Non-Furanic Humins-Based Non-Isocyanate Polyurethane (NIPU) Thermoset Wood Adhesives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Humins-NIPU Adhesives

- Resin A,

- Step 1: 20 g tannin + 15 g Gerhumin® + 5 g H2O +13.5 g DMC, at 60 °C for 1.5 h;

- Step 2: 38.8 g of diamine, at 90 °C for 2 h.

- Resin characteristics: viscosity at 23 °C 1620–1650 mPa.s; solids content 54.5%.

- Resin B,

- Step 1: 40 g Gerhumin® + 13.5 g DMC, at 60 °C for 1.5 h;

- Step 2: 38.8 g of diamine, at 90 °C for 2 h.

- After the end of the reaction, to obtain the final solid content of 45%, rotary evaporation under reduced pressure was used.

- Resin characteristics: viscosity at 23 °C 520–540 mPa.s; solids content 45%.

- Resin C,

- Step 1: 20 g tannin + 16.67 g H2O+ 13.5 g DMC, at 60 °C for 1.5 h;

- Step 2: 15 g Gerhumin®, 90 °C for 1 h;

- Step 3: 38.8 g of diamine, 90 °C for 1 h.

- Resin characteristics: viscosity at 23 °C 1050–1120 mPa.s; solids content 52.3%.

- Resin D,

- Step 1: 20 g tannin + 16.67 g H2O + 13.5 g DMC, at 60 °C for 1.5 h;

- Step 2: 38.8 g of diamine + 15 g Gerhumin®, at 90 °C for 2 h.

- Resin characteristics: viscosity at 23 °C 1230–1310 mPa.s; solids content 51.7%.

