Structural Behavior of Large-Scale Hollow Section RC Beams and Strength Enhancement Using Carbon Fiber Reinforced Polymer (CFRP) Composites

Abstract

:1. Introduction

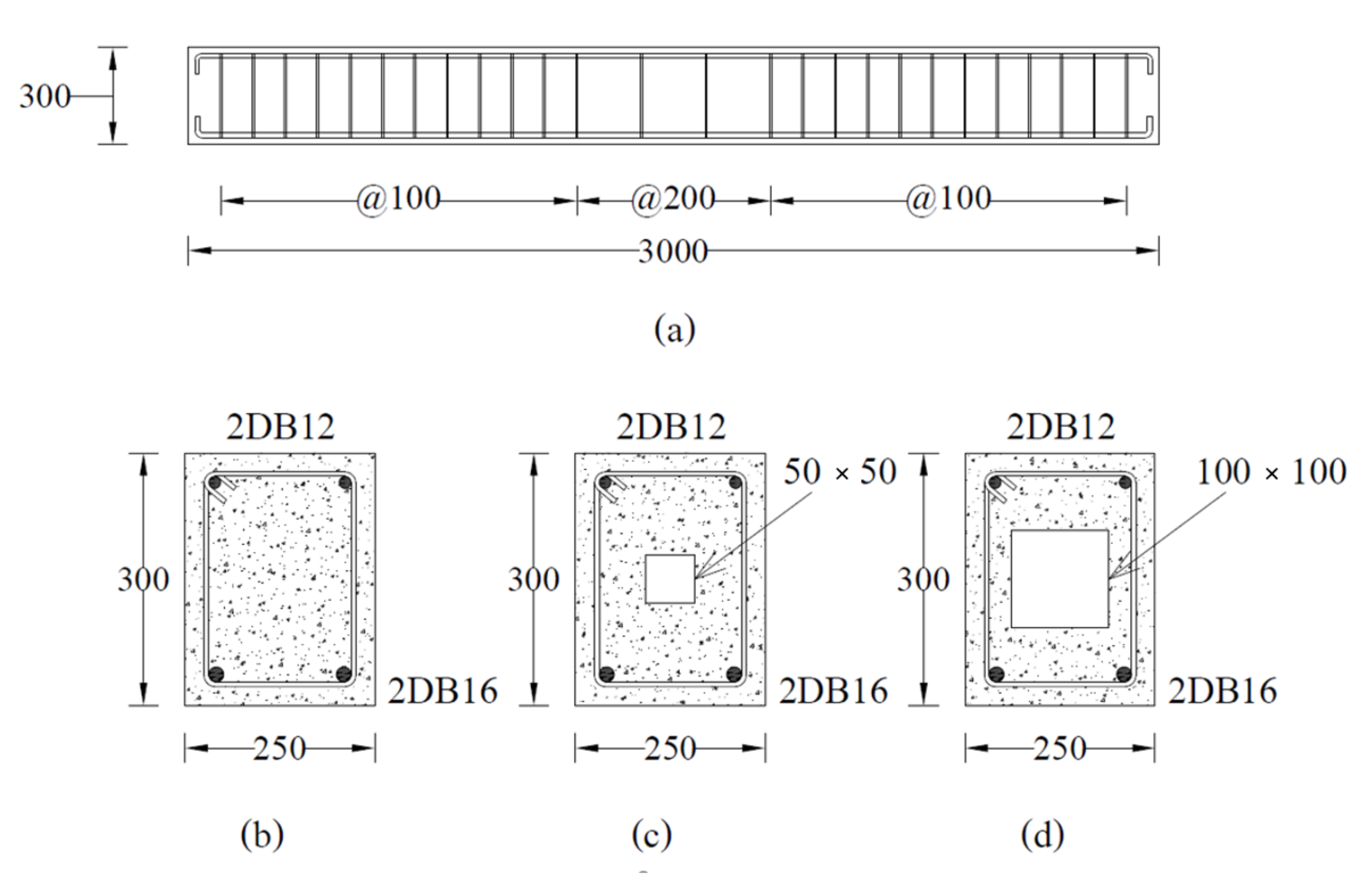

2. Experimental Program

2.1. Test Matrix

2.2. Material Properties

2.3. Construction and Strengthening

2.4. Instrumentation & Load Setup

3. Experimental Results

