Phase Equilibria and Interdiffusion in Bimodal High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) Based Compositions

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. HDPE and LLDPE Compatibility Study by DSC

3.2. HDPE and LLDPE Compatibility Study by X-ray Diffraction Analysis

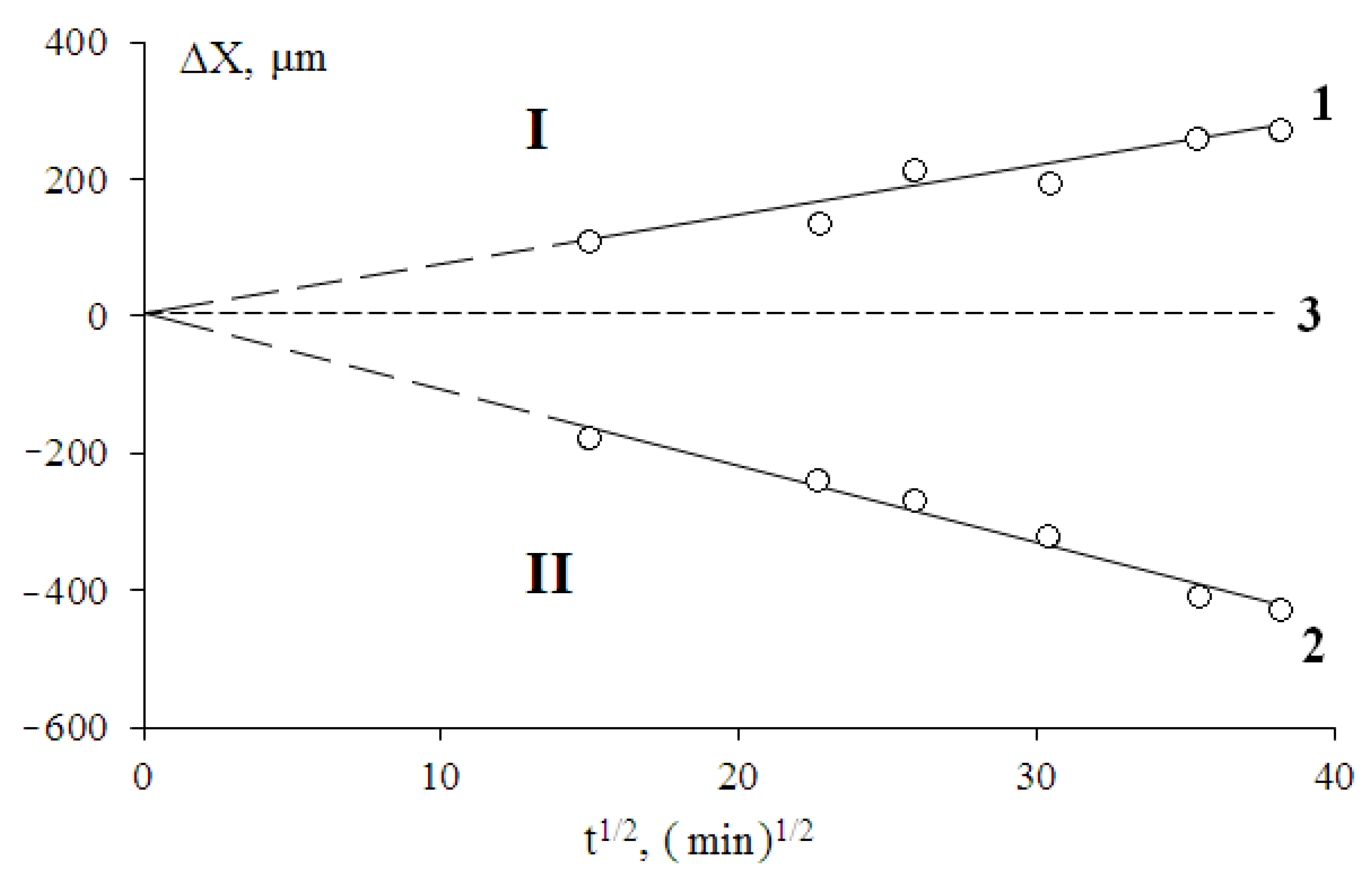

3.3. Interdiffusion in the HDPE-1 and LLDPE Mixtures

3.4. Thermodynamic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paulik, C.; Spiegel, G.; Jeremic, D. Bimodal polyethylene: Controlling polymer properties by molecular design. In Multimodal Polymers with Supported Catalysts; Springer: Cham, Switzerland, 2019; pp. 243–265. [Google Scholar] [CrossRef]

