Investigation of Fire Protection Performance and Mechanical Properties of Thin-Ply Bio-Epoxy Composites

Abstract

:1. Introduction

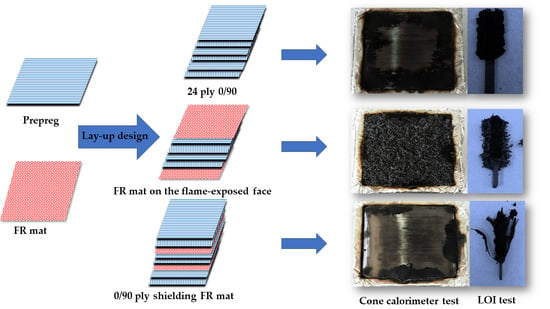

2. Materials and Methods

3. Results and Discussion

3.1. Morphology

3.2. LOI and Vertical Burning Test

3.3. Cone Calorimeter Tests

3.4. Thermal Degradation Test

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mangalgiri, P.D. Aeronautical Development. Composite Materials for Aerospace Applications. Bull. Mater. Sci. 1999, 22, 657–664. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.Q.; Zhang, J.W. High-Performance Biobased Epoxy Derived from Rosin. Polym. Int. 2010, 59, 607–609. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Li, H.; Sun, X.Y. Micromechanical Analysis of the Fibre-Reinforced-Epoxy Composites with Nanoparticles Embedded in the Interphase Region under Transverse Compression. Adv. Compos. Lett. 2018, 27, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.F.; Yu, J.; Liu, Y.P.; Chen, Y.; Wang, C.P.; Tang, C.B. Synthesis and Characterization of a Novel Rosin-Based Monomer: Free-Radical Polymerization and Epoxy Curing. Green Mater. 2012, 1, 105–113. [Google Scholar] [CrossRef]

- Liu, X.Q.; Xin, W.B.; Zhang, J.W. Rosin-Based Acid Anhydrides as Alternatives to Petrochemical Curing Agents. Green Chem. 2009, 11, 1018–1025. [Google Scholar] [CrossRef]

- Liu, X.Q.; Huang, W.; Jiang, Y.H.; Zhu, J.; Zhang, C.Z. Preparation of a Bio-Based Epoxy with Comparable Properties to Those of Petroleum-Based Counterparts. Express Polym. Lett. 2012, 6, 293–298. [Google Scholar] [CrossRef]

- Wang, H.H.; Wang, H.W.; Zhou, G.Y. Synthesis of Rosin-Based Imidoamine-Type Curing Agents and Curing Behavior with Epoxy Resin. Polym. Int. 2011, 60, 557–563. [Google Scholar] [CrossRef]

- Bhaskar, B.; Kandola, B.K. The Effect of Chemically Reactive Type Flame Retardant Additives on Flammability of PES Toughened Epoxy Resin and Carbon Fiber-Reinforced Composites. Polym. Adv. Technol. 2011, 22, 1192–1204. [Google Scholar]

- Liu, Y.; Kong, Q.H.; Zhao, X.M.; Zhu, P.; Zhao, J.Q.; Esteban-Cubillo, A.; Santarén, J.; Wang, D.Y. Effect of Fe3O4-doped Sepiolite of the Flammability and Thermal Degradation Properties of Epoxy Composites. Polym. Adv. Technol. 2017, 28, 971–978. [Google Scholar] [CrossRef] [Green Version]

- Xu, K.; Cai, H.L.; Su, J.X.; Liu, X.; Fu, Z.E.; Chen, M.C. Thermal Properties and Flame Retardancy of Novel Epoxy Based on Phosphorus-Modified Schiff-Base. Polym. Adv. Technol. 2012, 23, 114–121. [Google Scholar]

- Wang, J.S.; Wang, D.Y.; Liu, Y.; Ge, X.G. Polyamide-Enhanced Flame Retardancy of Ammonium Polyphosphate on Epoxy Resin. J. Appl. Polym. Sci. 2008, 108, 3644–3653. [Google Scholar] [CrossRef]