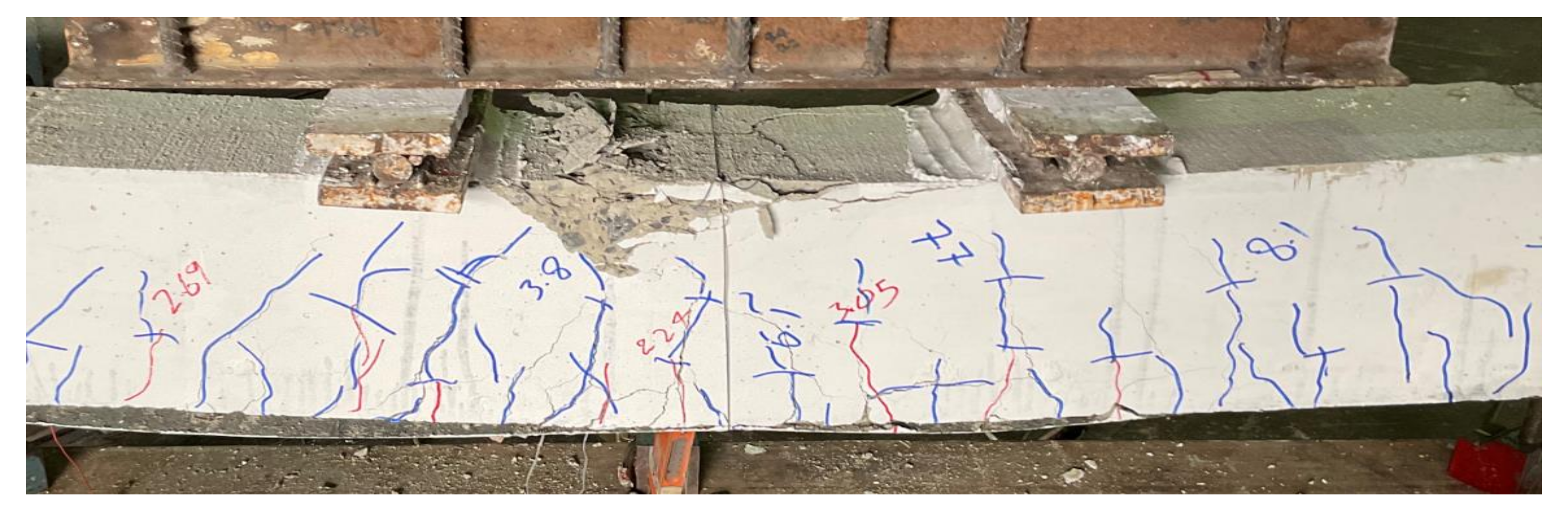

3.1. Failure Modes

3.2. Load-Deflection Response

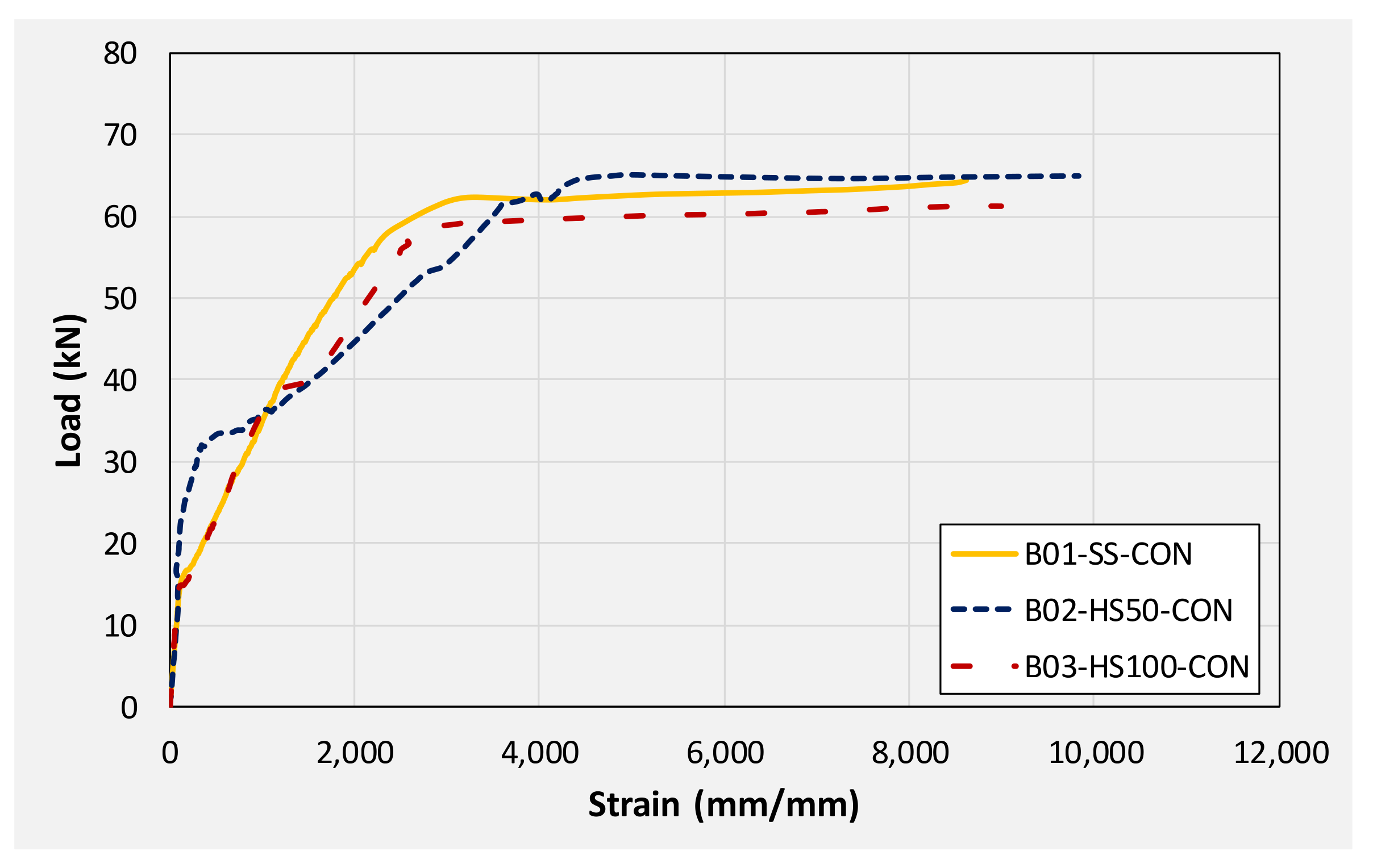

3.3. Steel Strains

3.4. Energy Dissipation

4. Cost-Benefit Analysis

5. Conclusions

- Comparing the load-deflection response of unstrengthened beams, cracking load decreased in beam with 50 mm opening compared with that of the solid section beam. It was further reduced in beam with a 100 mm opening. The presence of an opening inside the beam reduces its cracking load which is further reduced as the size of the opening is increased.

- Unstrengthened beams with 50 (B02) and 100 mm (B03) square openings experienced similar ultimate loads and deflections to those of their counterpart solid section beam (B01).

