Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites

Abstract

:1. Introduction

2. Experimental

2.1. Raw Materials

2.2. Surface Modification

2.3. Fabrication of the RFPCs

2.4. Characterization and Testing

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR) Characterization

2.4.2. SEM and EDX Characterization

2.4.3. Mechanical Testing

2.4.4. Dynamic Mechanical Testing

3. Results and Discussion

3.1. Characterization of RFs

3.2. Characterization of Unmodified and ASO Modified RFPCs

3.3. Mechanical Properties of RFPCs

3.3.1. Physical Properties of RFPCs

3.3.2. Mechanical Properties of RFPCs

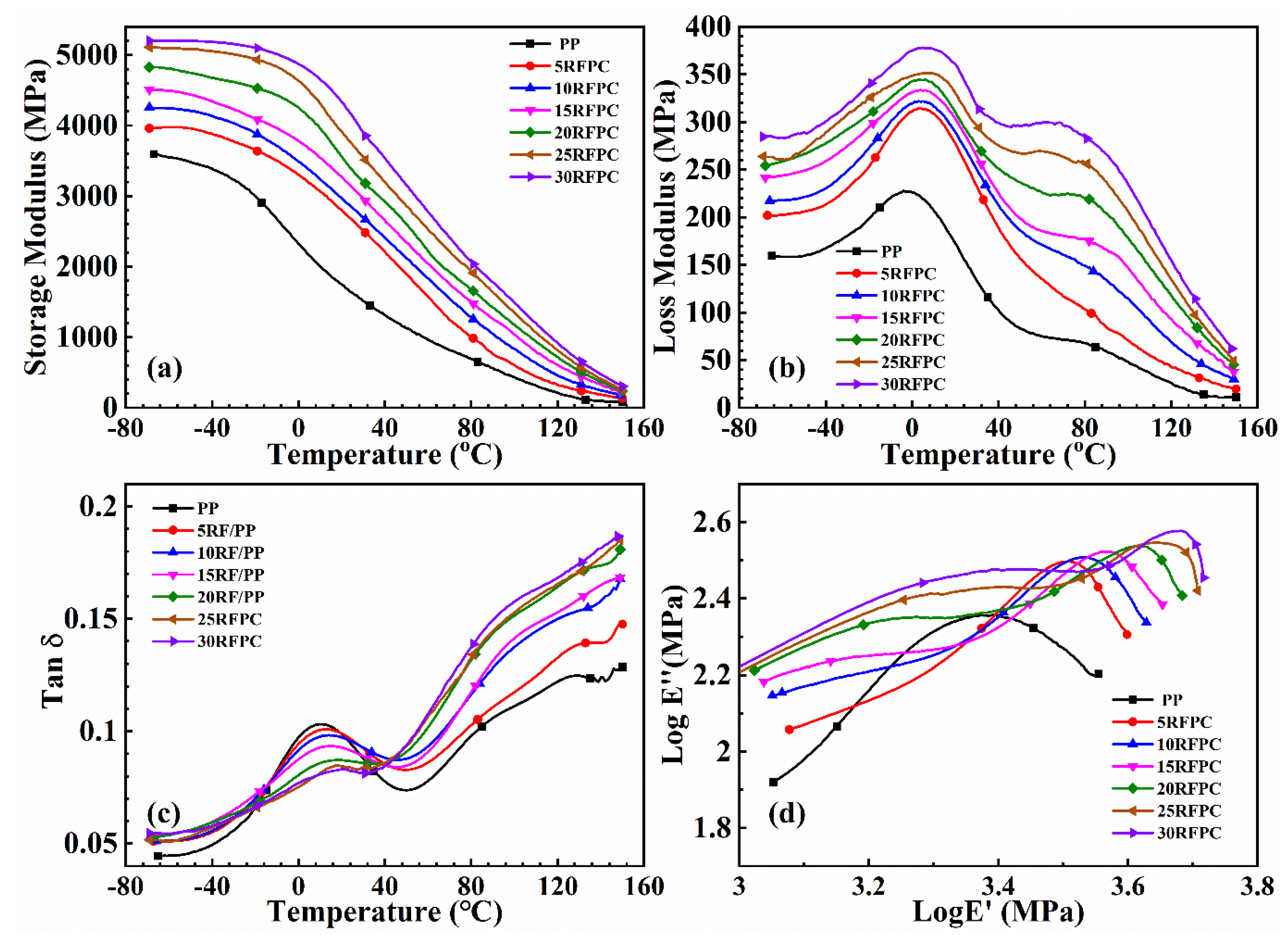

3.4. Dynamic Mechanical Analysis (DMA)

3.4.1. Storage Modulus (E′)

3.4.2. Loss Modulus (E″)

3.4.3. Damping Factor (tan δ)

3.4.4. Cole-Cole Plot

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- He, L.P.; Li, W.J.; Chen, D.C.; Lu, G.; Chen, L.P.; Zhou, D.W.; Yuan, J.M. Investigation on the microscopic mechanism of potassium permanganate modification and the properties of ramie fiber/polypropylene composites. Polym. Compos. 2018, 39, 3353–3362. [Google Scholar] [CrossRef]

- Prasob, P.A.; Sasikumar, M. Viscoelastic and mechanical behaviour of reduced graphene oxide and zirconium dioxide filled jute/epoxy composites at different temperature conditions. Mater. Today. Commun. 2019, 19, 252–261. [Google Scholar]

- Jariwala, H.; Jain, P. A review on mechanical behavior of natural fiber reinforced polymer composites and its applications. J. Reinf. Plast. Compos. 2019, 38, 441–453. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martinez, M.A. Recent Progress in Hybrid Biocomposites: Mechanical Properties, Water Absorption, and Flame Retardancy. Materials 2020, 13, 5145. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Yorseng, K.; Rangappa, S.M.; Pulikkalparambil, H.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: Morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 2020, 235, 117464. [Google Scholar] [CrossRef]