- Murariu, M.; Dechief, A.L.; Bonnaud, L.; Paint, Y.; Gallos, A.; Fontaine, G.; Bourbigot, S.; Dubois, P. The Production and Properties of Polylactide Composites Filled with Expanded Graphite. Polym. Degrad. Stab. 2010, 95, 889–900. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, Y.; Song, L.; Ni, J.X.; Xing, W.Y.; Wang, J. Effect of Expanded Graphite on Properties of High-Density Polyethylene/Paraffin Composite with Intumescent Flame Retardant as a Shape-Stabilized Phase Change Material. Sol. Energy Mater. Sol. Cells 2010, 94, 360–365. [Google Scholar] [CrossRef]

- Chiang, C.-L.; Hsu, S.-W. Novel Epoxy/Expandable Graphite Halogen-Free Flame Retardant Composites-Preparation, Characterization, and Properties. J. Polym. Res. 2010, 17, 315–323. [Google Scholar] [CrossRef]

- Laachachi, A.; Burger, N.; Apaydin, K.; Sonnier, R.; Ferriol, M. Is Expanded Graphite Acting as Flame Retardant in Epoxy Resin. Polym. Degrad. Stab. 2015, 117, 22–29. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Huo, S.; Wang, M.; Wang, J.; Zhang, B. Synergistic Flame-Retardant Effect of Expandable Graphite and Phosphorus-Containing Compounds for Epoxy Resin: Strong Bonding of Different Carbon Residues. Polym. Degrad. Stab. 2016, 128, 89–98. [Google Scholar] [CrossRef]

- He, D.; Zhao, C.; Gou, H.; Li, Y.; Xiang, D. Flame Retardancy and Toughening Properties of Epoxy Composites Containing Ammonium Polyphosphate Microcapsules and Expanded Graphite. High Perform. Polym. 2018, 30, 1247–1259. [Google Scholar] [CrossRef]

- Khalili, P.; Tshai, K.Y.; Kong, I. Natural fiber reinforced expandable graphite filled composites: Evaluation of the flame retardancy, thermal and mechanical performances. Compos. Part A Appl. Sci. Manuf. 2017, 100, 194–205. [Google Scholar] [CrossRef]

- Li, J.; Zhu, C.; Zhao, Z.; Khalili, P.; Clement, M.; Tong, J.; Liu, X.L.; Yi, X.S. Fire Properties of Carbon Fiber Reinforced Polymer Improved by Coating Nonwoven Flame Retardant Mat for Aerospace Application. J. Appl. Polym. Sci. 2019, 136, 1–14. [Google Scholar] [CrossRef]

- Khalili, P.; Blinzler, B.; Kádár, R.; Blomqvist, P.; Sandinge, A.; Bisschop, R.; Liu, X. Ramie fabric Elium® composites with flame retardant coating: Flammability, smoke, viscoelastic and mechanical properties. Compos. Part A 2020, 137, 105968. [Google Scholar] [CrossRef]

- Yi, X.S.; Zhang, X.; Ding, F.; Tong, J. Development of Bio-Sourced Epoxies for Bio-Composites. Aerospace 2018, 5, 65. [Google Scholar] [CrossRef] [Green Version]

- Gogoi, P.; Boruah, M.; Bora, C.; Dolui, S.K. Jatropha Curcas Oil Based Alkyd/Epoxy Resin/Expanded Graphite (EG) Reinforced Bio-Composite: Evaluation of the Thermal, Mechanical and Flame Retardancy Properties. Prog. Org. Coat. 2014, 77, 87–93. [Google Scholar] [CrossRef]

- Sacristán, M.; Hull, T.R.; Stec, A.A.; Ronda, J.C.; Galià, M.; Cádiz, V. Cone Calorimetry Studies of Fire Retardant Soybean-Oil-Based Copolymers Containing Silicon or Boron: Comparison of Additive and Reactive Approaches. Polym. Degrad. Stab. 2010, 95, 1269–1274. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Liu, X.; An, Z.; Yang, R. EG-based coatings for flame retardance of shape stabilized phase change materials. Polym. Degrad. Stab. 2019, 161, 114–120. [Google Scholar] [CrossRef]