- A comparison in ultimate loads sustained by beams with similar openings size or solid section beams revealed that the lowest ultimate loads were recorded for unstrengthened beams. Application of CFRP in both configurations enhanced ultimate loads. However, this improvement was far superior in beams strengthened with U-shape CFRP sheets.

- Beams strengthened with CFRP sheet bonded to their bottom sides experienced sudden debonding of CFRP at their ultimate loads resulting in an abrupt drop in the load. A similar drop in load was also observed for beams strengthened with U-shape CFRP due to sudden rupture along the beams’ corners. Nonetheless, degradation of peak load, in either case, did not fall below the corresponding load sustained by the control beam. This phenomenon was true for all beams except B09-HS100-SCB which experienced its load degradation lower than that of the control beam. This was attributed to excessive concrete crushing at its midspan resulting in such distinctive behavior.

- Beam strengthened with CFRP experienced higher compressive longitudinal steel strains. This is an important aspect in the flexural enhancement of beams with internal openings using CFRP. In the absence of inadequate negative longitudinal reinforcement, high compressive stresses above the neutral axis can crush concrete prematurely resulting in brittle failure. A glimpse of such an abrupt load drop was observed in beam B09 that experienced significant concrete crushing.

- This study has shown that the flexural behavior of the RC solid beams is almost identical to the RC hollow sections beams. In flexural bending, the behavior of RC beams is mainly controlled by longitudinal reinforcement. Further studies are required to clearly understand the presence of the hollow sections on the shear capacity of RC hollow section beams with varying shear span-depth ratios.

- The cost-benefit analysis showed that the feasibility of the hollow section RC beams is more than the solid section RC beams. Therefore, the out of this study can be further utilized to customize the design of the RC beams and to reduce the cost of the concrete structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alcocer, S.M.; Jirsa, J.O. Strength of Reinforced Concrete Frame Connections Rehabilitated by Jacketing. Struct. J. 1993, 90, 249–261. [Google Scholar] [CrossRef]

- Júlio, E.N.B.S.; Branco, F.A.B. Reinforced Concrete Jacketing--Interface Influence on Cyclic Loading Response. Struct. J. 2008, 105, 471–477. [Google Scholar] [CrossRef]

- Júlio, E.S.; Branco, F.; Silva, V.D. Structural Rehabilitation of Columns with Reinforced Concrete Jacketing. Prog. Struct. Eng. Mater. 2003, 5, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Wang, J.; Bao, Y.; Chen, G. Cyclic Behavior of Damaged Reinforced Concrete Columns Repaired with High-Performance Fiber-Reinforced Cementitious Composite. Eng. Struct. 2017, 136, 26–35. [Google Scholar] [CrossRef]

- Ong, K.C.G.; Kog, Y.C.; Yu, C.H.; Sreekanth, A.P.V. Jacketing of Reinforced Concrete Columns Subjected to Axial Load. Mag. Concr. Res. 2015, 56, 89–98. [Google Scholar] [CrossRef]

- Aboutaha, R.S.; Engelhardt, M.D.; Jirsa, J.O.; Kreger, M.E. Rehabilitation of Shear Critical Concrete Columns by Use of Rectangular Steel Jackets. Struct. J. 1999, 96, 68–78. [Google Scholar] [CrossRef] [Green Version]

- Choi, E.; Park, J.; Nam, T.H.; Yoon, S.J. A New Steel Jacketing Method for RC Columns. Mag. Concr. Res. 2015, 61, 787–796. [Google Scholar] [CrossRef]

- Ghobarah, A.; Aziz, T.S.; Biddah, A. Rehabilitation of Reinforced Concrete Frame Connections Using Corrugated Steel Jacketing. Struct. J. 1997, 94, 282–294. [Google Scholar] [CrossRef]

