Finite Element Analysis of Glass Fiber-Reinforced Polymer-(GFRP) Reinforced Continuous Concrete Beams

Abstract

:1. Introduction

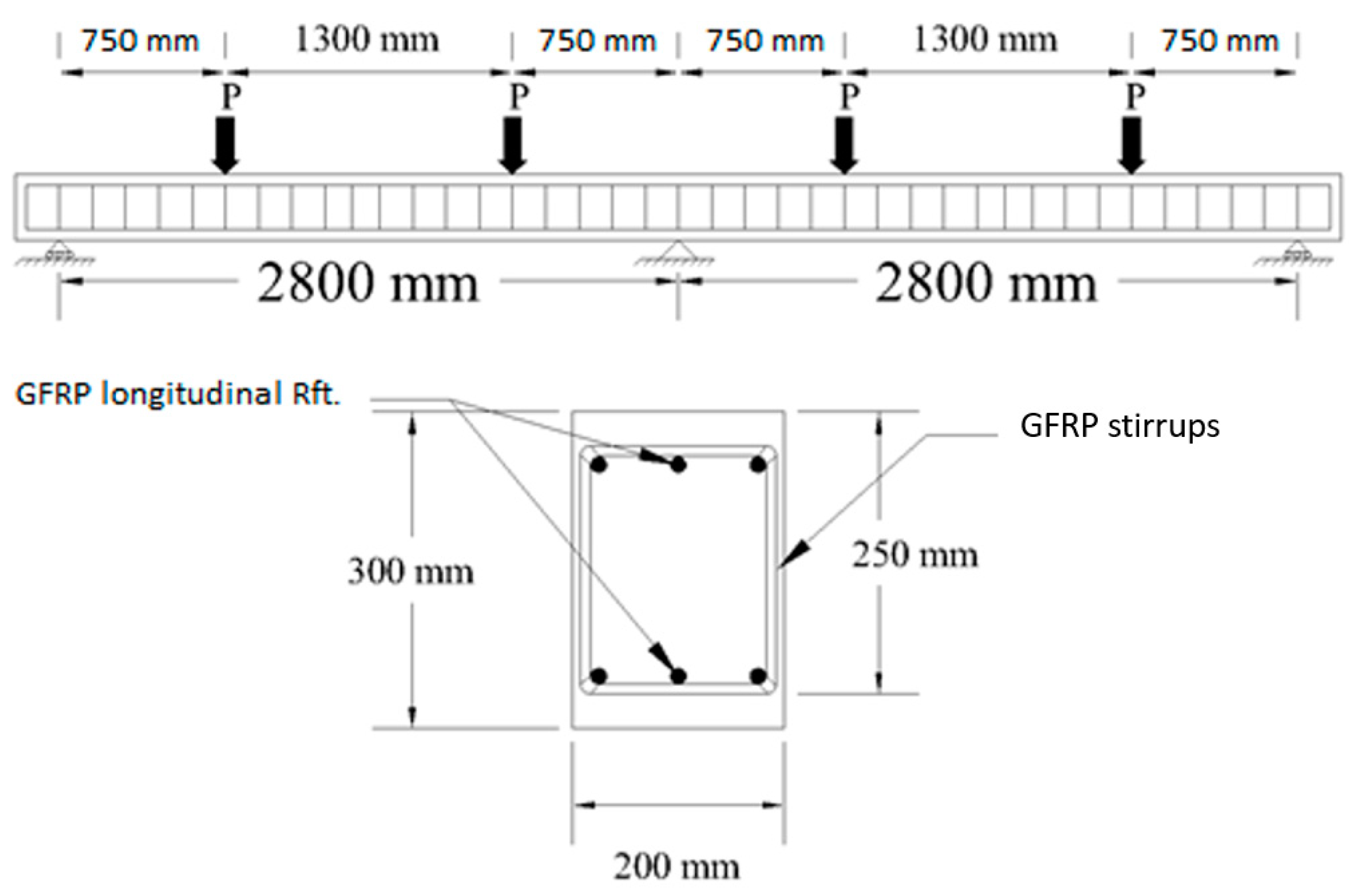

2. Methodology

3. Selection of Constitutive Models

3.1. Concrete

3.2. GFRP Reinforcement

3.3. The Bond between Concrete and Reinforcing Bars

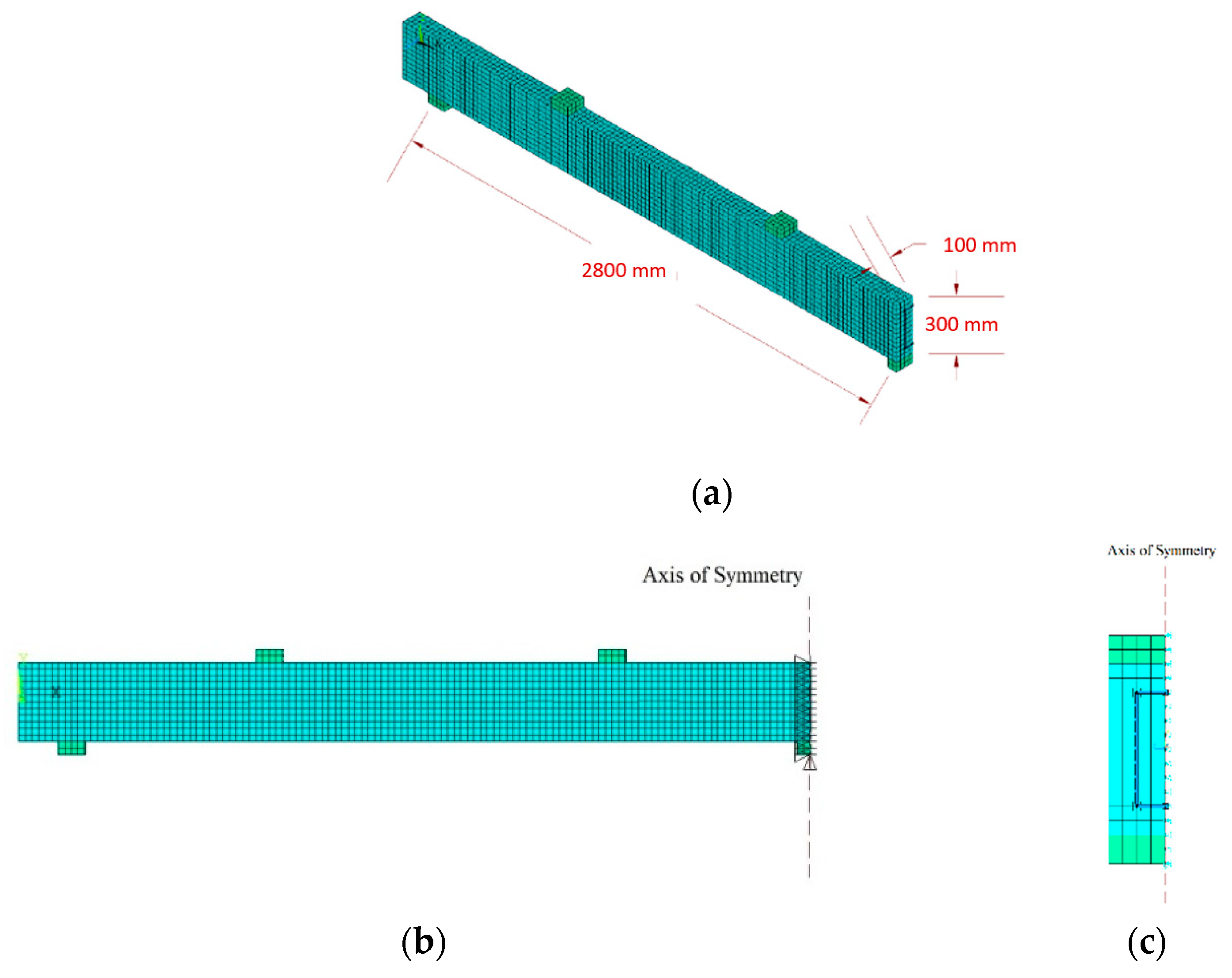

4. Model Calibration

4.1. Convergence and Meshing

4.2. Solution Procedure

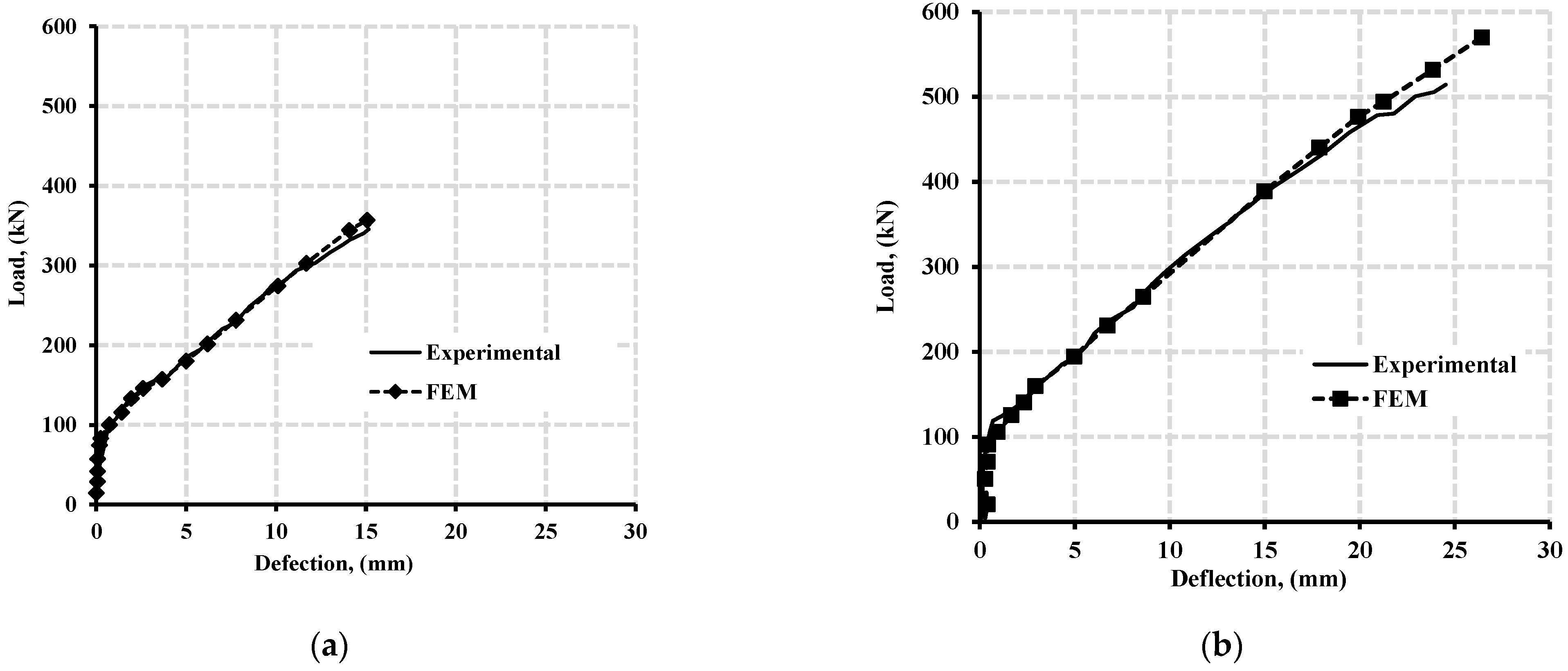

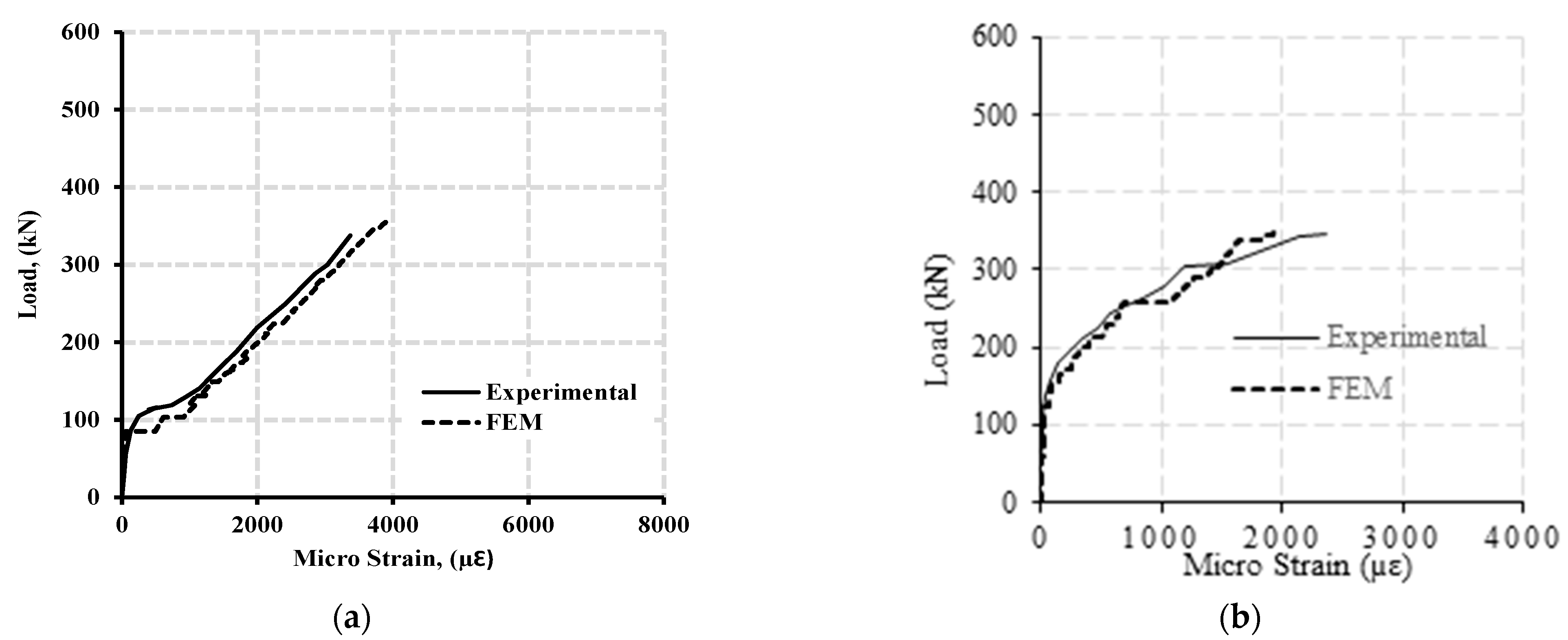

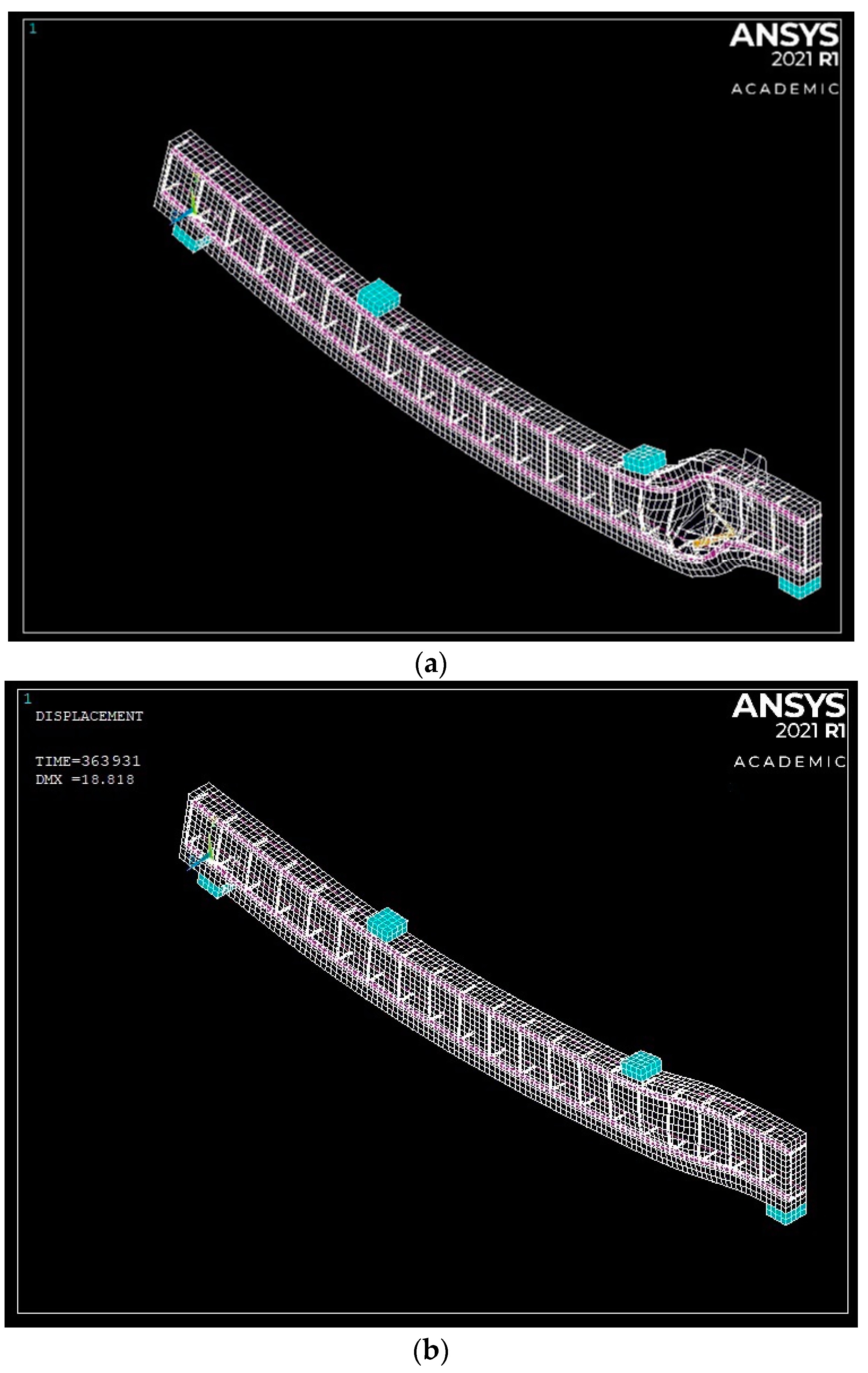

5. Model Validation and Results