- Oliveira, A.D.; Freitas, D.M.; Araújo, J.P.; Cavalcanti, S.N.; Câmara, D.S.; Agrawal, P.; Mélo, T.J. HDPE/LLDPE blends: Rheological, thermal, and mechanical properties. Mater. Res. Innov. 2020, 24, 289–294. [Google Scholar] [CrossRef]

- Van Belle, A.; Demets, R.; Mys, N.; Van Kets, K.; Dewulf, J.; Van Geem, K.; Ragaert, K. Microstructural Contributions of Different Polyolefins to the Deformation Mechanisms of Their Binary Blends. Polymers 2020, 12, 1171. [Google Scholar] [CrossRef] [PubMed]

- Freitas, D.M.; Oliveira, A.D.; Alves, A.M.; Cavalcanti, S.N.; Agrawal, P.; Mélo, T.J. Linear low-density polyethylene/high-density polyethylene blends: Effect of high-density polyethylene content on die swell and flow instability. J. Appl. Polym. Sci. 2020, 49910. [Google Scholar] [CrossRef]

- Li, Z.; Fan, M.; Zhong, Z.; Du, B. Coupling Effect of Molecular Chain Displacement and Carrier Trap Characteristics on DC Breakdown of HDPE/LDPE Blend Insulation. Polymers 2020, 12, 589. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.; Wang, H.; Liu, M.; Jin, Z.; Zhao, K. Effect of Core-Shell Morphology on the Mechanical Properties and Crystallization Behavior of HDPE/HDPE-g-MA/PA6 Ternary Blends. Polymers 2018, 10, 1040. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akkapeddi, M.K. Commercial Polymer Blends. In Polymer Blends Handbook; Utracki, L.A., Wilkie, C.A., Eds.; Springer Science+Business Media: Dordrecht, The Netherlands, 2014; Volume 1, pp. 1733–1883. ISBN 978-94-007-6064-6. [Google Scholar]

- Cho, K.; Lee, B.H.; Hwang, K.-M.; Lee, H.; Choe, S. Rheological and mechanical properties in polyethylene blends. J. Polym. Eng. Sci. 1998, 38, 1969–1975. [Google Scholar] [CrossRef]

- Liang, J.Z. Melt strength and drawability of HDPE, LDPE and HDPE/LDPE blends. J. Polym. Test. 2019, 73, 433–438. [Google Scholar] [CrossRef]

- Liang, S.; Yang, H.; Wang, K.; Zhang, Q.; Du, R.; Fu, Q. Unique crystal morphology and tensile properties of injection-molded bar of LLDPE by adding HDPE with different molecular weights. J. Acta Materialia. 2008, 56, 50–59. [Google Scholar] [CrossRef]

- Velisek, F.J. Film Properties and Applications for LLDPE and High Pressure LDPE Blends. J. Plast. Film Sheeting 1991, 7, 332–354. [Google Scholar] [CrossRef]

- Rungswang, W.; Wongpanit, P.; Jarumaneeroj, C.; Jirasukho, P.; Juabrum, S.; Soontaranon, S.; Rugmai, S. Structure–Property–Process Relationship for Blown Films of Bimodal HDPE and Its LLDPE Blend. Macromol. Mater. Eng. 2019, 304, 1900325. [Google Scholar] [CrossRef]

- Tan, X.; Rodrigue, D. A review on porous polymeric membrane preparation. Part II: Production techniques with polyethylene, polydimethylsiloxane, polypropylene, polyimide, and polytetrafluoroethylene. Polymers 2019, 11, 1310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Winotapun, C.; Phattarateera, S.; Aontee, A.; Junsook, N.; Daud, W.; Kerddonfag, N.; Chinsirikul, W. Development of multilayer films with improved aroma barrier properties for durian packaging application. Packag. Technol. Sci. 2019, 32, 405–418. [Google Scholar] [CrossRef]

- Gabriel, C.; Lilge, D. Comparison of different methods for the investigation of the short-chain branching distribution of LLDPE. Polymer 2001, 42, 297–303. [Google Scholar] [CrossRef]

- Wild, L.; Glöckner, G. Temperature rising elution fractionation. In Separation Techniques Thermodynamics Liquid Crystal Polymers; Springer: Berlin/Heidelberg, Germany, 1990. [Google Scholar] [CrossRef]