- Nagaprasad, P.; Sahoo, D.R.; Rai, D.C. Seismic Strengthening of RC Columns Using External Steel Cage. Earthq. Eng. Struct. Dyn. 2009, 38, 1563–1586. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Retrofit of Reinforced Concrete Columns Using Partially Stiffened Steel Jackets. J. Struct. Eng. 2003, 129, 725–732. [Google Scholar] [CrossRef]

- Raza, S.; Khan, M.K.I.; Menegon, S.J.; Tsang, H.H.; Wilson, J.L. Strengthening and Repair of Reinforced Concrete Columns by Jacketing: State-of-the-Art Review. Sustainability 2019, 11, 3208. [Google Scholar] [CrossRef] [Green Version]

- Yoddumrong, P.; Rodsin, K.; Katawaethwarag, S. Seismic Strengthening of Low-Strength RC Concrete Columns Using Low-Cost Glass Fiber Reinforced Polymers (GFRPs). Case Stud. Constr. Mater. 2020, 13, e00383. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Issa, M. Fatigue Performance of Reinforced Concrete Beams Strengthened with CFRP Sheets. Constr. Build. Mater. 2011, 25, 3520–3529. [Google Scholar] [CrossRef]

- Ceroni, F. Experimental Performances of RC Beams Strengthened with FRP Materials. Constr. Build. Mater. 2010, 24, 1547–1559. [Google Scholar] [CrossRef]

- Correia, J.R.; Branco, F.A.; Ferreira, J.G. Flexural Behaviour of GFRP–Concrete Hybrid Beams with Interconnection Slip. Compos. Struct. 2007, 77, 66–78. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Guan, Z. Structural Behaviour of RC Beams with External Flexural and Flexural–Shear Strengthening by FRP Sheets. Compos. Part B Eng. 2013, 44, 604–612. [Google Scholar] [CrossRef]

- Sheikh, S.A. Performance of Concrete Structures Retrofitted with Fibre Reinforced Polymers. Eng. Struct. 2002, 24, 869–879. [Google Scholar] [CrossRef]

- Alnuaimi, A.S.; Al-Jabri, K.S.; Hago, A. Comparison between Solid and Hollow Reinforced Concrete Beams. Mater. Struct. Mater. Constr. 2008, 41, 269–286. [Google Scholar] [CrossRef]

- Nasr, Z.H.; Hala, M.I.; Amany, M.S. Study Behavior of Hollow Reinforced Concrete Beams—Inpressco. Int. J. Curr. Eng. Technol. 2018, 8, 1640–1651. [Google Scholar]

- Balaji, G.; Vetturayasudharsanan, R. Experimental Investigation on Flexural Behaviour of RC Hollow Beams. Mater. Sci. 2020, 21, 351–356. [Google Scholar] [CrossRef]

- Hassan, S.A.; Hemzah, S.A.; Alyhya, W.S. Experimental Investigation of the Structural Behaviours of Self-Compacted Reinforced Concrete Hollow Beams with in-Place Circular Openings. In Proceedings of the 3rd International Conference on Engineering Sciences, Madrid, Spain, 28–30 October 2020. [Google Scholar]

- Altun, F.; Haktanir, T.; Ari, K.; Altun, F.; Haktanir, T.; Ari, K. Experimental Investigation of Steel Fiber Reinforced Concrete Box Beams under Bending. Mater. Struct. 2006, 39, 491–499. [Google Scholar] [CrossRef]

- Saud, T.; Al-Gasham, S. Reinforced Concrete Moderate Deep Beams with Embedded PVC Pipes. Wasit J. Eng. Sci. 2015, 3, 19–29. [Google Scholar] [CrossRef]

- Alshimmeri, A.J.H.; Al-Maliki, H. Structural Behavior of Reinforced Concrete Hollow Beams under Partial Uniformly Distributed Load. Mater. Sci. J. Eng. 2014, 20, 130–145. [Google Scholar]

