A Facile Solution Engineering of PEDOT:PSS-Coated Conductive Textiles for Wearable Heater Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of PEDOT:PSS Composite Solutions

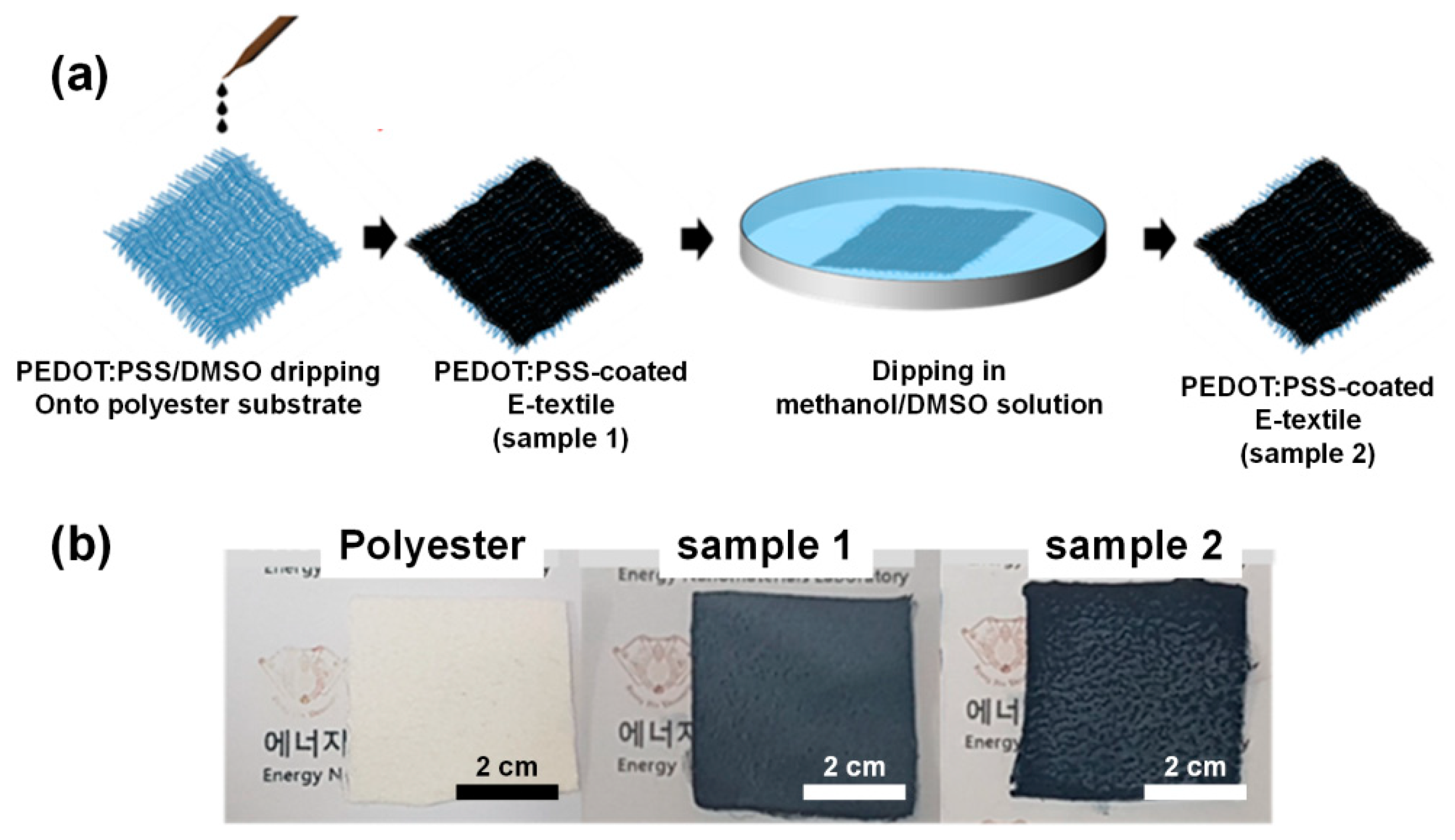