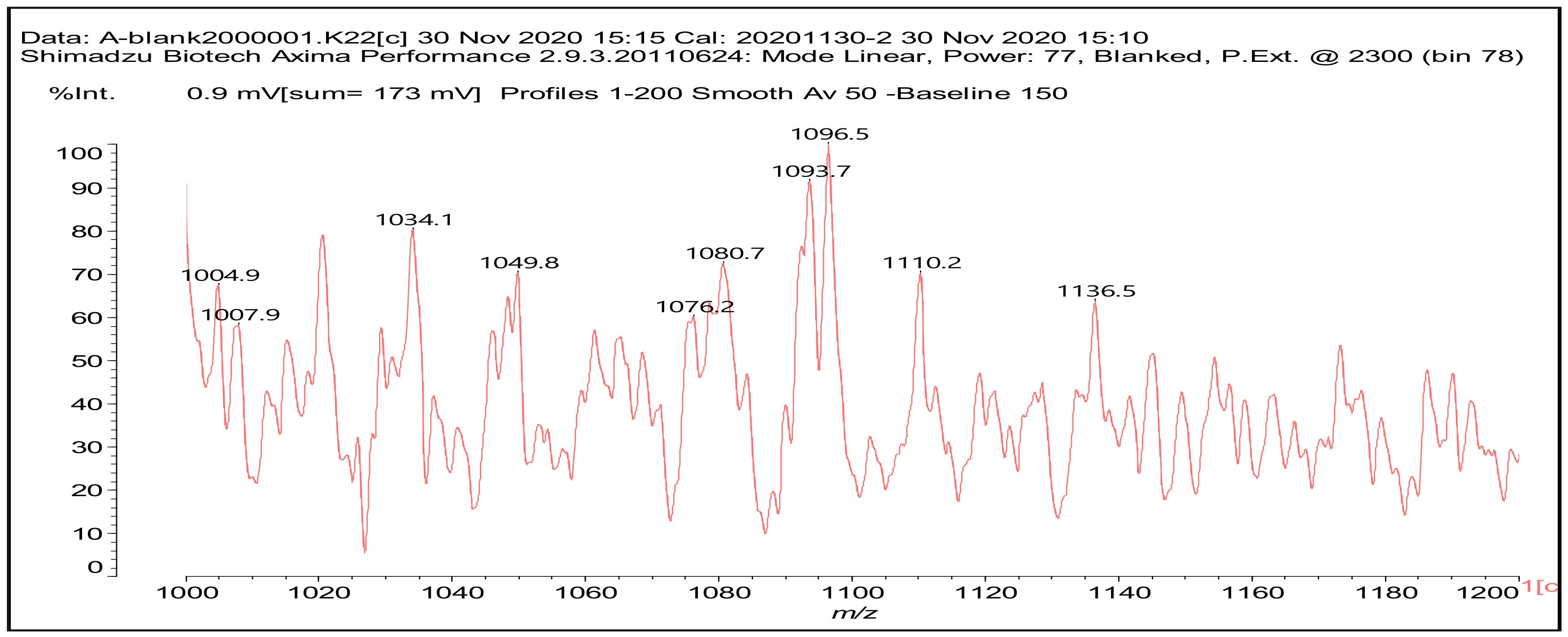

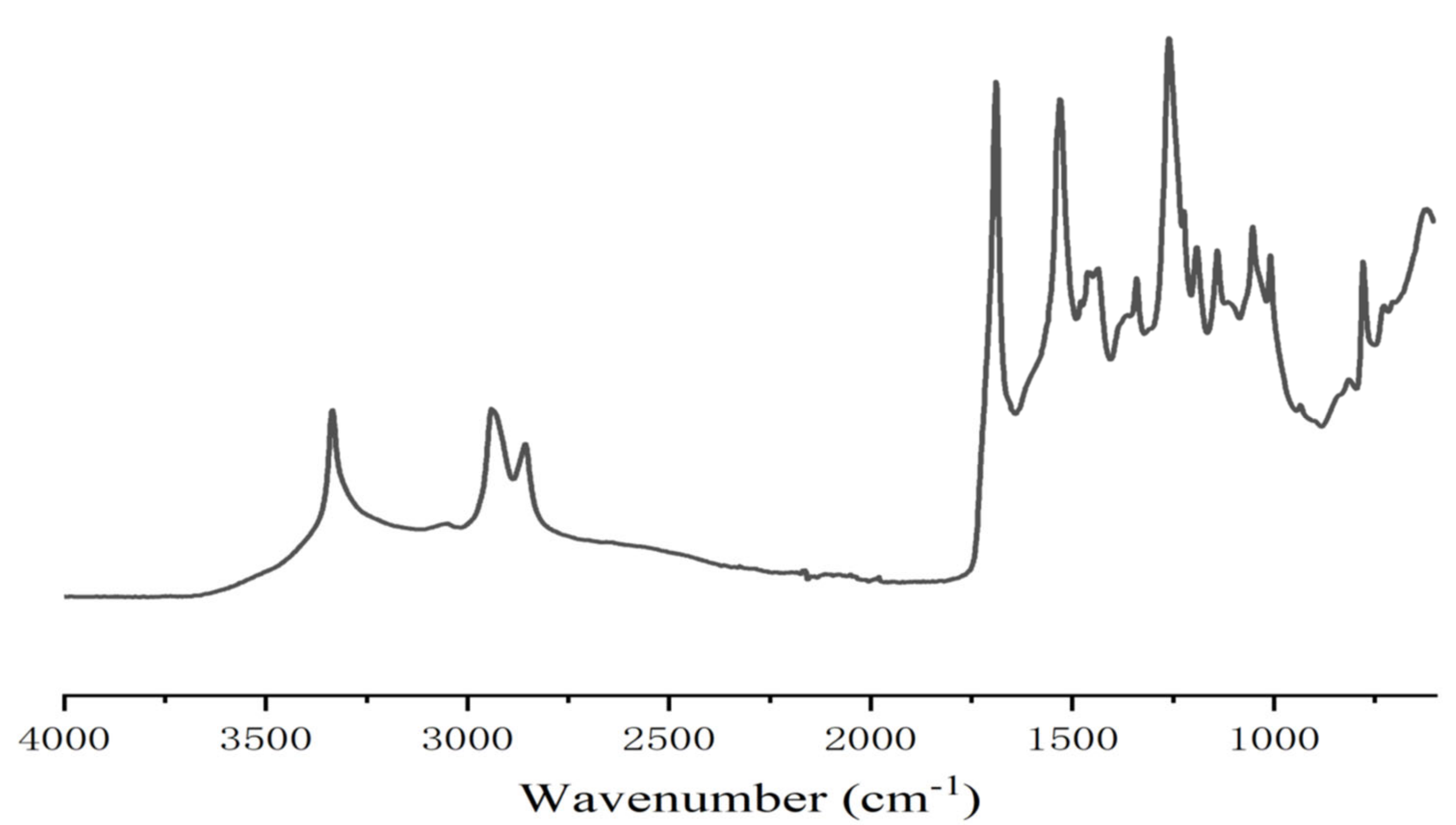

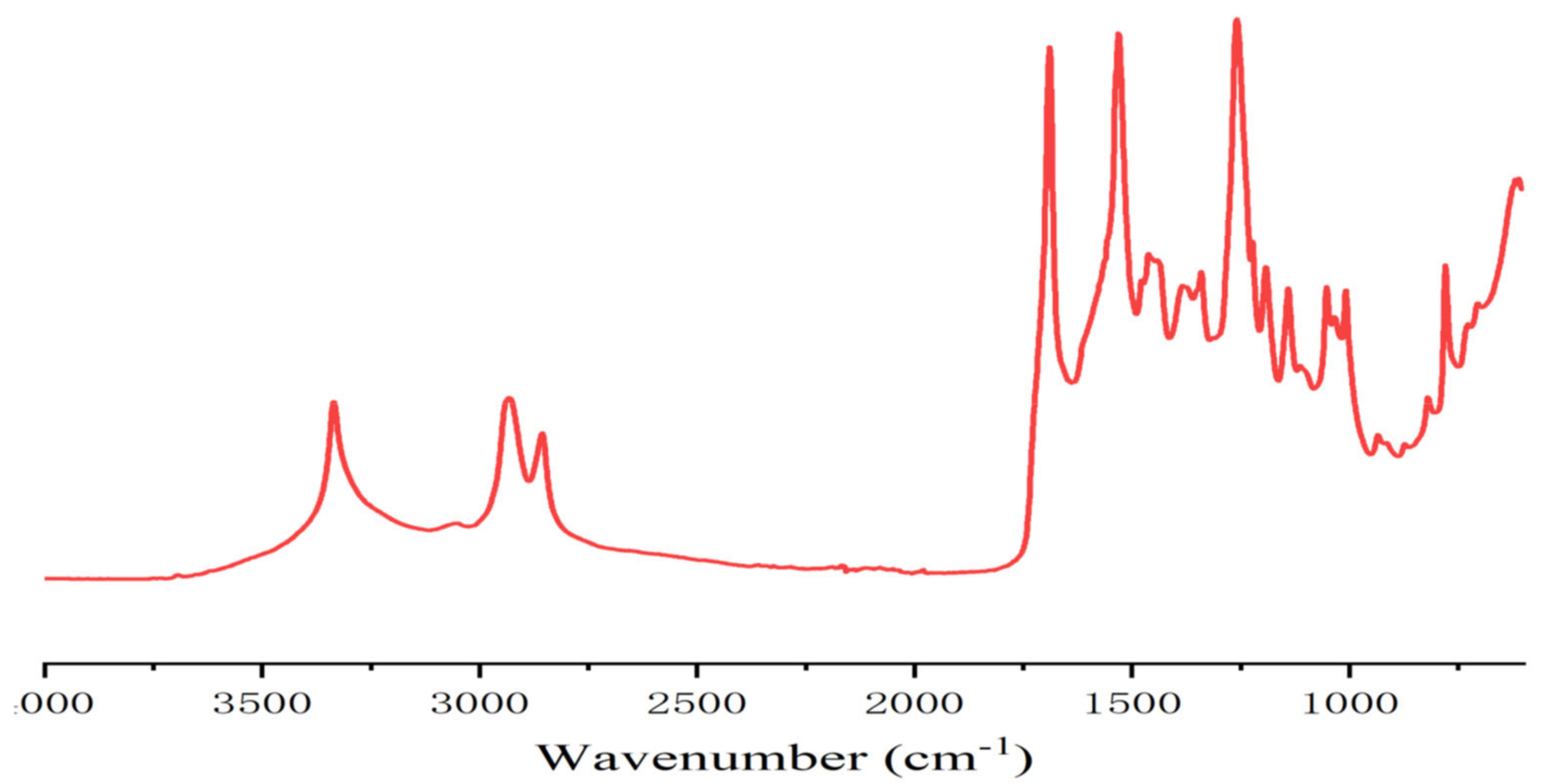

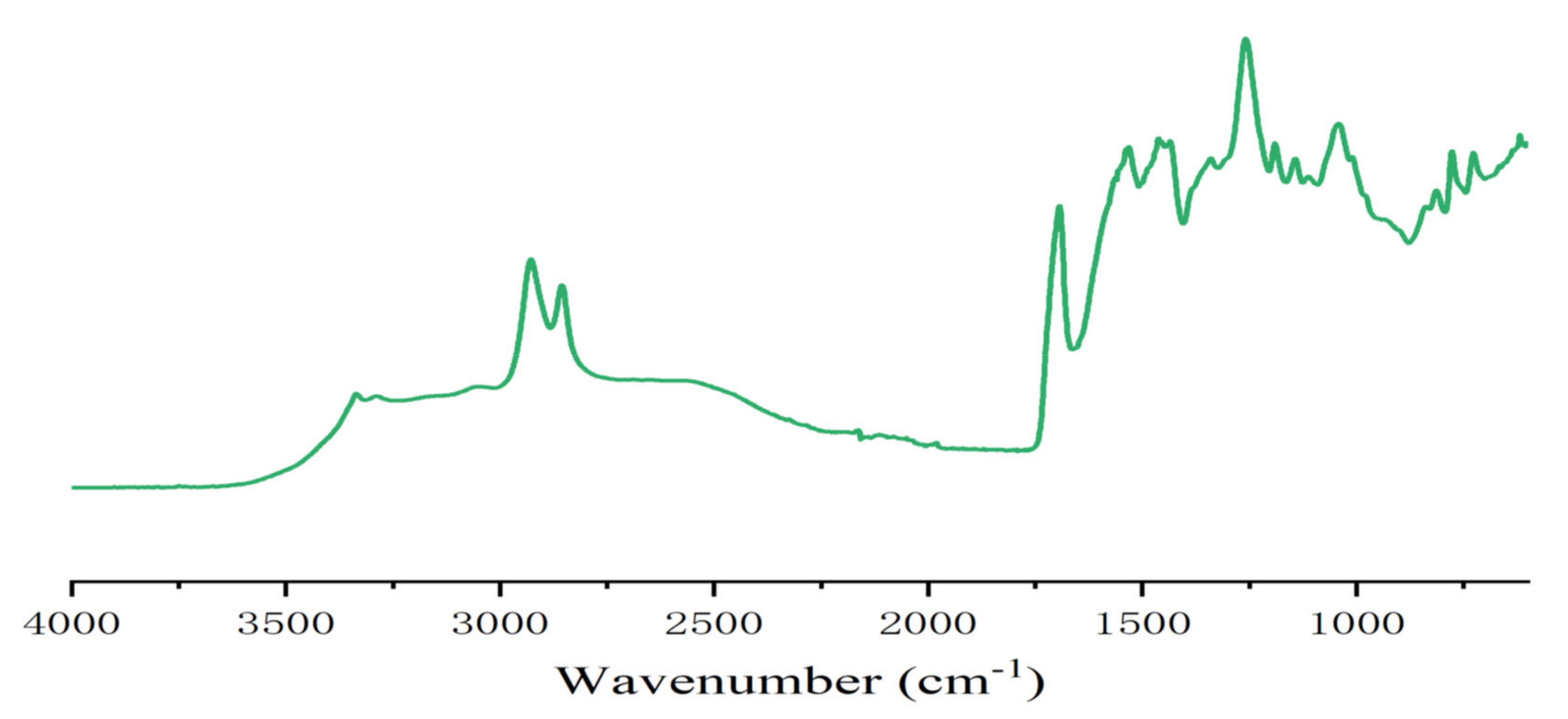

2.3. ATR-FT-MIR Analysis

2.4. Matrix-Assisted Laser Desorption Ionization Time-of-Flight (MALDI-ToF) Spectrometry Analysis

2.5. Thermomechanical Analysis (TMA)

2.6. Wood Particleboard Preparation and Testing

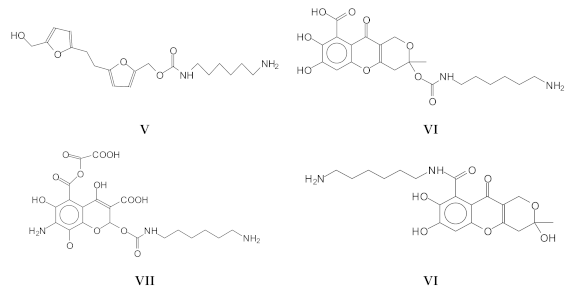

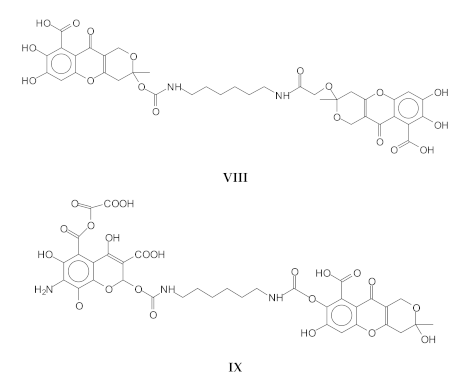