- Murugesan, A.; Narayanan, A. Influence of a Longitudinal Circular Hole on Flexural Strength of Reinforced Concrete Beams. Pract. Period. Struct. Des. Constr. 2017, 22, 04016021. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; He, D.; Guan, Z. CFRP Sheets for Flexural Strengthening of RC Beams. In Proceedings of the 2011 International Conference on Multimedia Technology, ICMT, Hangzhou, China, 26–28 July 2011; pp. 1000–1003. [Google Scholar] [CrossRef]

- Khuzaie, H.M.A.; Atea, R.S. Investigation of Torsional Behavior and Capacity of Reactive Powder Concrete (RPC) of Hollow T-Beam. J. Mater. Res. Technol. 2019, 8, 199–207. [Google Scholar] [CrossRef]

- Vijayakumar, A.; Madhavi, T.C. Behaviour of Self Compacting Concrete with Hybrid Fibers in Hollow Beams. Mater. Today Proc. 2021, 46, 3212–3219. [Google Scholar] [CrossRef]

- Chen, T.; Qi, M.; Gu, X.L.; Yu, Q.Q. Flexural Strength of Carbon Fiber Reinforced Polymer Repaired Cracked Rectangular Hollow Section Steel Beams. Int. J. Polym. Sci. 2015, 2015, 204861. [Google Scholar] [CrossRef]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Ferdous, W.; Mendis, P. A new design-oriented model of glass fiber-reinforced polymer-reinforced hollow concrete columns. ACI Struct. J. 2020, 117, 141–156. [Google Scholar]

- Hussain, Q.; Pimanmas, A. Shear strengthening of RC deep beams with openings using sprayed glass fiber reinforced polymer composites (SGFRP): Part 1. Experimental study. KSCE J. Civ. Eng. 2015, 19, 2121–2133. [Google Scholar] [CrossRef]

- Joyklad, P.; Suparp, S.; Hussain, Q. Flexural response of JFRP and BFRP strengthened RC beams. Int. J. Eng. Technol. 2019, 11. [Google Scholar] [CrossRef] [Green Version]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Alkinani, A.Q.; Fam, A. State-of-the-art of prefabricated FRP composite jackets for structural repair. Eng. Sci. Technol. Int. J. 2020, 23, 1244–1258. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). ACI 440.1R-06, Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars, ACI Committee 440; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2006. [Google Scholar]

- ASTM. ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM. ASTM A615/A615M-20; Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM. ASTM D7565/D7565M-10; Standard Test Method for Determining Tensile Properties of Fiber Reinforced Polymer Matrix Composites Used for Strengthening of Civil Structures. ASTM: West Conshohocken, PA, USA, 2017.

- Joyklad, P.; Ali, N.; Rashid, M.U.; Hussain, Q.; Magbool, H.M.; Elnemr, A.; Chaiyasarn, K. Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh. Infrastructures 2021, 6, 166. [Google Scholar] [CrossRef]

- Joyklad, P.; Ali, N.; Verre, S.; Magbool, H.M.; Elnemr, A.; Qureshi, M.I.; Hussain, Q.; Chaiyasarn, K. Experimental Study on the Out-of-Plane Behavior of Brick Masonry Walls Strengthened with Mortar and Wire Mesh: A Pioneer Study. Infrastructures 2021, 6, 165. [Google Scholar] [CrossRef]