- Rao, D.V.; Naidu, A.L.; Bahubalendruni, M.V.A.R. A Review on Mechanical Behaviour of Polymers/Sisal Fiber Reinforced Composites Material. Int. J. Sci. Dev. Res. 2018, 3, 190–199. [Google Scholar]

- Kabir, M.S.; Hossain, M.S.; Mia, M.; Islam, M.N.; Rahman, M.M.; Hoque, M.B.; Chowdhury, A.M.S. Mechanical Properties of Gamma-Irradiated Natural Fiber Reinforced Composites. Nano Hybrid. Compos. 2018, 23, 24–38. [Google Scholar] [CrossRef]

- Indra Reddy, M.; Varma, U.R.P.; Kumar, I.A.; Manikanth, V.; Raju, P.V.K. Comparative Evaluation on Mechanical Properties of Jute, Pineapple leaf fiber and Glass fiber Reinforced Composites with Polyester and Epoxy Resin Matrices. Mater. Today Proc. 2018, 5, 5649–5654. [Google Scholar] [CrossRef]

- Babu, K.; Kumar, A.; Sundarraj, M.; Renish, R. Fabrication and characterization of natural fiber reinforced hybrid composite materials. Int. J. Mech. Eng. Technol. 2018, 9, 79–84. [Google Scholar]

- Rokbi, M.; Khaldoune, A.; Sanjay, M.R.; Senthamaraikannan, P.; Ati, A.; Siengchin, S. Effect of processing parameters on tensile properties of recycled polypropylene based composites reinforced with jute fabrics. Int. J. Light. Mater. Manuf. 2020, 3, 144–149. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.Z.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Fei, M.; Qiu, R.; Yu, D.; Fu, T.; Qiu, J. Properties of natural fiber-reinforced biobased thermoset biocomposites: Effects of fiber type and resin composition. Compos. Part B Eng. 2019, 171, 87–95. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Zhang, J.; Khatibi, A.A.; Castanet, E.; Baum, T.; Komeily-Nia, Z.; Vroman, P.; Wang, X. Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-composites compression moulded by nonwoven mats. Compos. Commun. 2019, 13, 12–17. [Google Scholar] [CrossRef]