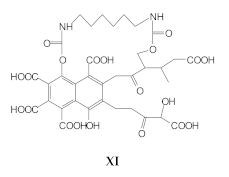

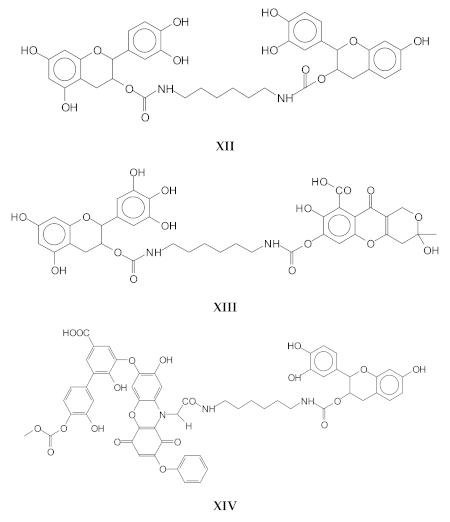

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sangregorio, A.; Guigo, N.; van der Waal, J.C.; Sbirrazzuoli, N. Humins from Biorefineries as Thermoreactive Macromolecular Systems. ChemSusChem 2018, 11, 4246–4255. [Google Scholar] [CrossRef] [PubMed]

- Sangregorio, A. Valorisation of Biorefinery-Derived Humins: Towards the Development of Sustainable Thermosets and Composites. Ph.D. Thesis, Université de la Cote d’Azur, Nice, France, 2019. [Google Scholar]

- van Zandvoort, I.; Wang, Y.; Rasrendra, C.B.; van Eck, E.R.H.; Bruijnincx, P.C.A.; Heeres, H.J.; Weckhuysen, B.M. Formation, Molecular Structure, and Morphology of Humins in Biomass Conversion: Influence of Feedstock and Processing Conditions. ChemSusChem 2013, 6, 1745–1758. [Google Scholar] [CrossRef] [PubMed]

- van Zandvoort, I.; Koers, E.J.; Weingarth, M.; Bruijnincx, P.C.A.; Baldus, M.; Weckhuysen, B.M. Structural characterization of 13C-enriched humins and alkali-treated 13C humins by 2D solid-state NMR. Green Chem. 2015, 17, 4383–4392. [Google Scholar] [CrossRef] [Green Version]

- Hoang, T.M.C.; van Eck, E.R.H.; Bula, W.P.; Gardeniers, J.G.E.; Lefferts, L.; Seshan, K. Humin based by-products from biomass processing as a potential carbonaceous source for synthesis gas production. Green Chem. 2015, 17, 959–972. [Google Scholar] [CrossRef]