| Beam ID | Square Opening Side Dimension (mm) | CFRP Configuration |

|---|---|---|

| B01-SS-CON | - | - |

| B02-HS50-CON | 50 | - |

| B03-HS100-CON | 100 | - |

| B04-SS-SCA | - | Tension side |

| B05-HS50-SCA | 50 | Tension side |

| B06-HS100-SCA | 100 | Tension side |

| B07-SS-SCB | - | U-shape |

| B08-HS50-SCB | 50 | U-shape |

| B09-HS100-SCB | 100 | U-shape |

| Steel Bar | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|

| RB-6 | 250 | 350 |

| DB-12 | 400 | 500 |

| DB-16 | 420 | 550 |

| Beam | Ultimate Load (kN) | Increase in Load (%) | Deflection (mm) |

|---|---|---|---|

| B01-SS-CON | 70.81 | - | 53.41 |

| B04-SS-SCA | 86.22 | 22 | 27.47 |

| B07-SS-SCB | 112.81 | 59 | 39.29 |

| B02-HS50-CON | 72.01 | - | 52.84 |

| B05-HS50-SCA | 98.52 | 36 | 32.35 |

| B08-HS50-SCB | 115.47 | 60 | 38.26 |

| B03-HS100-CON | 74.75 | - | 53.06 |

| B06-HS100-SCA | 86.51 | 16 | 25.00 |

| B09-HS100-SCB | 113.09 | 53 | 32.97 |

| Beam | Strain (tensile) | Strain (Compression) |

|---|---|---|

| B01-SS-CON | 8608 | 1906 |

| B02-HS50-CON | 9829 | 1726 |

| B03-HS100-CON | 8991 | 1501 |

| B04-SS-SCA | 9111 | 2266 |

| B05-HS50-SCA | 9115 | - |

| B06-HS100-SCA | 7612 | 20,882 |

| B07-SS-SCB | 9299 | - |

| B08-HS50-SCB | 8710 | 11,451 |

| B09-HS100-SCB | 8916 | 10,986 |

| Beam | Energy Dissipation (kN-mm) |

|---|---|

| B01-SS-CON | 3302 |

| B02-HS50-CON | 3240 |

| B03-HS100-CON | 2784 |

| B04-SS-SCA | 3257 |

| B05-HS50-SCA | 4301 |

| B06-HS100-SCA | 3293 |

| B07-SS-SCB | 4750 |

| B08-HS50-SCB | 4301 |

| B09-HS100-SCB | 3638 |

| Beam | Weight (Kg) | Price (USD) | Ultimate Load (kN) |

|---|---|---|---|

| B01-SS-CON | 540 | 24.53 | 70.81 |

| B02-HS50-CON | 522 | 23.71 | 72.01 |

| B03-HS100-CON | 468 | 21.26 | 74.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirisonthi, A.; Julphunthong, P.; Joyklad, P.; Suparp, S.; Ali, N.; Javid, M.A.; Chaiyasarn, K.; Hussain, Q. Structural Behavior of Large-Scale Hollow Section RC Beams and Strength Enhancement Using Carbon Fiber Reinforced Polymer (CFRP) Composites. Polymers 2022, 14, 158. https://doi.org/10.3390/polym14010158

Sirisonthi A, Julphunthong P, Joyklad P, Suparp S, Ali N, Javid MA, Chaiyasarn K, Hussain Q. Structural Behavior of Large-Scale Hollow Section RC Beams and Strength Enhancement Using Carbon Fiber Reinforced Polymer (CFRP) Composites. Polymers. 2022; 14(1):158. https://doi.org/10.3390/polym14010158

Chicago/Turabian StyleSirisonthi, Athasit, Phongthorn Julphunthong, Panuwat Joyklad, Suniti Suparp, Nazam Ali, Muhammad Ashraf Javid, Krisada Chaiyasarn, and Qudeer Hussain. 2022. "Structural Behavior of Large-Scale Hollow Section RC Beams and Strength Enhancement Using Carbon Fiber Reinforced Polymer (CFRP) Composites" Polymers 14, no. 1: 158. https://doi.org/10.3390/polym14010158

APA StyleSirisonthi, A., Julphunthong, P., Joyklad, P., Suparp, S., Ali, N., Javid, M. A., Chaiyasarn, K., & Hussain, Q. (2022). Structural Behavior of Large-Scale Hollow Section RC Beams and Strength Enhancement Using Carbon Fiber Reinforced Polymer (CFRP) Composites. Polymers, 14(1), 158. https://doi.org/10.3390/polym14010158