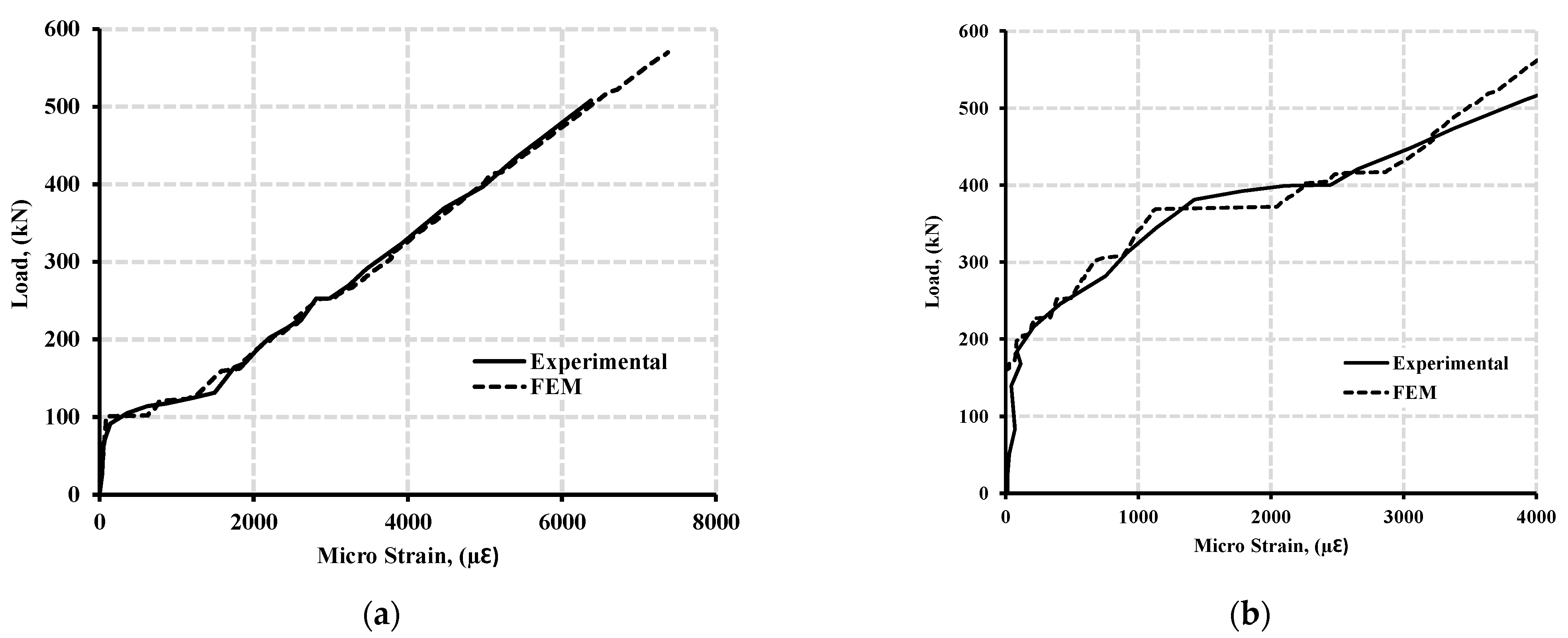

5.1. Model Validation

5.2. Model Validation Results

6. Parametric Studies

7. Results and Discussions

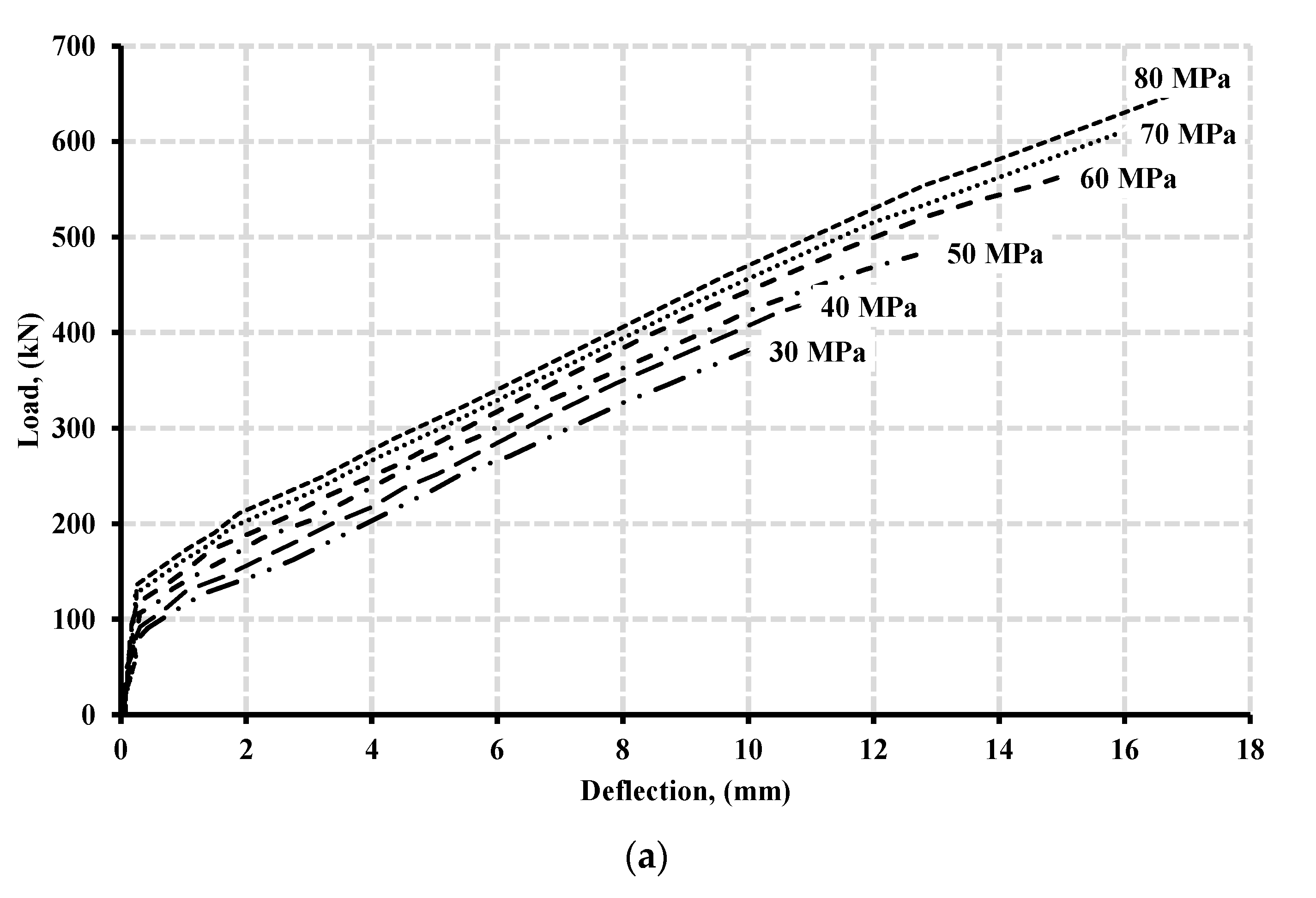

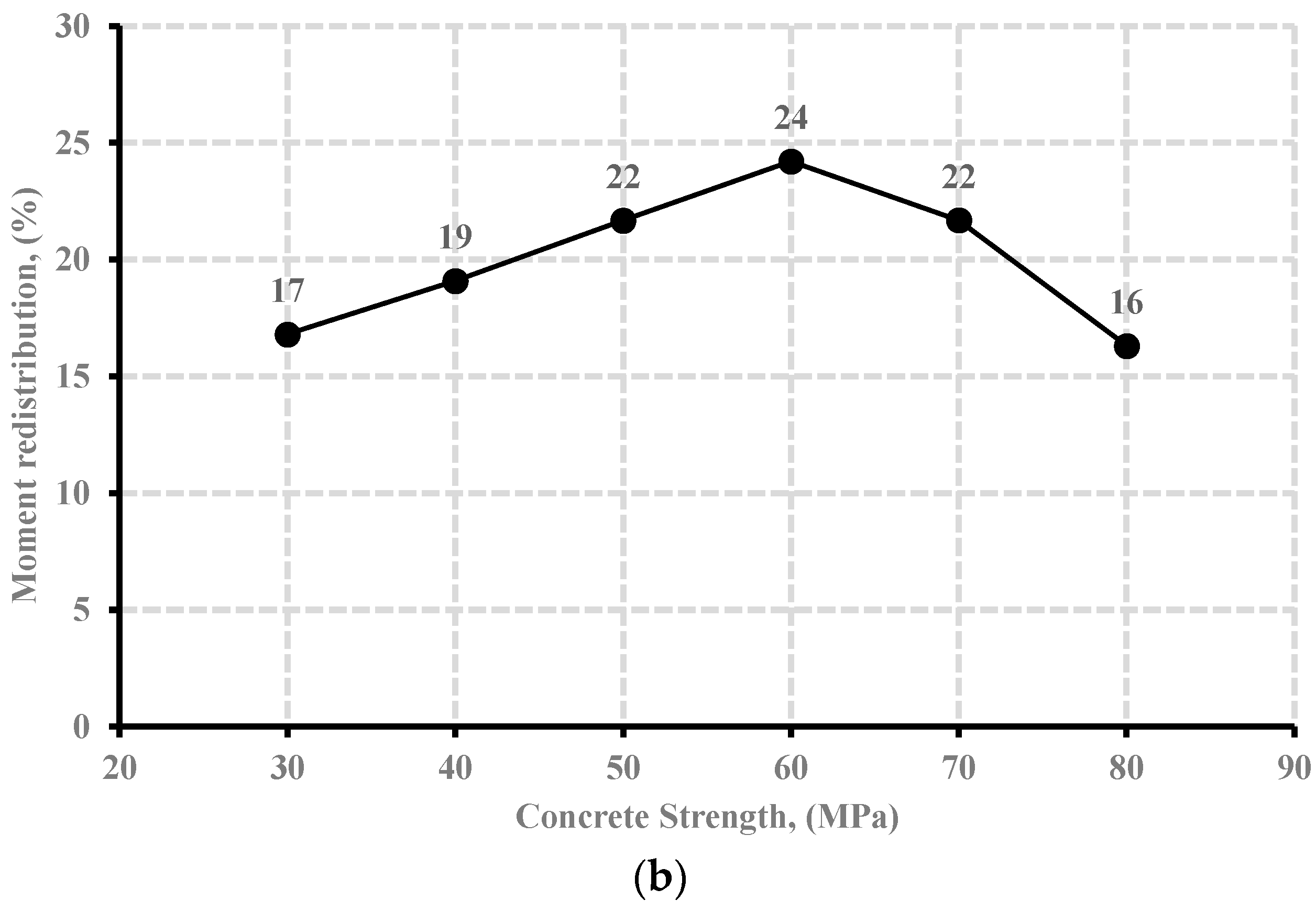

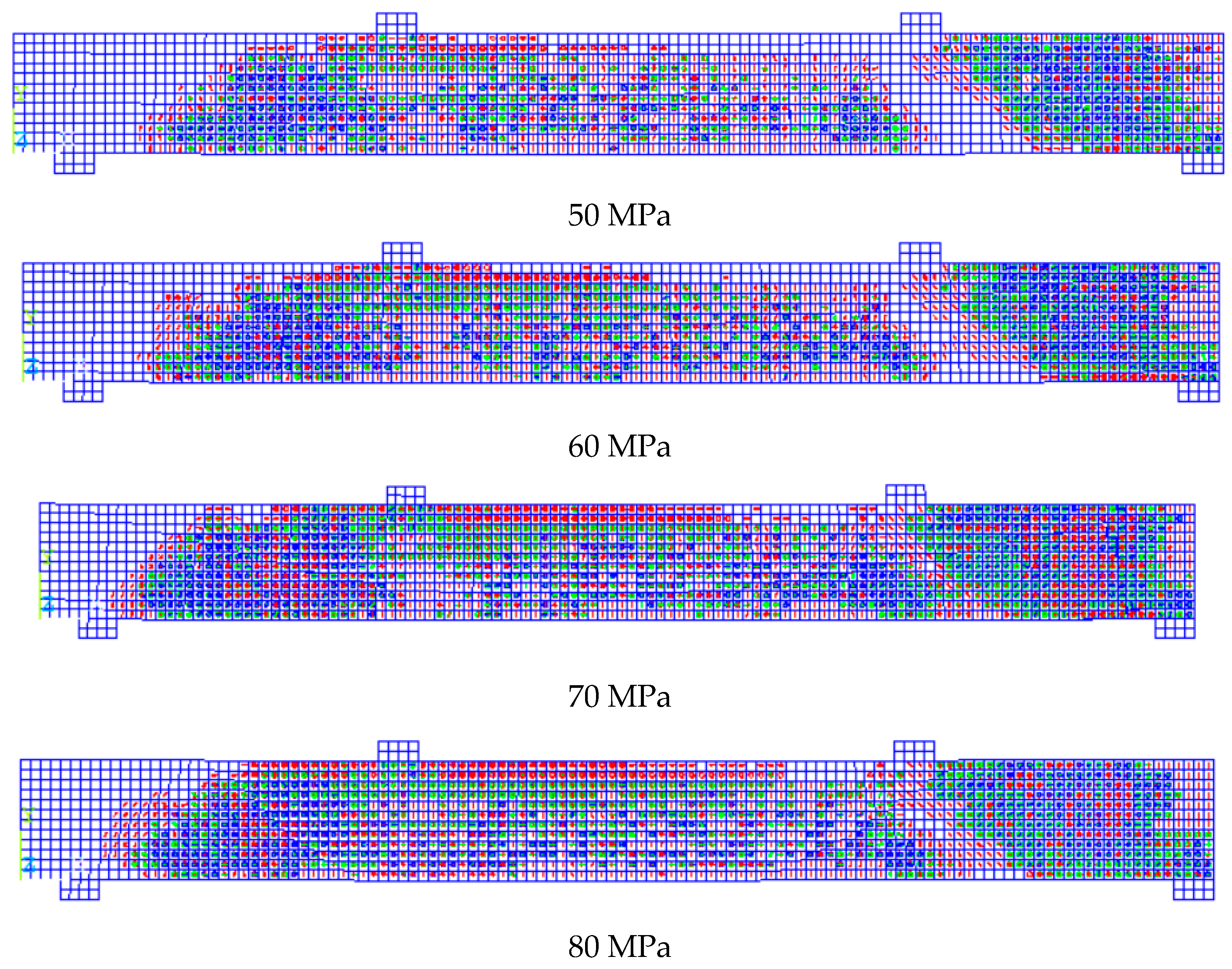

7.1. Effect of Concrete Compressive Strength

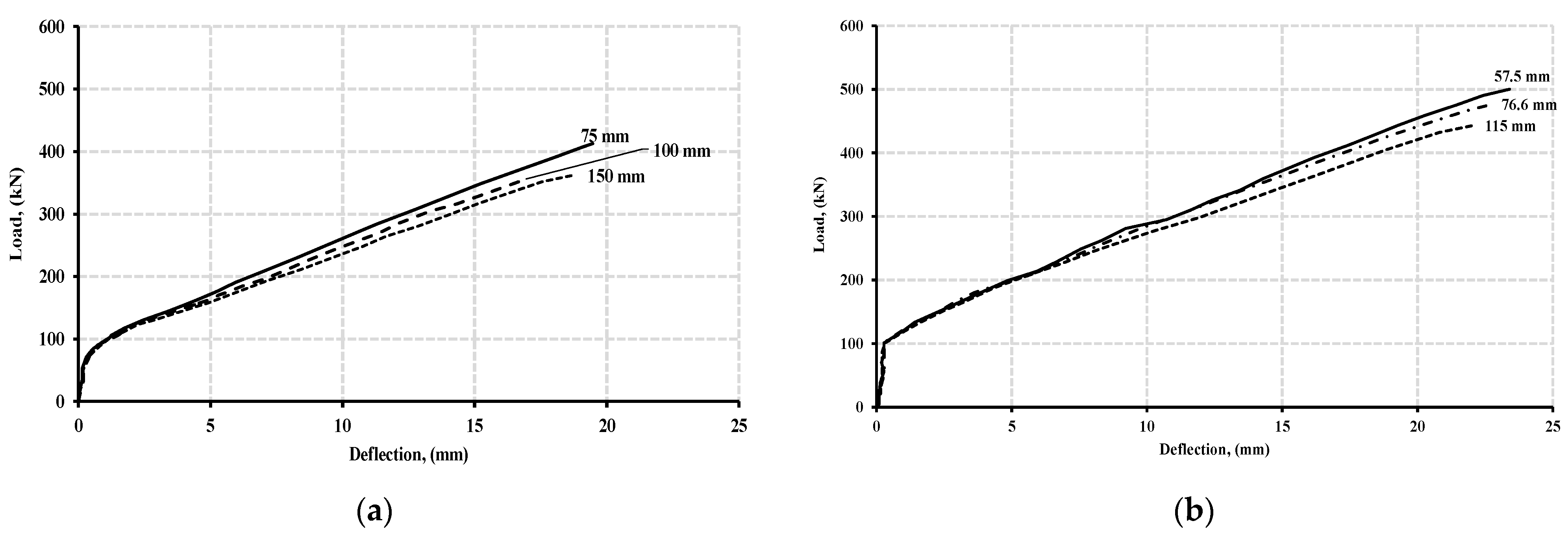

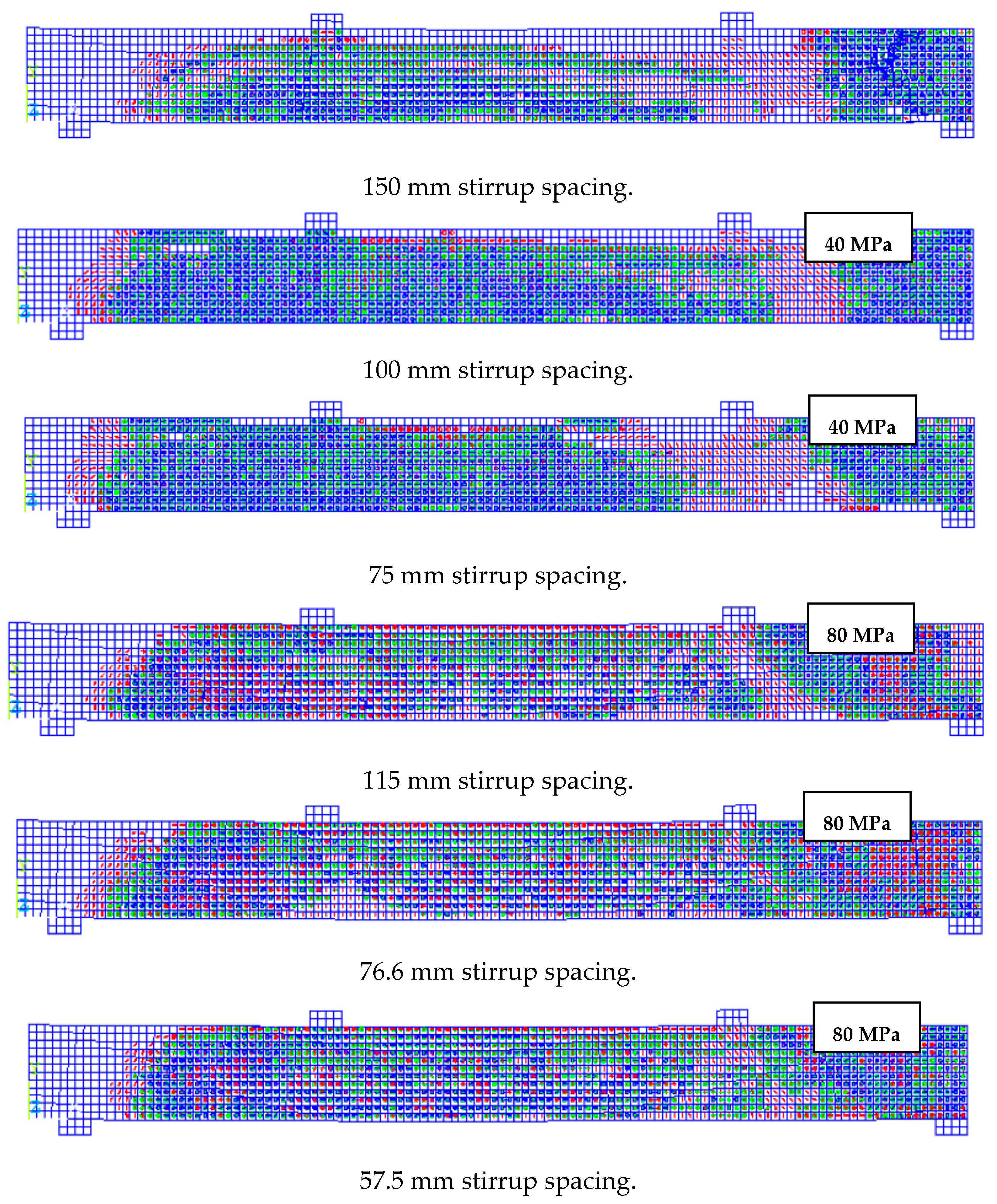

7.2. Effect of Stirrup Spacing

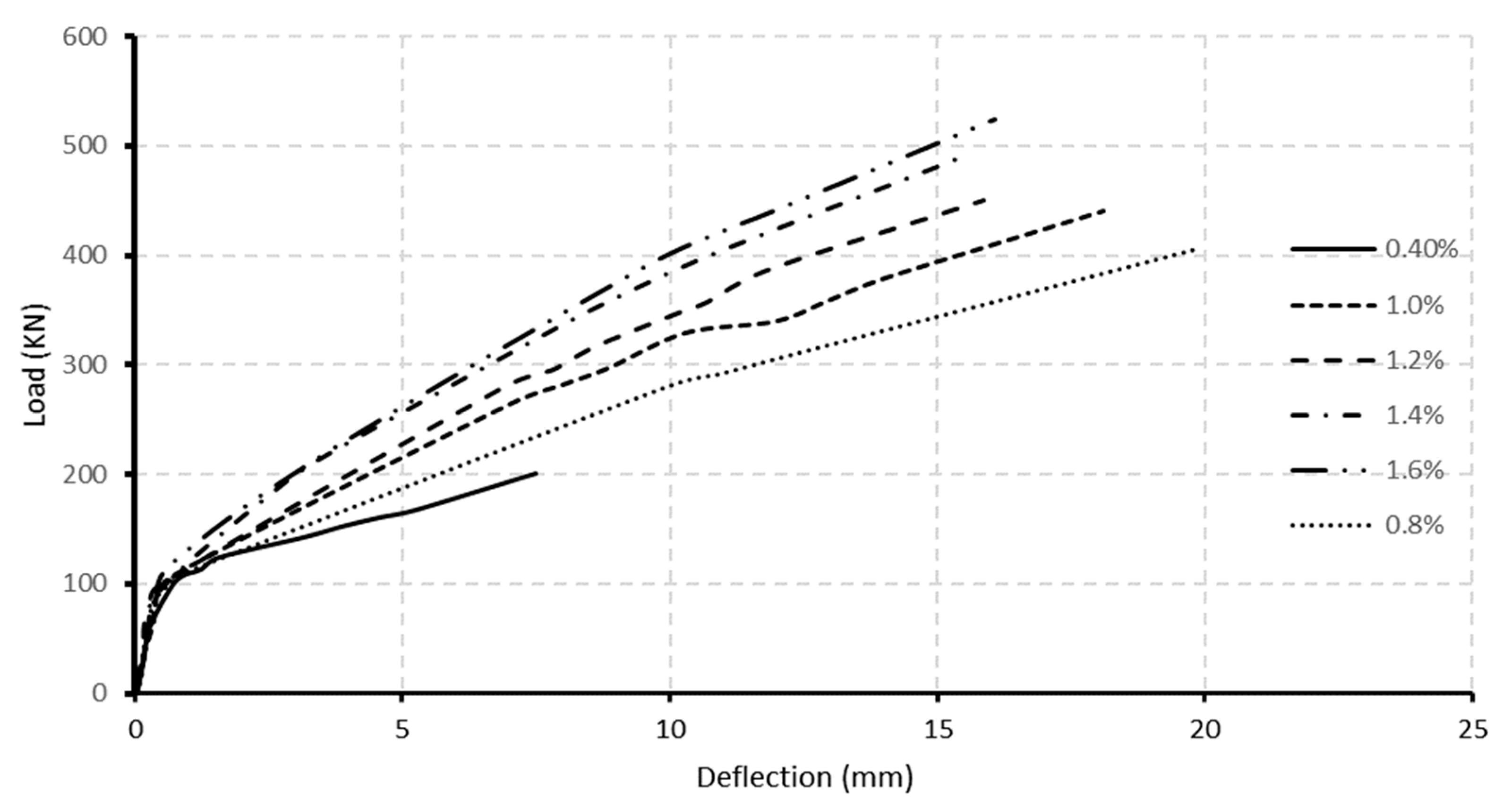

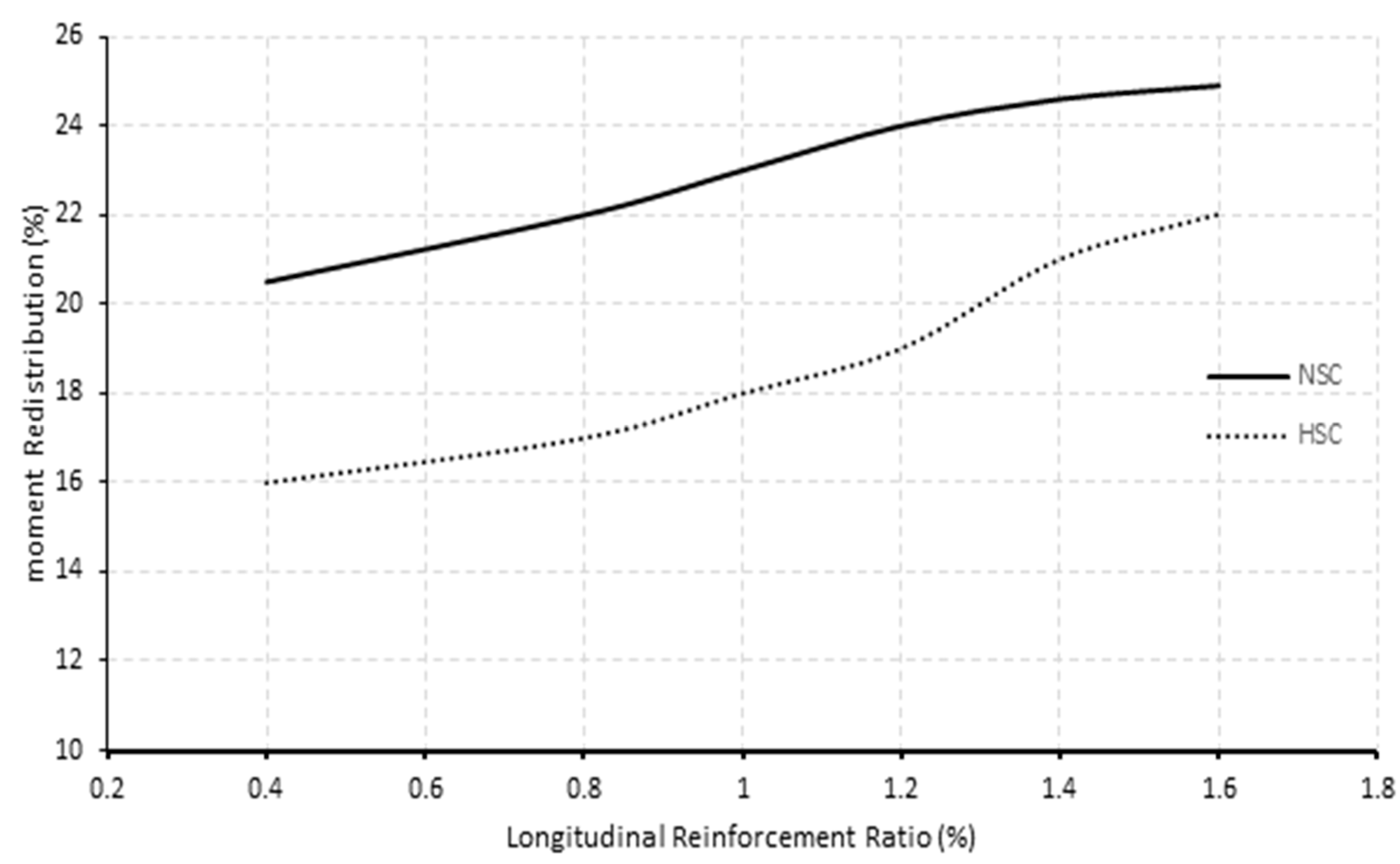

7.3. Effect of Longitudinal Reinforcement Ratio

8. Shear Capacity Provisions