- Sangregorio, A.; Guigo, N.; de Jong, E.; Sbirrazzuoli, N. Kinetics and Chemorheological Analysis of Cross-Linking Reactions in Humins. Polymers 2019, 11, 1804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sangregorio, A.; Muralidhara, A.; Guigo, N.; Marlair, G.; Angelici, C.; Thygesen, L.G.; de Jong, E.; Sbirrazzuoli, N. Humins based resin for wood modification and properties improvement. Green Chem. 2020, 22, 2786–2798. [Google Scholar] [CrossRef] [Green Version]

- Mija, A.C.; de Jong, E.; van der Waal, J.C.; van Klink, G.P.M. Humins-Containing Foam. U.S. Patent No. 10,752,747, 25 August 2020. [Google Scholar]

- Licsandru, E.; Mija, A.C. From biorefinery by-product to bioresins. Thermosets based on humins and epoxidized linseed oil. Cell. Chem. Technol. 2019, 53, 963–969. [Google Scholar] [CrossRef]

- Chen, X.; Guigo, N.; Pizzi, A.; Sbirrazzuoli, N.; Li, B.; Fredon, E.; Gerardin, C. Ambient Temperature Self-Blowing Tannin-Humins Biofoams. Polymers 2020, 12, 2732. [Google Scholar] [CrossRef]

- De Jong, E.; Avantium, Amsterdam, The Netherlands. Private communication, 2020.

- Heltzel, J.; Patil, S.K.R.; Lund, C.R.F.; Schlaf, M.; Zhang, Z.C. (Eds.) “Humin Formation Pathways”. Reaction Pathways and Mechanisms in Thermocatalytic Biomass Conversion II: Homogeneously Catalyzed Transformations, Acrylics from Biomass, Theoretical Aspects, Lignin Valorization and Pyrolysis Pathways, Green Chemistry and Sustainable Technology; Springer: Singapore, 2016; pp. 105–118. ISBN 9789812877697. [Google Scholar] [CrossRef]

- L.Gobbi SRL., Gerhumin. Available online: https://www.lgobbi.it/en/gerhumin-2/ (accessed on 1 June 2020).

- Filiciotto, L.; Balu, A.M.; Romero, A.A.; Rodriguez-Castellon, E.; van der Waal, J.C.; Luque, R. Benign-by-design preparation of humin-based iron oxide catalytic nanocomposites. Green Chem. 2017, 19, 4423–4434. [Google Scholar] [CrossRef] [Green Version]

- Kathalewar, M.S.; Joshi, P.B.; Sabnis, A.S.; Malshe, V.C. Non-isocyanate polyurethanes: From chemistry to applications. RSC Adv. 2013, 3, 4110–4129. [Google Scholar] [CrossRef]

- Poussard, L.; Mariage, J.; Grignard, B.; Detrembleur, C.; Jérôme, C.; Calberg, C.; Heinrichs, B.; De Winter, J.; Gerbaux, P.; Raquez, J.-M.; et al. Non-isocyanate polyurethanes from carbonated soybean oil using monomeric or oligomeric diamines to achieve thermosets or thermoplastics. Macromolecules 2016, 49, 2162–2171. [Google Scholar] [CrossRef]

- Ochiai, B.; Utsuno, T. Non-isocyanate synthesis and application of telechelic polyurethanes via polycondensation of diurethanes obtained from ethylene carbonate and diamines. J. Polym.Sci. Part A Polym. Chem. 2013, 51, 525–533. [Google Scholar] [CrossRef]

- Figovsky, O.; Shapovalov, L.; Leykin, A.; Birukova, O.; Potashnikova, R. Recent advances in the development of non-isocyanate polyurethanes based on cyclic carbonates. PU Mag. 2013, 10, 1–9. [Google Scholar]