- Ilangovan, S.; Kumaran, S.S.; Naresh, K. Effect of nanoparticles loading on free vibration response of epoxy and filament winding basalt/epoxy and E-glass/epoxy composite tubes: Experimental, analytical and numerical investigations. Mater. Res. Express 2020, 7, 025007. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Dynamic Mechanical Behavior Analysis of Flax/Jute Fiber-Reinforced Composites under Salt-Fog Spray Environment. Polymers 2020, 12, 716. [Google Scholar] [CrossRef] [Green Version]

- del Borrello, M.; Mele, M.; Campana, G.; Secchi, M. Manufacturing and characterization of hemp-reinforced epoxy composites. Polym. Compos. 2020, 41, 2316–2329. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Manaila, E.; Craciun, G.; Chirila, C. Development and Characterization of Polymer Eco-Composites Based on Natural Rubber Reinforced with Natural Fibers. Materials 2017, 10, 787. [Google Scholar] [CrossRef]

- Jiang, T.; Zeng, G.; Hu, C. Experimental Estimation of Relaxation Behavior for Hemp Fiber Reinforced Polypropylene Composite with Torque Rheometer. Macromol. Res. 2020, 28, 517–522. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Salinas, E. Mechanical, thermal, viscoelastic performance and product application of PP-rice husk Colombian biocomposites. Compos. Part B Eng. 2019, 176, 107135. [Google Scholar] [CrossRef]

- Kenned, J.J.; Sankaranarayanasamy, K.; Binoj, J.S.; Chelliah, S.K. Thermo-mechanical and morphological characterization of needle punched non-woven banana fiber reinforced polymer composites. Compos. Sci. Technol. 2020, 185, 107890. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R.; Majid, M.S.A. Thermal degradation and viscoelastic properties of Kevlar/Cocos nucifera sheath reinforced epoxy hybrid composites. Compos. Struct. 2019, 219, 194–202. [Google Scholar] [CrossRef]

- Gnatowski, A.; Kijo-Kleczkowska, A.; Golebski, R.; Mirek, K. Analysis of polymeric materials properties changes after addition of reinforcing fibers. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 2833–2843. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R. Enhanced Thermal and Dynamic Mechanical Properties of Synthetic/Natural Hybrid Composites with Graphene Nanoplateletes. Polymers 2019, 11, 1085. [Google Scholar]

- Ahmad, M.A.A.; Majid, M.S.A.; Ridzuan, M.J.M.; Mazlee, M.N.; Gibson, A.G. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef] [Green Version]

- Khuntia, T.; Biswas, S. An investigation on the flammability and dynamic mechanical behavior of coir fibers reinforced polymer composites. J. Ind. Text. 2020, 50, 1528083720905031. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Effect of fiber content on thermal behavior and viscoelastic properties of PALF/Epoxy and COIR/Epoxy composites. Mater. Res. Express 2018, 5, 125305. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

- Dang, C.Y.; Shen, X.J.; Nie, H.J.; Yang, S.; Shen, J.X.; Yang, X.H.; Fu, S.Y. Enhanced interlaminar shear strength of ramie fiber/polypropylene composites by optimal combination of graphene oxide size and content. Compos. Part B Eng. 2019, 168, 488–495. [Google Scholar] [CrossRef]

- Morales, M.A.; Martinez, C.L.A.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Li, W.; Chen, D.; Yuan, J.; Lu, G.; Zhou, D. Microscopic mechanism of amino silicone oil modification and modification effect with different amino group contents based on molecular dynamics simulation. Appl. Surf. Sci. 2018, 440, 331–340. [Google Scholar] [CrossRef]