8.1. CAN/CSA S806 Provisions

8.2. Oller’s Model Provision

9. Comparison between Analytical and Finite Element Models

10. Moment Redistribution Prediction through Empirical Methods

11. Conclusions

- The numerical simulation using the finite element model by ANSYS software adequately predicted the behavior of continuously supported GFRP reinforced beams. The results extracted from the FEMs were in good agreement regarding ultimate failure loads, deflection behavior, and moment redistribution against the experimental data provided by Mahmoud [25].

- Despite the absence of plastic behavior in GFRP reinforcement, moment redistribution still occurs on GFRP reinforcement beams at the post cracking stage and the degree of redistribution affected by GFRP reinforcement.

- At failure, the two FEMs established for simulating beam specimens, GN-1.2-0.48-d, and GH-1.2-0.63-d were in good agreement with their experimental results. The moment distribution observed about 21.5% from the FEM of beam specimen GN-1.2-0.48-d, while the experimental results achieved 24% at failure load. For high strength concrete presented in beam specimen GH-1.2-0.63-d, the result showed about 20.2% moment distribution as compared to that achieved experimentally of 23% at failure load.

- The increase in concrete strength resulted in an enhancement in moment distribution. The behavior was limited only to beams that had a concrete strength not exceeding 60 MPa. High-strength concrete specimens with concrete strengths more than 75 MPa generally distributed less moment than their normal strength concrete counterparts.

- The reduction in stirrups spacing from 150 to 75 mm caused an overall increase in moment redistribution by 13.7% at normal concrete strength. The reduction in stirrups spacing from 115 mm to 57.5 mm, resulted in an increase of 8.3% of moment redistribution for the beam specimens at high concrete strength.

- Stirrup spacing impacted the moment redistribution in continuous beams. However, its ability to influence moment redistribution seemed to diminish with high concrete strengths. In addition, the relationship between spacing and moment redistribution was not directly proportional. Reducing the shear reinforcement ratio by reducing the stirrups’ spacing while maintaining constant stirrup diameter did not always enhance moment redistribution.

