Volume Resistivity of Viton Polymer under Thermal Aging

Abstract

:1. Introduction

2. Background

3. Experimental Process

3.1. Materials

3.2. Test Apparatus

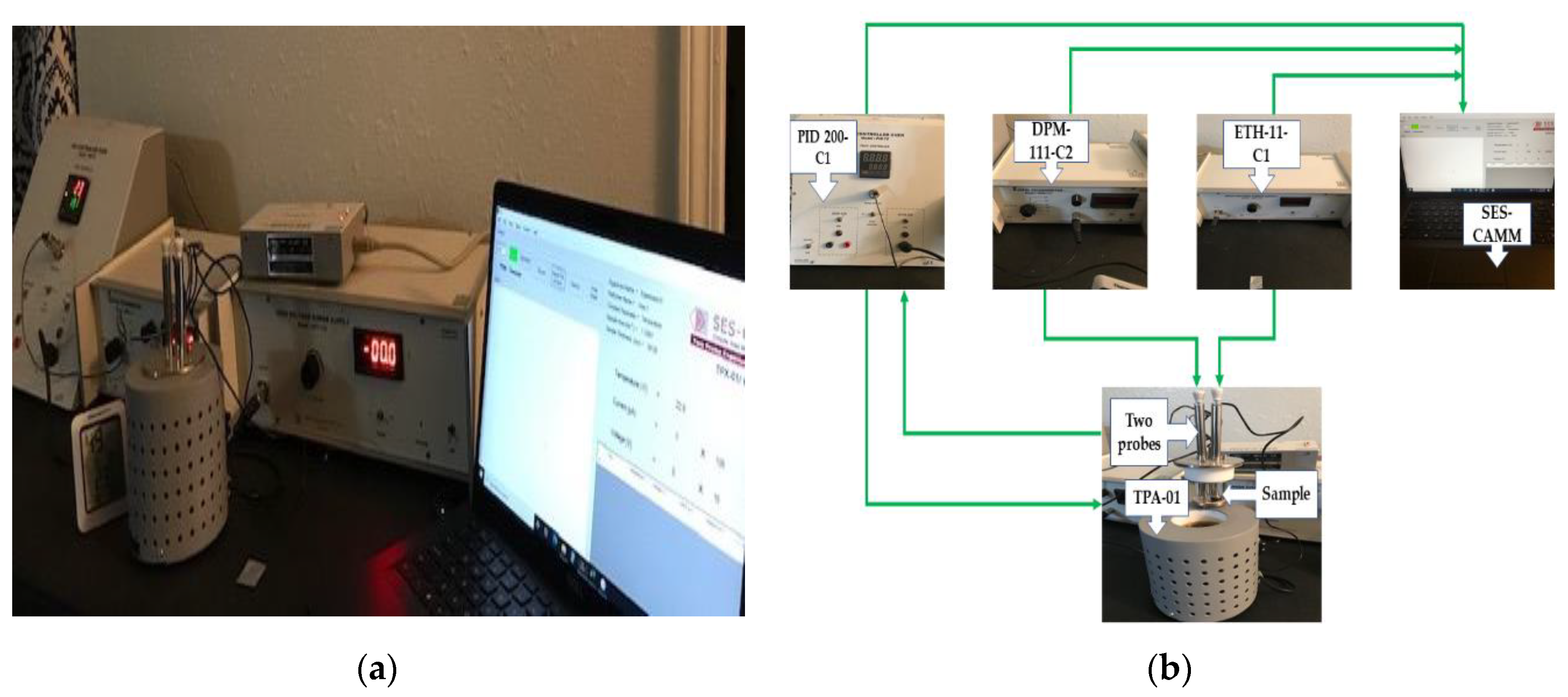

3.2.1. Two-Probe Method (TPX-200 C)

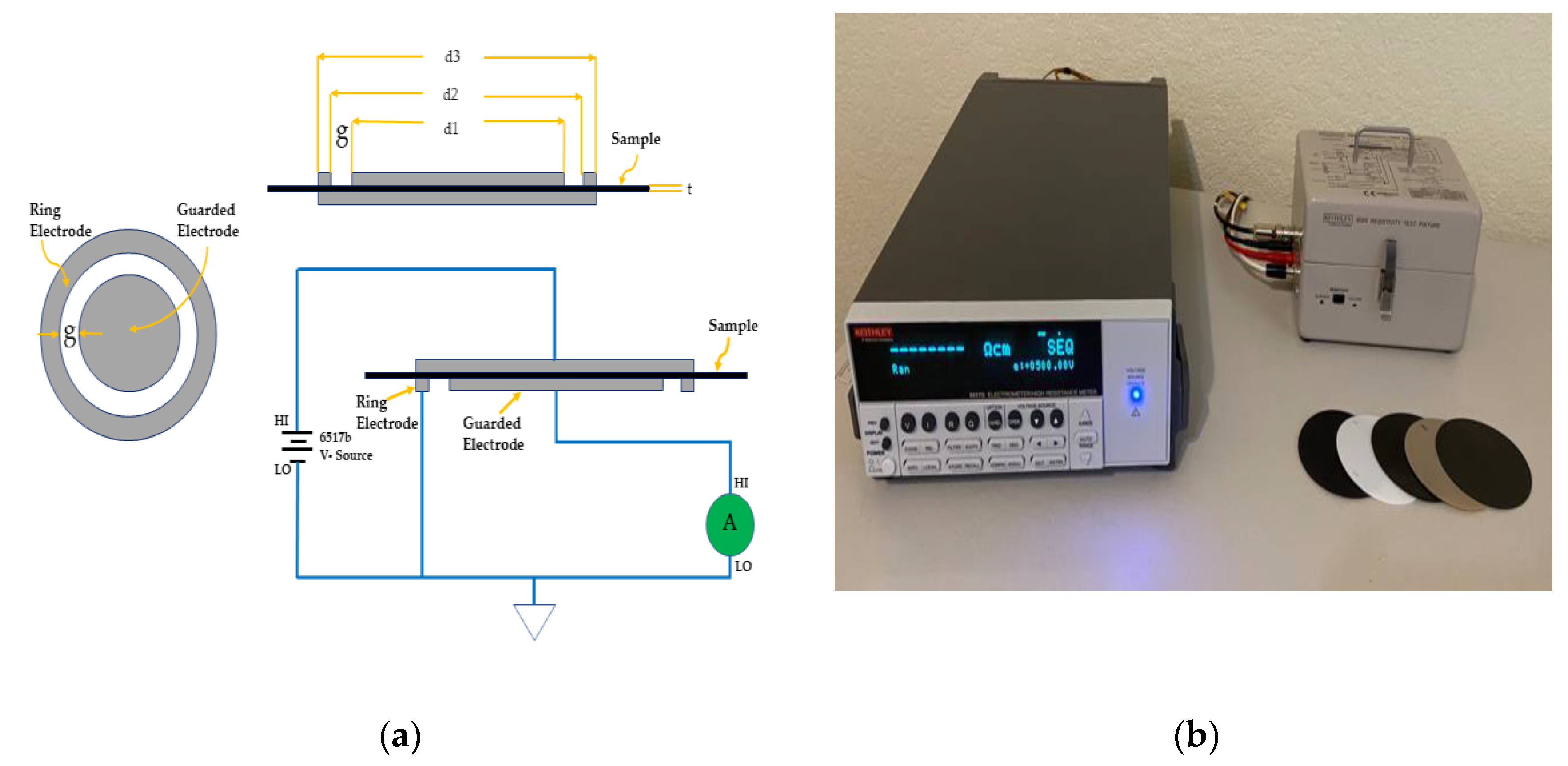

3.2.2. Alternating Polarity Method (Keithley 6517b + 8009)

3.3. Scanning Electron Microscopy (SEM)

3.4. Aging Process

3.5. Resistivity Measurement

- Cleaning the electrodes and samples with alcohol wipes frequently to avoid any contamination.

- Each sample rested for at least 48 h after each test before being tested again in order to remove any stored charge inside the sample. This is due to the fact the insulating materials behave similarly to the capacitors and store charges inside them. To have an accurate measurement, any charge history needs to be removed.

- Right before applying the voltage, any current reading was zeroed to prevent an inaccurate measurement. Especially for measurements at high temperatures, this is necessary since the temperature variation by itself creates a current inside the specimen.