- He, L.P.; Li, W.J.; Chen, D.C.; Zhou, D.W.; Lu, G.; Yuan, J.M. Effects of amino silicone oil modification on properties of ramie fiber and ramie fiber/polypropylene composites. Mater. Des. 2015, 77, 142–148. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Hejna, A. Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. J. Compos. Sci. 2020, 4, 167. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, J.; Mohanty, S.; Nayak, S.K. Influence of cellulose nanocrystal/sisal fiber on the mechanical, thermal, and morphological performance of polypropylene hybrid composites. Polym. Bull. 2021, 78, 1609–1635. [Google Scholar] [CrossRef]

- Chen, D.; Pi, C.; Chen, M.; He, L.; Xia, F.; Peng, S. Amplitude-dependent damping properties of ramie fiber-reinforced thermoplastic composites with varying fiber content. Polym. Compos. 2019, 40, 2681–2689. [Google Scholar] [CrossRef]

- Sahai, R.; Pardeshi, R. Comparative study of effect of different coupling agent on mechanical properties and water absorption on wheat straw-reinforced polystyrene composites. J. Thermoplast. Compos. Mater. 2021, 34, 433–450. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Nasir, M.; Saba, N. Effect of Fiber Loadings and Treatment on Dynamic Mechanical, Thermal and Flammability Properties of Pineapple Leaf Fiber and Kenaf Phenolic Composites. J. Renew. Mater. 2018, 6, 383–393. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Balakrishnan, P.; Sreekala, M.S.; Kunaver, M.; Huskić, M.; Thomas, S. Morphology, transport characteristics and viscoelastic polymer chain confinement in nanocomposites based on thermoplastic potato starch and cellulose nanofibers from pineapple leaf. Carbohydr. Polym. 2017, 169, 176–188. [Google Scholar] [CrossRef]

- Krishnasamy, P.; Rajamurugan, G.; Thirumurugan, M. Dynamic mechanical characteristics of jute fiber and 304 wire mesh reinforced epoxy composite. J. Ind. Text. 2019, 51, 10. [Google Scholar] [CrossRef]

- Einstein, A. Investigations on the Theory of the Brownian Movement; Dover Publications: New York, NY, USA, 1956. [Google Scholar]

- Jabbar, A.; Militký, J.; Wiener, J.; Kale, B.M.; Ali, U.; Rwawiire, S. Nanocellulose coated woven jute/green epoxy composites: Characterization of mechanical and dynamic mechanical behavior. Compos. Struct. 2017, 161, 340–349. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Correa-Aguirre, J.P.; García-Navarro, S.; Roca-Blay, L. Injection Molding of Coir Coconut Fiber Reinforced Polyolefin Blends: Mechanical, Viscoelastic, Thermal Behavior and Three-Dimensional Microscopy Study. Polymers 2020, 12, 1507. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.; Schneider, K.; Vogel, R.; Heinrich, G. Influence of Annealing on Mechanical αc-Relaxation of Isotactic Polypropylene: A Study from the Intermediate Phase Perspective. Macromol. Mater. Eng. 2017, 302, 1700291. [Google Scholar] [CrossRef]

- Rathinasabapathi, G.; Krishnamoorthy, A. Cole-cole plot of graphene nano filler disseminated glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 3816–3822. [Google Scholar] [CrossRef]

| Technical Specification | Value |

|---|---|

| Fiber length/mm | 3–5 |

| Mean diameter/μm | 20–80 |

| Density/g·cm−3 | 1.55 |

| Young’s modulus/GPa | 61.4–128 |

| Tensile strength/MPa | 400–1000 |

| Technical Specification | Value |

|---|---|

| Melt-flow index (MFI)/g·(10 min)−1 | 0.33 |

| Melting point/°C | 170 |

| Density/g·cm−3 | 0.904 |

| Poisson ratio | 0.42 |

| Young’s modulus/MPa | 1550 |

| Sample | C (wt.%) | O (wt.%) | Si (wt.%) | O/C |

|---|---|---|---|---|

| unmodified RFPC (point 1) | 57.5 | 46.5 | - | 0.81 |

| modified RFPC (point 2) | 76.5 | 17.9 | 5.6 | 0.23 |

| Modified RFPC (point 3) | 48.3 | 32.8 | 18.9 | 0.68 |

| Parameter | PP | 5RFPC | 10RFPC | 15RFPC | 20RFPC | 25RFPC | 30RFPC |

|---|---|---|---|---|---|---|---|

| Theoretical density, g/cm3 | 0.904 | 0.919 | 0.938 | 0.959 | 0.980 | 1.003 | 1.026 |