- This study has shown that the GFRP reinforcement can be effectively modelled in ANSYS software. The finite element analysis results were found to be in close agreement with the experimental results. The finite element analysis is always considered a more affordable and faster analysis approach as compared to the labor-intensive investigations (experimental research). Therefore, the outcome of this study is very useful, and the proposed analysis can be further used for the economical and safe design of GFRP reinforced concrete structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New hybrid basalt/E-glass FRP jacketing for enhanced confinement of recycled aggregate concrete with clay brick aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Kocaoz, S.; Samaranayake, V.A.; Nanni, A. Tensile characterization of glass FRP bars. Compos. Part B Eng. 2005, 36, 127–134. [Google Scholar] [CrossRef]

- Habeeb, M.N.; Ashour, A.F. Flexural Behavior of Continuous GFRP Reinforced Concrete Beams. J. Compos. Constr. 2008, 12, 115–124. [Google Scholar] [CrossRef] [Green Version]

- Gravina, R.J.; Smith, S.T. Flexural behaviour of indeterminate concrete beams reinforced with FRP bars. Eng. Struct. 2008, 30, 2370–2380. [Google Scholar] [CrossRef]

- Kara, I.F.; Ashour, A.F. Moment redistribution in continuous FRP reinforced concrete beams. Constr. Build. Mater. 2013, 49, 939–948. [Google Scholar] [CrossRef] [Green Version]

- Santos, P.; Laranja, G.; França, P.M.; Correia, J.R. Ductility and moment redistribution capacity of multi-span T-section concrete beams reinforced with GFRP bars. Constr. Build. Mater. 2013, 49, 949–961. [Google Scholar] [CrossRef]

- El-Mogy, M.; El-Ragaby, A.; El-Salakawy, E. Experimental testing and finite element modeling on continuous concrete beams reinforced with fibre reinforced polymer bars and stirrups. Can. J. Civ. Eng. 2013, 40, 1091–1102. [Google Scholar] [CrossRef]

- Mahmoud, K.; El-Salakawy, E. Effect of Transverse Reinforcement Ratio on the Shear Strength of GFRP-RC Continuous Beams. J. Compos. Constr. 2016, 20, 04015023. [Google Scholar] [CrossRef]

- El-Mogy, M.; El-Ragaby, A.; El-Salakawy, E. Flexural Behavior of Continuous FRP-Reinforced Concrete Beams. J. Compos. Constr. 2010, 14, 669–680. [Google Scholar] [CrossRef]

- El-Mogy, M.; El-Ragaby, A.; El-Salakawy, E. Effect of Transverse Reinforcement on the Flexural Behavior of Continuous Concrete Beams Reinforced with FRP. J. Compos. Constr. 2011, 15, 672–681. [Google Scholar] [CrossRef]

- Szczech, D.; Kotynia, R. Effect of Shear Reinforcement Ratio on the Shear Capacity of GFRP Reinforced Concrete Beams. Arch. Civ. Eng. 2021, 67, 425–437. [Google Scholar]

- Shehata, E.F.G. Fibre-Reinforced Polymer (FRP) for Shear Reinforcement in Concrete Prisms. Ph.D. Thesis, Department of Civil and Geological Engineering, University of Manitoba, Winnipeg, MB, Canada, 1999. [Google Scholar]

- Ahmed, E.; El-Salakawy, E.; Benmokrane, B. Performance Evaluation of Glass Fiber-Reinforced Polymer Shear Reinforcement for Concrete Beams. ACI Struct. J. 2010, 107, 53–62. [Google Scholar]

- ACI Committee 440. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; ACI 440.1R-15; ACI Committee 440: Farmington Hills, CA, USA, 2015. [Google Scholar]

- CSA Standard S806. Design and construction of building components with fibre reinforced polymers—A current overview. In Design, Manufacturing and Applications of Composites; CRC Press: Boca Raton, FL, USA, 2012; pp. 375–384. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W. Numerical parametric investigation on the moment redistribution of basalt FRC continuous beams with basalt FRP bars. Compos. Struct. 2021, 277, 114618. [Google Scholar] [CrossRef]

- Araba, A.M.; Ashour, A.F. Flexural performance of hybrid GFRP-Steel reinforced concrete continuous beams. Compos. Part B Eng. 2018, 154, 321–336. [Google Scholar] [CrossRef] [Green Version]

- Baša, N.; Ulićević, M.; Zejak, R. Experimental Research of Continuous Concrete Beams with GFRP Reinforcement. Adv. Civ. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- ANSYS Mechanical Enterprise. A Finite Element Computer Software and User Manual for Nonlinear Structural Analysis; Mechanical APDL Release 18.1 UP20170403; ANSYS Mechanical Enterprise: Canonsburg, PA, USA, 2018. [Google Scholar]

- Alam, M.S.; Hussein, A. 3D-Finite Element Analysis (FEA) of Glass Fiber Reinforced Polymer (GFRP) Reinforced Concrete Members. In Proceedings of the 2019 8th International Conference on Modeling Simulation and Applied Optimization (ICMSAO), Manama, Bahrain, 15–17 April 2019; pp. 1–4. [Google Scholar]

- Yooprasertchai, E.; Dithaem, R.; Arnamwong, T.; Sahamitmongkol, R.; Jadekittichoke, J.; Joyklad, P.; Hussain, Q. Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers 2021, 13, 2369. [Google Scholar] [CrossRef] [PubMed]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Ferdous, W.; Mendis, P. A new design-oriented model of glass fiber-reinforced polymer-reinforced hollow concrete columns. ACI Struct. J. 2020, 117, 141–156. [Google Scholar]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravinthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending behaviour of precast concrete slab with externally flanged hollow FRP tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Mahmoud, K.A. Shear Behaviour of Continuous Concrete Beams. Ph.D. Thesis, The University of Manitoba, Winnipeg, MB, Canada, 2015. [Google Scholar]

- Wight, J.K.; MacGregor, J.G. Reinforced Concrete: Mechanics and Design; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Wolanski, A.J. Flexural Behavior of Reinforced and Prestressed Concrete Beams Using Finite Element Analysis. Master’s Thesis, Marquette University, Milwaukee, WI, USA, 2004. [Google Scholar]

- Diab, H.; Khaled, T.; Rashwan, M. Flexural behavior of RC continuous T-beams reinforced with hybrid CFRP/steel bars (experimental and numerical study). JES J. Eng. Sci. 2021, 49, 215–248. [Google Scholar] [CrossRef]

- Alves, J.; El-Ragaby, A.; El-Salakawy, E. Durability of GFRP Bars’ Bond to Concrete under Different Loading and Environmental Conditions. J. Compos. Constr. 2011, 15, 249–262. [Google Scholar] [CrossRef]

- Figiel, Ł.; Kamiński, M. Numerical probabilistic approach to sensitivity analysis in a fatigue delamination problem of a two layer composite. Appl. Math. Comput. 2009, 209, 75–90. [Google Scholar] [CrossRef]

- Tahenni, T.; Bouziadi, F.; Boulekbache, B.; Amziane, S. Experimental and nonlinear finite element analysis of shear behaviour of reinforced concrete beams. Structures 2021, 29, 1582–1596. [Google Scholar] [CrossRef]

- Hussein, L.F.; Khattab, M.M.; Farman, M.S. Experimental and finite element studies on the behavior of hybrid reinforced concrete beams. Case Stud. Constr. Mater. 2021, 15, e00607. [Google Scholar] [CrossRef]

- Oller, E.; Marí, A.; Bairán, J.M.; Cladera, A. Shear design of reinforced concrete beams with FRP longitudinal and transverse reinforcement. Compos. Part B Eng. 2015, 74, 104–122. [Google Scholar] [CrossRef] [Green Version]