- Sixty seconds of electrification as suggested by ASTM D257 [55].

- Readings were recorded 60 s after applying the voltage to the specimen.

- Cleaning the electrodes and samples with an alcohol wipe frequently to avoid any contamination.

- Similar to the two-probe method, each sample rested for at least 48 h after each test in order to be tested again to remove any stored charge inside the sample.

- Each alternation lasted for 60 s.

- At least 10 alterations were performed to stabilize the reading.

- For the alternating polarity test, there were four alternations before the first reading to calculate the average current.

4. Results and Discussion

4.1. The Transient Effect

4.2. Temperature Dependence of Volume Resistivity

4.3. Voltage Dependence of Resistivity

4.4. Surface Morphology

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saleem, A.; Frormann, L.; Iqbal, A. High Performance Thermoplastic Composites: Study on the Mechanical, Thermal, and Electrical Resistivity Properties of Carbon Fiber-Reinforced Polyetheretherketone and Polyethersulphone. Polym. Compos. 2007, 28, 785–796. [Google Scholar] [CrossRef]

- Abdelkarim, M.F.; Nasrat, L.S.; Elkhodary, S.M.; Soliman, A.M.; Hassan, A.M.; Mansour, S.H. Volume Resistivity and Mechanical Behavior of Epoxy Nanocomposite Materials. Eng. Technol. Appl. Sci. Res. 2015, 5, 775–780. [Google Scholar] [CrossRef]

- Fan, X.; Lin, L.; Messersmith, P.B. Surface-Initiated Polymerization from TiO2 Nanoparticle Surfaces through a Biomimetic Initiator: A New Route toward Polymer–Matrix Nanocomposites. Compos. Sci. Technol. 2006, 66, 1198–1204. [Google Scholar] [CrossRef]

- Nicodemo, L.; Nicolais, L.; Romeo, G.; Scafora, E. Temperature Effect on the Electrical Resistivity of Metal/Polymer Composites. Polym. Eng. Sci. 1978, 18, 293–298. [Google Scholar] [CrossRef]

- Srinivas, K.; Bhagyashekar, M.S.; Darshan, B.G. Effect of Fillers on Electrical Conductivity of Epoxy Composites. J. Polym. Compos. 2018, 6, 25–30. [Google Scholar]

- Dal Lago, E.; Cagnin, E.; Boaretti, C.; Roso, M.; Lorenzetti, A.; Modesti, M. Influence of Different Carbon-Based Fillers on Electrical and Mechanical Properties of a PC/ABS Blend. Polymers 2020, 12, 29. [Google Scholar] [CrossRef] [Green Version]

- Warfield, R.W.; Petree, M.C. Electrical Resistivity of Polymers. Polym. Eng. Sci. 1961, 1, 80–85. [Google Scholar] [CrossRef]

- Blythe, A.R. Electrical Resistivity Measurements of Polymer Materials. Polym. Test. 1984, 4, 195–209. [Google Scholar] [CrossRef]

- Brown, R. Handbook of Polymer Testing: Physical Methods; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Shah, V. Handbook of Plastics Testing and Failure Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 21. [Google Scholar]

- Dabbak, S.; Illias, H.; Chin, A.B.; Tunio, M.A. Surface Discharge Characteristics on HDPE, LDPE and PP. Available online: https://www.scientific.net/AMM.785.383 (accessed on 25 September 2020).

- Mali, A.D.; Shimpi, N.G.; Mishra, S. Thermal, Mechanical and Morphological Properties of Surface-Modified Montmorillonite-Reinforced Viton Rubber Nanocomposites. Polym. Int. 2014, 63, 338–346. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Luo, Y.; Jia, D. Aging Behavior and Thermal Degradation of Fluoroelastomer Reactive Blends with Poly-Phenol Hydroxy EPDM. Polym. Degrad. Stab. 2009, 94, 443–449. [Google Scholar] [CrossRef]

- Wu, J. VITON Fuser Member Containing Fluorinated Nano Diamonds. U.S. Patent 8,192,817, 5 June 2012. [Google Scholar]

- Zhong, A. Challenges for High-Pressure High-Temperature Applications of Rubber Materials in the Oil and Gas Industry. In Proceedings of the Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems, 2016; Bossuyt, S., Schajer, G., Carpinteri, A., Eds.; Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Cham, Switzerland, 2016; Volume 9, pp. 65–79. [Google Scholar]