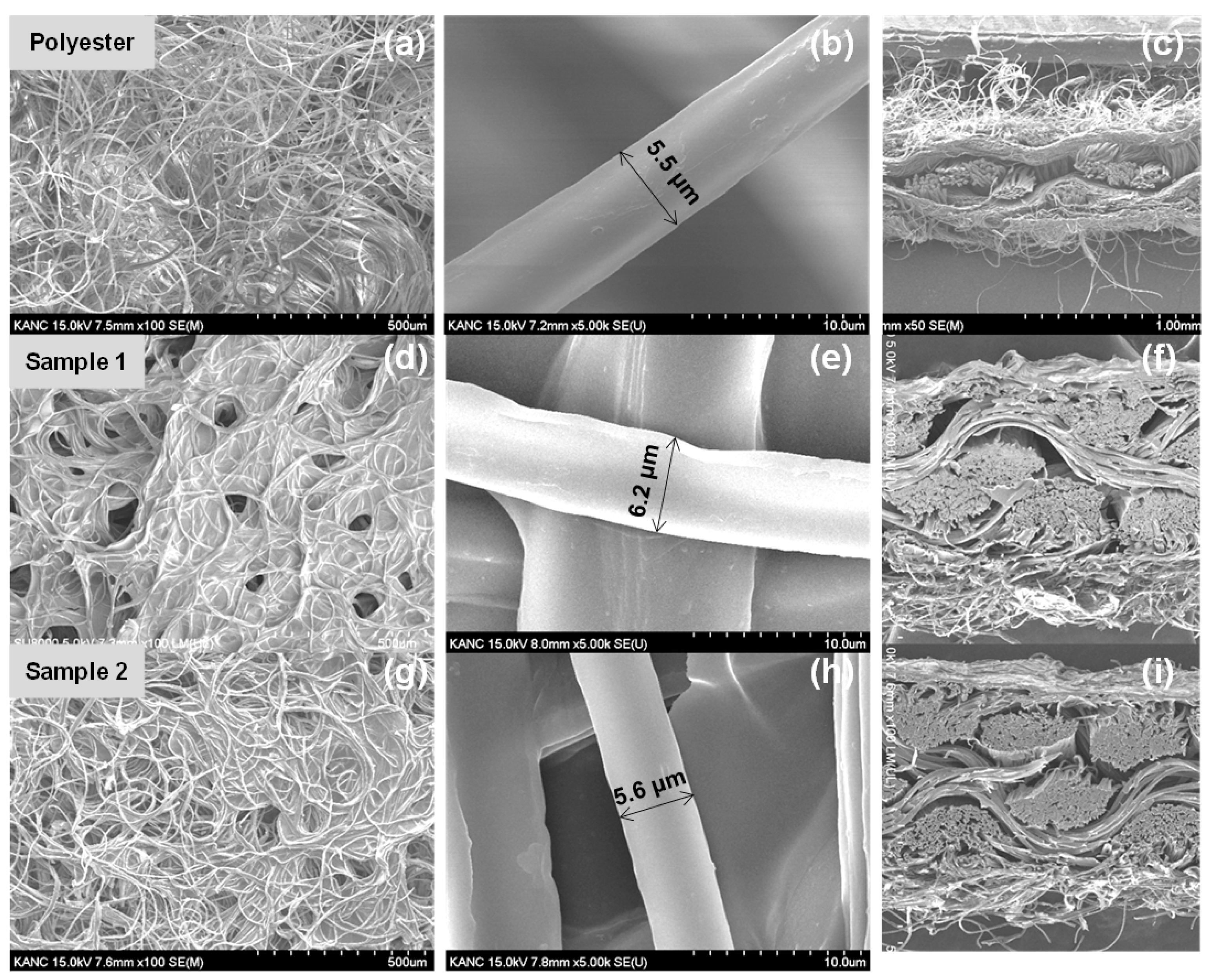

2.2. Preparation of E-Textiles

2.3. Characterizations

3. Results

3.1. Preparation of PEDOT:PSS-Coated E-Textiles

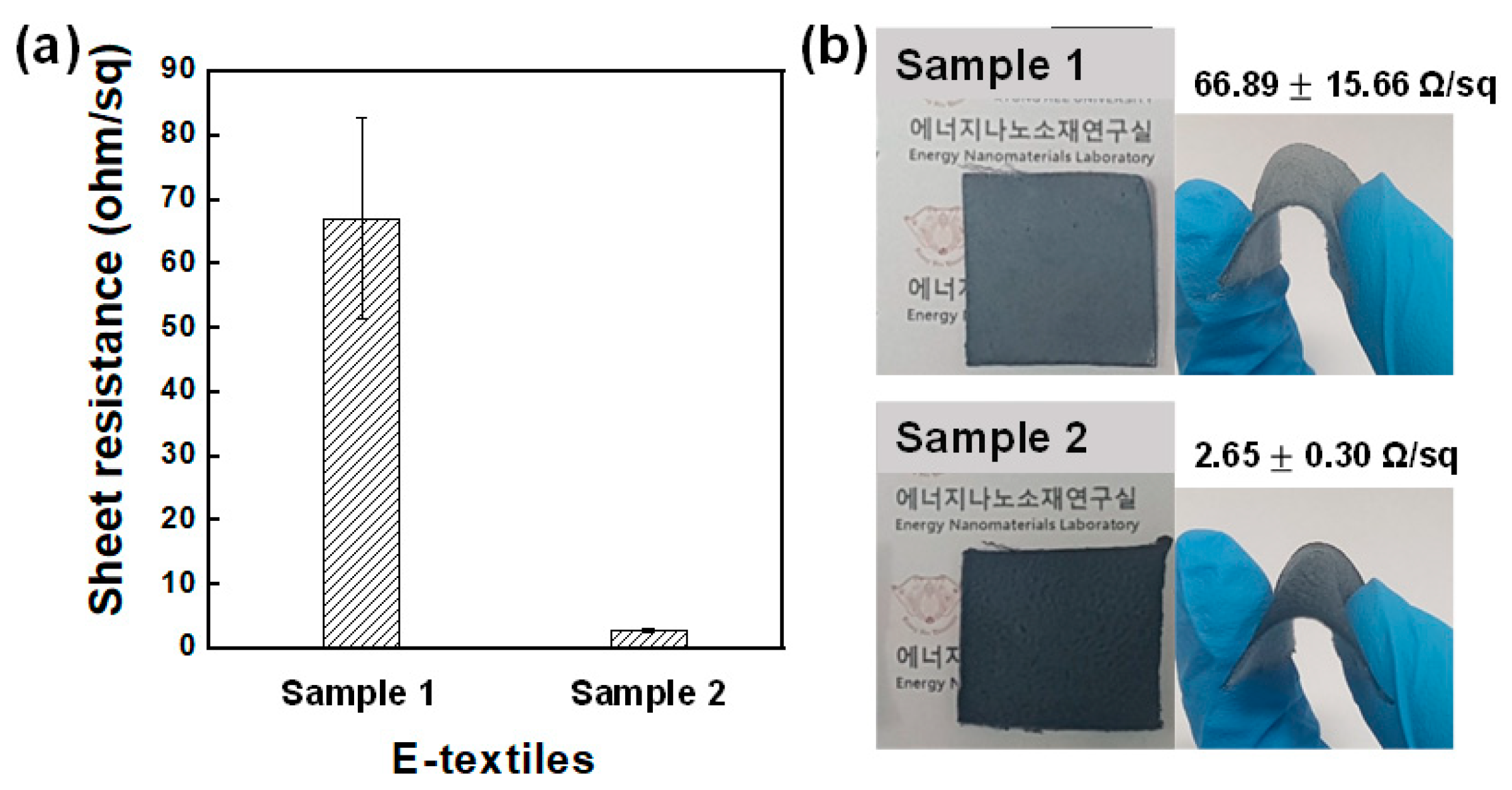

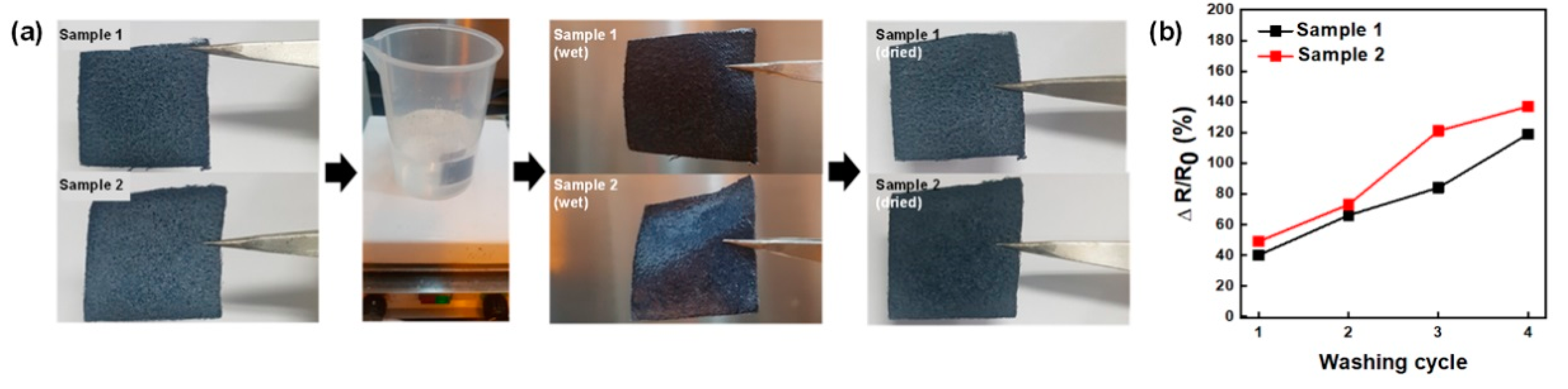