| Experimental density, g/cm3 | 0.904 | 0.911 | 0.928 | 0.945 | 0.957 | 0.963 | 0.975 |

| Porosity, % | 0 | 0.845 | 1.102 | 1.438 | 2.364 | 3.944 | 4.969 |

| Fiber volume fraction Vf, vol% | 0 | 2.978 | 6.086 | 9.332 | 12.725 | 16.277 | 19.997 |

| Average particle distance, μm | - | 128.020 | 83.926 | 62.157 | 48.194 | 38.096 | 30.264 |

| Interface surface area, nm−1 | 0 | 2.234 | 4.564 | 6.999 | 9.544 | 12.207 | 14.998 |

| Paramerters | 5RFPC | 10RFPC | 15RFPC | 20RFPC | 25RFPC | 30RFPC |

|---|---|---|---|---|---|---|

| C (100 °C) | 0.806 | 0.619 | 0.527 | 0.499 | 0.462 | 0.427 |

| C (110 °C) | 0.802 | 0.817 | 0.741 | 0.456 | 0.425 | 0.386 |

| C (120 °C) | 0.734 | 0.55 | 0.441 | 0.4 | 0.374 | 0.337 |

| C (130 °C) | 0.597 | 0.467 | 0.365 | 0.34 | 0.316 | 0.284 |

| degree of entanglement ϕ | 0.032 | 0.045 | 0.056 | 0.063 | 0.072 | 0.080 |

| reinforcing efficiency r | 13.099 | 15.295 | 15.029 | 13.485 | 12.969 | 12.162 |

| Composite | Tg Obtained from E″ Curves (°C) | E″ at Tg (MPa) | Tg Obtained from tan δ Curves (°C) | tan δ at Tg | Adhesion Factor | Constrained Chain Volume, % |

|---|---|---|---|---|---|---|

| PP | −4 | 227.7 | 10 | 0.103 | - | - |

| 5RFPC | 2.7 | 314.5 | 13.2 | 0.101 | 0.011 | 1.474 |

| 10RFPC | 4.8 | 321.6 | 14.1 | 0.098 | 0.013 | 3.712 |

| 15RFPC | 5.5 | 333.4 | 15.3 | 0.093 | −0.004 | 7.514 |

| 20RFPC | 6.1 | 344.5 | 17.8 | 0.087 | −0.032 | 12.2 |

| 25RFPC | 7.9 | 351.4 | 18.9 | 0.085 | −0.014 | 13.793 |

| 30RFPC | 8.9 | 378.0 | 21.1 | 0.081 | −0.017 | 17.027 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Xia, F.; Wang, Y.; Yuan, J.; Chen, D.; Zheng, J. Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites. Polymers 2021, 13, 4083. https://doi.org/10.3390/polym13234083

He L, Xia F, Wang Y, Yuan J, Chen D, Zheng J. Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites. Polymers. 2021; 13(23):4083. https://doi.org/10.3390/polym13234083

Chicago/Turabian StyleHe, Liping, Fan Xia, Yuan Wang, Jianmin Yuan, Dachuan Chen, and Junchao Zheng. 2021. "Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites" Polymers 13, no. 23: 4083. https://doi.org/10.3390/polym13234083

APA StyleHe, L., Xia, F., Wang, Y., Yuan, J., Chen, D., & Zheng, J. (2021). Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites. Polymers, 13(23), 4083. https://doi.org/10.3390/polym13234083