Kim, K.D.; Park, Y.O.; Hwang, J. Filter layer structure effect on the most penetrating particle size of multilayered flat sheet filter. Powder Technol. 2019, 344, 270–277. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Hung, C.H.; Yuen, P.T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Purif. Technol. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Zuo, F.; Tan, D.H.; Wang, Z.; Jeung, S.; Macosko, C.W.; Bates, F.S. Nanofibers from melt blown fiber-in-fiber polymer blends. ACS Macro Lett. 2013, 2, 301–305. [Google Scholar] [CrossRef]

- Sikdar, P.; Bhat, G.S.; Hinchliff, D.; Islam, S.; Condon, B. Microstructure and physical properties of composite nonwovens produced by incorporating cotton fibers in elastic spunbond and meltblown webs for medical textiles. J. Ind. Textiles 2021, 15280837211004287. [Google Scholar] [CrossRef]

- Chang, D.Q.; Tien, C.Y.; Peng, C.Y.; Tang, M.; Chen, S.C. Development of composite filters with high efficiency, low pressure drop, and high holding capacity PM2.5 filtration. Sep. Purif. Technol. 2019, 212, 699–708. [Google Scholar] [CrossRef]

- Tian, X.; Ou, Q.; Pei, C.; Li, Z.; Liu, J.; Liang, Y.; Pui, D.Y. Effect of main-stage filter media selection on the loading performance of a two-stage filtration system. Build. Environ. 2021, 195, 107745. [Google Scholar] [CrossRef]

- Chen, C.W.; Huang, S.H.; Chiang, C.M.; Hsiao, T.C.; Chen, C.C. Filter quality of pleated filter cartridges. Ann. Occup. Hyg. 2008, 52, 207–212. [Google Scholar]

- Uppal, R.; Bhat, G.; Eash, C.; Akato, K. Meltblown nanofiber media for enhanced quality factor. Fibers Polym. 2013, 14, 660–668. [Google Scholar] [CrossRef]

- Todea, A.M.; Schmidt, F.; Schuldt, T.; Asbach, C. Development of a Method to Determine the Fractional Deposition Efficiency of Full-Scale HVAC and HEPA Filter Cassettes for Nanoparticles ≥3.5 nm. Atmosphere 2020, 11, 1191. [Google Scholar] [CrossRef]

- Yesil, Y.; Bhat, G.S. Structure and mechanical properties of polyethylene melt blown nonwovens. Int. J. Cloth. Sci. Tech. 2016, 28. [Google Scholar] [CrossRef]

- Masaeli, E.; Morshed, M.; Tavanai, H. Study of the wettability properties of polypropylene nonwoven mats by low-pressure oxygen plasma treatment. Surf. Interface Anal. 2007, 39, 770–774. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, L. Contact angle measurement of natural materials. Colloids Surfaces B 2018, 161, 324–330. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Zhou, X.; Yue, Y. Determination of pore size and pore size distribution on the surface of hollow-fiber filtration membranes: A review of methods. Desalination 2000, 129, 107–123. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Zhou, B.; Tseng, C.H.; Hu, S.C.; Shiue, A.; Leggett, G. Evaluation of characterization and filtration performance of air cleaner materials. Int. J. Environ. Sci. Technol. 2020, 18, 1–12. [Google Scholar] [CrossRef]

- Gültekin, E.; Çelik, H.İ.; Nohut, S.; Elma, S.K. Predicting air permeability and porosity of nonwovens with image processing and artificial intelligence methods. J. Text. Inst. 2020, 111, 1641–1651. [Google Scholar] [CrossRef]

- Lim, T.H.; Yeo, S.Y.; Lee, S.H. Multidirectional evaluations of a carbon air filter to verify their lifespan and various performances. J. Aerosol. Sci. 2018, 126, 205–216. [Google Scholar] [CrossRef]

- Roh, S.; Park, K.; Kim, J. Design of web-to-web spacing for the reduced pressure drop and effective depth filtration. Polymers 2019, 11, 1822. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, B.; Li, S.; Chu, W.; Liu, C.; Hu, S.; Jin, H.; Zhou, F. Improving filtration and pulse-jet cleaning performance of metal web filter media by coating with polytetrafluoroethylene microporous membrane. Process Saf. Environ. Protect. 2020, 136, 105–114. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Jin, X. Design of electret polypropylene melt blown air filtration material containing nucleating agent for effective PM2. 5 capture. RSC Adv. 2018, 8, 7932–7941. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Liang, Y.; He, W.; Jiang, F.; Song, Q.; Tang, M.; Wang, J. Filtration performance and loading capacity of nano-structured composite filter media for applications with high soot concentrations. Sep. Purif. Technol. 2019, 221, 175–182. [Google Scholar] [CrossRef]