- Guler, T.; Tayfun, U.; Bayramli, E.; Dogan, M. Effect of Expandable Graphite on Flame Retardant, Thermal and Mechanical Properties of Thermoplastic Polyurethane Composites Filled with Huntite & Hydromagnesite Mineral. Thermochim. Acta 2017, 647, 70–80. [Google Scholar]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical Properties of Banana/Kenaf Fiber-Reinforced Hybrid Polyester Composites: Effect of Woven Fabric and Random Orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Visweswaraiah, S.B.; Lessard, L.; Hubert, P. Tensile behaviour of hybrid fibre architectures of randomly oriented strands combined with laminate groups. J. Compos. Mater. 2019, 53, 3725–3740. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Qian, C.; Harper, L.T.; Turner, T.A.; Warrior, N.A. Notched behaviour of discontinuous carbon fibre composites: Comparison with quasi-isotropic non-crimp fabric. Compos. Part A Appl. Sci. Manuf. 2011, 42, 293–302. [Google Scholar] [CrossRef]

- Feraboli, P.; Cleveland, T.; Ciccu, M.; Stickler, P.; DeOto, L. Defect and damage analysis of advanced discontinuous carbon/epoxy composite materials. Compos. Part A Appl. Sci. Manuf. 2010, 41, 888–901. [Google Scholar] [CrossRef]

- Fadime, K.; Mustaf, E.; Ali, S. Cleaner production of flame-retardant-glass reinforced epoxy resin composite for aviation and reducing smoke toxicity. J. Clean. Prod. 2020, 276, 124025. [Google Scholar]

- Zhu, C.; Li, S.; Li, J.; Clement, M.; Rudd, C.; Yi, X.; Liu, X. Sandwich Structure Composite with Expandable Graphite Filled or Coated: Evaluation of Flame Retardancy and Mechanical Performances. Fire Saf. J. 2020, 116, 103205. [Google Scholar] [CrossRef]

| Product Name | Area Weight (Kg/m3) | Thickness (mm) | Typical Expansion Ration | Composition |

|---|---|---|---|---|

| E20MI | 327 | 0.5 | 20:1 | Mineral wool 20–50 wt.% Chopped glass fibre 4.5–40 wt.% Expanded Graphite 10–40 wt.% Binder 2.5–40 wt.% |

| Sample Code | Laminate 1 | Laminate 2 | Laminate 3 |

|---|---|---|---|

| Resin content (wt.%) | 36.3 | 31.1 | 33.7 |

| Sample Code | LOI (%) | Vertical Burning | ||

|---|---|---|---|---|

| Flame Time(s) | Drip Flame Time(s) | FAR Requirement | ||

| Laminate 1 (Control) | 33.1 | 22 | 0 | Failed |

| Laminate 2 | 47.5 | 0 | 0 | Pass |

| Laminate 3 | 45.8 | 0 | 0 | Pass |

| Sample Code | Laminate 1 (Control) | Laminate 2 | Laminate 3 |

|---|---|---|---|

| TTI (s) | 39 | 47 | 45 |

| PHRR (kW/m2) | 278 | 72 | 109 |

| THR (MJ/m2) | 36 | 30 | 31 |

| FIGRA(kW/m2s) | 3.71 | 0.73 | 0.41 |

| FPI (s m2/KW) | 0.14 | 0.65 | 0.23 |

| TSP (m2) | 13.2 | 3.6 | 5.5 |

| PSPR (m2/s) | 0.11 | 0.02 | 0.03 |

| MARHE (KW/m2) | 143 | 48 | 61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, X.; Khalili, P.; Zhu, C.; Li, S.; Li, J.; Rudd, C.; Liu, X. Investigation of Fire Protection Performance and Mechanical Properties of Thin-Ply Bio-Epoxy Composites. Polymers 2021, 13, 731. https://doi.org/10.3390/polym13050731

Cong X, Khalili P, Zhu C, Li S, Li J, Rudd C, Liu X. Investigation of Fire Protection Performance and Mechanical Properties of Thin-Ply Bio-Epoxy Composites. Polymers. 2021; 13(5):731. https://doi.org/10.3390/polym13050731

Chicago/Turabian StyleCong, Xiaoye, Pooria Khalili, Chenkai Zhu, Saihua Li, Jingjing Li, Chris Rudd, and Xiaoling Liu. 2021. "Investigation of Fire Protection Performance and Mechanical Properties of Thin-Ply Bio-Epoxy Composites" Polymers 13, no. 5: 731. https://doi.org/10.3390/polym13050731

APA StyleCong, X., Khalili, P., Zhu, C., Li, S., Li, J., Rudd, C., & Liu, X. (2021). Investigation of Fire Protection Performance and Mechanical Properties of Thin-Ply Bio-Epoxy Composites. Polymers, 13(5), 731. https://doi.org/10.3390/polym13050731