- Rokicki, G.; Parzuchowski, P.G.; Mazurek, M. Non-isocyanate polyurethanes: Synthesis, properties, and applications. Polym. Advan. Technol. 2015, 26, 707–761. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Ameer, S.T.; Zahoor, F. Bio-based polyurethane: An efficient and environment friendly coating systems: A review. Prog. Org. Coat. 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Birukov, O.; Potashnikova, R.; Leykin, A.; Figovsky, O.; Shapovalov, L. Advantages in chemistry and technology of non-isocyanate polyurethane. J. Sci. Israel-Technol. Advan. 2014, 16, 92–102. [Google Scholar]

- Kathalewar, M.; Sabnis, A.; Waghoo, G. Effect of incorporation of surface treated zinc oxide on non-isocyanate polyurethane based nano-composite coatings. Prog.Org.Coat. 2013, 76, 1215–1229. [Google Scholar] [CrossRef]

- Grignard, B.; Thomassin, J.M.; Gennen, S.; Poussard, L.; Bonnaud, L.; Raquez, J.-M.; Dubois, P.; Tran, M.-P.; Park, C.B.; Jerome, C.; et al. CO2-blown microcellular non-isocyanate polyurethane (NIPU) foams: From bio-and CO2-sourced monomers to potentially thermal insulating materials. Green Chem. 2016, 18, 2206–2215. [Google Scholar] [CrossRef]

- Cornille, A.; Guillet, C.; Benyahya, S.; Negrell, C.; Boutevin, B.; Caillol, S. Room temperature flexible isocyanate-free polyurethane foams. Eur. Polym. J. 2016, 84, 873–888. [Google Scholar] [CrossRef]

- Thébault, M.; Pizzi, A.; Dumarçay, S.; Gerardin, P.; Fredon, E.; Delmotte, L. Polyurethanes from hydrolysable tannins obtained without using isocyanates. Ind. Crop. Prod. 2014, 59, 329–336. [Google Scholar] [CrossRef]

- Thébault, M.; Pizzi, A.; Essawy, H.A.; Barhoum, A.; Van Assche, G. Isocyanate free condensed tannin-based polyurethanes. Eur. Polym. J. 2015, 67, 513–526. [Google Scholar] [CrossRef]

- Thébault, M.; Pizzi, A.; Santiago-Medina, F.J.; Al-Marzouki, F.M.; Abdalla, S. Isocyanate-free polyurethanes by coreaction of condensed tannins with aminated tannins. J. Renew. Mater. 2017, 5, 21–29. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Gerardin, C.; Du, G. Glucose-biobased Non-Isocyanate Polyurethane Rigid Foams. J. Renew. Mater. 2018, 7, 301–312. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Pizzi, A.; Gerardin, C.; Lei, H.; Chen, X.; Amirou, S. Preparation and evaluation of Glucose based Non-Isocyanate polyurethane Self-blowing Rigid Foams. Polymers 2019, 11, 1802. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Li, J.; Xi, X.; Pizzi, A.; Zhou, X.; Fredon, E.; Du, G.; Gerardin, C. Condensed Glucose-Tannin-based NIPU BioFoams of Improved Fire Retardancy. Polym. Degrad. Stabil. 2020, 175, 109121. [Google Scholar] [CrossRef]

- Chen, X.; Xi, X.; Pizzi, A.; Fredon, E.; Zhou, X.; Li, J.; Gerardin, C.; Du, G. Preparation and Characterization of Condensed Tannin Non-Isocyanate Polyurethane (NIPU) Rigid Foams by Ambient Temperature Blowing. Polymers 2020, 12, 750. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Pizzi, A.; Delmotte, L. Isocyanate-Free Polyurethane Coatings and Adhesives from Mono-and Di-Saccharides. Polymers 2018, 10, 402. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.; Wu, Z.; Pizzi, A.; Gerardin, C.; Lei, H.; Zhang, B.; Du, G. Non-isocyanate polyurethane adhesive from sucrose used for particleboard. Wood Sci. Technol. 2019, 53, 393–405. [Google Scholar] [CrossRef]

- Santiago-Medina, F.J.; Basso, M.C.; Pizzi, A.; Delmotte, L. Polyurethanes from Kraft lignin without using isocyanates. J. Renew. Mater. 2018, 6, 413–425. [Google Scholar] [CrossRef]

- Pizzi, A. Tannin-based Biofoams. J. Renew. Mater. 2019, 7, 477–492. [Google Scholar] [CrossRef] [Green Version]

- European Norm EN 312-2010. In Particleboards-Specifications; European Commission: Bruxelles, Belgium, 2010.