3.2. Electrical Properties of E-Textiles

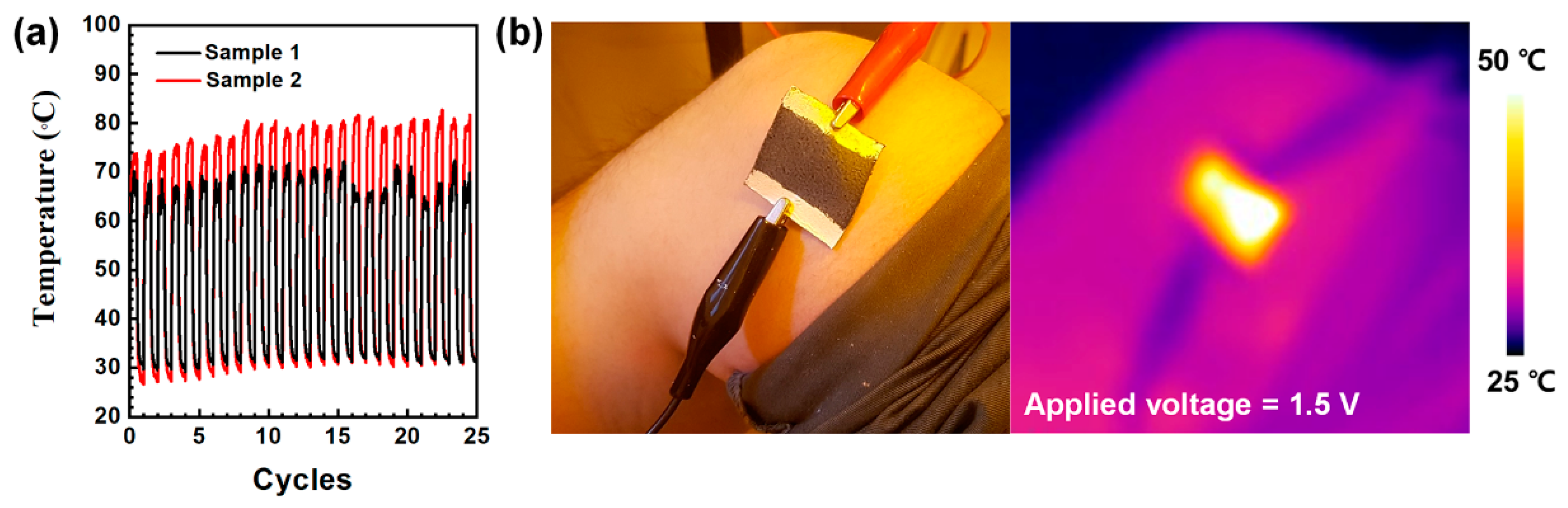

3.3. Joule Heating Properties of E-Textiles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoon, S.S.; Lee, K.E.; Cha, H.-J.; Seong, D.G.; Um, M.-K.; Byun, J.-H.; Oh, Y.; Oh, J.H.; Lee, W.; Lee, J.K. Highly Conductive Graphene/Ag Hybrid Fibers for Flexible Fiber-Type Transistors. Sci. Rep. 2015, 5, 16366. [Google Scholar] [CrossRef] [Green Version]