- Anantawaraskul, S.; Soares, J.B.; Wood-Adams, P.M. Fractionation of Semicrystalline polymers by crystallization analysis Fractionationand temperature rising elution fractionation. In Polymer Analysis Polymer Theory; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–54. [Google Scholar] [CrossRef]

- Monrabal, B. Crystallization analysis fractionation: A new technique for the analysis of branching distribution in polyolefins. J. Appl. Polym. Sci. 1994, 52, 491–499. [Google Scholar] [CrossRef]

- Müller, A.J.; Arnal, M.L. Thermal fractionation of polymers. Prog. Polym. Sci. 2005, 30, 559–603. [Google Scholar] [CrossRef]

- Starck, P. Studies of the comonomer distributions in low density polyethylenes using temperature rising elution fractionation and stepwise crystallization by DSC. Polym. Int. 1996, 40, 111–122. [Google Scholar] [CrossRef]

- Zhang, M.; Lynch, D.T.; Wanke, S.E. Characterization of commercial linear low-density polyethylene by TREF-DSC and TREF-SEC cross-fractionation. J. Appl. Polym. Sci. 2000, 75, 960–967. [Google Scholar] [CrossRef]

- Androsch, R.; Di Lorenzo, M.L.; Schick, C.; Wunderlich, B. Mesophases in polyethylene, polypropylene, and poly (1-butene). Polymer 2010, 51, 4639–4662. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Shen, G.; Shen, H.; Xie, B.; Yang, W.; Yang, M. Co-crystallization of blends of high-density polyethylene with linear low-density polyethylene: An investigation with successive self-nucleation and annealing (SSA) technique. J. Macromol. Sci. Part B 2013, 52, 1372–1387. [Google Scholar] [CrossRef]

- Rana, S.K. Crystallization of high-density polyethylene–linear low-density polyethylene blend. J. Appl. Polym. Sci. 1998, 69, 2599–2607. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, S.; Yang, D. Crystallization behavior of blends of high-density polyethylene with novel linear low-density polyethylene. Macromol. Chem. Phys. 1997, 198, 1427–1436. [Google Scholar] [CrossRef]

- Arnal, M.L.; Sanchez, J.J.; Müller, A.J. Miscibility of linear and branched polyethylene blends by thermal fractionation: Use of the successive self-nucleation and annealing (SSA) technique. Polymer 2001, 42, 6877–6890. [Google Scholar] [CrossRef]

- Koningsveld, R.; Koningsveld, R.; Stockmayer, W.H.; Nies, E. Polymer phase diagrams; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Malkin, A.; Ascadsky, A.; Kovriga, V.; Chalykh, A.E. Experimental Methods of Polymer Physics; Mir Publishers: Moscow, Russia, 1983. (In Russian) [Google Scholar]

- Gedde, U.W.; Hedengvist, M.S. Fundamental Polymer Science, 2nd ed.; Springer Nature Switzerland & AG: Cham, Switzerland, 2019; p. 487. [Google Scholar]

- Nikulova, U.V.; Chalykh, A.E. Phase Equilibrium and Interdiffusion in Poly(Vinyl Methyl Ether)-Water System. Polymers 2020, 12, 2445. [Google Scholar] [CrossRef] [PubMed]

- Shapagin, A.V.; Budylin NYu Chalykh, A.E.; Solodilov, V.I.; Korokhin, R.A.; Poteryaev, A.A. Phase Equilibrium, Morphology, and Physico-Mechanics in Epoxy–Thermoplastic Mixtures with Upper and Lower Critical Solution Temperatures. Polymers 2021, 13, 35. [Google Scholar] [CrossRef] [PubMed]

- Ponrrahimi, A.M.; Olsson, R.T.; Hedengvist, M.S. The Role of Interfaces in Polyethylene/Metal—Oxide Nanocomposites for Ultrahigh—Voltage Insulating Materials. Adv. Mater. 2017, 1703624. [Google Scholar] [CrossRef]

- Taimoori, M.; Modarress, H.; Mansoori Grials, A. Generalized Flory–Huggins model for heat-of-mixing and phase-behavior calculations of polymer–polymer mixtures. J. Appl. Polym. Sci. 2000, 78, 1328–1340. [Google Scholar] [CrossRef]

- Flory, P.J. Thermodynamics of high polymer solutions. J. Chem. Phys. 1942, 10, 51–61. [Google Scholar] [CrossRef]