- Pizzi, A.; Garcia, R.; Deglise, X. Thermomechanical analysis of entanglement networks—Correlation of some calculated and experimental parameters. J. Appl. Polym. Sci. 1998, 67, 1673–1678. [Google Scholar] [CrossRef]

- Kamoun, C.; Pizzi, A. Particleboard IB forecast by TMA bending in MUF adhesives curing. Holz Roh Werkst. 2000, 58, 288–289. [Google Scholar] [CrossRef]

- Lecourt, M.; Humphrey, P.; Pizzi, A. Comparison of TMA and ABES as forecasting systems of wood bonding effectiveness. Holz Roh Werkst. 2003, 61, 75–76. [Google Scholar] [CrossRef]

- Garcia, R.; Pizzi, A. Cross-linked and entanglement networks in thermomechanical analysis of polycondensation resins. J. Appl. Polym. Sci. 1998, 70, 1111–1116. [Google Scholar] [CrossRef]

- Kamoun, C.; Pizzi, A.; Garcia, R. The effect of humidity on cross-linked and entanglement networking of formaldehyde-based wood adhesives. Holz Roh Werkst. 1998, 56, 235–243. [Google Scholar] [CrossRef]

- Pizzi, A.; Lu, X.; Garcia, R. Lignocellulosic substrates influence on TTT and CHT curing diagrams of polycondensation resins. J. Appl. Polym. Sci. 1999, 71, 915–925. [Google Scholar] [CrossRef]

| Samples | Density (g/cm3) | Internal Bond (MPa) | Bending Strength (MPa) | Elastic Modulus (MPa) |

|---|---|---|---|---|

| A-220 °C | 0.77 ± 0.03 | 0.70 ± 0.08 | 14.1 ± 1.4 | 6700.8 ± 523.5 |

| B-220 °C | 0.73 ± 0.02 | 0.44 ± 0.04 | 6.4 ± 0.4 | 968.6 ± 34.2 |

| C-220 °C | 0.73 ± 0.01 | 0.65 ± 0.07 | 12.9 ± 2.0 | 4081.5 ± 56.0 |

| D-220 °C | 0.75 ± 0.03 | 0.74 ± 0.01 | 14.4 ± 2.7 | 4805.2 ± 80.7 |

| EN requirements | >0.35 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Pizzi, A.; Essawy, H.; Fredon, E.; Gerardin, C.; Guigo, N.; Sbirrazzuoli, N. Non-Furanic Humins-Based Non-Isocyanate Polyurethane (NIPU) Thermoset Wood Adhesives. Polymers 2021, 13, 372. https://doi.org/10.3390/polym13030372

Chen X, Pizzi A, Essawy H, Fredon E, Gerardin C, Guigo N, Sbirrazzuoli N. Non-Furanic Humins-Based Non-Isocyanate Polyurethane (NIPU) Thermoset Wood Adhesives. Polymers. 2021; 13(3):372. https://doi.org/10.3390/polym13030372

Chicago/Turabian StyleChen, Xinyi, Antonio Pizzi, Hisham Essawy, Emmanuel Fredon, Christine Gerardin, Nathanael Guigo, and Nicolas Sbirrazzuoli. 2021. "Non-Furanic Humins-Based Non-Isocyanate Polyurethane (NIPU) Thermoset Wood Adhesives" Polymers 13, no. 3: 372. https://doi.org/10.3390/polym13030372

APA StyleChen, X., Pizzi, A., Essawy, H., Fredon, E., Gerardin, C., Guigo, N., & Sbirrazzuoli, N. (2021). Non-Furanic Humins-Based Non-Isocyanate Polyurethane (NIPU) Thermoset Wood Adhesives. Polymers, 13(3), 372. https://doi.org/10.3390/polym13030372