- Chauraya, A.; Seager, R.; Whittow, W.; Zhang, S.; Vardaxoglou, Y. Embroidered Frequency Selective Surfaces on textiles for wearable applications. In Proceedings of the IEEE 2013 Loughborough Antennas & Propagation Conference (LAPC), Loughborough, UK, 11–12 November 2013; pp. 388–391. [Google Scholar]

- Christ, J.; Aliheidari, N.; Pötschke, P.; Ameli, A. Bidirectional and Stretchable Piezoresistive Sensors Enabled by Multimaterial 3D Printing of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Polymers 2019, 11, 11. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Xu, W.; Wang, W.; Fong, H.; Zhu, Z. Scalable and Facile Preparation of Highly Stretchable Electrospun PEDOT:PSS @ PU Fibrous Nonwovens toward Wearable Conductive Textile Applications. ACS Appl. Mater. Interfaces 2017, 9, 30014–30023. [Google Scholar] [CrossRef]

- Seyedin, S.; Razal, J.M.; Innis, P.C.; Jeiranikhameneh, A.; Beirne, S.; Wallace, G.G. Knitted Strain Sensor Textiles of Highly Conductive All-Polymeric Fibers. ACS Appl. Mater. Interfaces 2015, 7, 21150–21158. [Google Scholar] [CrossRef]

- Heller, L.; Vokoun, D.; Šittner, P.; Finckh, H. 3D Flexible Niti-Braided Elastomer Composites for Smart Structure Applications. Smart Mater. Struct. 2012, 21, 045016. [Google Scholar] [CrossRef]

- Shahzad, A.; Ali, Z.; Ali, U.; Khaliq, Z.; Zubair, M.; Kim, I.S.; Hussain, T.; Khan, M.Q.; Rasheed, A.; Qadir, M.B. Development and Characterization of Conductive Ring Spun Hybrid Yarns. J. Text. Inst. 2019, 110, 141–150. [Google Scholar] [CrossRef]

- Okuzaki, H.; Ishihara, M. Spinning and Characterization of Conducting Microfibers. Macromol. Rapid Commun. 2003, 24, 261–264. [Google Scholar] [CrossRef]

- Xie, J.; Pan, W.; Guo, Z.; Jiao, S.S.; Ping Yang, L. In Situ Polymerization of Polypyrrole on Cotton Fabrics as Flexible Electrothermal Materials. J. Eng. Fibers Fabr. 2019, 14, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Imai, T.; Shibayama, N.; Takamatsu, S.; Shiraishi, K.; Marumoto, K.; Itoh, T. High-Speed Coating Method for Photovoltaic Textiles with Closed-Type Die Coater. Jpn. J. Appl. Phys. 2013, 52, 201. [Google Scholar] [CrossRef]

- Thibodeaux, D.P.; Baril, A. Electroless Plating of Metallic Coatings on Fabric. J. Coat. Fibrous Mater. 1973, 2, 219–230. [Google Scholar] [CrossRef]

- Sen, P.; Xiong, Y.; Zhang, Q.; Park, S.; You, W.; Ade, H.; Kudenov, M.W.; Connor, B.T.O. Shear-Enhanced Transfer Printing of Conducting Polymer Thin Films. ACS Appl. Mater. Interfaces 2018, 10, 31560–31567. [Google Scholar] [CrossRef]

- Tao, X. Handbook of Smart Textiles, 1st ed.; Tao, X., Ed.; Springer Science+ Business Media: Singapore, 2014; ISBN 9789814451680. [Google Scholar]

- Du, D.; Tang, Z.; Ouyang, J. Highly washable e-textile prepared by ultrasonic nanosoldering of carbon nanotubes onto polymer fibers. J. Mater. Chem. C 2018, 6, 883–889. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Nanomaterial-enabled Stretchable Conductors: Strategies. Mater. Devices Adv. Mater. 2015, 27, 1480–1511. [Google Scholar] [CrossRef]