- Huggins, M.L. Solutions of long chain compounds. J. Chem. Phys. 1941, 9, 440-440. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Hoftyzer, P.J. Correlations with Chemical Structure. Properties of Polymers; Elsevier Pub. Co: Amsterdam, NY, USA, 1972. [Google Scholar]

| PE Sample Name | Polymer Type | MFI, 5 kg, g/10 min | Density, g/cm3 | Mn, kg/mol | Mw, kg/mol | Mw/Mn | CH3/ 1000C * |

|---|---|---|---|---|---|---|---|

| HDPE-1 (HMW) | High molecular weight bimodal copolymer of ethylene with hexene-1 | 1.1 | 0.950 | 11 | 160 | 14.5 | 5.2 |

| HDPE-2 (LMW) | Low molecular weight monomodal homopolymer of ethylene | 90 | 0.967 | 6.8 | 45 | 6.6 | - |

| LLDPE | Monomodal copolymer of ethylene with butane-1 and hexene-1 | 8.2 | 0.918 | 17 | 88 | 5.2 | 26 |

| Composition Name | Mass Content of HDPE-1, %mass | Mass Content of LLDPE, %mass |

|---|---|---|

| 100/0 (HDPE-1) | 100 | 0 |

| 80/20 | 80 | 20 |

| 70/30 | 70 | 30 |

| 60/40 | 60 | 40 |

| 50/50 | 50 | 50 |

| 40/60 | 40 | 60 |

| 20/80 | 20 | 80 |

| 0/100 (LLDPE) | 0 | 100 |

| No. | HDPE-1/LLDPE Ratio | Density | Tm | Tcr | −ΔHm | ∆Hc | X | Mw | Mw/Mn |

|---|---|---|---|---|---|---|---|---|---|

| g/cm3 | °C | °C | J/g | J/g | % | kg/mol | |||

| 1 | 100/0 | 0.950 | 135 | 114 | 203 | 204 | 69 | 160 | 14.5 |

| 2 | 80/20 | 0.945 | 134 | 113 | 184 | 184 | 63 | 145 | 13 |

| 3 | 70/30 | 0.942 | 132 | 114 | 174 | 178 | 60 | 135 | 10.6 |

| 4 | 60/40 | 0.940 | 130 | 114 | 170 | 175 | 58 | 130 | 9.3 |

| 5 | 50/50 | 0.936 | 129 | 114 | 156 | 157 | 53 | 120 | 8.2 |

| 6 | 40/60 | 0.933 | 129 | 113 | 142 | 142 | 49 | 110 | 7.3 |

| 7 | 20/80 | 0.928 | 128 | 113 | 133 | 139 | 45 | 100 | 5.9 |

| 8 | 0/100 | 0.918 | 126 | 106 | 121 | 128 | 41 | 88 | 5.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salakhov, I.I.; Chalykh, A.E.; Shaidullin, N.M.; Shapagin, A.V.; Budylin, N.Y.; Khasbiullin, R.R.; Nifant’ev, I.E.; Gerasimov, V.K. Phase Equilibria and Interdiffusion in Bimodal High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) Based Compositions. Polymers 2021, 13, 811. https://doi.org/10.3390/polym13050811

Salakhov II, Chalykh AE, Shaidullin NM, Shapagin AV, Budylin NY, Khasbiullin RR, Nifant’ev IE, Gerasimov VK. Phase Equilibria and Interdiffusion in Bimodal High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) Based Compositions. Polymers. 2021; 13(5):811. https://doi.org/10.3390/polym13050811

Chicago/Turabian StyleSalakhov, Ildar I., Anatoly E. Chalykh, Nadim M. Shaidullin, Alexey V. Shapagin, Nikita Yu. Budylin, Ramil R. Khasbiullin, Ilya E. Nifant’ev, and Vladimir K. Gerasimov. 2021. "Phase Equilibria and Interdiffusion in Bimodal High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) Based Compositions" Polymers 13, no. 5: 811. https://doi.org/10.3390/polym13050811

APA StyleSalakhov, I. I., Chalykh, A. E., Shaidullin, N. M., Shapagin, A. V., Budylin, N. Y., Khasbiullin, R. R., Nifant’ev, I. E., & Gerasimov, V. K. (2021). Phase Equilibria and Interdiffusion in Bimodal High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) Based Compositions. Polymers, 13(5), 811. https://doi.org/10.3390/polym13050811