- Yazdan, M.M.S.; Ahad, M.T.; Jahan, I.; Mazumder, M. Review on the Evaluation of the Impacts of Wastewater Disposal in Hydraulic Fracturing Industry in the United States. Technologies 2020, 8, 67. [Google Scholar] [CrossRef]

- Wang, H.; Rehwoldt, M.; Kline, D.J.; Wu, T.; Wang, P.; Zachariah, M.R. Comparison Study of the Ignition and Combustion Characteristics of Directly-Written Al/PVDF, Al/Viton and Al/THV Composites. Combust. Flame 2019, 201, 181–186. [Google Scholar] [CrossRef]

- De Barros, L.; Pinheiro, A.P.M.; Câmara, J.D.E.; Iha, K. Qualification of Magnesium/Teflon/Viton Pyrotechnic Composition Used in Rocket Motors Ignition System. J. Aerosp. Technol. Manag. 2016, 8, 130–136. [Google Scholar] [CrossRef]

- Rakowska, A.; Hajdrowski, K. Influence of Different Test Conditions on Volume Resistivity of Polymeric Insulated Cables and Polyethylene Samples. In Proceedings of the 2000 Eighth International Conference on Dielectric Materials, Measurements and Applications, Edinburgh, UK, 17–21 September 2000; pp. 281–284. [Google Scholar]

- Wang, Y.; Wang, C.; Zhang, Z.; Xiao, K. Effect of Nanoparticles on the Morphology, Thermal, and Electrical Properties of Low-Density Polyethylene after Thermal Aging. Nanomaterials 2017, 7, 320. [Google Scholar] [CrossRef] [PubMed]

- Han, B.; Yin, C.; Chang, J.; Pang, Y.; Lv, P.; Song, W.; Wang, X. Study on the Structure and Dielectric Properties of Zeolite/LDPE Nanocomposite under Thermal Aging. Polymers 2020, 12, 2108. [Google Scholar] [CrossRef] [PubMed]

- Shimada, A.; Sugimoto, M.; Kudoh, H.; Tamura, K.; Seguchi, T. Degradation Distribution in Insulation Materials of Cables by Accelerated Thermal and Radiation Ageing. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2107–2116. [Google Scholar] [CrossRef]

- Daire, A. Improving the Repeatability of Ultra-High Resistance and Resistivity Measurements. Keithley White Pap. 2004, 4645. [Google Scholar]

- Dennison, J.R.; Brunson, J.; Swaminathan, P.; Green, N.W.; Frederickson, A.R. Methods for High Resistivity Measurements Related to Spacecraft-Charging. IEEE Trans. Plasma Sci. 2006, 34, 2191–2203. [Google Scholar] [CrossRef]

- Elastomers, D.P. Perfluoroelastomer and Fluoroelastomer Seals for Photovoltaic Cell Manufacturing Processes. Intersol. SMET May. 2009. [Google Scholar]

- Fluorocarbon (Viton® FKM)|Eastern Seals (UK) Ltd. Available online: https://www.easternseals.co.uk/materials/viton-fkm-fpm-fluorocarbon/ (accessed on 23 September 2020).

- Evans, K.M.; Hardy, J.K. Predicting Solubility and Permeation Properties of Organic Solvents in Viton Glove Material Using Hansen’s Solubility Parameters. J. Appl. Polym. Sci. 2004, 93, 2688–2698. [Google Scholar] [CrossRef]

- Ol’khov, Y.A.; Allayarov, S.R.; Allayarova, U.Y.; Dixon, D.A. Effect of γ-Irradiation on the Molecular-Topological Structure of Viton® Fluoroelastomers. High Energy Chem. 2016, 50, 101–108. [Google Scholar] [CrossRef]

- Knox, R.E.; Nersasian, A. VITON®: A High Performance Fluorocarbon Elastomer for Use in Hostile Environments; SAE Technical Paper; SAE: Warrendale, PA, USA, 1977. [Google Scholar]

- Non-Asbestos Gasket Material. Available online: https://www.gasketing.net/viton.php (accessed on 21 September 2020).