- Jun, S.; Ju, B.-K.; Kim, J.-W. Ultra-Facile Fabrication of Stretchable and Transparent Capacitive Sensor Employing Photo-Assisted Patterning of Silver Nanowire Networks. Adv. Mater. Technol. 2016, 1, 201600062. [Google Scholar] [CrossRef]

- Khair, N.; Islam, R.; Shahariar, H. Carbon-Based Electronic Textiles: Materials, Fabrication Processes and Applications. J. Mater. Sci. 2019, 54, 10079–10101. [Google Scholar] [CrossRef]

- Guo, Y.; Otley, M.T.; Li, M.; Zhang, X.; Sinha, S.K.; Treich, G.M.; Sotzing, G.A. PEDOT:PSS “Wires” Printed on Textile for Wearable Electronics. ACS Appl. Mater. Interfaces 2016, 8, 26998–27005. [Google Scholar] [CrossRef]

- Ding, Y.; Invernale, M.A.; Sotzing, G.A. Conductivity Trends of PEDOT-PSS. Impregnated Fabric and the Effect of Conductivity on Electrochromic Textile. ACS Appl. Mater. Interfaces 2010, 2, 1588–1593. [Google Scholar] [CrossRef] [PubMed]

- Jin, I.S.; Lee, W.; Lim, S.J.; Ko, J.H.; Jung, J.W. Ultra-Flexible, Stretchable, Highly Conductive and Multi-Functional Textiles Enabled by Brush-Painted PEDOT:PSS. Smart Mater. Struct. 2020, 29, 095002. [Google Scholar] [CrossRef]

- Hojati-Talemi, P.; Bächler, C.; Fabretto, M.; Murphy, P.; Evans, D. Ultrathin Polymer Films for Transparent Electrode Applications Prepared by Controlled Nucleation. ACS Appl. Mater. Interfaces 2013, 5, 11654–11660. [Google Scholar] [CrossRef] [PubMed]

- Bubnova, O.; Crispin, X. Towards Polymer-Based Organic Thermoelectric Generators. Energy Environ. Sci. 2012, 5, 9345–93462. [Google Scholar] [CrossRef] [Green Version]

- Kim, N.; Kang, H.; Lee, J.-H.; Kee, S.; Lee, S.H.; Lee, K. Highly Conductive All-Plastic Electrodes Fabricated Using a Novel Chemically Controlled Transfer-Printing Method. Adv. Mater. 2015, 27, 2317–2323. [Google Scholar] [CrossRef]

- Badre, C.; Marquant, L.; Alsayed, A.M.; Hough, L.A. Highly Conductive Poly(3,4-ethylenedioxythiophene):Poly (styrenesulfonate) Films Using 1-Ethyl-3-methylim3idazolium Tetracyanoborate Ionic Liquid. Adv. Funct. Mater. 2012, 22, 2723–2727. [Google Scholar] [CrossRef]

- Gueye, M.N.; Carella, A.; Massonnet, N.; Yvenou, E.; Brenet, S.; Faure-Vincent, J.; Pouget, S.; Rieutord, F.; Okuno, H.; Benayad, A. Structure and Dopant Engineering in PEDOT Thin Films: Practical Tools for a Dramatic Conductivity Enhancement. Chem. Mater. 2016, 28, 3462–3468. [Google Scholar] [CrossRef]

- Caironi, M.; Noh, Y. Large Area and Flexible Electronics; Wiley: New York, NY, USA, 2015. [Google Scholar]

- Thomas, J.P.; Zhao, L.; McGillivray, D.; Leung, K.T. High-Efficiency Hybrid Solar Cells by Nanostructural Modification in PEDOT:PSS with Co-Solvent Addition. J. Mater. Chem. A 2014, 2, 2383. [Google Scholar] [CrossRef] [Green Version]

- Niu, Z.; Zheng, E.; Dong, H.; Tosado, G.A.; Yu, Q. Manipulation of PEDOT:PSS with Polar and Nonpolar Solvent Post-treatment for Efficient Inverted Perovskite Solar Cells. ACS Appl. Energy Mater. 2020, 3, 9656–9666. [Google Scholar] [CrossRef]