- Razaqpur, A.G.; Spadea, S. Shear Strength of FRP Reinforced Concrete Members with Stirrups. J. Compos. Constr. 2015, 19, 04014025. [Google Scholar] [CrossRef]

| Bar Type | Designated Diameter | Nominal Cross-Sectional Area (mm2) | CSA/S806(2012) Annex A (mm2) | Tensile Strength, ffu, (MPa) | Modulus of Elasticity, Ef, (GPa) | Ultimate Strain (%) |

|---|---|---|---|---|---|---|

| GFRP | 15.9 | 198 | 282.7 | 1442 | 67 | 2.1 |

| 19.1 | 285 | 396.6 | 1383 | 53 | 2.6 | |

| 6.3 * | 32 * | 44.0 * | 1383 * | 53 * | 2.6 * | |

| 9.5 * | 72 * | 84.7 * | 1215 * | 53 * | 2.7 * | |

| 12.7 * | 127 * | 145.7 * | 1328 * | 53 * | 2.5 * |

| Element Type | Element Count | Node Count | Behavior Modelled |

|---|---|---|---|

| Solid 45 | 68 | 210 | Loading Plates |

| Solid 65 | 5760 | 7865 | Concrete |

| Link 180 | 480 | 484 | Longitudinal Reinforcement |

| Link 180 | 294 | 315 | Stirrup reinforcement |

| Combin39 | 1600 | 3200 | Bond-slip behavior and bar shear strength |

| Total | 8205 | 12,074 |

| Parameter | Ultimate Moment CSA/S806 (kN·m) | Shear Force at Ultimate Moment (kN) | Shear Strength CSA/S806 (kN) | Failure Mode | ||

|---|---|---|---|---|---|---|

| Variable Concrete Strength, (MPa) | Concrete Strength | 30 | 79.3 | 120.2 | 130.7 | flexural |

| 40 | 93.6 | 141.9 | 135.1 | Shear | ||

| 50 | 105.4 | 159.7 | 138.5 | |||

| 60 | 115.2 | 174.6 | 139.4 | |||

| 70 | 123.4 | 187.0 | 141.9 | |||

| 80 | 130.3 | 197.5 | 144.2 | |||

| Variable Stirrup Spacing, (mm) | 40 MPa | 150 | 70.9 | 107.5 | 75.4 | Shear |

| 100 | 70.9 | 107.5 | 78.3 | |||

| 75 | 70.9 | 107.5 | 78.7 | |||

| 80 MPa | 115 | 94.1 | 142.5 | 91.4 | ||

| 76.6 | 94.1 | 142.5 | 92.4 | |||

| 57.5 | 94.1 | 142.5 | 93.4 | |||

| Variable Longitudinal Reinforcement Ratio, (%) | 40 MPa | 0.4 | 53.6 | 81.3 | 45.5 | Shear |

| 0.8 | 70.9 | 107.5 | 75.0 | |||

| 1.0 | 77.2 | 117.0 | 83.2 | |||

| 1.2 | 82.6 | 125.2 | 90.0 | |||

| 1.4 | 87.3 | 132.3 | 95.7 | |||

| 1.6 | 91.5 | 138.7 | 100.8 | |||

| 80 MPa | 0.4 | 70.0 | 106.1 | 54.4 | Shear | |

| 0.8 | 94.1 | 142.5 | 92.5 | |||

| 1.0 | 103.0 | 156.1 | 102.9 | |||

| 1.2 | 110.8 | 167.9 | 111.4 | |||

| 1.4 | 117.7 | 178.3 | 118.7 | |||

| 1.6 | 123.9 | 187.7 | 125.1 | |||

| Concrete Strength (MPa) | Model Shear Strength (kN) | Predicted Shear Strength Using CSA/S806, (kN) | VFEM/VPred | Predicted Shear Strength Using Oller et al. [33], (kN) | VFEM/VPred |

|---|---|---|---|---|---|

| 30 | 118.6 | 130.7 | 0.91 | 194 | 0.61 |

| 40 | 132.5 | 135.1 | 0.98 | 201 | 0.66 |

| 50 | 148.9 | 138.5 | 1.08 | 208 | 0.72 |

| 60 | 171.9 | 139.4 | 1.23 | 213 | 0.81 |

| 70 | 187.2 | 141.9 | 1.32 | 219 | 0.86 |

| 80 | 203.9 | 144.2 | 1.41 | 224 | 0.91 |

| Mean | 1.16 | 0.76 | |||

| SD | 0.20 | 0.12 | |||

| COV (%) | 17% | 15% | |||

| Series By Concrete Strength, (MPa) | Stirrup Spacing (mm) | Model Shear Strength (kN) | Predicted Shear Strength Using CSA/S806 (kN) | VFEM/VPred | Predicted Shear Strength Using Oller et al. [33], (kN) | VFEM/VPred |

|---|---|---|---|---|---|---|

| 40 | 150 | 125.8 | 75.4 | 1.67 | 79.8 | 1.58 |

| 100 | 109.9 | 78.3 | 1.4 | 92.9 | 1.18 | |

| 75 | 111.5 | 78.7 | 1.42 | 105.9 | 1.05 | |

| Mean | 1.50 | 1.27 | ||||

| SD | 0.15 | 0.28 | ||||

| COV (%) | 10% | 22% | ||||

| 80 | 115 | 157 | 91.4 | 1.72 | 108.06 | 1.45 |

| 76.6 | 149.2 | 92.4 | 1.62 | 125.13 | 1.19 | |

| 57.7 | 135.9 | 93.4 | 1.45 | 142.1 | 0.96 | |

| Mean average: | 1.60 | 1.20 | ||||

| SD | 0.14 | 0.25 | ||||

| COF-V (%): | 9% | 20% | ||||

| Series By Concrete Strength, (MPa) | Longitudinal Reinforcement Ratio (%) | Model Shear Strength (kN) | Predicted Shear Strength Using CSA/S806, (kN) | VFEM/VPred | Predicted Shear Strength Using Oller et al. [33], (kN) | VFEM/VPred |

|---|---|---|---|---|---|---|

| 40 | 0.4 | 62.0 | 45.5 | 1.36 | 96.1 | 0.65 |

| 0.8 | 124.9 | 75.0 | 1.67 | 107.6 | 1.16 | |

| 1.0 | 135.1 | 83.2 | 1.62 | 112.0 | 1.21 | |

| 1.2 | 137.8 | 90.0 | 1.53 | 115.8 | 1.19 | |

| 1.4 | 149.3 | 95.7 | 1.56 | 119.3 | 1.25 | |

| 1.6 | 160.3 | 100.8 | 1.59 | 122.4 | 1.31 | |

| Mean | 1.56 | 1.13 | ||||

| SD | 0.11 | 0.24 | ||||

| COV (%) | 7% | 21% | ||||

| 80 | 0.4 | 89.5 | 54.4 | 1.65 | 120.0 | 0.75 |

| 0.8 | 143.5 | 92.5 | 1.55 | 133.2 | 1.08 | |

| 1.0 | 148.3 | 102.9 | 1.44 | 138.3 | 1.07 | |

| 1.2 | 170.1 | 111.4 | 1.53 | 142.8 | 1.19 | |

| 1.4 | 176.8 | 118.7 | 1.49 | 146.8 | 1.20 | |

| 1.6 | 180.2 | 125.1 | 1.44 | 150.5 | 1.20 | |

| Mean average: | 1.52 | 1.08 | ||||

| SD | 0.08 | 0.18 | ||||

| COF-V (%): | 5% | 16% | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, H.; Elnemr, A.; Ali, N.; Hussain, Q.; Chaiyasarn, K.; Joyklad, P. Finite Element Analysis of Glass Fiber-Reinforced Polymer-(GFRP) Reinforced Continuous Concrete Beams. Polymers 2021, 13, 4468. https://doi.org/10.3390/polym13244468

Ahmad H, Elnemr A, Ali N, Hussain Q, Chaiyasarn K, Joyklad P. Finite Element Analysis of Glass Fiber-Reinforced Polymer-(GFRP) Reinforced Continuous Concrete Beams. Polymers. 2021; 13(24):4468. https://doi.org/10.3390/polym13244468

Chicago/Turabian StyleAhmad, Hazem, Amr Elnemr, Nazam Ali, Qudeer Hussain, Krisada Chaiyasarn, and Panuwat Joyklad. 2021. "Finite Element Analysis of Glass Fiber-Reinforced Polymer-(GFRP) Reinforced Continuous Concrete Beams" Polymers 13, no. 24: 4468. https://doi.org/10.3390/polym13244468

APA StyleAhmad, H., Elnemr, A., Ali, N., Hussain, Q., Chaiyasarn, K., & Joyklad, P. (2021). Finite Element Analysis of Glass Fiber-Reinforced Polymer-(GFRP) Reinforced Continuous Concrete Beams. Polymers, 13(24), 4468. https://doi.org/10.3390/polym13244468