- JPA Density of Solid Materials, Mechanical Reviews. Available online: http://www.jaredzone.info/2010/09/densities.html (accessed on 23 September 2020).

- Aflas® vs. Viton®—What Is the Difference?|Polymax Blog. Available online: https://www.polymax.co.uk/blog/aflas-vs-viton/ (accessed on 21 September 2020).

- Dabbak, S.Z.A.; Illias, H.A.; Ang, B.C.; Latiff, N.A.A.; Makmud, M.Z.H. Electrical Properties of Polyethylene/Polypropylene Compounds for High-Voltage Insulation. Energies 2018, 11, 1448. [Google Scholar] [CrossRef] [Green Version]

- Mohiuddin, M.; Van Hoa, S. Electrical Resistance of CNT-PEEK Composites under Compression at Different Temperatures. Nanoscale Res. Lett. 2011, 6, 419. [Google Scholar] [CrossRef] [Green Version]

- Kato, S.; Yusof, F.A.A.; Harimoto, T.; Takada, K.; Kaneko, T.; Kawai, M.; Mitsumata, T. Electric Volume Resistivity for Biopolyimide Using 4,4′-Diamino-α-Truxillic Acid and 1,2,3,4-Cyclobutanetetracarboxylic Dianhydride. Polymers 2019, 11, 1552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Omastová, M.; Podhradská, S.; Prokeš, J.; Janigová, I.; Stejskal, J. Thermal Ageing of Conducting Polymeric Composites. Polym. Degrad. Stab. 2003, 82, 251–256. [Google Scholar] [CrossRef]

- Sugimoto, M.; Shimada, A.; Kudoh, H.; Tamura, K.; Seguchi, T. Product Analysis for Polyethylene Degradation by Radiation and Thermal Ageing. Radiat. Phys. Chem. 2013, 82, 69–73. [Google Scholar] [CrossRef]

- Bouguedad, D.; Jbara, O.; Rondot, S.; Mekhaldi, A.; Hadjadj, A. Investigation of Accelerated Thermal Aging of EPDM Polymer by Electric Tests in Air and by Means of a SEM Technique in High Vacuum. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 981–989. [Google Scholar] [CrossRef]

- Bhutta, M.S.; Akram, S.; Meng, P.; Castellon, J.; Agnel, S.; Li, H.; Guo, Y.; Rasool, G.; Hussain, S.; Nazir, M.T. Steady-State Conduction Current Performance for Multilayer Polyimide/SiO2 Films. Polymers 2021, 13, 640. [Google Scholar] [CrossRef]

- Akram, S.; Castellon, J.; Agnel, S.; Habas, J.; Kai, Z.; Nazir, M.T. Impact of Nanocomposite Thin Layer on Nanoparticles Dispersion and Their Dielectric Properties. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Richland, DC, USA, 20–23 October 2019; pp. 336–339. [Google Scholar]

- Maryniak, W.A.; Uehara, T.; Noras, M.A. Surface Resistivity and Surface Resistance Measurements Using a Concentric Ring Probe Technique. Trek Appl. Note 2003, 1005, 1–4. [Google Scholar]

- Orlova, T.S.; Popov, V.V.; Cancapa, J.Q.; Maldonado, D.H.; Magarino, E.E.; Feria, F.V.; de Arellano, A.R.; Fernández, J.M. Electrical Properties of Biomorphic SiC Ceramics and SiC/Si Composites Fabricated from Medium Density Fiberboard. J. Eur. Ceram. Soc. 2011, 31, 1317–1323. [Google Scholar] [CrossRef] [Green Version]

- Lukianova, O.A.; Khmara, A.N.; Perevislov, S.N.; Kolesnikov, D.A.; Krasilnikov, V.V. Electrical Resistivity of Silicon Nitride Produced by Various Methods. Ceram. Int. 2019, 45, 9497–9501. [Google Scholar] [CrossRef]

- Naik, J.B.; Mishra, S. Studies on Electrical Properties of Natural Fiber: HDPE Composites. Polym. Plast. Technol. Eng. 2005, 44, 687–693. [Google Scholar] [CrossRef]