- Calle, S.; Contal, P.; Thomas, D.; Bemer, D.; Leclerc, D. Evolutions of efficiency and pressure drop of filter media during clogging and cleaning cycles. Powder Technol. 2002, 128, 213–217. [Google Scholar] [CrossRef]

- Yu, J.; Liang, Y.; Tang, M.; Yao, Y. A novel energy-efficient kapok filter paper with high DHC for solid-oil mixed aerosol: Performance and loading behavior evolution mechanism. Sep. Purif. Technol. 2020, 235, 116180. [Google Scholar] [CrossRef]

| Sample | Weight (gsm) | Thickness (μm) | Fibre Diameter (μm) |

|---|---|---|---|

| MB1 | 10 | 55 ± 3 | 1.80 ± 0.42 |

| MB2 | 15 | 79 ± 2 | 1.61 ± 0.29 |

| MB3 | 20 | 99 ± 6 | 1.92 ± 0.29 |

| MB4 | 22 | 110 ± 2 | 1.97 ± 0.33 |

| MB1 | MB2 | MB3 | MB4 | |

|---|---|---|---|---|

| Contact angle (°) | 132.4 ± 0.3 | 139.2 ± 0.5 | 142.1 ± 0.4 | 146.6 ± 0.2 |

| Image |  |  |  |  |

| Analysis | MB1 | MB2 | MB3 | MB4 |

|---|---|---|---|---|

| Mean pore size diameter (μm) | 12.54 | 11.22 | 10.25 | 10.47 |

| Bubble pore size diameter (μm) | 24.56 | 22.08 | 21.06 | 20.03 |

| Analysis | PTFE | PTFE + MB1 | PTFE + MB2 | PTFE + MB3 | PTFE + MB4 |

|---|---|---|---|---|---|

| Mean pore size diameter (μm) | 1.08 | 0.85 | 0.81 | 0.85 | 0.74 |

| Bubble pore size diameter (μm) | 8.13 | 7.49 | 6.12 | 8.45 | 8.18 |

| PTFE | PTFE + MB1 | PTFE + MB2 | PTFE + MB3 | PTFE + MB4 | |

|---|---|---|---|---|---|

| Dust loading capacity (g/m2) | 1.0 | 3.0 | 3.8 | 4.4 | 5.9 |

| Glass Media | PTFE Media | PTFE + MB Composite | ||||

|---|---|---|---|---|---|---|

| Pressure Drop (mmAq) | Efficiency (%) | Pressure Drop (mmAq) | Efficiency (%) | Pressure Drop (mmAq) | Efficiency (%) | |

| Initial measurement | 28.8 | 99.981 | 14.8 | 99.934 | 14.5 | 99.961 |

| After 15 days | 28.7 | 99.983 | 15.2 | 99.926 | 14.6 | 99.967 |

| After 60 days | 28.3 | 99.993 | 16.5 | 99.966 | 14.6 | 99.986 |

| After 120 days | 28.4 | 99.978 | 17.0 | 99.968 | 14.6 | 99.984 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shim, E.; Jang, J.-P.; Moon, J.-J.; Kim, Y. Improvement of Polytetrafluoroethylene Membrane High-Efficiency Particulate Air Filter Performance with Melt-Blown Media. Polymers 2021, 13, 4067. https://doi.org/10.3390/polym13234067

Shim E, Jang J-P, Moon J-J, Kim Y. Improvement of Polytetrafluoroethylene Membrane High-Efficiency Particulate Air Filter Performance with Melt-Blown Media. Polymers. 2021; 13(23):4067. https://doi.org/10.3390/polym13234067

Chicago/Turabian StyleShim, Euijin, Jeong-Phil Jang, Jai-Joung Moon, and Yeonsang Kim. 2021. "Improvement of Polytetrafluoroethylene Membrane High-Efficiency Particulate Air Filter Performance with Melt-Blown Media" Polymers 13, no. 23: 4067. https://doi.org/10.3390/polym13234067

APA StyleShim, E., Jang, J.-P., Moon, J.-J., & Kim, Y. (2021). Improvement of Polytetrafluoroethylene Membrane High-Efficiency Particulate Air Filter Performance with Melt-Blown Media. Polymers, 13(23), 4067. https://doi.org/10.3390/polym13234067