- Alshammari, A.S. Effect of solvents treatment on the electrical stability and surface wetting properties of PEDOT:PSS thin films. Mater. Lett. 2019, 250, 30–33. [Google Scholar] [CrossRef]

- Li, X.-Y.; Zhang, L.-P.; Tang, F.; Bao, Z.-M.; Lin, J.; Li, Y.-Q.; Chen, L.; Ma, C.-Q. The solvent treatment effect of the PEDOT:PSS anode interlayer in inverted planar perovskite solar cells. RSC Adv. 2016, 6, 24501–24507. [Google Scholar] [CrossRef]

- Kim, N.; Kee, S.; Lee, S.H.; Lee, B.H.; Kahng, Y.H.; Jo, Y.-R.; Kim, B.-J.; Lee, K. Highly Conductive PEDOT:PSS Nanofibrils Induced by Solution-Processed Crystallization. Adv. Mater. 2014, 26, 2268–2272. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, C.H.; Kim, Y.; Kim, N.; Lee, W.J.; Lee, E.H.; Kim, D.; Park, S.; Lee, K.; Rivnay, J.; et al. Influence of PEDOT:PSS Crystallinity and Composition on Electrochemical Transistor Performance and Long-Term Stability. Nat. Commun. 2018, 9, 3858. [Google Scholar] [CrossRef] [Green Version]

- Crispin, X.; Marciniak, S.; Osikowicz, W.; Zotti, G.; Gon, A.W.D.v.d.; Louwet, F.; Fahlman, M.; Groenendaal, L.; Schryver, F.D.; Salaneck, W.R. Conductivity, Morphology, Interfacial Chemistry, and Stability of Poly (3, 4-ethylene dioxythiophene)–poly (styrene Sulfonate): A Photoelectron Spectroscopy Study. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2561–2583. [Google Scholar] [CrossRef]

- Song, W.; Fan, X.; Xu, B.; Yan, F.; Cui, H.; Wei, Q.; Peng, R.; Hong, L.; Huang, J.; Ge, Z. All Solution Processed Metal Oxide Free Flexible Organic Solar Cells with Over 10% Efficiency. Adv. Mater. 2018, 30, 1800075. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [Green Version]

- Zaman, S.U.; Tao, X.; Cochrane, C.; Koncar, V. E-Textile Systems Reliability Assessment-A Miniaturized Accelerometer Used to Investigate Damage during Their Washing. Sensors 2021, 21, 605. [Google Scholar] [CrossRef]

- Jin, I.S.; Choi, J.; Jung, J.W. Silver-Nanowire-Embedded Photopolymer Films for Transparent Film Heaters with Ultra-Flexibility, Quick Thermal Response, and Mechanical Reliability. Adv. Electron. Mater. 2021, 7, 2000698. [Google Scholar] [CrossRef]

- Jin, I.S.; Lee, H.D.; Hong, S.I.; Lee, W.; Jung, J.W. Facile Post Treatment of Ag Nanowire/Polymer Composites for Flexible Transparent Electrodes and Thin Film Heaters. Polymers 2021, 13, 586. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, I.S.; Lee, J.U.; Jung, J.W. A Facile Solution Engineering of PEDOT:PSS-Coated Conductive Textiles for Wearable Heater Applications. Polymers 2021, 13, 945. https://doi.org/10.3390/polym13060945

Jin IS, Lee JU, Jung JW. A Facile Solution Engineering of PEDOT:PSS-Coated Conductive Textiles for Wearable Heater Applications. Polymers. 2021; 13(6):945. https://doi.org/10.3390/polym13060945

Chicago/Turabian StyleJin, In Su, Jea Uk Lee, and Jae Woong Jung. 2021. "A Facile Solution Engineering of PEDOT:PSS-Coated Conductive Textiles for Wearable Heater Applications" Polymers 13, no. 6: 945. https://doi.org/10.3390/polym13060945

APA StyleJin, I. S., Lee, J. U., & Jung, J. W. (2021). A Facile Solution Engineering of PEDOT:PSS-Coated Conductive Textiles for Wearable Heater Applications. Polymers, 13(6), 945. https://doi.org/10.3390/polym13060945