- Levy, L.; Sarrail, D.; Siguier, J.M. Conductivity and Secondary Emission Properties of Dielectrics as Required by NASCAP(Spacecraft Charging). Proc. 3rd Eur. Symp. Spacecr. Mater. Space Environ. 1985, 1985, 113–123. [Google Scholar]

- Romero, M.; Levy, L. Internal charging and secondary effects. In The Behavior of Systems in the Space Environment; Springer: Berlin/Heidelberg, Germany, 1993; pp. 565–580. [Google Scholar]

- Green, N.W.; Frederickson, A.R.; Dennison, J.R. Charge Storage Measuremens of Resistivity for Dielectric Samples from the CRRES Internal Discharge Monitor. In Proceedings of the 9th Spacecraft Charging Technology Conference, Tsukuba, Japan, 4–8 April 2005. [Google Scholar]

- Frederickson, A.R.; Dennison, J.R. Measurement of Conductivity and Charge Storage in Insulators Related to Spacecraft Charging. IEEE Trans. Nucl. Sci. 2003, 50, 2284–2291. [Google Scholar] [CrossRef]

- de Souza, F.G., Jr.; Soares, B.G.; Pinto, J.C. Electrical Surface Resistivity of Conductive Polymers—A Non-Gaussian Approach for Determination of Confidence Intervals. Eur. Polym. J. 2008, 44, 3908–3914. [Google Scholar] [CrossRef]

- McMaster-Carr. Available online: https://www.mcmaster.com/ (accessed on 20 September 2020).

- SES Electronics Two Probe Method for Resistivity Measurement of Insulators, TPX-200C, for Laboratory Experiment—PDF Catalogue. Available online: https://pdf.indiamart.com/impdf/4850424948/MY-526573/two-probe-method-for-resistivity-measurement-of-insulators-tpx-200c.pdf (accessed on 20 September 2020).

- Bargan, L.; Neacşu, O.; Bicleanu, P.; Beniugă, O.; Nicuţă, A. Electrostatic Charging Control According to Surface Resistivity Based on Alternating Polarity Method. In Proceedings of the International Symposium on Electromagnetic Compatibility-EMC EUROPE, Barcelona, Spain, 2–6 September 2019; IEEE: Piscataway, NJ, USA, 2012; pp. 1–4. [Google Scholar]

- Kempe, M.D.; Miller, D.C.; Nobles, D.L.; Sakurai, K.; Tucker, J.; Bokria, J.G.; Shioda, T.; Nanjundiah, K.; Yoshihara, T.; Birchmier, J.; et al. Development of a Resistivity Standard for Polymeric Materials Used in Photovoltaic Modules. In Proceedings of the Reliability of Photovoltaic Cells, Modules, Components, and Systems VIII, San Diego, CA, USA, 9–10 August 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9563, p. 956302. [Google Scholar]

- 6517B—Source Meter/Unit, Electrometer/High Resistance Meter, 20 MA. Available online: https://www.newark.com/keithley/6517b/electrometer-high-resistance-meter/dp/56P3700 (accessed on 20 September 2020).

- D257-14, A. Standard Test Methods for DC Resistance or Conductance of Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Next Generation Tabletop Microscope TM3000: Hitachi High-Tech GLOBAL. Available online: https://www.hitachi-hightech.com/global/about/news/2010/nr20100129.html (accessed on 7 October 2020).

- Bel-Art Secador Auto Desiccator Cabinets: Vertical Models—Desiccation and Evaporation, Desiccators. Available online: https://www.fishersci.com/shop/products/bel-art-scienceware-secador-auto-desiccator-cabinets-vertical-models-20/p-4901863 (accessed on 21 September 2020).

- Dow, P.C. An Analysis of Certain Errors in Electronic Differential Analyzers II-Capacitor Dielectric Absorption. IEEE Trans. Electron. Comput. 1958, EC-7, 17–22. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A.; Campus, A.; Nilsson, U.H. Polymeric HVDC Cable Design and Space Charge Accumulation. Part 1: Insulation/Semicon Interface. IEEE Electr. Insul. Mag. 2007, 23, 11–19. [Google Scholar] [CrossRef]

- Delpino, S.; Fabiani, D.; Montanari, G.C.; Laurent, C.; Teyssedre, G.; Morshuis, P.H.F.; Bodega, R.; Dissado, L.A. Polymeric HVDC Cable Design and Space Charge Accumulation. Part 2: Insulation Interfaces. IEEE Electr. Insul. Mag. 2008, 24, 14–24. [Google Scholar] [CrossRef]

- Cole, K.S.; Cole, R.H. Dispersion and Absorption in Dielectrics II. Direct Current Characteristics. J. Chem. Phys. 1942, 10, 98–105. [Google Scholar] [CrossRef]

- Narkis, M.; Vaxman, A. Resistivity Behavior of Filled Electrically Conductive Crosslinked Polyethylene. J. Appl. Polym. Sci. 1984, 29, 1639–1652. [Google Scholar] [CrossRef]

- Shrout, T.R.; Moffatt, D.; Huebner, W. Composite PTCR Thermistors Utilizing Conducting Borides, Silicides, and Carbide Powders. J. Mater. Sci. 1991, 26, 145–154. [Google Scholar] [CrossRef]

- Gomaa, M.M.; Hugenschmidt, C.; Dickmann, M.; Abdel-Hady, E.E.; Mohamed, H.F.M.; Abdel-Hamed, M.O. Crosslinked PVA/SSA Proton Exchange Membranes: Correlation between Physiochemical Properties and Free Volume Determined by Positron Annihilation Spectroscopy. Phys. Chem. Chem. Phys. 2018, 20, 28287–28299. [Google Scholar] [CrossRef] [PubMed]

- Chekanov, Y.; Ohnogi, R.; Asai, S.; Sumita, M. Positive Temperature Coefficient Effect of Epoxy Resin Filled with Short Carbon Fibers. Polym. J. 1998, 30, 381–387. [Google Scholar] [CrossRef]

- Sakai, J.; Kitagawa, A.; Tamada, T.; Sakai, M.; Hirao, T.; Imai, S. Field Effect in Perovskite-Type Manganite Films on High-T/Sub c/Superconductor. IEEE Trans. Appl. Supercond. 2001, 11, 248–251. [Google Scholar] [CrossRef]

- Takenaka, K.; Cho, K.; Ohchi, Y.; Otani, H.; Uchida, G.; Setsuhara, Y. Low-Temperature Formation of Amorphous InGaZnOx Films with Inductively Coupled Plasma-Enhanced Reactive Sputter Deposition. Jpn. J. Appl. Phys. 2015, 54, 06GC02. [Google Scholar] [CrossRef]

- Vlastos, A.E.; Gubanski, S.M. Surface Structural Changes of Naturally Aged Silicone and EPDM Composite Insulators. IEEE Trans. Power Deliv. 1991, 6, 888–900. [Google Scholar] [CrossRef]

- Ghosh, D.; Khastgir, D. Degradation and Stability of Polymeric High-Voltage Insulators and Prediction of Their Service Life through Environmental and Accelerated Aging Processes. ACS Omega 2018, 3, 11317–11330. [Google Scholar] [CrossRef] [PubMed]

| Material | Thickness (mm) | Area (mm2) | Setup | Sample Size |

|---|---|---|---|---|

| Viton (McMaster-Carr) | Thin (0.7493 ± 0.0127) | 113.097 | (TPX 200C) |  |

| Thick (1.47066 ± 0.0127) | 147.3 | (Keithley 6517b + 8009) |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdihamzehkolaei, A.; Ahad, M.T.; Siddique, Z. Volume Resistivity of Viton Polymer under Thermal Aging. Polymers 2021, 13, 773. https://doi.org/10.3390/polym13050773

Abdihamzehkolaei A, Ahad MT, Siddique Z. Volume Resistivity of Viton Polymer under Thermal Aging. Polymers. 2021; 13(5):773. https://doi.org/10.3390/polym13050773

Chicago/Turabian StyleAbdihamzehkolaei, Alireza, Md Tanvir Ahad, and Zahed Siddique. 2021. "Volume Resistivity of Viton Polymer under Thermal Aging" Polymers 13, no. 5: 773. https://doi.org/10.3390/polym13050773

APA StyleAbdihamzehkolaei, A., Ahad, M. T., & Siddique, Z. (2021). Volume Resistivity of Viton Polymer under Thermal Aging. Polymers, 13(5), 773. https://doi.org/10.3390/polym13050773